ASTM A467/A467M-01

(Specification)Standard Specification for Machine and Coil Chain

Standard Specification for Machine and Coil Chain

SCOPE

1.1 These specifications cover welded carbon steel machine chain and coil chain. Although these chains are not intended for pocket wheel use, they can be used for pocket and sprocket wheel use. This chain shall never be used for overhead lifting applications.

1.2 There are two classes each of machine and coil chain:

1.2.1 Class MS—Machine, straight-link steel chain,

1.2.2 Class MT—Machine, twist-link steel chain,

1.2.3 Class CS—Coil, straight-link chain, and

1.2.4 Class CT—Coil, twist-link steel chain.

1.3 The values stated in inch-pound units or SI units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 467/A 467M – 01

Standard Specification for

1

Machine and Coil Chain

ThisstandardisissuedunderthefixeddesignationA467/A467M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

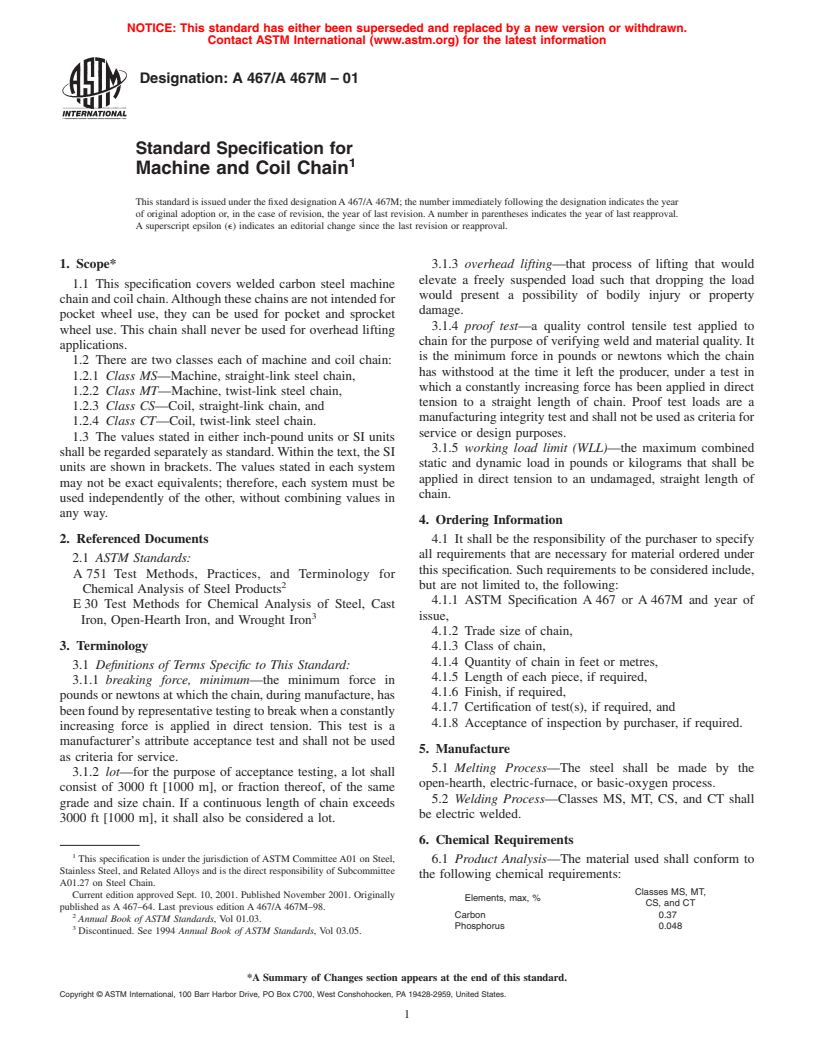

1. Scope* 3.1.3 overhead lifting—that process of lifting that would

elevate a freely suspended load such that dropping the load

1.1 This specification covers welded carbon steel machine

would present a possibility of bodily injury or property

chainandcoilchain.Althoughthesechainsarenotintendedfor

damage.

pocket wheel use, they can be used for pocket and sprocket

3.1.4 proof test—a quality control tensile test applied to

wheel use. This chain shall never be used for overhead lifting

chain for the purpose of verifying weld and material quality. It

applications.

is the minimum force in pounds or newtons which the chain

1.2 There are two classes each of machine and coil chain:

has withstood at the time it left the producer, under a test in

1.2.1 Class MS—Machine, straight-link steel chain,

which a constantly increasing force has been applied in direct

1.2.2 Class MT—Machine, twist-link steel chain,

tension to a straight length of chain. Proof test loads are a

1.2.3 Class CS—Coil, straight-link chain, and

manufacturingintegritytestandshallnotbeusedascriteriafor

1.2.4 Class CT—Coil, twist-link steel chain.

service or design purposes.

1.3 The values stated in either inch-pound units or SI units

3.1.5 working load limit (WLL)—the maximum combined

shallberegardedseparatelyasstandard.Withinthetext,theSI

static and dynamic load in pounds or kilograms that shall be

units are shown in brackets. The values stated in each system

applied in direct tension to an undamaged, straight length of

may not be exact equivalents; therefore, each system must be

chain.

used independently of the other, without combining values in

any way.

4. Ordering Information

2. Referenced Documents 4.1 It shall be the responsibility of the purchaser to specify

all requirements that are necessary for material ordered under

2.1 ASTM Standards:

this specification. Such requirements to be considered include,

A 751 Test Methods, Practices, and Terminology for

2 but are not limited to, the following:

Chemical Analysis of Steel Products

4.1.1 ASTM Specification A467 or A467M and year of

E30 Test Methods for Chemical Analysis of Steel, Cast

3 issue,

Iron, Open-Hearth Iron, and Wrought Iron

4.1.2 Trade size of chain,

3. Terminology 4.1.3 Class of chain,

4.1.4 Quantity of chain in feet or metres,

3.1 Definitions of Terms Specific to This Standard:

4.1.5 Length of each piece, if required,

3.1.1 breaking force, minimum—the minimum force in

4.1.6 Finish, if required,

poundsornewtonsatwhichthechain,duringmanufacture,has

4.1.7 Certification of test(s), if required, and

beenfoundbyrepresentativetestingtobreakwhenaconstantly

4.1.8 Acceptance of inspection by purchaser, if required.

increasing force is applied in direct tension. This test is a

manufacturer’s attribute acceptance test and shall not be used

5. Manufacture

as criteria for service.

5.1 Melting Process—The steel shall be made by the

3.1.2 lot—for the purpose of acceptance testing, a lot shall

open-hearth, electric-furnace, or basic-oxygen process.

consist of 3000 ft [1000 m], or fraction thereof, of the same

5.2 Welding Process—Classes MS, MT, CS, and CT shall

grade and size chain. If a continuous length of chain exceeds

be electric welded.

3000 ft [1000 m], it shall also be considered a lot.

6. Chemical Requirements

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

6.1 Product Analysis—The material used shall conform to

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

the following chemical requirements:

A01.27 on Steel Chain.

Classes MS, MT,

Current edition approved Sept. 10, 2001. Published November 2001. Originally

Elements, max, %

CS, and CT

published as A467–64. Last previous edition A467/A467M–98.

2 Carbon 0.37

Annual Book of ASTM Standards, Vol 01.03.

Phosphorus 0.048

3

Discontinued. See 1994 Annual Book of ASTM Standards, Vol 03.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

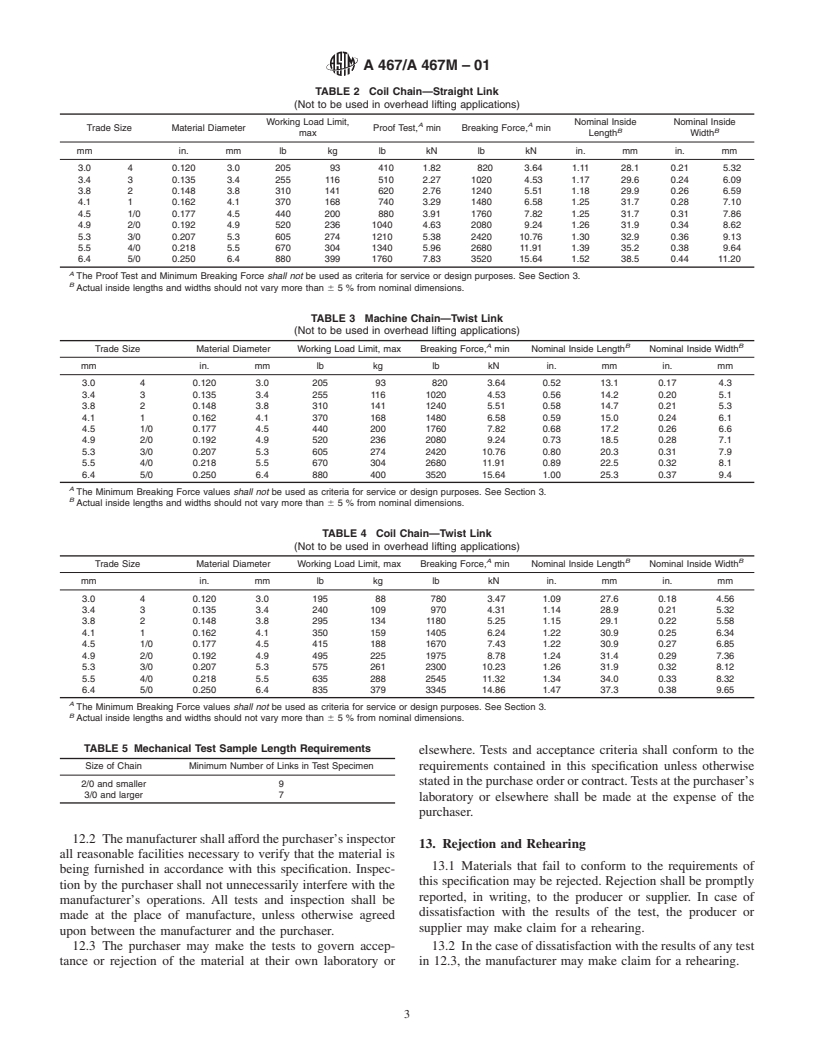

A 467/A 467M – 01

Sulfur 0.058

where:

DL = test specimen final length at fracture – test speci-

6.2 The analysis may be made by the purchaser from the

men original gage length L{0}, and

bars or finished chain. Samples for analysis shall represent the

L{0} = original gage length (sum or the insid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.