ASTM D3895-02

(Test Method)Standard Test Method for Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry

Standard Test Method for Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry

SCOPE

1.1 This test method outlines a procedure for the determination of oxidative-induction time (OIT) of polymeric materials by differential scanning calorimetry (DSC). It is applicable to polyolefin resins that are in a fully stabilized/compounded form.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards information is given in Section 8.

Note 1—This test method is similar to ISO 11357-6, but not identical. The temperature used by ISO is 210°C.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: D 3895 – 02

Standard Test Method for

Oxidative-Induction Time of Polyolefins by Differential

1

Scanning Calorimetry

This standard is issued under the fixed designation D 3895; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* interval to onset of exothermic oxidation of a material at a

specified temperature in an oxygen atmosphere.

1.1 This test method outlines a procedure for the determi-

3.2.2 Abbreviations:

nation of oxidative-induction time (OIT) of polymeric materi-

3.2.3 HDPE—high-density polyethylene.

als by differential scanning calorimetry (DSC). It is applicable

3.2.4 LDPE—low-density polyethylene.

to polyolefin resins that are in a fully stabilized/compounded

3.2.5 LLDPE—linear low-density polyethylene.

form.

3.2.6 OIT—oxidative induction time.

1.2 The values stated in SI units are to be regarded as the

standard.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 The sample to be tested and the reference material are

safety concerns, if any, associated with its use. It is the

heated at a constant rate in an inert gaseous environment

responsibility of the user of this standard to establish appro-

(nitrogen). When the specified temperature has been reached,

priate safety and health practices and determine the applica-

the atmosphere is changed to oxygen maintained at the same

bility of regulatory limitations prior to use. Specific hazards

flow rate. The specimen is then held at constant temperature

information is given in Section 8.

until the oxidative reaction is displayed on the thermal curve.

NOTE 1—This test method is similar to ISO 11357–6, but not identical.

The time interval from when the oxygen flow is first initiated

The temperature used by ISO is 210°C.

to the oxidative reaction is referred to as the induction period.

4.1.1 The end of the induction period is signaled by an

2. Referenced Documents

abrupt increase in the specimen’s evolved heat or temperature

2.1 ASTM Standards:

and may be observed by a differential scanning calorimeter

D 4703 Practice for Compression Molding Thermoplastic

(DSC). The OIT is determined from the data recorded during

2

Materials into Test Specimens, Plaques, or Sheets

the isothermal test.

3

E 473 Terminology Relating to Thermal Analysis

4.2 The type of containment system used depends on the

E 691 Practice for Conducting an Interlaboratory Study to

intended application use of the material being tested. Polyole-

3

Determine the Precision of a Test Method

fins used in the wire and cable industry typically require copper

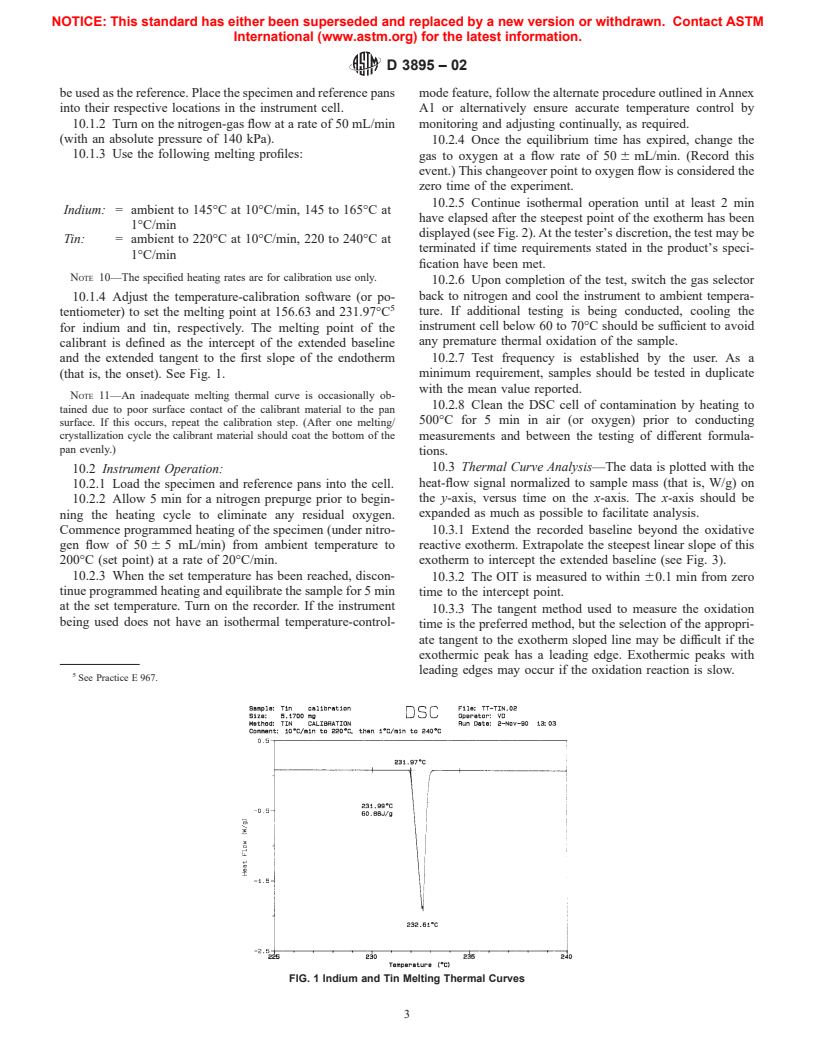

E 967 Practice for Temperature Calibration of Differential

or aluminum pans, whereas polyolefins used in geomembrane

Scanning Calorimeters and Differential Thermal Analyz-

and vapor-barrier film applications exclusively use aluminum

3

ers

pans.

4.3 Unless otherwise specified, the analysis temperature

3. Terminology

used in this test has been set arbitrarily at 200.0°C. For samples

3.1 Definitions—Definitions of terms applying to thermal

that have relatively low or high stabilization levels, a different

analysis appear in Terminology E 473.

temperature may be selected (typically between 180 and

3.2 Description of Term Specific to This Standard:

220°C) to yield a thermal curve that can be interpreted and

3.2.1 oxidative induction time—a relative measure of a

analyzed easily.

material’s resistance to oxidative decomposition; it is deter-

mined by the thermoanalytical measurement of the time

5. Significance and Use

5.1 The OIT is a qualitative assessment of the level (or

1

degree) of stabilization of the material tested. This test can be

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties used as a quality control measure to monitor the stabilization

(Section D 20.30.07).

level in formulated resin as received from a supplier, prior to

Current edition approved November 10, 2002. Published January 2003. Origi-

extrusion.

nally approved in 1980. Last previous edition approved in 1998 as D 3895 – 98.

2

Annual Book of ASTM Standards, Vol 08.01.

3

Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D 3895 – 02

NOTE

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.