ASTM F622-79(1998)

(Specification)Standard Specification for Preformed Cranioplasty Plates that can be Altered

Standard Specification for Preformed Cranioplasty Plates that can be Altered

SCOPE

1.1 This specification covers preformed cranioplasty plates that allow alteration for covering skull defects.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

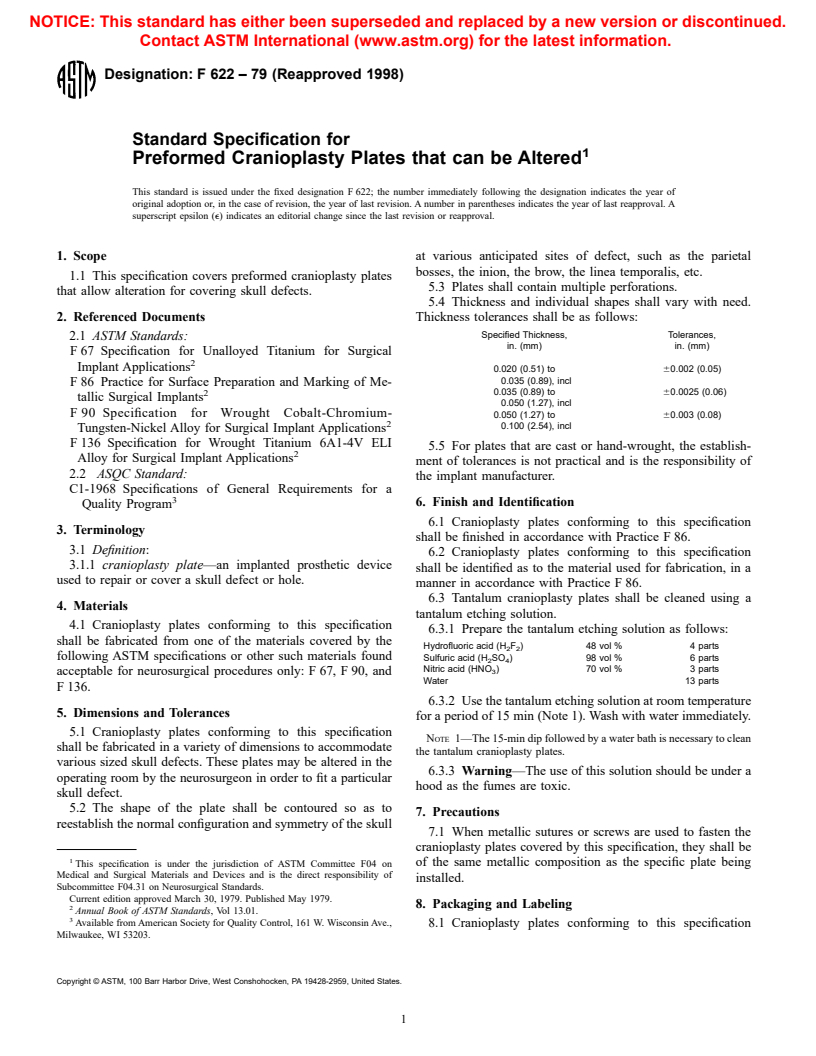

Designation: F 622 – 79 (Reapproved 1998)

Standard Specification for

Preformed Cranioplasty Plates that can be Altered

This standard is issued under the fixed designation F 622; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope at various anticipated sites of defect, such as the parietal

bosses, the inion, the brow, the linea temporalis, etc.

1.1 This specification covers preformed cranioplasty plates

5.3 Plates shall contain multiple perforations.

that allow alteration for covering skull defects.

5.4 Thickness and individual shapes shall vary with need.

2. Referenced Documents

Thickness tolerances shall be as follows:

Specified Thickness, Tolerances,

2.1 ASTM Standards:

in. (mm) in. (mm)

F 67 Specification for Unalloyed Titanium for Surgical

Implant Applications

0.020 (0.51) to 60.002 (0.05)

0.035 (0.89), incl

F 86 Practice for Surface Preparation and Marking of Me-

0.035 (0.89) to 60.0025 (0.06)

tallic Surgical Implants

0.050 (1.27), incl

F 90 Specification for Wrought Cobalt-Chromium-

0.050 (1.27) to 60.003 (0.08)

0.100 (2.54), incl

Tungsten-Nickel Alloy for Surgical Implant Applications

F 136 Specification for Wrought Titanium 6A1-4V ELI

5.5 For plates that are cast or hand-wrought, the establish-

Alloy for Surgical Implant Applications

ment of tolerances is not practical and is the responsibility of

2.2 ASQC Standard:

the implant manufacturer.

C1-1968 Specifications of General Requirements for a

6. Finish and Identification

Quality Program

6.1 Cranioplasty plates conforming to this specification

3. Terminology

shall be finished in accordance with Practice F 86.

3.1 Definition:

6.2 Cranioplasty plates conforming to this specification

3.1.1 cranioplasty plate—an implanted prosthetic device

shall be identified as to the material used for fabrication, in a

used to repair or cover a skull defect or hole.

manner in accordance with Practice F 86.

6.3 Tantalum cranioplasty plates shall be cleaned using a

4. Materials

tantalum etching solution.

4.1 Cranioplasty plates conforming to this specification

6.3.1 Prepare the tantalum etching solution as follows:

shall be fabricated from one of the materials covered by the

Hydrofluoric acid (H F ) 48 vol % 4 parts

2 2

following ASTM specifications or other such materials found Sulfuric acid (H SO ) 98 vol % 6 parts

2 4

Nitric acid (HNO ) 70 vol % 3 parts

acceptable for neurosurgical procedures only: F 67, F 90, and

Water 13 parts

F 136.

6.3.2 Use the tantalum etching solution at room temperature

5. Dimensions and Tolerances

for a period of 15 min (Note 1). Wash with water immediately.

5.1 Cranioplasty plates conforming to this specification

NOTE 1—The 15-min dip followed by a water bath is necessary to clean

shall be fabricated in a variety of dimensions to accommodate

the tantalum cranioplasty plates.

various sized skull defects. These plates may be altered in the

6.3.3 Warning—The use o

...

This May Also Interest You

SIGNIFICANCE AND USE

4.1 This procedure measures the amount of hydrogen gas generation potential of aluminized emulsion roof coating. There is the possibility of water reacting with aluminum pigment to generate hydrogen gas. This situation is to be avoided, so this test was designed to evaluate coating formulations and assess the propensity to gassing.

SCOPE

1.1 This test method covers a hydrogen gas and stability test for aluminum emulsified asphalt coatings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the physical requirements and testing of three types of lap cement for use with asphalt roll roofing. Type I is a brushing consistency lap cement intended for use in the exposed-nailing method of roll roofing application, and contains no mineral or other stabilizers. This type is further divided into two grades, as follows: Grade 1, which is made with an air-blown asphalt; and Grade 2, which is made with a vacuum-reduced or steam-refined asphalt. Both Types II and III, on the other hand, are heavy brushing or light troweling consistency lap cement intended for use in the concealed-nailing method of roll roofing application, only that Type II cement contains a quantity of short-fibered asbestos, while Type III cement contains a quantity of mineral or other stabilizers, or both, but contains no asbestos. The lap cements shall be sampled for testing, and shall adhere to specified values of the following properties: water content; distillation (total distillate at given temperatures); softening point of residue; solubility in trichloroethylene; and strength at indicated age.

SCOPE

1.1 This specification covers lap cement consisting of asphalt dissolved in a volatile petroleum solvent with or without mineral or other stabilizers, or both, for use with roll roofing. The fibered version of these cements excludes the use of asbestos fibers.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The following precautionary caveat applies only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Coefficients of linear thermal expansion are used, for example, for design purposes and to determine if failure by thermal stress may occur when a solid body composed of two different materials is subjected to temperature variations.

5.2 This test method is comparable to Test Method D3386 for testing electrical insulation materials, but it covers a more general group of solid materials and it defines test conditions more specifically. This test method uses a smaller specimen and substantially different apparatus than Test Methods E228 and D696.

5.3 This test method may be used in research, specification acceptance, regulatory compliance, and quality assurance.

SCOPE

1.1 This test method determines the technical coefficient of linear thermal expansion of solid materials using thermomechanical analysis techniques.

1.2 This test method is applicable to solid materials that exhibit sufficient rigidity over the test temperature range such that the sensing probe does not produce indentation of the specimen.

1.3 The recommended lower limit of coefficient of linear thermal expansion measured with this test method is 5 μm/(m·°C). The test method may be used at lower (or negative) expansion levels with decreased accuracy and precision (see Section 12).

1.4 This test method is applicable to the temperature range from −120 °C to 900 °C. The temperature range may be extended depending upon the instrumentation and calibration materials used.

1.5 SI units are the standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Research O.N. correlates with commercial automotive spark-ignition engine antiknock performance under mild conditions of operation.

5.2 Research O.N. is used by engine manufacturers, petroleum refiners and marketers, and in commerce as a primary specification measurement related to the matching of fuels and engines.

5.2.1 Empirical correlations that permit calculation of automotive antiknock performance are based on the general equation:

Values of k1, k2, and k3 vary with vehicles and vehicle populations and are based on road-O.N. determinations.

5.2.2 Research O.N., in conjunction with Motor O.N., defines the antiknock index of automotive spark-ignition engine fuels, in accordance with Specification D4814. The antiknock index of a fuel approximates the Road octane ratings for many vehicles, is posted on retail dispensing pumps in the U.S., and is referred to in vehicle manuals.

This is more commonly presented as:

5.2.3 Research O.N. is also used either alone or in conjunction with other factors to define the Road O.N. capabilities of spark-ignition engine fuels for vehicles operating in areas of the world other than the United States.

5.3 Research O.N. is used for measuring the antiknock performance of spark-ignition engine fuels that contain oxygenates.

5.4 Research O.N. is important in relation to the specifications for spark-ignition engine fuels used in stationary and other nonautomotive engine applications.

SCOPE

1.1 This laboratory test method covers the quantitative determination of the knock rating of liquid spark-ignition engine fuel in terms of Research O.N., including fuels that contain up to 25 % v/v of ethanol. However, this test method may not be applicable to fuel and fuel components that are primarily oxygenates.2 The sample fuel is tested using a standardized single cylinder, four-stroke cycle, variable compression ratio, carbureted, CFR engine run in accordance with a defined set of operating conditions. The O.N. scale is defined by the volumetric composition of PRF blends. The sample fuel knock intensity is compared to that of one or more PRF blends. The O.N. of the PRF blend that matches the K.I. of the sample fuel establishes the Research O.N.

1.2 The O.N. scale covers the range from 0 to 120 octane number but this test method has a working range from 40 to 120 Research O.N. Typical commercial fuels produced for spark-ignition engines rate in the 88 to 101 Research O.N. range. Testing of gasoline blend stocks or other process stream materials can produce ratings at various levels throughout the Research O.N. range.

1.3 The values of operating conditions are stated in SI units and are considered standard. The values in parentheses are the historical inch-pound units. The standardized CFR engine measurements continue to be in inch-pound units only because of the extensive and expensive tooling that has been created for this equipment.

1.4 For purposes of determining conformance with all specified limits in this standard, an observed value or a calculated value shall be rounded “to the nearest unit” in the last right-hand digit used in expressing the specified limit, in accordance with the rounding method of Practice E29.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 8, 14.4.1, 15.5.1, 16.6.1, Annex A1, A2.2.3.1, A2.2.3.3 (6) and (9), A2.3.5, X3.3.7, X4.2.3.1, X4.3.4.1, X4.3.9.3, X4.3.11.4, and X4.5.1.8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Gu...

- Standard48 pagesEnglish languagesale 15% off

- Standard48 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 This test method measures a lubricant's ability to protect hypoid final drive axles from abrasive wear, adhesive wear, plastic deformation, and surface fatigue when subjected to low-speed, high-torque conditions. Lack of protection can lead to premature gear or bearing failure, or both.

5.2 This test method is used, or referred to, in specifications and classifications of rear-axle gear lubricants such as:

5.2.1 Specification D7450.

5.2.2 American Petroleum Institute (API) Publication 1560.

5.2.3 SAE J308.

5.2.4 SAE J2360.

SCOPE

1.1 This test method, commonly referred to as the L-37-1 test, describes a test procedure for evaluating the load-carrying capacity, wear performance, and extreme pressure properties of a gear lubricant in a hypoid axle under conditions of low-speed, high-torque operation.3

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exceptions—Where there is no direct SI equivalent such as National Pipe threads/diameters, tubing size, or where there is a sole source supply equipment specification.

1.2.1.1 The drawing in Annex A6 is in inch-pound units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are provided in 7.2 and 10.1.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard18 pagesEnglish languagesale 15% off

- Standard18 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The kinematic viscosity characterizes flow behavior. The method is used to determine the consistency of liquid asphalt as one element in establishing the uniformity of shipments or sources of supply. The specifications are usually at temperatures of 60 and 135 °C.

Note 3: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method covers procedures for the determination of kinematic viscosity of liquid asphalts, road oils, and distillation residues of liquid asphalts all at 60 °C [140 °F] and of liquid asphalt binders at 135 °C [275 °F] (see table notes, 11.1) in the range from 6 to 100 000 mm2/s [cSt].

1.2 Results of this test method can be used to calculate viscosity when the density of the test material at the test temperature is known or can be determined. See Annex A1 for the method of calculation.

Note 1: This test method is suitable for use at other temperatures and at lower kinematic viscosities, but the precision is based on determinations on liquid asphalts and road oils at 60 °C [140 °F] and on asphalt binders at 135 °C [275 °F] only in the viscosity range from 30 to 6000 mm2/s [cSt].

Note 2: Modified asphalt binders or asphalt binders that have been conditioned or recovered are typically non-Newtonian under the conditions of this test. The viscosity determined from this method is under the assumption that asphalt binders behave as Newtonian fluids under the conditions of this test. When the flow is non-Newtonian in a capillary tube, the shear rate determined by this method may be invalid. The presence of non-Newtonian behavior for the test conditions can be verified by measuring the viscosity with viscometers having different-sized capillary tubes. The defined precision limits in 11.1 may not be applicable to non-Newtonian asphalt binders.

1.3 Warning—Mercury has been designated by the United States Environmental Protection Agency (EPA) and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for details and the EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury, mercury-containing products, or both, in your state may be prohibited by state law.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior ...

- Standard11 pagesEnglish languagesale 15% off

- Standard11 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 Flash X-ray facilities provide intense bremsstrahlung radiation environments, usually in a single sub-microsecond pulse, which often fluctuates in amplitude, shape, and spectrum from shot to shot. Therefore, appropriate dosimetry must be fielded on every exposure to characterize the environment, see ICRU Report 34. These intense bremsstrahlung sources have a variety of applications which include the following:

(1) Studies of the effects of X-rays and gamma rays on materials.

(2) Studies of the effects of radiation on electronic devices such as transistors, diodes, and capacitors.

(3) Computer code validation studies.

4.2 This guide is written to assist the experimenter in selecting the needed dosimetry systems for use at pulsed X-ray facilities. This guide also provides a brief summary on how to use each of the dosimetry systems. Other guides (see Section 2) provide more detailed information on selected dosimetry systems in radiation environments and should be consulted after an initial decision is made on the appropriate dosimetry system to use. There are many key parameters which describe a flash X-ray source, such as dose, dose rate, spectrum, pulse width, etc., such that typically no single dosimetry system can measure all the parameters simultaneously. However, it is frequently the case that not all key parameters must be measured in a given experiment.

SCOPE

1.1 This guide provides assistance in selecting and using dosimetry systems in flash X-ray experiments. Both dose and dose rate techniques are described.

1.2 Operating characteristics of flash X-ray sources are given, with emphasis on the spectrum of the photon output.

1.3 Assistance is provided to relate the measured dose to the response of a device under test (DUT). The device is assumed to be a semiconductor electronic part or system.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide19 pagesEnglish languagesale 15% off

- Guide19 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 Since the information provided by this test method is largely qualitative in nature, specific limits covering the following characteristics are required in referring to this test method in specifications for kerosene:

5.1.1 Duration of the test: 16 h is understood, if not otherwise specified;

5.1.2 Permissible change in flame shape and dimensions during the test;

5.1.3 Description of the acceptable appearance of the chimney deposit.

SCOPE

1.1 This test method covers the qualitative determination of the burning properties of kerosene to be used for illuminating purposes. (Warning—Combustible. Vapor harmful.)

Note 1: The corresponding Energy Institute (IP) test method is IP 10 which features a quantitative evaluation of the wick-char-forming tendencies of the kerosene, whereas Test Method D187 features a qualitative performance evaluation of the kerosene. Both test methods subject the kerosene to somewhat more severe operating conditions than would be experienced in typical designated applications.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific warning statements appear throughout the test method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers unreinforced vulcanized rubber sheets made from ethylene propylene diene terpolymer (EPDM) or butyl (IIR), intended for use in preventing water under hydrostatic pressure from entering a structure. The tests and property limits used to characterize these sheets are specific for each classification and are minimum values to make the product fit for its intended purpose. Types used to identify the principal polymer component of the sheet include: type I - ethylene propylene diene terpolymer, and type II - butyl. The sheet shall be formulated from the appropriate polymers and other compounding ingredients. The thickness, tensile strength, elongation, tensile set, tear resistance, brittleness temperature, and linear dimensional change shall be tested to meet the requirements prescribed. The water absorption, factory seam strength, water vapour permeance, hardness durometer, resistance to soil burial, resistance to heat aging, and resistance to puncture shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers unreinforced vulcanized rubber sheets made from ethylene propylene diene terpolymer (EPDM) or butyl (IIR), intended for use in preventing water under hydrostatic pressure from entering a structure.

1.2 The tests and property limits used to characterize these sheets are specific for each classification and are minimum values to make the product fit for its intended purpose.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the testing and requirements for two types and two classes of asbestos-free asphalt roof cement consisting of an asphalt base, volatile petroleum solvents, and mineral and/or other stabilizers, mixed to a smooth, uniform consistency suitable for trowel application to roofing and flashing. Type I is made from asphalts characterized as self-healing, adhesive, and ductile, while Type II is made from asphalt characterized by high softening point and relatively low ductility. Class I is used for application to essentially dry surfaces, while Class II is used for application to damp, wet, or underwater surfaces. The roof cements shall comply with composition limits for water, nonvolatile matter, mineral and/or other stabilizers, and bitumen (asphalt). They shall also meet physical requirements such as uniformity, workability, and pliability and behavior at given temperatures.

SCOPE

1.1 This specification covers asbestos-free asphalt roof cement suitable for trowel application to roofings and flashings.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.