ASTM E238-84(1996)

(Test Method)Standard Test Method for Pin-Type Bearing Test of Metallic Materials

Standard Test Method for Pin-Type Bearing Test of Metallic Materials

SCOPE

1.1 This test method covers a pin-type bearing test of metallic materials to determine bearing yield strength and bearing strength. Note-The presence of incidental lubricants on the bearing surfaces may significantly lower the value of bearing yield strength obtained by this method.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: E 238 – 84 (Reapproved 1996) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

1

Pin-Type Bearing Test of Metallic Materials

This standard is issued under the fixed designation E 238; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a pin-type bearing test of

metallic materials to determine bearing yield strength and

bearing strength.

NOTE 1—The presence of incidental lubricants on the bearing surfaces

may significantly lower the value of bearing yield strength obtained by

this method.

1.2 The values stated in inch-pound units are to be regarded

as the standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

E 4 Practices for Force Verification of Testing Machines

E 6 Terminology Relating to Methods of Mechanical Test-

2

ing

E 83 Practice for Verification and Classification of Exten-

2

someters

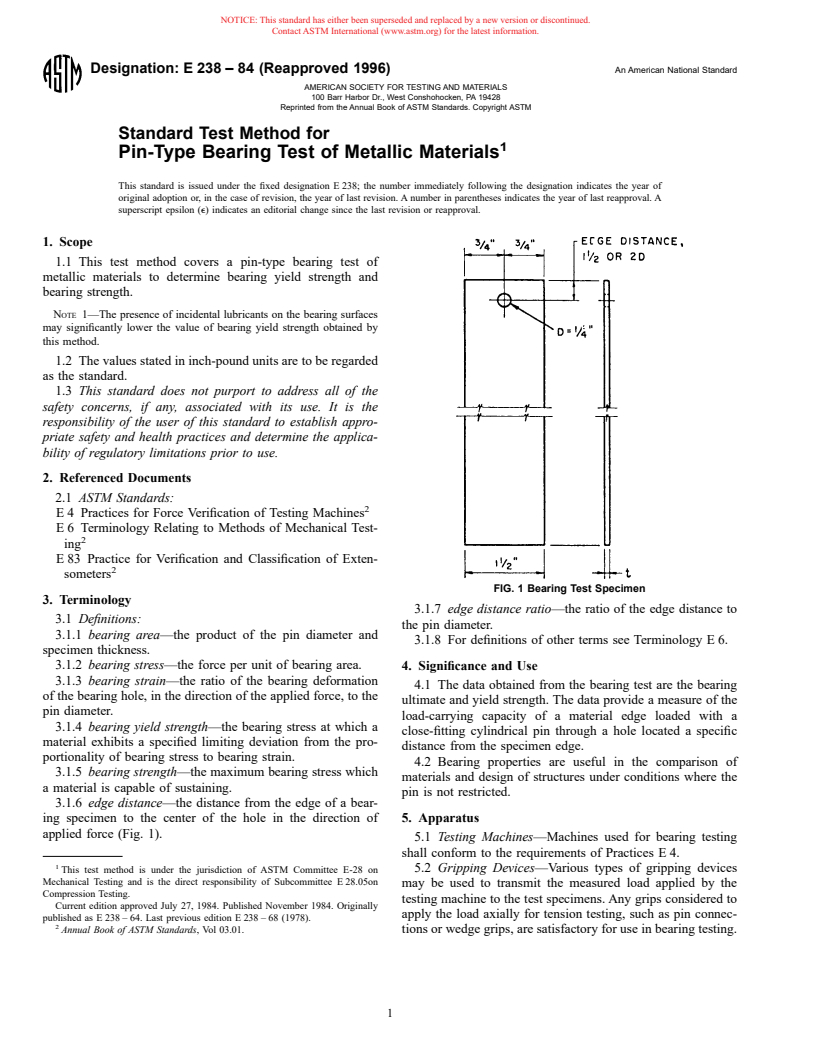

FIG. 1 Bearing Test Specimen

3. Terminology

3.1.7 edge distance ratio—the ratio of the edge distance to

3.1 Definitions:

the pin diameter.

3.1.1 bearing area—the product of the pin diameter and

3.1.8 For definitions of other terms see Terminology E 6.

specimen thickness.

3.1.2 bearing stress—the force per unit of bearing area. 4. Significance and Use

3.1.3 bearing strain—the ratio of the bearing deformation

4.1 The data obtained from the bearing test are the bearing

of the bearing hole, in the direction of the applied force, to the

ultimate and yield strength. The data provide a measure of the

pin diameter.

load-carrying capacity of a material edge loaded with a

3.1.4 bearing yield strength—the bearing stress at which a

close-fitting cylindrical pin through a hole located a specific

material exhibits a specified limiting deviation from the pro-

distance from the specimen edge.

portionality of bearing stress to bearing strain.

4.2 Bearing properties are useful in the comparison of

3.1.5 bearing strength—the maximum bearing stress which

materials and design of structures under conditions where the

a material is capable of sustaining.

pin is not restricted.

3.1.6 edge distance—the distance from the edge of a bear-

ing specimen to the center of the hole in the direction of 5. Apparatus

applied force (Fig. 1).

5.1 Testing Machines—Machines used for bearing testing

shall conform to the requirements of Practices E 4.

1

5.2 Gripping Devices—Various types of gripping devices

This test method is under the jurisdiction of ASTM Committee E-28 on

Mechanical Testing and is the direct responsibility of Subcommittee E 28.05on

may be used to transmit the measured load applied by the

Compression Testing.

testing machine to the test specimens. Any grips considered to

Current edition approved July 27, 1984. Published November 1984. Originally

apply the load axially for tension testing, such as pin connec-

published as E 238 – 64. Last previous edition E 238 – 68 (1978).

2

Annual Book of ASTM Standards, Vol 03.01. tions or wedge grips, are satisfactory for use in bearing testing.

1

---------------------- Page: 1 ----------------------

E 238

5.3 Pin—The bearing load is generally applied to the in test results may be obtained with holes of different diam-

specimen through a close-fitting cylindrical pin. The pin shall eters. The width of the specimen should be about 4 to 8 times

be harder and stronger than the material being tested. Restraint the hole diameter. The edge distance ratio shall be specified and

of movement of the specimen where it is in contact with the pin the edge distance held within a tolerance of 62 %. Edge

1

has a considerable effect upon the hole deformation obtained as distance ratios of 1 ⁄2 and 2 are commonly used (see Fig. 1). A

a function of the load applied. Close control of surface close fit between the specimen and pin is required since a loose

conditions on both the specimen and pin is needed to assure fit will tend to give lower results. The diameter of the hole

reproducible results. The pins used should be uniform in should not exceed the pin diameter by more than 0.001 in.

diameter, hardness, and surface roughness. Pin materials, (0.02 mm). The total length of the test specimen is not critical

hardness, and surface roughness as shown in Table 1 are and may depend on the method used to grip the specimen. Fig.

recommended for testing the materials listed. The pin should 1 shows a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.