ASTM D2594-04(2008)e1

(Test Method)Standard Test Method for Stretch Properties of Knitted Fabrics Having Low Power

Standard Test Method for Stretch Properties of Knitted Fabrics Having Low Power

SIGNIFICANCE AND USE

This test method specifies test conditions for measuring the fabric growth and fabric stretch of knitted fabrics intended for use in swimwear, anchored slacks, and other form-fitting apparel (also commonly known as semi-support apparel) applications, as well as test conditions for measuring the fabric growth of knitted fabrics intended for use in sportswear and other loose-fitting apparel (also commonly known as comfort stretch apparel) applications. The applicability of this test method to the measurement of fabric growth and fabric stretch of knitted fabrics intended for use in slacks, sport coats, and suits has not been determined.

This test method is not recommended for acceptance testing of commercial shipment because the between-laboratory precision is known to be poor.

5.2.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if their is a statistical bias between them, using competent statistical assistance. As a minimum, ensure the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results are obtained, and are assigned randomly in equal numbers to each laboratory for testing. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

SCOPE

1.1 This test method covers the measurement of fabric stretch and fabric growth of knitted fabrics intended for applications requiring low-power stretch properties.

1.2 This test method includes procedures for fabric growth and stretch and can be used individually when required by individual specifications.

1.3 This test method is not applicable to fabrics intended for support or other applications requiring high-power stretch properties.Note 1

For information on testing high-power and woven stretch fabrics, refer to Test Methods D 3107 and D 6614.

1.4 The values stated in either SI or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D2594–04 (Reapproved 2008)

Standard Test Method for

Stretch Properties of Knitted Fabrics Having Low Power

This standard is issued under the fixed designation D2594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made in August 2008.

1. Scope D2904 Practice for Interlaboratory Testing of a Textile Test

Method that Produces Normally Distributed Data

1.1 This test method covers the measurement of fabric

D2906 Practice for Statements on Precision and Bias for

stretch and fabric growth of knitted fabrics intended for

Textiles

applications requiring low-power stretch properties.

D3107 Test Methods for Stretch Properties of Fabrics Wo-

1.2 This test method includes procedures for fabric growth

ven from Stretch Yarns

and stretch and can be used individually when required by

D4849 Terminology Related to Yarns and Fibers

individual specifications.

D4850 Terminology Relating to Fabrics and Fabric Test

1.3 Thistestmethodisnotapplicabletofabricsintendedfor

Methods

support or other applications requiring high-power stretch

D6614 TestMethodforStretchPropertiesofTextileFabrics

properties.

− CRE Method

NOTE 1—For information on testing high-power and woven stretch

fabrics, refer to Test Methods D3107 and D6614.

3. Terminology

1.4 The values stated in either SI or inch-pound units are to

3.1 Definitions:

be regarded separately as the standard. Within the text, the

3.1.1 Fordefinitionoftextiletermsusedinthistestmethod:

inch-pound units are shown in parentheses. The values stated

bench marks, refer to Terminology D4849.

in each system are not exact equivalents; therefore, each

3.1.2 For definitions of textile terms used in this test

system shall be used independently of the other. Combining

method: fabric growth; fabric stretch; low-power stretch and

values from the two systems may result in nonconformance

tension, refer to Terminology D4850.

with the specification.

3.1.3 For definitions of other textile terms used in this test

1.5 This standard does not purport to address all of the

method, refer to Terminology D123.

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 Fabric Growth—Bench marks of a known distance are

bility of regulatory limitations prior to use. made on a fabric specimen.Aspecified tension is applied to a

fabricspecimenbyaprescribedcyclingtechnique.Thetension

2. Referenced Documents

isremovedandafterseveralspecificrecoverytimesunderzero

2.1 ASTM Standards:

tension, the distance between the bench marks is remeasured

D123 Terminology Relating to Textiles

after each time interval. The fabric growth is calculated from

D1776 Practice for Conditioning and Testing Textiles

the length difference between the bench marks prior to appli-

cation of the tension and after each respective recovery time

interval.

4.2 Fabric Stretch—Bench marks of a known distance are

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

made on a fabric specimen.Aspecified tension is applied to a

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

General. fabric specimen by a prescribed cycling technique and the

Current edition approved July 1, 2008. Published August 2008. Originally

resulting distance between the bench marks measured. The

approvedin1969.DiscontinuedNovember1997andreinstatedasD2594–99.Last

fabric stretch is calculated from the length difference between

previouseditionapprovedin2004asD2594–04.DOI:10.1520/D2594-04R08E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D2594–04 (2008)

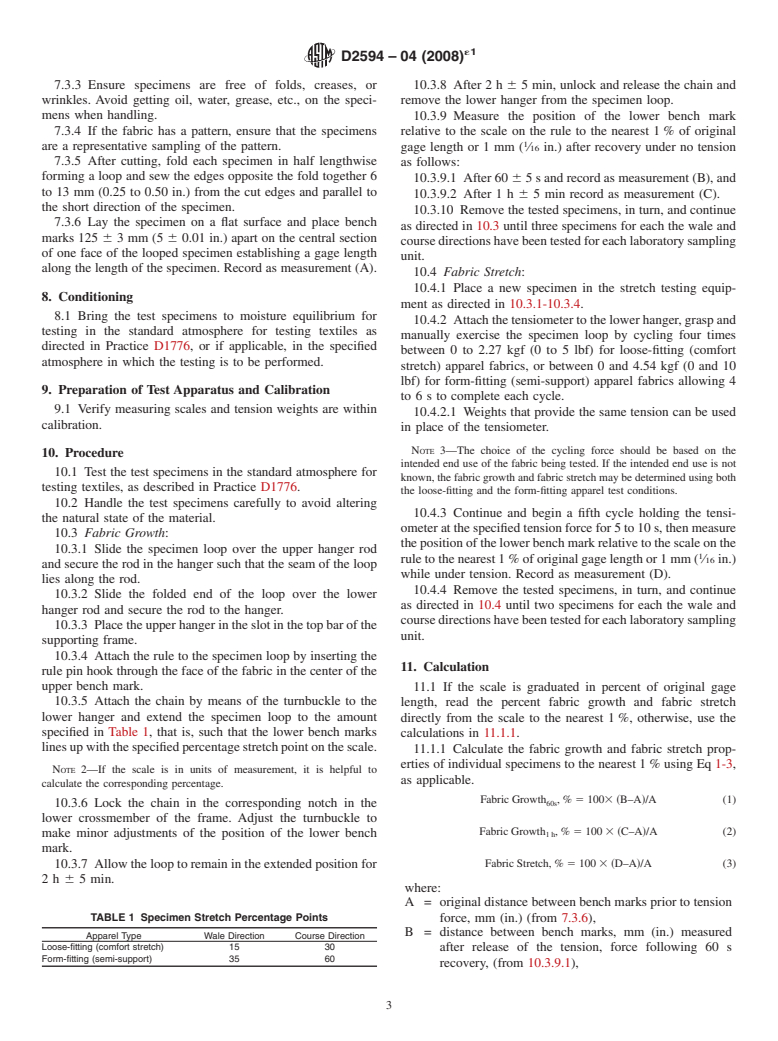

the bench marks prior to application of the tension and under 6.2 Hanger Assembly , consisting of hangers, hanger rods,

while under the tension. and chain.

6.3 Lightweight Rule , fitted with a pin hook at the zero

5. Significance and Use

point of the scale for attachment to the specimen, graduated

either in units of percent of original gage length of 125 mm (5

5.1 This test method specifies test conditions for measuring

in.) or in units of 1 mm ( ⁄16 in.).

the fabric growth and fabric stretch of knitted fabrics intended

for use in swimwear, anchored slacks, and other form-fitting 6.4 Tensiometer or Weights , that can be attached to the

apparel (also commonly known as semi-support apparel) bottom hanger of the hanger assembly, capable of providing

applications,aswellastestconditionsformeasuringthefabric total tensions of 2.27 kgf (5 lbf) and 4.54 kgf (10 lbf) to the

growth of knitted fabrics intended for use in sportswear and specimen, 61%.

other loose-fitting apparel (also commonly known as comfort

6.5 Turnbuckle , or equivalent, having a length of 25 to 75

stretch apparel) applications. The applicability of this test

mm (1 to 3 in.).

method to the measurement of fabric growth and fabric stretch

6.6 Sanforized Marker, to establish bench marks on the

of knitted fabrics intended for use in slacks, sport coats, and

specimen.

suits has not been determined.

6.7 Timer, with increments of at least 1 min.

5.2 This test method is not recommended for acceptance

testing of commercial shipment because the between-

7. Sampling and Test Specs

laboratory precision is known to be poor.

7.1 Primary Sampling Unit—Consider rolls of fabric or

5.2.1 If there are differences of practical significance be-

fabric components of fabricated systems to be the primary

tween reported test results for two laboratories (or more),

sampling unit, as applicable.

comparative tests should be performed to determine if their is

7.2 Laboratory Sampling Unit—As a laboratory sampling

a statistical bias between them, using competent statistical

unit take from rolls at least one full-width piece of fabric that

assistance. As a minimum, ensure the test samples to be used

is2m(2yd)in length along the selvage (machine direction),

are as homogeneous as possible, are drawn from the material

after removing a first 1 mm (1 yd) length. For fabric compo-

from which the disparate test results are obtained, and are

nents of fabricated systems use the entire system.

assigned randomly in equal numbers to each laboratory for

7.3 Test Specimens—From each laboratory sampling unit,

testing. The test results from the two laboratories should be

cut 5 wale-wise (lengthwise) and 5 course-wise (widthwise)

compared using a statistical test for unpaired data, at a

test specimens 125 63mm(5 6 0.1 in.) by 500 6 10 mm

probability level chosen prior to the testing series. If a bias is

(15.5 6 0.3 in.). Cut the long dimension of the wale-wise

found, either its cause must be found and corrected, or future

specimens parallel to the wale direction and the course-wise

test results for that material must be adjusted in consideration

specimens parallel to the course direction. Take specimens

of the known bias.

representing a broad distribution from different positions

diagonally across the width of the laboratory sampling unit.

6. Apparatus

Consider the long direction as the direction of test. Label to

6.1 Frame , suitable for supporting the hanger assembly

maintain specimen identity.

illustrated in Fig. 1 and tension forces applied during testing.

7.3.1 For fabric widths 125 mm (5 in.) or more, take no

specimen closer than 25 mm (1 in.) from the edges of the

laboratory sampling unit.

7.3.2 For fabric widths less than 125 mm (5 in.), use the

For additional information on obtaining apparatus, equipment, or supplies that

may be suitable for use in this standard, please visit the ASTM Manufacturers’

entire width of the laboratory sampling unit for specimens.

Equipment Directory at www.astm.org.

FIG. 1 Hanger Assembly

´1

D2594–04 (2008)

7.3.3 Ensure specimens are free of folds, creases, or 10.3.8 After 2 h 6 5 min, unlock and release the chain and

wrinkles. Avoid getting oil, water, grease, etc., on the speci- remove the lower hanger from the specimen loop.

mens when handling.

10.3.9 Measure the position of the lower bench mark

7.3.4 If the fabric has a pattern, ensure that the specimens relative to the scale on the rule to the nearest 1% of original

are a representative sampling of the pattern.

gage length or 1 mm ( ⁄16 in.) after recovery under no tension

7.3.5 After cutting, fold each specimen in half lengthwise as follows:

forming a loop and sew the edges opposite the fold together 6

10.3.9.1 After60 65sandrecordasmeasurement(B),and

to 13 mm (0.25 to 0.50 in.) from the cut edges and parallel to

10.3.9.2 After 1 h 6 5 min record as measurement (C).

the short direction of the specimen.

10.3.10 Remove the tested specimens, in turn, and continue

7.3.6 Lay the specimen on a flat surface and place bench

as directed in 10.3 until three specimens for each the wale and

marks 125 63mm(5 6 0.01 in.) apart on the central section

coursedirectionshavebeentestedforeachlaboratorysampling

of one face of the looped specimen establishing a gage length

unit.

along the length of the specimen. Record as measurement (A).

10.4 Fabric Stretch:

10.4.1 Place a new specimen in the stretch testing equip-

8. Conditioning

ment as dir

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D2594–99a Designation:D2594–04 (Reapproved 2008)

Standard Test Method for

Stretch Properties of Knitted Fabrics Having Low Power

This standard is issued under the fixed designation D 2594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made in August 2008.

1. Scope

1.1 This test method covers the measurement of fabric stretch and fabric growth of knitted fabrics intended for applications

requiring low-power stretch properties.

1.2 Thistestmethodincludesproceduresforfabricgrowthandstretchandcanbeusedindividuallywhenrequiredbyindividual

specifications.

1.3 This test method is not applicable to fabrics intended for support or other applications requiring high-power stretch

properties.

NOTE1—For information on testing high-power stretch fabrics, refer to Test Method D1775 1—For information on testing high-power and woven

stretch fabrics, refer to Test Methods D 3107 and D 6614.

1.4 The values stated in either SI or inch-pound units are to be regarded separately as the standard. Within the text, the

inch-pound units are shown in parentheses.The values stated in each system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles D1775Test Method for Tension and Elongation of Wide Elastic Fabrics

D 1776 Practice for Conditioning and Testing Textiles

D 2904 Practice for Interlaboratory Testing of a Textile Test Method Thatthat Produces Normally Distributed Data

D 2906Practice for Statements on Precision and Bias for Textiles Practice for Statements on Precision and Bias for Textiles

D 3107 Test Methods for Stretch Properties of Fabrics Woven from Stretch Yarns

D4848Terminology of Force, Deformation, and Related Properties of Textiles 4849 Terminology Related to Yarns and Fibers

D 4850 Terminology Relating to Fabric

D 6614 Test Method for Stretch Properties of Textile Fabrics CRE Method

3. Terminology

3.1 Definitions:

3.1.1bench marks, n—marks placed on a specimen to define gage length, that is, the portion of the specimen that will be

evaluated in a specific test.

3.1.2fabric stretch, n—the increase in length of a specimen of fabric resulting from a tension force applied under specified

conditions.

3.1.2.1Discussion—Thedifferenceusuallyisexpressedasapercentageoftheinitiallengthofthefabricspecimen.Fabricstretch

differs from fabric elongation in that the latter (up to the point of rupture) reflects the instantaneously existing amount of stretch

under a constantly increasing tension force.

3.1.3fabric growth, n—the difference between the original length of a specimen and its length after the application of a specified

tension for a prescribed time and the subsequent removal of the tension.

This test method is under the jurisdiction of ASTM Committee D-13D13 on Textiles and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

General.

Current edition approved Dec. 10, 1999.July 1, 2008. Published January 2000.August 2008. Originally published as D2594–69 T. approved in 1969. Discontinued

November 1997 and reinstated as D 2594 – 99. Last previous edition D2594–99approved in 2004 as D 2594 – 04.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 07.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D2594–04 (2008)

3.1.3.1Discussion—Fabric growth usually is expressed as a percentage of the length of the specimen prior to application of the

tension (see also permanent deformation).

3.1.4low-power stretch, n—that property of a fabric whereby it exhibits high fabric stretch and good recovery from low tension.

3.1.5tension , n—a uniaxial force tending to cause the extension of a body or the balancing force within that body resisting the

extension

3.1.6For definitions of other textile terms used in this test method, refer to Terminologies D123 and D4848Definitions:

3.1.1 For definition of textile terms used in this test method: bench marks, refer to Terminology D 4849.

3.1.2 For definitions of textile terms used in this test method: fabric growth; fabric stretch; low-power stretch and tension, refer

to Terminology D 4850.

3.1.3 For definitions of other textile terms used in this test method, refer to Terminology D 123.

4. Summary of Test Method

4.1 Fabric Growth— Bench marks of a known distance are made on a fabric specimen.Aspecified tension is applied to a fabric

specimen by a prescribed cycling technique. The tension is removed and after several specific recovery times under zero tension,

the distance between the bench marks is remeasured after each time interval. The fabric growth is calculated from the length

difference between the bench marks prior to application of the tension and after each respective recovery time interval.

4.2 Fabric Stretch— Bench marks of a known distance are made on a fabric specimen.Aspecified tension is applied to a fabric

specimen by a prescribed cycling technique and the resulting distance between the bench marks measured. The fabric stretch is

calculatedfromthelengthdifferencebetweenthebenchmarkspriortoapplicationofthetensionandunderwhileunderthetension.

5. Significance and Use

5.1 This test method specifies test conditions for measuring the fabric growth and fabric stretch of knitted fabrics intended for

use in swimwear, anchored slacks, and other form-fitting apparel (also commonly known as semi-support apparel) applications,

as well as test conditions for measuring the fabric growth of knitted fabrics intended for use in sportswear and other loose-fitting

apparel (also commonly known as comfort stretch apparel) applications. The applicability of this test method to the measurement

of fabric growth and fabric stretch of knitted fabrics intended for use in slacks, sport coats, and suits has not been determined.

5.2 This test method is not recommended for acceptance testing of commercial shipment because the between-laboratory

precision is known to be poor.

5.2.1 If there are differences orof practical significance between reported test results for two laboratories (or more), comparative

tests should be performed to determine if their is a statistical bias between them, using competent statistical assistance. As a

minimum, ensure the test samples shouldto be used that are as homogeneous as possible, that are drawn from the material from

which the disparate test results are obtained, and that are assigned randomly in equal numbers to each laboratory for testing. Other

materials with established test values may be used for this purpose. The test results from the two laboratories should be compared

using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause

must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

6. Apparatus

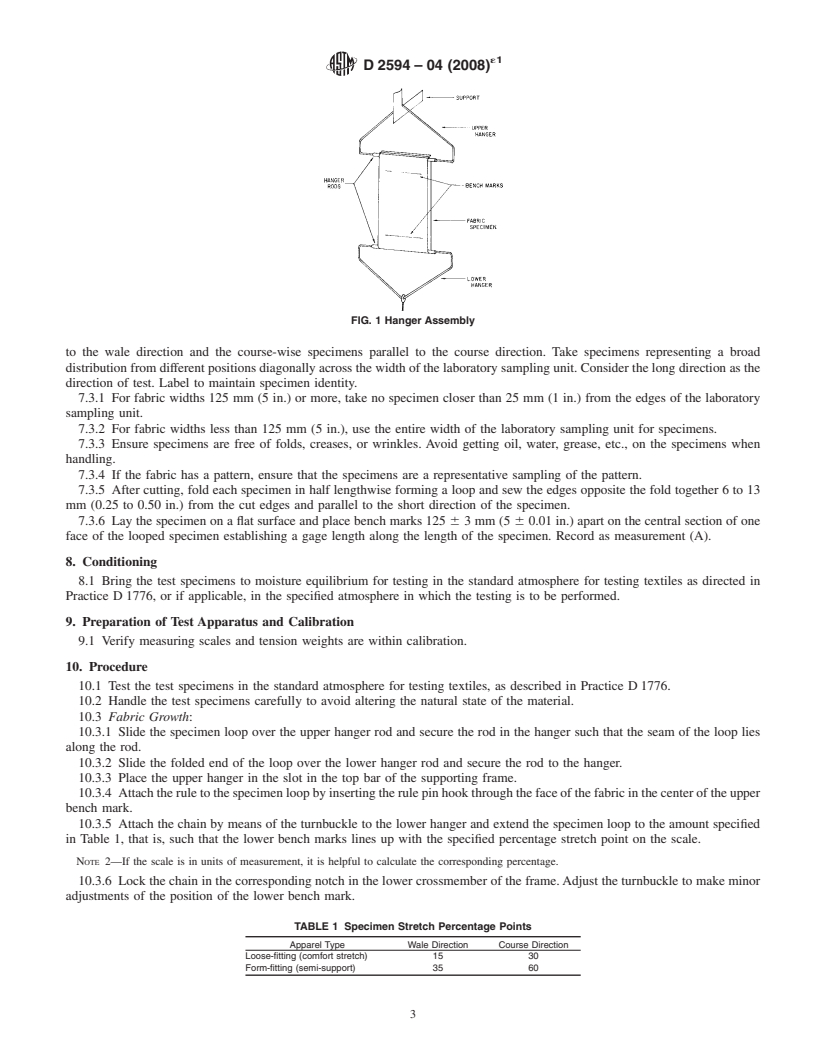

6.1 Frame , suitable for supporting the hanger assembly illustrated in Fig. 1 and tension forces applied during testing.

6.2 Hanger Assembly , consisting of hangers, hanger rods, and chain.

6.3 Lightweight Rule , fitted with a pin hook at the zero point of the scale for attachment to the specimen, graduated either in

units of percent of original gage length of 125 mm (5 in.) or in units of 1 mm ( ⁄16 in.).

6.4 Tensiometer or Weights , that can be attached to the bottom hanger of the hanger assembly, capable of providing total

tensions of 2.27 kgf (5 lbf) and 4.54 kgf (10 lbf) to the specimen, 61%.

6.5 Turnbuckle , or equivalent, having a length of 25 to 75 mm (1 to 3 in.).

6.6 Sanforized Marker, to establish bench marks on the specimen.

6.7 Timer, with increments of at least 1 min.

7. Sampling and Test Specs

7.1 Primary Sampling Unit—Consider rolls of fabric or fabric components of fabricated systems to be the primary sampling

unit, as applicable.

7.2 Laboratory Sampling Unit—As a laboratory sampling unit take from rolls at least one full-width piece of fabric that is 2

m (2 yd) in length along the selvage (machine direction), after removing a first 1 mm (1 yd) length. For fabric components of

fabricated systems use the entire system.

7.3 Test Specimens— From each laboratory sampling unit, cut 5 wale-wise (lengthwise) and 5 course-wise (widthwise) test

specimens125 63mm(5 60.1in.)by500 610mm(15.5 60.3in.).Cutthelongdimensionofthewale-wisespecimensparallel

Annual Book of ASTM Standards, Vol 07.02.

For additional information on obtaining apparatus, equipment, or supplies that may be suitable for use in this standard, please visit theASTM Manufacturers’Equipment

Directory at www.astm.org.

´1

D2594–04 (2008)

FIG. 1 Hanger Assembly

to the wale direction and the course-wise specimens parallel to the course direction. Take specimens representing a broad

distribution from different positions diagonally across the width of the laboratory sampling unit. Consider the long direction as the

direction of test. Label to maintain specimen identity.

7.3.1 For fabric widths 125 mm (5 in.) or more, take no specimen closer than 25 mm (1 in.) from the edges of the laboratory

sampling unit.

7.3.2 For fabric widths less than 125 mm (5 in.), use the entire width of the laboratory sampling unit for specimens.

7.3.3 Ensure specimens are free of folds, creases, or wrinkles. Avoid getting oil, water, grease, etc., on the specimens when

handling.

7.3.4 If the fabric has a pattern, ensure that the specimens are a representative sampling of the pattern.

7.3.5 After cutting, fold each specimen in half lengthwise forming a loop and sew the edges opposite the fold together 6 to 13

mm (0.25 to 0.50 in.) from the cut edges and parallel to the short direction of the specimen.

7.3.6 Lay the specimen on a flat surface a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.