ASTM C1393-00

(Specification)Standard Specification for Perpendicularly Oriented Mineral Fiber Roll and Sheet Thermal Insulation for Pipes and Tanks

Standard Specification for Perpendicularly Oriented Mineral Fiber Roll and Sheet Thermal Insulation for Pipes and Tanks

SCOPE

1.1 This specification covers the composition, dimensions, and physical properties of compression-resistant, perpendicularly oriented mineral fiber (rock, slag, or glass) roll and sheet insulation intended for use on flat, curved, or round surfaces up to 1000oF (538oC). This product (pipe and tank insulation) is typically used on nominal 24 in. (610 mm) or greater diameter surfaces. For specific applications, the actual use temperatures and diameters shall be agreed upon between the manufacturer and the purchaser.

1.2 The orientation of the fibers within the roll or sheet insulation is essentially perpendicular to the heated/cooled surface (parallel to heat flow). This specification does not apply to flat block, board, duct wrap, or preformed pipe mineral fiber insulation where the insulation fiber orientation is generally parallel to the heated/cooled surface (across the heat flow).

1.3 For satisfactory performance, properly installed protective vapor retarders must be used in low-temperature (below ambient) applications to prevent movement of water vapor through or around the insulation towards the colder surface.

1.4 The values stated in inch-pound units are to be regarded as standard. The SI equivalents of inch-pound units are given in parentheses for information only and may be approximate.

1.5 When the installation or use of thermal materials, accessories, and systems may pose safety or health problems, the manufacturer shall provide the user-appropriate current information regarding any known problems associated with the recommended use of the company's products and shall also recommend protective measures to be employed in their safe utilization. The user shall establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1393 – 00

Standard Specification for

Perpendicularly Oriented Mineral Fiber Roll and Sheet

Thermal Insulation for Pipes and Tanks

This standard is issued under the fixed designation C 1393; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers the composition, dimensions, 2.1 ASTM Standards:

and physical properties of compression-resistant, perpendicu- C 165 Test Method for Measuring Compressive Properties

larly oriented mineral fiber (rock, slag, or glass) roll and sheet of Thermal Insulations

insulation intended for use on flat, curved, or round surfaces up C 168 Terminology Relating to Thermal Insulation Materi-

to 1000°F (538°C). This product (pipe and tank insulation) is als

typically used on nominal 24 in. (610 mm) or greater diameter C 177 Test Method for Steady-State Heat Flux Measure-

surfaces. For specific applications, the actual use temperatures ments and Thermal Transmission Properties by Means of

and diameters shall be agreed upon between the manufacturer the Guarded-Hot-Plate Apparatus

and the purchaser. C 303 Test Method for Density of Preformed Block-Type

1.2 The orientation of the fibers within the roll or sheet Thermal Insulation

insulation is essentially perpendicular to the heated/cooled C 390 Criteria for Sampling and Acceptance of Preformed

surface (parallel to heat flow). This specification does not apply Thermal Insulation Lots

to flat block, board, duct wrap, or preformed pipe mineral fiber C 411 Test Method for Hot-Surface Performance of High-

insulation where the insulation fiber orientation is generally Temperature Thermal Insulation

parallel to the heated/cooled surface (across the heat flow). C 447 Practice for Estimating the Maximum Use Tempera-

1.3 For satisfactory performance, properly installed protec- ture of Thermal Insulations

tive vapor retarders must be used in low-temperature (below C 518 Test Method for Steady-State Heat Flux Measure-

ambient) applications to prevent movement of water vapor ments and Thermal Transmission Properties by Means of

through or around the insulation towards the colder surface. the Heat Flow Meter Apparatus

1.4 The values stated in inch-pound units are to be regarded C 665 Specification for Mineral-Fiber Blanket Thermal In-

as standard. The SI equivalents of inch-pound units are given sulation for Light Frame Construction and Manufactured

in parentheses for information only and may be approximate. Housing

1.5 When the installation or use of thermal materials, C 680 Practice for Determination of Heat Gain or Loss and

accessories, and systems may pose safety or health problems, the Surface Temperatures of Insulated Pipe and Equipment

the manufacturer shall provide the user-appropriate current Systems by the Use of a Computer Program

information regarding any known problems associated with the C 795 Specification for Thermal Insulation for Use in Con-

recommended use of the company’s products and shall also tact with Austenitic Stainless Steel

recommend protective measures to be employed in their safe C 1045 Practice for Calculating Thermal Transmission

utilization. The user shall establish appropriate safety and Properties Under Steady-State Conditions

health practices and determine the applicability of regulatory C 1058 Practice for Selecting Temperatures for Evaluating

requirements prior to use. and Reporting Thermal Properties of Thermal Insulation

1.6 This standard does not purport to address all of the C 1104/C 1104M Test Method for Determining the Water

safety concerns, if any, associated with its use. It is the Vapor Sorption of Unfaced Mineral Fiber Insulation

responsibility of the user of this standard to establish appro- C 1114 Test Method for Steady-State Thermal Transmission

priate safety and health practices and determine the applica- Properties by Means of the Thin-Heater Apparatus

bility of regulatory limitations prior to use. C 1136 Specification for Flexible, Low Permeance Vapor

Retarders for Thermal Insulation

C 1335 Test Method for Measuring the Non-Fibrous Con-

tent of Man-Made Rock and Slag Mineral Fiber Insulation

This specification is under the jurisdiction of ASTM Committee C-16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

Homogeneous Inorganic Thermal Insulation.

Annual Book of ASTM Standards, Vol 04.06.

Current edition approved Jan. 10, 2000. Published March 2000.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1393

E 84 Test Method for Surface Burning Characteristics of 4.1.1.4 Type IIIB—Maximum use temperature up to 850°F

Building Materials (454°C).

4.1.1.5 Type IVA—Maximum use temperature up to 1000°F

3. Terminology

(538°C).

3.1 Definitions—Definitions pertaining to insulation are in 4.1.1.6 Type IVB—Maximum use temperature up to 1000°F

accordance with Terminology C 168. (538°C).

3.2 Definitions of Terms Specific to This Standard: 4.1.2 Categories:

3.2.1 delivered density—the actual density of the product 4.1.2.1 Category 1—Greater minimum compressive resis-

shipped by the manufacturer or the seller and received by the tance properties are required.

purchaser. 4.1.2.2 Category 2—Lesser minimum compressive resis-

3.2.2 facing—a layer or foundation of thin material which is tance properties are required.

adhered to the insulation to form a continuous roll or sheet of

5. Ordering Information

insulation.

5.1 The type, category, dimensions, and facing shall be

3.2.3 mean temperature—the sum of the cold surface tem-

specified by the purchaser. Shot content and delivered density

perature and the hot surface temperature divided by two.

certification may be requested by the purchaser after consulting

4. Classification

with the supplier or the manufacturer.

4.1 Mineral fiber roll or sheet insulation covered by this

6. Materials and Manufacture

specification is classified into the six types and two categories

6.1 Composition—Mineral fiber roll or sheet shall be com-

shown in Table 1. This classification is based upon the

posed of rock, slag, or glass processed from the molten state

maximum use temperature, maximum apparent thermal con-

into fibrous form, bonded with an organic binder, and the

ductivity, and compressive resistance properties.

orientation of the fibers within the roll or sheet insulation is

4.1.1 Types:

essentially perpendicular to the heated or cooled surface

4.1.1.1 Type I—Maximum use temperature up to 450°F

(parallel to heat flow).

(232°C).

6.2 Facings:

4.1.1.2 Type II—Maximum use temperature up to 650°F

6.2.1 The purchaser must specify the insulation facing and

(343°C).

type required.

4.1.1.3 Type IIIA—Maximum use temperature up to 850°F

CAUTION: The user is advised that the maximum use

(454°C).

temperature of the facings and adhesives may be lower than the

maximum use temperature of the insulation. The specifier shall

ensure that sufficient insulation thickness is installed so none of

Annual Book of ASTM Standards, Vol 04.07.

A

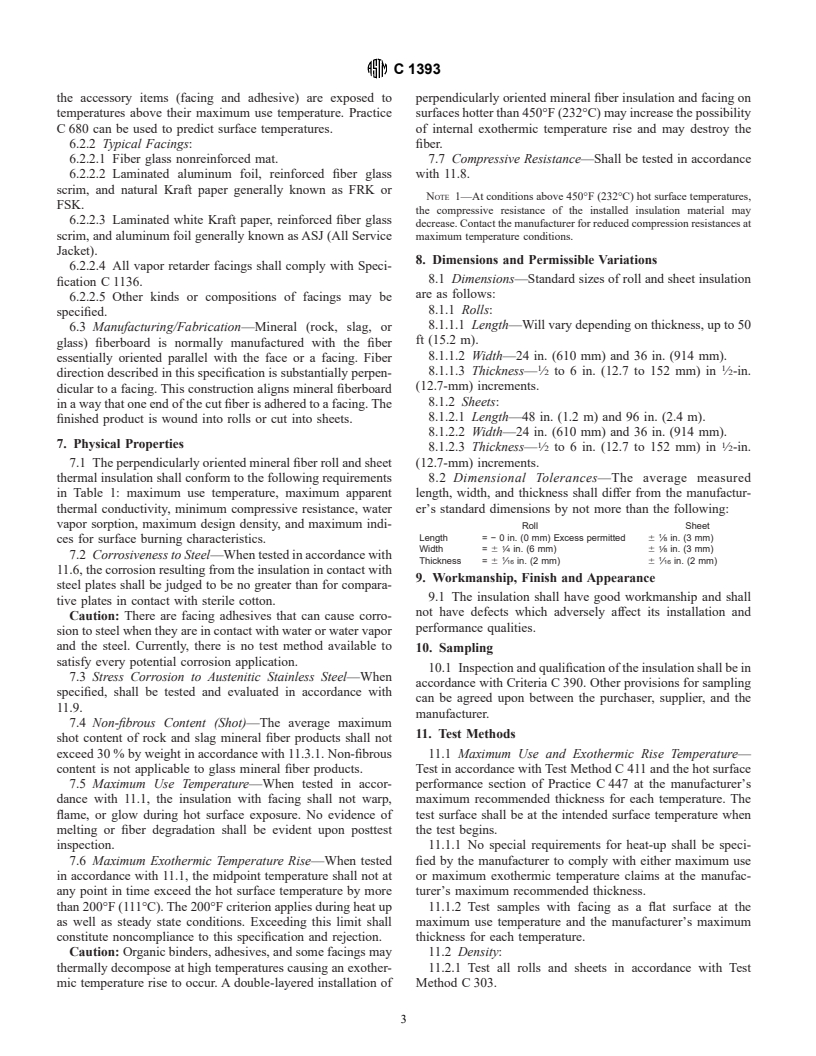

TABLE 1 Physical Property Requirements

Properties Type I Type II Type IIIA Type IIIB Type IVA Type IVB

Maximum Use Temperature,° F (°C) Up to 450 (232) 650 (343) 850 (454) 850 (454) 1000 (538) 1000 (538)

See Caution in 6.2.1

Apparent thermal conductivity Maximum Btu

in./h·ft °F (W/m·K) Mean temperature,° F (°C)

75 (24) 0.27(0.039) 0.27(0.039) 0.27(0.039) 0.27(0.039) 0.27(0.039) 0.28(0.040)

100 (38) 0.29(0.042) 0.29(0.042) 0.29(0.042) 0.29(0.042) 0.29(0.042) 0.30(0.043)

200 (93) 0.38(0.055) 0.38(0.055) 0.38(0.055) 0.36(0.052) 0.36(0.052) 0.36(0.052)

300 (149) 0.48(0.069) 0.48(0.069) 0.48(0.069) 0.45(0.065) 0.45(0.065) 0.43(0.062)

400 (204) 0.61(0.088) 0.61(0.088) 0.61(0.088) 0.54(0.078) 0.54(0.078) 0.50(0.072)

500 (260) 0.81(0.117) 0.81(0.117) 0.66(0.095) 0.66(0.095) 0.58(0.084)

600 (316) 0.82(0.118) 0.67(0.097)

Category 1—Greater compressive resistance,

minimum load required to produce a 10 % 120 (5.7) 120 (5.7) 120 (5.7) 120 (5.7) 120 (5.7) 200 (9.6)

(kPa)

reduction in thickness, lb/ft

Category 2—Lesser compressive resistance,

minimum load required to produce a 10 % 25 (1.2) 25 (1.2) 25 (1.2) 25 (1.2) 25 (1.2) 25 (1.2)

reduction in thickness, lb/ft (kPa)

Water vapor sorption, max % by weight 5.0 5.0 5.0 5.0 5.0 5.0

3 3 B

Density, maximum lb/ft (kg/m ) 6 (96) 6 (96) 6 (96) 6 (96) 6 (96) 8 (128)

Surface burning characteristics:

Maximum flame spread index 25 25 25 25 25 25

Maximum smoke developed index 50 50 50 50 50 50

A

Refer to Section 7 for additional physical property requirements.

B

The maximum density specified is for weight design purposes only. Additional density requirements may be specified as agreed upon between the purchaser and the

manufacturer.

C 1393

the accessory items (facing and adhesive) are exposed to perpendicularly oriented mineral fiber insulation and facing on

temperatures above their maximum use temperature. Practice surfaces hotter than 450°F (232°C) may increase the possibility

C 680 can be used to predict surface temperatures. of internal exothermic temperature rise and may destroy the

6.2.2 Typical Facings: fiber.

6.2.2.1 Fiber glass nonreinforced mat. 7.7 Compressive Resistance—Shall be tested in accordance

6.2.2.2 Laminated aluminum foil, reinforced fiber glass with 11.8.

scrim, and natural Kraft paper generally known as FRK or

NOTE 1—At conditions above 450°F (232°C) hot surface temperatures,

FSK.

the compressive resistance of the installed insulation material may

6.2.2.3 Laminated white Kraft paper, reinforced fiber glass

decrease. Contact the manufacturer for reduced compression resistances at

scrim, and aluminum foil generally known as ASJ (All Service

maximum temperature conditions.

Jacket).

8. Dimensions and Permissible Variations

6.2.2.4 All vapor retarder facings shall comply with Speci-

8.1 Dimensions—Standard sizes of roll and sheet insulation

fication C 1136.

are as follows:

6.2.2.5 Other kinds or compositions of facings may be

8.1.1 Rolls:

specified.

8.1.1.1 Length—Will vary depending on thickness, up to 50

6.3 Manufacturing/Fabrication—Mineral (rock, slag, or

ft (15.2 m).

glass) fiberboard is normally manufactured with the fiber

8.1.1.2 Width—24 in. (610 mm) and 36 in. (914 mm).

essentially oriented parallel with the face or a facing. Fiber

1 1

8.1.1.3 Thickness— ⁄2 to 6 in. (12.7 to 152 mm) in ⁄2-in.

direction described in this specification is substantially perpen-

(12.7-mm) increments.

dicular to a facing. This construction aligns mineral fiberboard

8.1.2 Sheets:

in a way that one end of the cut fiber is adhered to a facing. The

8.1.2.1 Length—48 in. (1.2 m) and 96 in. (2.4 m).

finished product is wound into rolls or cut into sheets.

8.1.2.2 Width—24 in. (610 mm) and 36 in. (914 mm).

7. Physical Properties 1 1

8.1.2.3 Thickness— ⁄2 to 6 in. (12.7 to 152 mm) in ⁄2-in.

7.1 The perpendicularly oriented mineral fiber roll and sheet (12.7-mm) increments.

thermal insulation shall conform to the following requirements 8.2 Dimensional Tolerances—The average measured

in Table 1: maximum use temperature, maximum apparent length, width, and thickness shall differ from the manufactur-

thermal conductivity, minimum compressive resistance, water er’s standard dimensions by not more than the following:

vapor sorption, maximum design density, and maximum indi- Roll Sheet

Length = − 0 in. (0 mm) Excess permitted 6 ⁄8 in. (3 mm)

ces for surface burning characteristics.

1 1

Width = 6 ⁄4 in. (6 mm) 6 ⁄8 in. (3 mm)

7.2 Corrosiveness to Steel—When tested in accordance with

1 1

Thickness = 6 ⁄16 in. (2 mm) 6 ⁄16 in. (2 mm)

11.6, the corrosion resulting from the insulation in contact with

9. Workmanship, Finish and Appearance

steel plates shall be judged to be no greater than for compara-

9.1 The insulation shall have good workmanship and shall

tive plates in contact with sterile cotton.

not have defects which adversely affect its installation and

Caution: There are facing adhesives that can cause corro-

performance qualities.

sion to steel when they are in contact with water or water vapor

and the steel. Currently, there is no test method available to

10. Sampling

satisfy every potential corrosion application.

10.1 Inspection and qualification of the insulation shall be in

7.3 Stress Corrosion to Austenitic Stainless Steel—When

accordance with Criteria C 390. Other provisions for sampling

specified, shall be tested and evaluated in accordance with

can be agreed upon between the purchaser, supplier, and the

11.9.

manufacturer.

7.4 Non-fibrous Content (Shot)—The average maximum

11. Test Methods

shot content of rock and slag mineral fiber products shall not

exceed 30 % by weight in accordance with 11.3.1. Non-fibrous 11.1 Maximum Use and Exothermic Rise Temperature—

content is not applicable to glass mineral fiber products. Test in accordance with Test Method C 411 and the hot surface

7.5 Maximum Use Temperature—When tested in accor- performance section of Practice C 447 at the manufacturer’s

dance with 11.1, the insulation with facing shall not warp, maximum recommended thickness for each temperature. The

flame, or glow during hot surface exposure. No evidence of test surface shall be at the intended surface temperature when

melting or fiber degradation shall be evident upon posttest the test begins.

11.1.1 No special requirements for heat-up shall be speci-

inspection.

7.6 Maximum Exothermic Temperature Rise—When tested fied by the manufacturer to comply with either maximum use

in accordance with 11.1, the midpoint temperature shall not at or maximum exothermic temperature claims at the manufac-

any point in time exceed the hot surface temperature by more turer’s maximum recommended thickness.

than 200°F (111°C). The 200°F criterion applies during heat up 11.1.2 Test samples with facing as a flat surface at the

as well as steady state conditions. Exceeding this limit shall maximum use temperature and the manufacturer’s maximum

constitute noncompliance to this specification and rejection. thickness for each temperature.

Caution: Organic binders, adhesives, and some facings may 11.2 Density:

thermally decompose at high temperatures causing an exother- 11.2.1 Test all rolls and sheets in accordance with Test

mic temperature rise to occur. A double-layered installation of Method C 303.

C 1393

11.2.2 The maximum density of a rock-, slag-, or glass-type cold surface temperatures, is required to determine the effec-

insulation shall not ex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.