ASTM F1052-97(2002)

(Test Method)Standard Test Method for Pressure Testing Vapor Protective Ensembles

Standard Test Method for Pressure Testing Vapor Protective Ensembles

SIGNIFICANCE AND USE

Workers involved in the production, use, and transportation of liquid and gaseous chemicals can be exposed to numerous compounds capable of causing harm upon contact with the human body. The deleterious effects of these chemicals can range from acute trauma such as skin irritation and burn to chronic degenerative disease such as cancer. Since engineering controls may not eliminate all possible exposures, attention is often placed on reducing the potential for direct skin contact through the use of protective clothing that resists permeation, penetration, and degradation.

This test method is only appropriate for chemical protective ensembles, such as totally encapsulating protective suits, that are designed and manufactured to prevent the inward leakage of solids, liquids, gases, and vapors. Garments designed to prevent the penetration of solid and liquid chemicals should be tested according to Test Method F 1359.

This non-destructive test method is useful as a quality control tool for manufactures and as a field method for end users to determine changes in garment integrity following use.

This test method is useful to end users for determining the integrity of vapor protective suits upon receipt from the manufacturer, prior to use, following use and decontamination, following repairs, and as a periodic maintenance test.

SCOPE

1.1 This test method measures the ability of a vapor protective ensemble (VPE), including seams, and closures to maintain a fixed, positive pressure.

1.2 This test method measures the integrity of the suit, glove, boot/bootie, and visor materials, as well as the seams, and closures of a VPE. Exhaust valves fitted in the VPE must be sealed or blocked for this test and therefore are not functionally tested.

1.3 The values as stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1052 – 97 (Reapproved 2002)

Standard Test Method for

Pressure Testing Vapor Protective Ensembles

This standard is issued under the fixed designation F 1052; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Personnel in industry and emergency response can be exposed to numerous chemicals capable of

causing harm upon contact with the human body. The deleterious effects of these chemicals can range

from acute trauma such as skin irritation and burn, to chronic degenerative disease such as cancer.

Since engineering controls may not eliminate all possible exposures, attention is often placed on

reducing the potential for direct skin contact through the use of protective clothing.

Protective clothing is available in a variety of constructions, configurations and materials, and is

designed to provide various levels of protection against many hazards. Chemical protective ensembles

offering the highest level of chemical protection are constructed to prevent contact of solid, liquid, or

gaseous chemicals with the wearer. This test method evaluates the integrity and construction of vapor

protective ensembles by way of an internal pressure test. Other related whole suit tests include Test

Method F 1359 for evaluating splash resistance using a Shower test, and Practice F 1154 for

evaluating the overall form, fit, and function of a garment using a simulated wear test.

Resistance to chemical permeation of materials used in protective clothing should be evaluated by

Test Methods F 739 for continuous contact and F 1383 for intermittent contact (that is, splash), or by

Test Method F 1407 according to the permeation cup method. Resistance of protective clothing

materials to liquid penetration should be determined by Test Method F 903.

Physical properties of materials used in the construction of protective clothing can be determined

usingavarietyoftestmethods,includingTestMethodsD 751(dimensions,weight,breakingstrength,

elongation, burst, tear resistance, hydrostatic resistance, coating adhesion, tack-tear, low temperature

impact and bend, accelerated aging, blocking, and crush resistance), D 2582 (puncture propagation

tear), D 4157 (abrasion resistance), F 392 (flexural fatigue), F 1358 (flammability), as well as many

others.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

1.1 This test method measures the ability of a vapor

statements, see Section 7.

protective ensemble (VPE), including seams, and closures to

maintain a fixed, positive pressure.

2. Referenced Documents

1.2 This test method measures the integrity of the suit,

2.1 ASTM Standards:

glove, boot/bootie, and visor materials, as well as the seams,

D 751 Test Methods for Coated Fabrics

and closures of a VPE. Exhaust valves fitted in the VPE must

D 2582 Test Method for Puncture-Propagation Tear Resis-

be sealed or blocked for this test and therefore are not

tance of Plastic Film and Thin Sheeting

functionally tested.

D 4157 Test Method for Abrasion Resistance of Textile

1.3 The values as stated in in.-H O (mm-H O) units are to

2 2

Fabrics (Oscillatory Cylinder Method)

be regarded as the standard.

F 392 Test Method for Flex and Durability of Flexible

1.4 This standard does not purport to address all of the

Barrier Materials

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1 2

This test method is under the jurisdiction of ASTM Committee F23 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Protective Clothing and is the direct responsibility of Subcommittee F23.30 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Chemicals. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 10, 1997. Published July 1997. Originally the ASTM website.

published as F 1052 – 87. Last previous edition F 1052 – 87 (1991). Withdrawn

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1052 – 97 (2002)

F 739 Test Method for Resistance of Protective Clothing 3.1.8 vapor protective ensemble, (VPE), n—a chemical

Materials to Permeation by Liquids or Gases under Con- protective ensemble used to protect the wearer from chemical

ditions of Continuous Contact liquids, vapors, and gases.

3.1.8.1 Discussion—In this test method, the vapor protec-

F 903 Test Method for Resistance of Materials Used in

tive ensemble will only include those protective clothing items

Protective Clothing to Penetration by Liquids

or accessories that are necessary for providing air-tight integ-

F 1154 Practices for Qualitatively Evaluating the Comfort,

rity.

Fit, Function, and Integrity of Chemical Protective Suit

3.1.9 vapor protective suit, n—a chemical protective suit

Ensembles

used to protect the wearer from chemical liquids, vapors, and

F 1358 Test Method for the Effects of Flame Impingement

gases.

on Materials Used in Protective Clothing Not Designated

Primarily for Flame Resistance

4. Summary of Test Method

F 1359 Test Method for Determining the Liquid Penetration

4.1 The VPE is visually inspected and modified for the test.

Resistance Protective Clothing or Protective Ensembles

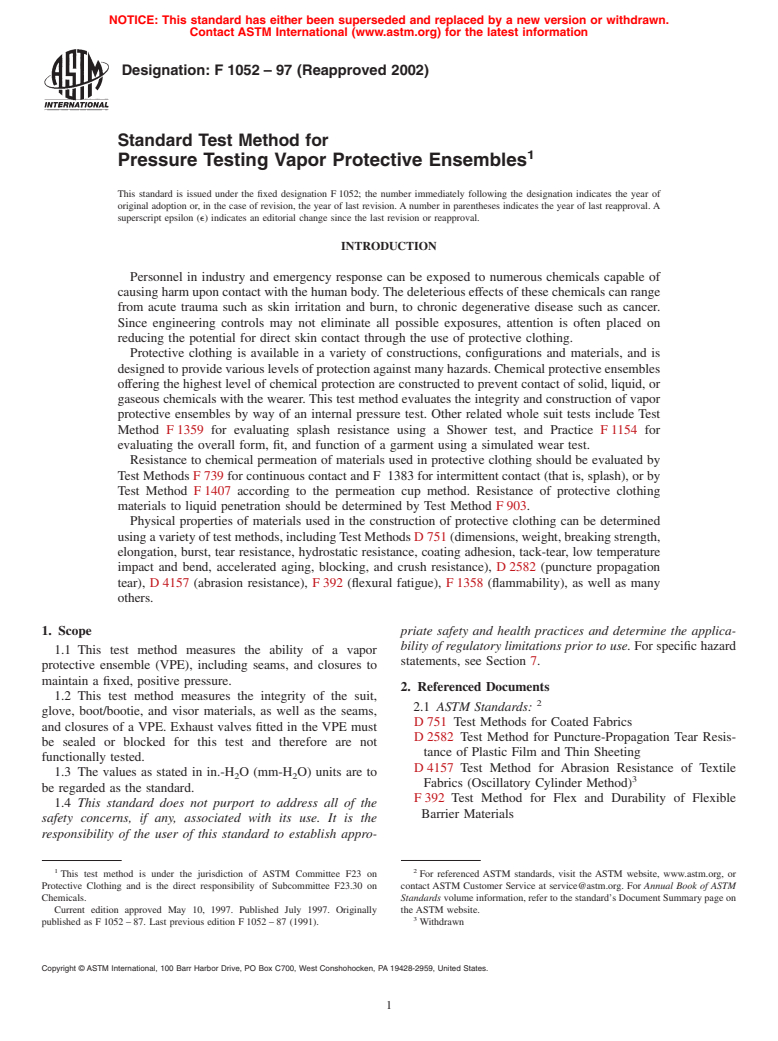

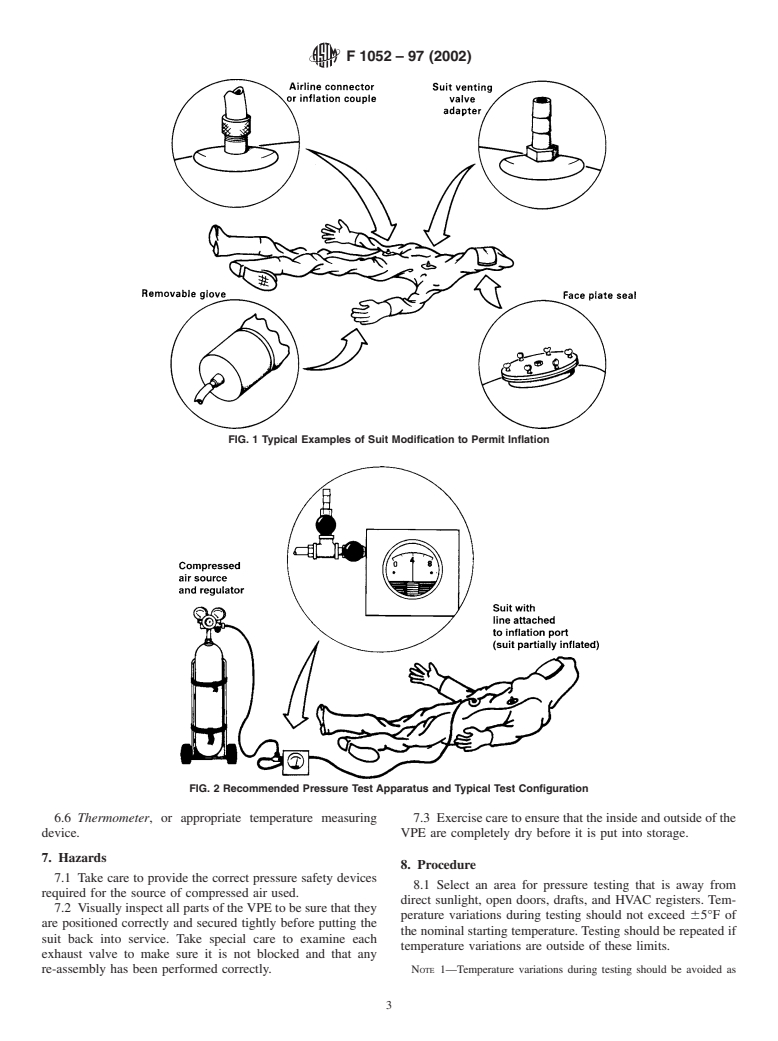

A test apparatus is attached to the VPE (Fig. 1) to permit

Under a Shower Spray Wheel on a Mannequin

inflation to the pre-test suit expansion pressure for removal of

F 1383 Test Method for Resistance of Clothing Materials to

wrinkles and creases, and to equalize/stabilize the air tempera-

Permeation by Liquids or Gases Under Conditions of

tures internal and external to the VPE. The pressure is lowered

Intermittent Contact

to the test pressure and monitored for 4 min. If the pressure

F 1407 Test Method for Resistance of Chemical Protective

drop is excessive, the VPE fails the test and is removed from

ClothingMaterialstoLiquidPermeation—PermeationCup

service. The test is repeated after leak location and repair.

Method

4.2 Pressure testing of VPEs should be conducted at a

frequency recommended by the manufacturer but no less often

3. Terminology

than upon receipt of the garment, after each wearing if the suit

3.1 Definitions of Terms Specific to This Standard:

is to be reused, and at least annually thereafter.

3.1.1 chemical protective ensemble, n—a combination of a

chemical protective suit, gloves, boots, respiratory protective

5. Significance and Use

equipment, and any other clothing and equipment worn to

5.1 Workers involved in the production, use, and transpor-

providethewearerwithintegrityagainstexposuretohazardous

tation of liquid and gaseous chemicals can be exposed to

chemicals.

numerous compounds capable of causing harm upon contact

3.1.2 chemical protective suit, n—an item of protective

with the human body. The deleterious effects of these chemi-

clothing which is designed and configured to provide the

cals can range from acute trauma such as skin irritation and

wearer’s torso, head, arms, and legs with integrity against

burn to chronic degenerative disease such as cancer. Since

exposure to hazardous chemicals either by itself or in conjunc-

engineering controls may not eliminate all possible exposures,

tion with other protective clothing.

attention is often placed on reducing the potential for direct

3.1.3 integrity, n—the ability of protective clothing or a

skin contact through the use of protective clothing that resists

protective ensemble to prevent inward leakage of hazardous

permeation, penetration, and degradation.

substances from the outside environment.

5.2 This test method is only appropriate for chemical

3.1.3.1 Discussion—For evaluating air-tight integrity, the

protective ensembles, such as totally encapsulating protective

abilityofvaporprotectiveensemblestopreventinwardleakage

suits,thataredesignedandmanufacturedtopreventtheinward

of gases is determined by the amount of leakage following the

leakage of solids, liquids, gases, and vapors. Garments de-

inflation of a vapor protective ensemble to a specified pressure

signed to prevent the penetration of solid and liquid chemicals

over a specified per

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.