ASTM A49-12(2019)

(Specification)Standard Specification for Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint Bars

Standard Specification for Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint Bars

ABSTRACT

This specification covers heat-treated carbon steel joint bars, microalloyed joint bars, and forged compromise joint bars to be used in standard railroad track and production of insulated joints. Manufacturing of the steel shall be done either by basic-oxygen process, electric-furnace process, or both. The chemical composition of the steel joint bars shall be within the limits specified for carbon, manganese, phosphorus, and sulfur. Requirements for heat or cast analysis, product analysis, and tensile testing are detailed. Specifications for the material tensile properties such as tensile strength, yield point, yield strength, and elongation are given.

SCOPE

1.1 This specification covers heat-treated carbon steel joint bars, microalloyed joint bars, and forged compromise joint bars for general use in standard railroad track.

1.2 The joint bars may be used for the production of insulated joints.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A49 −12 (Reapproved 2019)

Standard Specification for

Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint

Bars, and Forged Carbon Steel Compromise Joint Bars

This standard is issued under the fixed designationA49; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Ordering Information

1.1 This specification covers heat-treated carbon steel joint 3.1 Orders for joint bars under this specification shall

bars,microalloyedjointbars,andforgedcompromisejointbars include the following information as appropriate:

for general use in standard railroad track. 3.1.1 Quantity—number of pairs of bars,

3.1.2 Type—design or type bar along with section designa-

1.2 The joint bars may be used for the production of

tion and weight of rails being joined,

insulated joints.

3.1.3 Dimension—overall length,

1.3 The values stated in inch-pound units are to be regarded

3.1.4 Punching—type (elliptical, oval, round, or

as standard. The values given in parentheses are mathematical

combinations), size, number, location, spacing and elevation of

conversions to SI units that are provided for information only

punched holes, with dimensional drawing if necessary,

and are not considered standard.

3.1.5 Head Easement—if required, and

1.4 This international standard was developed in accor- 3.1.6 Certification and Test Report Requirements (see 12.1).

dance with internationally recognized principles on standard-

4. Manufacture

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 4.1 The steel shall be made by one or both of the following

mendations issued by the World Trade Organization Technical processes: basic-oxygen or electric-furnace.

Barriers to Trade (TBT) Committee. 4.1.1 The steel may be cast by a continuous process, or in

ingots.

2. Referenced Documents

4.2 Heating and Quenching—Quenched carbon-steel joint

2.1 ASTM Standards: bars and forged compromise joint bars shall be uniformly

A29/A29M SpecificationforGeneralRequirementsforSteel heated for punching, slotting, shaping, and forging and subse-

Bars, Carbon and Alloy, Hot-Wrought quently quenched. Maximum depth of decarburized layer of

A370 Test Methods and Definitions for Mechanical Testing forged bars shall not exceed 0.040 in.

of Steel Products

4.3 Microalloyed joint bars shall be produced from hot

A700 Guide for Packaging, Marking, and Loading Methods

rolled steel sections. Bars shall be sheared or sawed cold, and

for Steel Products for Shipment

holes shall be drilled. No reheating and quenching is required.

2.2 AREMA Publications:

5. Chemical Requirements

AREMA Manual for Railway Engineering

5.1 The chemical composition of the quenched carbon-steel

joint bars and forged compromise joint bars determined as

prescribed in 5.3 shall be within the limits shown in Table 1.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

5.2 Thechemicalcompositionofthemicroalloyedjointbars

A01.01 on Steel Rails and Accessories.

shall be agreed upon by the purchaser and the manufacturer.

Current edition approved March 1, 2019. Published March 2019. Originally

Microalloying shall be accomplished with columbium,

approved in 1915. Last previous edition approved in 2012 as A49 – 12. DOI:

10.1520/A0049-12R19.

vanadium, and nitrogen, or combinations thereof.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 Heat or Cast Analysis—Separate analysis shall be made

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

from test samples representing one of the first three and one of

the ASTM website.

the last three ingots or continuously cast blooms preferably

Available from American Railway Engineering and Maintenance-of-Way

taken during the pouring of the heat. Determinations may be

Association (AREMA), 4501 Forbes Blvd., Suite 130, Lanham, MD 20706,

https://www.arema.org. made chemically or spectrographically.Any portion of the heat

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

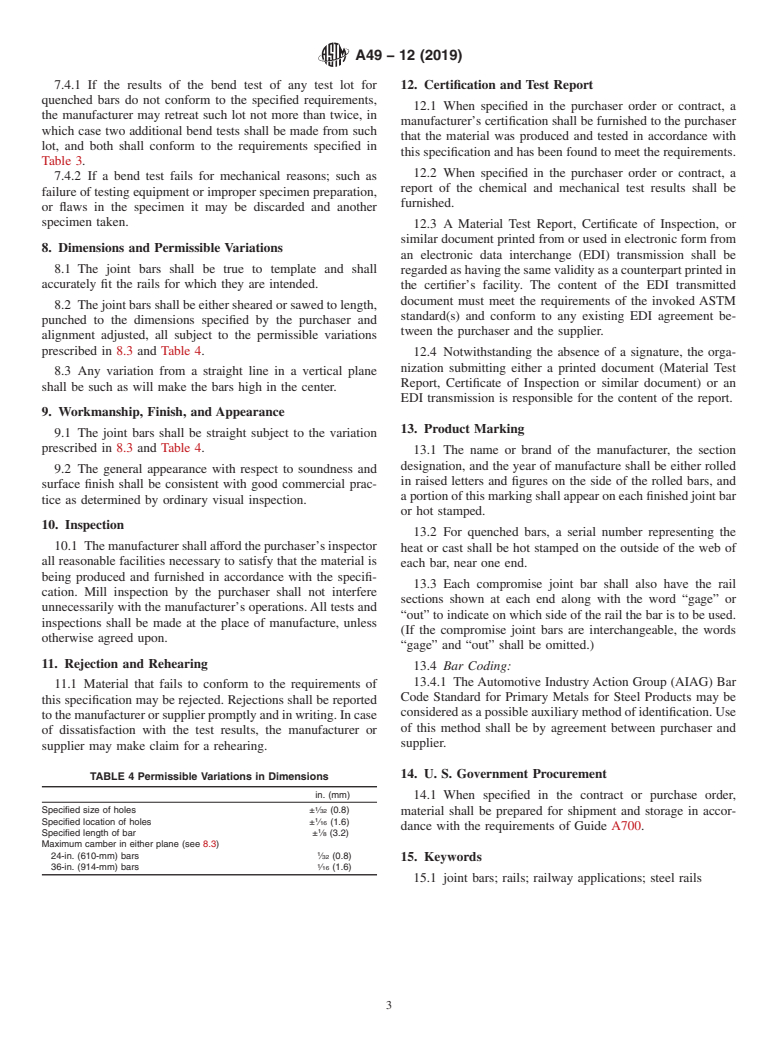

A49−12 (2019)

TABLE 1 Chemical Requirements

6.2 Test Specimens—The tension test specimen shall be

Element Composition, % taken from the middle of the head at the center of a finished

Carbon 0.35–0.60 joint bar, and shall be machined to the form and dimensions for

Manganese, max 1.20

a standard round tension test specimen with 2-in., or 50-mm

Phosphorus, max 0.04

gage length as described in Test Methods and Definitions

Sulfur, max 0.050

A370.

6.3 Number of Tests—One tension test shall be made from

TABLE 2 Product Analyses

each lot of 1000 bars or less, but not less than one test from

Allowance Beyond Limits of Specified Chemical Analysis

each heat or cast on each day in which bars are heated and

Percent under Percent over

quenched. For microalloyed bars, one tension test shall be

min limit max limit

made from each heat or cast.

Carbon 0.04 0.04

Manganese 0.06 0.06

6.4 Retests:

Phosphorus . . . 0.008

6.4.1 If the results of the tension test of any test lot for

Sulfur . . . 0.008

quenched bars do not conform to the specified requirements,

the manufacturer may retreat such lot not more than twice, in

TABLE 3 Tensile Requirements which case two additional tension tests shall be made from

such lot, and both shall conform to the requirements specified

ksi MPa

in Table 3.

Tensile strength, min 100 690

A

Yield point or yield strength, minimum 70 485

6.4.2 If the results of the tension test for microalloyed bars

Elongation in 2 in. or 50 mm, min, % 12

do not conform to the specified requirements, a retest may be

Reduction in area, min, % 25

made on two random samples from the heat or cast, and both

A

Determination by either the 0.2 % offset method or the 0.5 % extension-under-

shall conform to the requirements specified in Table 3.

load method.

6.4.3 If any test specimen fails because of mechanical

reasons such as failure of testing equipment or improper

specimen preparation, it may be discarded and another speci-

meeting the chemical analysis requirements of Table 1 may be

men taken.

applied. The first heat analysis shall be recorded as the official

heat analysis, but the purchaser shall have access to all ladle

7. Bending Requirements

analyses.Additionally, any material meeting the product analy-

7.1 Properties:

sis limits shown in Table 2 may be applied after testing such

7.1.1 The material as represented by a bend test specimen

material in accordance with Specification A29/A29M.

shall conform to the bend properties prescribed below.

5.4 Product Analysis—When ladle tests are not available,

7.1.2 The bend test shall stand being bent cold through 90

finished material representing the heat may be product tested.

degrees without cracking on the outside of the bent portion

The product analysis allowance beyond the limits of the

around a pin the diameter of which is not greater than three

specified ladle analysis shall be within the limits for product

times the thickness of the specimen. If preferred the manufac-

analyses specified in Table 2.

turer may get approval by the purchaser to substitute a full

5.4.1 An analysis may be made by the purchaser from a

section bar. It shall stand being bent cold through 45 degrees

sampletakenfromafinishedjointbarrepresentingeachheator

withoutcrackingontheoutsideofthebentportionaroundapin

cast. The chemical composit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.