ASTM A453/A453M-00

(Specification)Standard Specification for High-Temperature Bolting Materials, with Expansion Coefficients Comparable to Austenitic Stainless Steels

Standard Specification for High-Temperature Bolting Materials, with Expansion Coefficients Comparable to Austenitic Stainless Steels

SCOPE

1.1 This specification covers four grades of bolting materials with nine classes of yield strength ranging from 50 to 120 ksi [345 to 827 MPa] for use in high-temperature service such as fasteners for pressure vessel and valve flanges. The material requires special processing and is not intended for general purpose applications. The term "bolting material," as used in this specification, covers rolled, forged, or hot-extruded bars; bolts, nuts, screws, washers, studs, and stud bolts. Headed bolts and rolled threads may be supplied.

Note 1 - Other bolting materials are covered by Specification A193/A193M and Specification A437/A437M.

1.2 Supplementary Requirement S 1 of an optional nature is provided. This shall apply only when specified by the purchaser in the order.

1.3 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 453/A 453M – 00 An American National Standard

Standard Specification for

High-Temperature Bolting Materials, with Expansion

Coefficients Comparable to Austenitic Stainless Steels

This standard is issued under the fixed designation A 453/A 453M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope A 962/A 962M Specification for Steel Fasteners or Fastener

Materials, or Both, Intended for Use at Any Temperature

1.1 This specification covers four grades of bolting mate-

from Cryogenic to the Creep Range

rials with nine classes of yield strength ranging from 50 to 120

E 139 Practice for Conducting Creep, Creep-Rupture, and

ksi [345 to 827 MPa] for use in high-temperature service such

Stress-Rupture Tests of Metallic Materials

as fasteners for pressure vessel and valve flanges. The material

requires special processing and is not intended for general

3. Terminology

purpose applications. The term “bolting material,” as used in

3.1 Definitions of Terms Specific to This Standard:

this specification, covers rolled, forged, or hot-extruded bars;

3.1.1 bolting material—this covers rolled, forged, or hot-

bolts, nuts, screws, washers, studs, and stud bolts. Headed bolts

extruded bars; bolts, nuts, screws, washers, studs, and stud

and rolled threads may be supplied.

bolts; and also includes those manufactured by upset heading

NOTE 1—Other bolting materials are covered by Specification A 193/

or roll threading techniques.

A 193M and Specification A 437/A 437M.

3.1.2 heat-treatment charge—one heat of material heat

1.2 Supplementary RequirementS1ofan optional nature is

treated in one batch. If a continuous operation is used, the

provided. This shall apply only when specified by the pur-

weight processed as a heat-treatment charge shall not exceed

chaser in the order.

the weights in Table 1.

1.3 This specification is expressed in both inch-pound units

3.1.3 lot—a lot shall consist of the quantities shown in Table

and in SI units. However, unless the order specifies the

2.

applicable “M” specification designation (SI units), the mate-

4. Ordering Information

rial shall be furnished to inch-pound units.

1.4 The values stated in either inch-pound units or SI units

4.1 The inquiry and order shall indicate the following:

are to be regarded separately as standard. Within the text, the 4.1.1 Quantity (weight or number of pieces),

SI units are shown in brackets. The values stated in each

4.1.2 Type of material (bars, bolts, nuts, etc.),

system are not exact equivalents; therefore, each system must 4.1.3 Grade and class,

be used independently of the other. Combining values from the

4.1.4 Method of finishing (see 6.1),

two systems may result in nonconformance with the specifi- 4.1.5 Type of thread desired (see 6.1.1),

cation.

4.1.6 Alternative test method option (see 7.2.4.3),

4.1.7 Bolt shape option, if any,

2. Referenced Documents

4.1.8 Thread option, if any,

2.1 ASTM Standards:

4.1.9 Test method for surface quality, if any,

A 193/A 193M Specification for Alloy-Steel and Stainless

4.1.10 Test location option, if any,

Steel Bolting Materials for High-Temperature Service

4.1.11 Rejection option, if any, and

A 437/A 437M Specification for Alloy-Steel Turbine-Type

4.1.12 If stress-rupture testing is not required (see 7.2.1).

Bolting Material Specially Heat Treated for High-

5. Common Requirements

Temperature Service

5.1 Material and fasteners supplied to this specification shall

conform to the requirements of Specification A 962/A 962M.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee These requirements include test methods, finish, thread dimen-

A01.22 on Valves, Fittings, Bolting, and Flanges for High and Subatmospheric

sions, marking, certification, optional supplementary require-

Temperatures.

ments, and others. Failure to comply with the requirements of

Current edition approved March 10, 2000. Published May 2000. Originally

published as A 453 – 61 T. Last previous edition A 453/A 453M – 99. Specification A 962/A 962M constitutes nonconformance with

For ASME Boiler and Pressure Vessel Code Applications see related Specifi-

cation SA-453 in Section II of that Code.

3 4

Annual Book of ASTM Standards, Vol 01.01. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 453/A 453M

TABLE 1 Continuous Heat-Treatment Charge Sizes

heat-treatment charge (see 3.1.2). When more than two sizes of

Diameter, in. [mm] Weight, lb [kg] bars are treated in the same charge, one tension test shall be

3 made from one bar of each of the two largest diameters from

To 1 ⁄4 [44] 3000 [1400]

3 1

Over 1 ⁄4[44] to 2 ⁄2 [63] 6000 [2700]

each heat of material in the heat-treating charge.

Over 2 ⁄2 [63] 12000 [5400]

7.1.2.2 Finished Parts—One tension test shall be made if

the lot consists of parts of the same nominal diameter. If the lot

consists of parts of more than one nominal diameter, one

TABLE 2 Lot Sizes

tension test shall be made from each nominal diameter of each

Diameter, in. [mm] Maximum Lot Size, lb [kg]

heat involved in the lot (see 3).

1 ⁄2 [38] and under 200 [90]

7.1.2.3 The diameter range shall be in increments of ⁄2 in.

1 3

Over 1 ⁄2 [38] to 1 ⁄4[44], incl 300 [140]

3 1

Over 1 ⁄4 [44] to 2 ⁄2[63], incl 600 [270] [12.5 mm].

Over 2 ⁄2 [63] 20 pieces

7.2 Stress-Rupture Test:

7.2.1 Requirements—The material shall conform to the

stress-rupture requirements prescribed in Table 6 for design

this specification. In case of conflict between the requirements

temperatures above 800°F [427°C]. Material not stress-rupture

of this specification and Specification A 962/A 962M, this

tested shall be permanently stamped NR.

specification shall prevail.

7.2.2 The number of specimens shall be the same as the

required number of tension test specimens.

6. Materials and Manufacture

7.2.3 The test location and orientation shall be the same as

6.1 Finishing Process:

that required for the tension test specimens.

6.1.1 Threads may be performed by machining or rolling.

7.2.4 Test Method:

For Type 1 bolting, threading shall be performed after precipi-

7.2.4.1 The rupture test shall be performed in accordance

tation heat treatment. Types M1 and M2 bolting shall have

with Practice E 139.

machine cut threads. For Types 2 R1 and R2 bolting shall have

7.2.4.2 A combination smooth and notched test specimen,

rolled threads. Types R1 and M1 bolting, threading shall be

machined to the dimensions prescribed in Fig. 1 and Table 7,

threaded performed after precipitation heat treatment. Types

shall be tested in accordance with the stress-rupture require-

R2 and M2 bolting shall be threaded after solution heat

ments prescribed in Table 6. The test shall be continued to

treatment but prior to precipitation heat treatment. When not

rupture. The rupture shall occur in the smooth section of the

specified by the purchaser, the type supplied shall be the option

bar.

of the manufacturer.

6.2 Heat Treatment—Each grade and class shall be heat 7.2.4.3 As an alternative procedure and, when specifically

approved by the purchaser, separate smooth and notched test

treated as prescribed in Table 3.

specimens, machined from adjacent sections of the same piece,

7. Mechanical Properties

with gage sections conforming to the respective dimensions of

Table 7, may be tested under the above conditions. The notched

7.1 Tension Test:

specimen need not be tested to rupture but shall not rupture in

7.1.1 Requirements—The material in each heat-treatment

less time than the companion smooth specimen.

charge shall conform to the room-temperature tensile require-

ments in Table 5. 7.2.4.4 When the minimum specified time to rupture in

7.1.2 Number of Specimens: Table 6 has been achieved, incremental loading may be used to

7.1.2.1 Heat-Treated Bars—When not more than two sizes accelerate the time to rupture. At intervals of 8 to 16 h,

of bars are heat treated in the same load, one tension test shall preferably 8 to 10 h, the stress shall be increased in increments

be made from each size in each heat of material in the of 5000 psi [34.5 MPa]. Rupture location, and elongation

A

TABLE 3 Heat Treatment Requirements

Grade Class Solution Treatment Hardening Treatment

660 A 16506 25°F [900 6 14°C], hold 2 h, min, and liquid quench 1325 6 25°F [720 6 14°C], hold 16 h, air cool

B 1800 6 25°F [980 6 14°C], hold 1 h, min, and liquid

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:A 453/A453M–99 Designation: A 453/A 453M – 00

Standard Specification for

High-Temperature Bolting Materials, with Expansion

Coefficients Comparable to Austenitic Stainless Steels

ThisstandardisissuedunderthefixeddesignationA453/A453M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers four grades of bolting materials with nine classes of yield strength ranging from 50 to 120 ksi

[345to827MPa]foruseinhigh-temperatureservicesuchasfastenersforpressurevesselandvalveflanges.Thematerialrequires

special processing and is not intended for general purpose applications. The term “bolting material,” as used in this specification,

coversrolled,forged,orhot-extrudedbars;bolts,nuts,screws,washers,studs,andstudbolts.Headedboltsandrolledthreadsmay

be supplied.

NOTE 1—Other bolting materials are covered by Specification A193/A193M and Specification A437/A437M.

1.2 Supplementary RequirementS1ofan optional nature is provided. This shall apply only when specified by the purchaser

in the order.

1.3 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable

“M” specification designation (SI units), the material shall be furnished to inch-pound units.

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

2. Referenced Documents

2.1 ASTM Standards:

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service

A370Test Methods and Definitions for Mechanical Testing of Steel Products

A437/A437M Specification for Alloy-Steel Turbine-Type Bolting Material Specially Heat Treated for High-Temperature

Service

A962/A962M Specification for Steel Fasteners or Fastener Materials, or Both, Intended for Use at Any Temperature from

Cryogenic to the Creep Range

E30Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron

E59Practice for Sampling Steel and Iron for Determination of Chemical Composition

E139 Practice for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

2.2 ANSI Standards:

B1.1Unified Screw Threads

B18.2.1 Square and Hex Bolts and Screws Including Hex Cap Screws and Lag Screws

B18.2.2 Square and Hex Nuts

B18.3Hexagon Socket and Spline Socket Screws

2.3 AIAG Standard:

B-5 02.00 Primary Metals Identification Tag Application Standard

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

This specification is under the jurisdiction ofASTM CommitteeA-1A01 on Steel, Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

A01.22 on Valves, Fittings, Bolting, and Flanges for High and Subatmospheric Temperatures.

´1

Current edition approved March 10, 1999.2000. Published May 1999.2000. Originally published as A453–61T. Last previous edition A453/A453M–96 .

A453/A453M–99.

For ASME Boiler and Pressure Vessel Code Applications see related Specification SA-453 in Section II of that Code.

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 01.03., Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 453/A 453M – 00

3.1.1 bolting material—this covers rolled, forged, or hot-extruded bars; bolts, nuts, screws, washers, studs, and stud bolts; and

also includes those manufactured by upset heading or roll threading techniques.

3.1.2 heat-treatment charge—one heat of material heat treated in one batch. If a continuous operation is used, the weight

processed as a heat-treatment charge shall not exceed the weights in Table 1.

3.1.3 lot—a lot shall consist of the quantities shown in Table 2.

4. Ordering Information

4.1 The inquiry and order shall indicate the following:

4.1.1 Quantity (weight or number of pieces),

4.1.2 Type of material (bars, bolts, nuts, etc.),

4.1.3 Grade and class,

4.1.4 Method of finishing (see 5.26.1),

4.1.5 Type of thread desired (see 5.2.26.1.1),

4.1.6 Alternative test method option (see 7.2.4.3),

4.1.7Bolt shape option, if any (see 8.2),

4.1.8Thread option, if any (see 8.3),

4.1.9Test method for surface quality, if any (see 10),

4.1.10Test location option, if any (see 11),

4.1.11Rejection option, if any (see 12.1), and

4.1.12If stress-rupture testing is not required (see

4.1.7 Bolt shape option, if any,

4.1.8 Thread option, if any,

4.1.9 Test method for surface quality, if any,

4.1.10 Test location option, if any,

4.1.11 Rejection option, if any, and

4.1.12 If stress-rupture testing is not required (see 7.2.1).

5. Common Requirements

5.1 Material and fasteners supplied to this specification shall conform to the requirements of Specification A962/A962M.

These requirements include test methods, finish, thread dimensions, marking, certification, optional supplementary requirements,

and others. Failure to comply with the requirements of Specification A962/A962M constitutes nonconformance with this

specification. In case of conflict between the requirements of this specification and SpecificationA962/A962M, this specification

shall prevail.

6. Materials and Manufacture

5.1Melting Process:

5.1.1The material shall be made by one or more of the following processes: electric-furnace, induction furnace, or

consumable-electrode practice.

5.1.2Vacuum, protective atmospheres, or protective slags may be used during melting or pouring of the heat.

5.2

6.1 Finishing Process:

5.2.1The product shall be hot finished or cold finished (ground, rough turned or cold drawn) as specified on the purchase order.

5.2.2

6.1.1 Threads may be performed by machining or rolling. For Type 1 bolting, threading shall be performed after precipitation

heattreatment.TypesM1andM2boltingshallhavemachinecutthreads.ForTypes2R1andR2boltingshallhaverolledthreads.

Types R1 and M1 bolting, threading shall be threaded performed after precipitation heat treatment.Types R2 and M2 bolting shall

be threaded after solution heat treatment but prior to precipitation heat treatment. When not specified by the purchaser, the type

supplied shall be the option of the manufacturer.

5.3

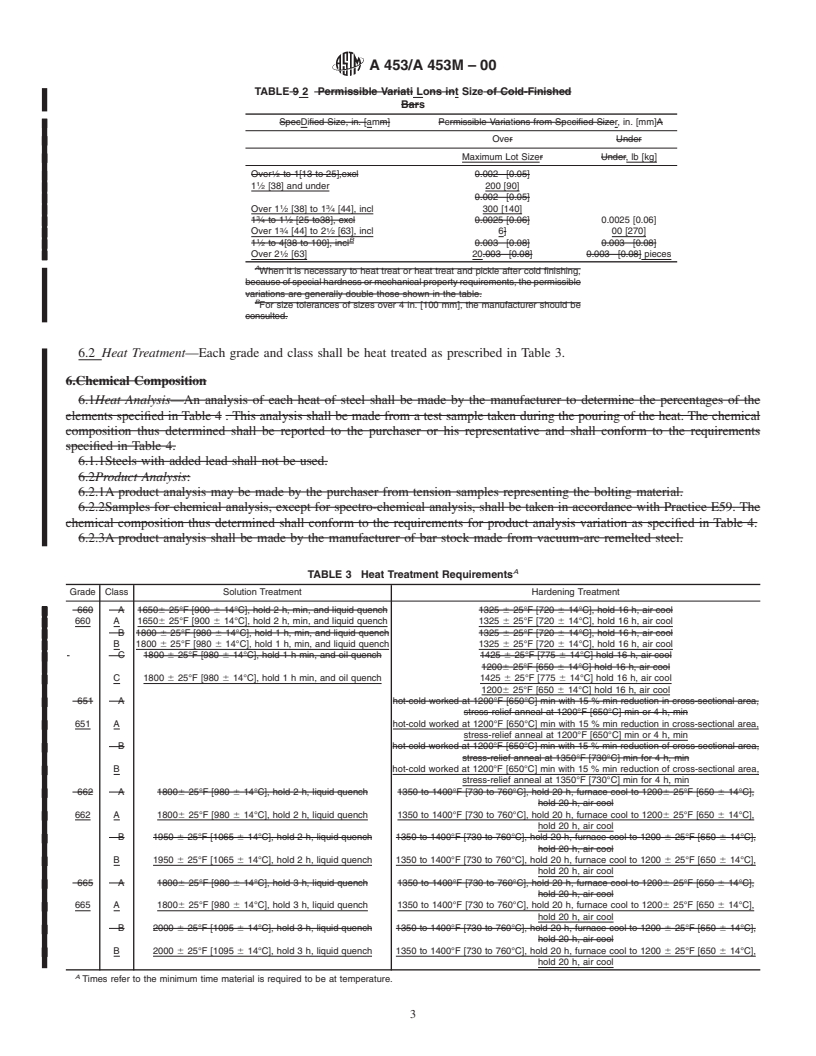

TABLE 2 1 L Continuous Heat-Treatment Charge Sizes

Diameter, in. [mm] MaxWeimum Loght Size, lb [kg]

1 ⁄2 [38] and under 200 [90]

1 3

Over 1 ⁄2 [38] to 1 ⁄4 [44], incl 300 [140]

To 1 ⁄4 [44] 3000 [1400]

3 1

Over 1 ⁄4 [44] to 2 ⁄2 [63], incl 600 [270]

3 1

Over 1 ⁄4 [44] to 2 ⁄2 [63] 6000 [2700]

Over 2 ⁄2 [63] 20 pieces

Over 2 ⁄2 [63] 12000 [5400]

A 453/A 453M – 00

TABLE 9 2 Permissible Variati Lons int Size of Cold-Finished

Bars

SpecDified Size, in. [amm] Permissible Variations from Specified Sizer, in. [mm]A

Over Under

Maximum Lot Sizer Under, lb [kg]

Over ⁄2 to 1[13 to 25],excl 0.002 [0.05]

1 ⁄2 [38] and under 200 [90]

0.002 [0.05]

1 3

Over 1 ⁄2 [38] to 1 ⁄4 [44], incl 300 [140]

3 1

1 ⁄4 to 1 ⁄2 [25 to38], excl 0.0025 [0.06] 0.0025 [0.06]

3 1

Over 1 ⁄4 [44] to 2 ⁄2 [63], incl 6] 00 [270]

B

1 ⁄2 to 4[38 to 100], incl 0.003 [0.08] 0.003 [0.08]

Over 2 ⁄2 [63] 20.003 [0.08] 0.003 [0.08] pieces

A

When it is necessary to heat treat or heat treat and pickle after cold finishing,

becauseofspecialhardnessormechanicalpropertyrequirements,thepermissible

variations are generally double those shown in the table.

B

For size tolerances of sizes over 4 in. [100 mm], the manufacturer should be

consulted.

6.2 Heat Treatment—Each grade and class shall be heat treated as prescribed in Table 3.

6.Chemical Composition

6.1Heat Analysis—An analysis of each heat of steel shall be made by the manufacturer to determine the percentages of the

elements specified in Table 4 . This analysis shall be made from a test sample taken during the pouring of the heat. The chemical

composition thus determined shall be reported to the purchaser or his representative and shall conform to the requirements

specified in Table 4.

6.1.1Steels with added lead shall not be used.

6.2Product Analysis:

6.2.1A product analysis may be made by the purchaser from tension samples representing the bolting material.

6.2.2Samples for chemical analysis, except for spectro-chemical analysis, shall be taken in accordance with Practice E59. The

chemical composition thus determined shall conform to the requirements for product analysis variation as specified in Table 4.

6.2.3A product analysis shall be made by the manufacturer of bar stock made from vacuum-arc remelted steel.

A

TABLE 3 Heat Treatment Requirements

Grade Class Solution Treatment Hardening Treatment

660 A 16506 25°F [900 6 14°C], hold 2 h, min, and liquid quench 1325 6 25°F [720 6 14°C], hold 16 h, air cool

660 A 16506 25°F [900 6 14°C], hold 2 h, min, and liquid quench 1325 6 25°F [720 6 14°C], hold 16 h, air cool

B 1800 6 25°F [980 6 14°C], hold 1 h, min, and liquid quench 1325 6 25°F [720 6 14°C], hold 16 h, air cool

B 1800 6 25°F [980 6 14°C], hold 1 h, min, and liquid quench 1325 6 25°F [720 6 14°C], hold 16 h, air cool

C 1800 6 25°F [980 6 14°C], hold1hmin,andoil quench 1425 6 25°F [775 6 14°C] hold 16 h, air cool

12006 25°F [650 6 14°C] hold 16 h, air cool

C 1800 6 25°F [980 6 14°C], hold1hmin,andoil quench 1425 6 25°F [775 6 14°C] hold 16 h, air cool

12006 25°F [650 6 14°C] hold 16 h, air cool

651 A hot-cold worked at 1200°F [650°C] min with 15 % min reduction in cross-sectional area,

stress-relief anneal at 1200°F [650°C] min or 4 h, min

651 A hot-cold worked at 1200°F [650°C] min with 15 % min reduction in cross-sectional area,

stress-relief anneal at 1200°F [650°C] min or 4 h, min

B hot-cold worked at 1200°F [650°C] min with 15 % min reduction of cross-sectional area,

stress-relief anneal at 1350°F [730°C] min for 4 h, min

B hot-cold worked at 1200°F [650°C] min with 15 % min reduction of cross-sectional area,

stress-relief anneal at 1350°F [730°C] min for 4 h, min

662 A 18006 25°F [980 6 14°C], hold 2 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 12006 25°F [650 6 14°C],

hold 20 h, air cool

662 A 18006 25°F [980 6 14°C], hold 2 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 12006 25°F [650 6 14°C],

hold 20 h, air cool

B 1950 6 25°F [1065 6 14°C], hold 2 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 1200 6 25°F [650 6 14°C],

hold 20 h, air cool

B 1950 6 25°F [1065 6 14°C], hold 2 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 1200 6 25°F [650 6 14°C],

hold 20 h, air cool

665 A 18006 25°F [980 6 14°C], hold 3 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 12006 25°F [650 6 14°C],

hold 20 h, air cool

665 A 18006 25°F [980 6 14°C], hold 3 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 12006 25°F [650 6 14°C],

hold 20 h, air cool

B 2000 6 25°F [1095 6 14°C], hold 3 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 1200 6 25°F [650 6 14°C],

hold 20 h, air cool

B 2000 6 25°F [1095 6 14°C], hold 3 h, liquid quench 1350 to 1400°F [730 to 760°C], hold 20 h, furnace cool to 1200 6 25°F [650 6 14°C],

hold 20 h, air cool

A

Times refer to the minimum time material is required to be at temperature.

A 453/A 453M – 00

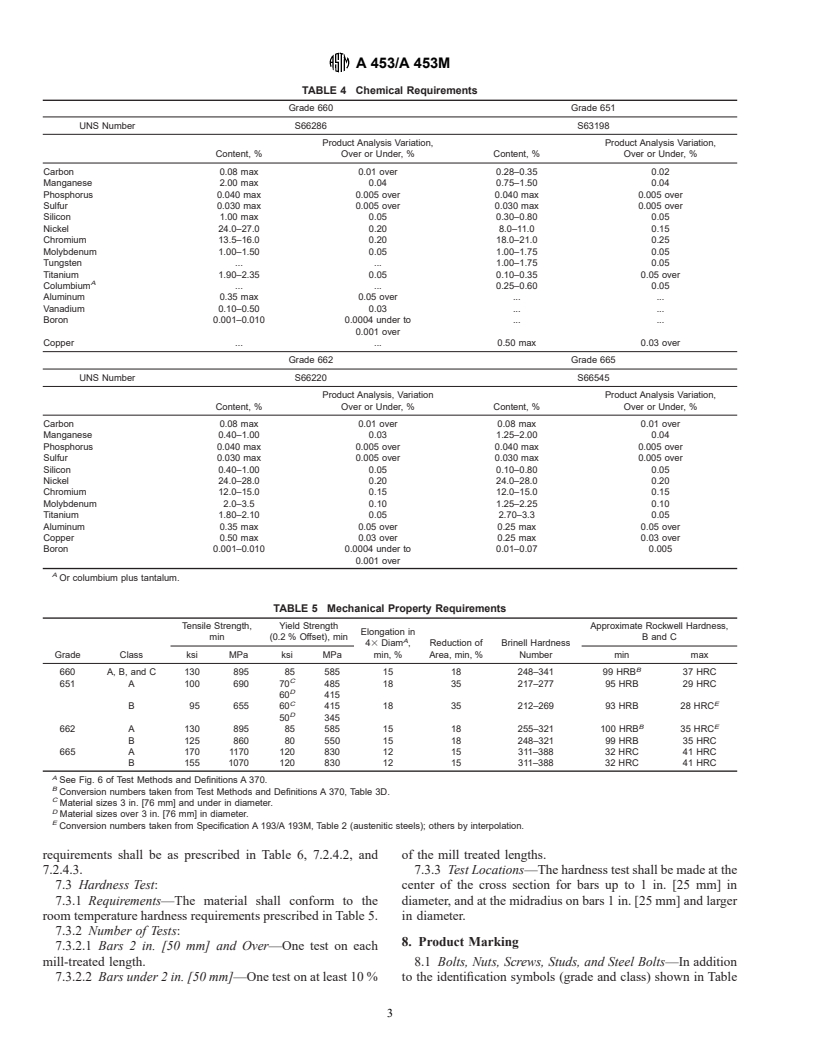

TABLE 4 Chemical Requirements

Grade 660 Grade 651

UNS Number S66286 S63198

Product Analysis Variation, Product Analysis Variation,

Content, % Content, % Over or Under, % Content, % Over or Under, %

Carbon 0.08 max 0.01 over 0.28–0.35 0.02

Manganese 2.00 max 0.04 0.75–1.50 0.04

Phosphorus 0.040 max 0.005 over 0.040 max 0.005 over

Sulfur 0.030 max 0.005 over 0.030 max 0.005 over

Silicon 1.00 max 0.05 0.30–0.80 0.05

Nickel 24.0–27.0 0.20 8.0–11.0 0.15

Chromium 13.5–16.0 0.20 18.0–21.0 0.25

Molybdenum 1.00–1.50 0.05 1.00–1.75 0.05

Tungsten . . 1.00–1.75 0.05

Titanium 1.90–2.35 0.05 0.10–0.35 0.05 over

A

Columbium . . 0.25–0.60 0.05

Aluminum 0.35 max 0.05 over . .

Vanadium 0.10–0.50 0.03 . .

Boron 0.001–0.010 0.0004 under to . .

0.001 over

0.001 over

Copper . . 0.50 max 0.03 over

Grade 662 Grade 665

Grade 662 Grade 665

UNS Number S66220 S66545

Content, % Product Analysis, Variation Product Analysis Variation,

Over or Under, % Content, % Over or Under, %

Product Analysis, Variation Product Analysis Variation,

Content, % Over or Under, % Content, % Over or Under, %

Carbon 0.08 max 0.01 over 0.08 max 0.01 over

Manganese 0.40–1.00 0.03 1.25–2.00 0.04

Phosphorus 0.040 max 0.005 over 0.040 max 0.005 over

Sulfur 0.030 max 0.005 over 0.030 max 0.005 over

Silicon 0.40–1.00 0.05 0.10–0.80 0.05

Nickel 24.0–28.0 0.20 24.0–28.0 0.20

Chromium 12.0–15.0 0.15 12.0–15.0 0.15

Molybdenum 2.0–3.5 0.10 1.25–2.25 0.10

Titanium 1.80–2.10 0.05 2.70–3.3 0.05

Aluminum 0.35 max 0.05 over 0.25 max 0.05 over

Copper 0.50 max 0.03 over 0.25 max 0.03 over

Boron 0.001–0.010 0.0004 under to 0.01–0.07 0.005

0.001 over

0.001 over

A

Or columbium plus tantalum.

6.3Methods of Analysis—For referee purposes, Test Methods E30 shall be used.

7. Mechanical Properties

7.1 Tension Test:

7.1.1 Requirements—The material shall conform to the room-temperature tensile in each heat-treatment charge (see 3). —The

material in each heat-treatment charge shall conform to the room-temperature tensile requirements in Table 5.

7.1.2 Number of Specimens:

7.1.2.1 Heat-Treated Bars—When not more than two sizes of bars are heat treated in the same load, one tension test shall be

madefromeachsizeineachheatofmaterialintheheat-treatmentcharge(see3.1.2).Whenmorethantwosizesofbarsaretreated

in the same charge, one tension test shall be made from one bar of each of the two largest diameters from each heat of material

in the heat-treating charge.

7.1.2.2 Finished Parts—One tension test shall be made if the lot consists of parts of the same nominal diameter. If the lot

consists of parts of more than one nominal diameter, one tension test shall be made from each n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.