ASTM F2502-05

(Specification)Standard Specification and Test Methods for Bioabsorbable Plates and Screws for Internal Fixation Implants

Standard Specification and Test Methods for Bioabsorbable Plates and Screws for Internal Fixation Implants

SIGNIFICANCE AND USE

Biodegradable devices are expected by intention to deteriorate over time once they are implanted into the body. This makes the removal operation obsolete, which is advantageous especially for pediatrics.

While the polymer degrades due to hydrolytic reaction with the environment, the mechanical performance of the device also deteriorates. The key to developing effective fracture fixation systems based on biodegradable devices is to provide an adequate level of fixation strength for a time frame that exceeds that expected for fracture healing. Once the fracture is healed, the device can be completely resorbed by the body.

Generally, biodegradable devices will be tested with similar test methods that are used to evaluate conventional metallic devices. In addition, one has to take into consideration the pre-test conditioning requirements, handling requirements, and time-dependent mechanical property evaluations for biodegradable devices.

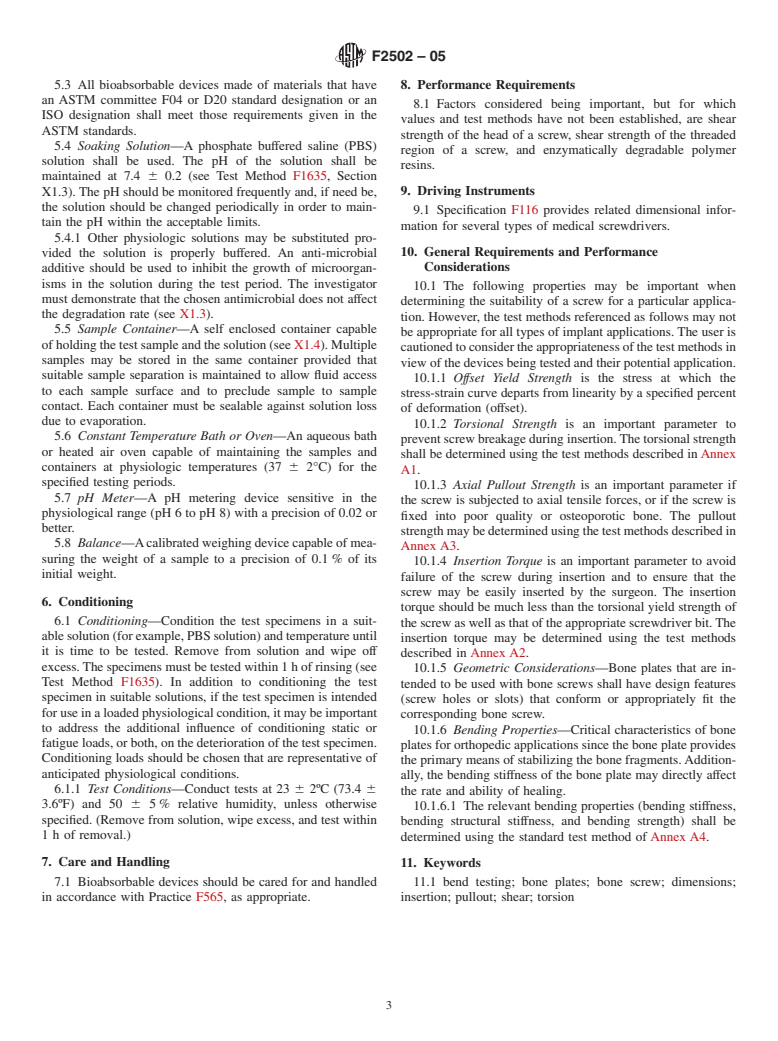

FIG. 1 Screw Parameters

SCOPE

1.1 This specification and test methods covers a mechanical characterization reference for hydrolytically degradable polymer resin (from this point on referenced as "bioabsorbable") plates and screws for orthopedic internal fixation.

1.2 This specification establishes common terminology to describe the size and other physical characteristics of bioabsorbable implants and performance definitions related to the performance of bioabsorbable devices.

1.3 This specification establishes standard test methods to consistently measure performance-related mechanical characteristics of bioabsorbable devices when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed.

1.4 This specification may not be appropriate for all bioabsorbable devices. The user is cautioned to consider the appropriateness of the standard in view of the particular bioabsorbable device and its potential application.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F2502 – 05

Standard Specification and Test Methods for

Bioabsorbable Plates and Screws for Internal Fixation

Implants

This standard is issued under the fixed designation F2502; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope With Specified Precision, the Average for a Characteristic

of a Lot or Process

1.1 This specification and test methods covers a mechanical

E1823 Terminology Relating to Fatigue and Fracture Test-

characterization reference for hydrolytically degradable poly-

ing

mer resin (from this point on referenced as “bioabsorbable”)

F116 Specification for Medical Screwdriver Bits

plates and screws for orthopedic internal fixation.

F382 Specification and Test Method for Metallic Bone

1.2 This specification establishes common terminology to

Plates

describe the size and other physical characteristics of bioab-

F543 Specification and Test Methods for Metallic Medical

sorbable implants and performance definitions related to the

Bone Screws

performance of bioabsorbable devices.

F565 Practice for Care and Handling of Orthopedic Im-

1.3 This specification establishes standard test methods to

plants and Instruments

consistently measure performance-related mechanical charac-

F1635 Test Method for in vitro Degradation Testing of

teristics of bioabsorbable devices when tested under defined

Hydrolytically Degradable Polymer Resins and Fabricated

conditions of pretreatment, temperature, humidity, and testing

Forms for Surgical Implants

machine speed.

F1839 Specification for Rigid Polyurethane Foam for Use

1.4 This specification may not be appropriate for all bioab-

as a Standard Material for Testing Orthopaedic Devices

sorbable devices. The user is cautioned to consider the appro-

and Instruments

priateness of the standard in view of the particular bioabsorb-

F1925 Specification for Semi-Crystalline Poly(lactide)

able device and its potential application.

Polymer and Copolymer Resins for Surgical Implants

1.5 This standard does not purport to address all of the

2.2 ISO Standards:

safety concerns, if any, associated with its use. It is the

ISO 13781 Poly (L-Lactide) Resins and Fabricated Forms

responsibility of the user of this standard to establish appro-

for Surgical Implants—In Vitro Degradation Testing

priate safety and health practices and determine the applica-

ISO 14630 Non-Active Surgical Implants—General Re-

bility of regulatory limitations prior to use.

quirements

2. Referenced Documents ISO 15814 Copolymers and Blends Based on

Polylactide—In Vitro Degradation Testing

2.1 ASTM Standards:

D790 Test Methods for Flexural Properties of Unreinforced

3. Terminology

and Reinforced Plastics and Electrical Insulating Materials

3.1 Definitions:

E4 Practices for Force Verification of Testing Machines

3.1.1 Unless otherwise defined in this specification, the

E6 TerminologyRelatingtoMethodsofMechanicalTesting

terminology related to mechanical testing that is used in these

E122 Practice for Calculating Sample Size to Estimate,

test methods will be in accordance with the definitions of

Terminologies E6 and E1823, and Specifications F382 and

F543.

This specification and test methods is under the jurisdiction of ASTM

3.2 General Definitions:

Committee F04 on Medical and Surgical Materials and Devices and is the direct

3.2.1 bioabsorbable device—a class of implants that are

responsibility of Subcommittee F04.21 on Osteosynthesis.

designed to deteriorate by means of biological resorption once

Current edition approved Oct. 1, 2005. Published October 2005. DOI: 10.1520/

F2502-05.

they are implanted into the body.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2502 – 05

3.2.2 biological resorption—process by which degraded ment and fixation of two or more bone sections, primarily by

biomaterials(thatis,productsofdegradation)areeliminatedor spanning the fracture or defect.

incorporated, or both, by means of physiological metabolic

3.5.2 bone plate length, L (mm)—the linear dimension of

routes.

the bone plate measured along the longitudinal axis as illus-

3.2.3 deterioration (of a bioabsorbable device)—the action

trated in Fig. A4.2.

or process that results in a reduction of mass or mechanical

3.5.3 bone plate thickness, b (mm)—the linear dimension of

performance properties, or both.

the bone plate measured parallel to the screw hole axis as

3.2.4 hydrolytically degradable polymer (HDP)—any poly-

shown in Fig. A4.2. For a bone plate with a crescent section,

meric material in which the primary mechanism of chemical

the thickness is measured at the thickest point along the

degradation in the body is by hydrolysis (water reacting with

section.

the polymer resulting in cleavage of the chain).

3.5.4 bone plate width, w (mm)—thelineardimensionofthe

3.3 Definitions for Apparatus:

bone plate measured perpendicular to both the length and

3.3.1 data acquisition device—the data recorder shall be

thickness axes as shown in Fig. A4.2.

suitable to continuously record torque versus angle of rotation,

as well as linear displacement, calibrated in units of Newton-

4. Significance and Use

metres for torque and degrees for angle of rotation. The value

4.1 Biodegradable devices are expected by intention to

of torque shall have a resolution of 5 % of torsional yield

deteriorate over time once they are implanted into the body.

strength.Theangulardisplacementscaleshallhaveaminimum

This makes the removal operation obsolete, which is advanta-

sensitivity so as to enable an accurate offset measurement

geous especially for pediatrics.

capability for a 2° angular displacement (see A1.5.3).

4.2 While the polymer degrades due to hydrolytic reaction

3.3.2 pilot holes in test block—pilot holes shall be drilled in

with the environment, the mechanical performance of the

the test block for insertion and removal of the test specimen.

device also deteriorates. The key to developing effective

See Specification F543, Annex 2.

fracture fixation systems based on biodegradable devices is to

3.3.3 test block—the test block shall be fabricated from a

provide an adequate level of fixation strength for a time frame

uniform material that conforms to Specification F1839. See

that exceeds that expected for fracture healing. Once the

Specification F543, Annex 2.

fractureishealed,thedevicecanbecompletelyresorbedbythe

3.3.4 testing fixture—the torsion testing apparatus that is to

body.

be used for applying the required torque to the specimen shall

4.3 Generally, biodegradable devices will be tested with

be calibrated for the range of torques and rotational displace-

similar test methods that are used to evaluate conventional

ments used in the determination. A suitable testing fixture for

metallic devices. In addition, one has to take into consideration

the torsional yield strength-maximum torque-breaking angle

the pre-test conditioning requirements, handling requirements,

test is illustrated in Fig. A1.1.

and time-dependent mechanical property evaluations for bio-

3.3.5 test specimen—the test specimen shall be a com-

degradable devices.

pletely fabricated and finished bioabsorbable bone screw.

3.3.6 torque transducer—a transducer to translate the ap-

5. Materials and Manufacture

plied torque into an electrical signal amenable to continuous

recording, calibrated over the range of torques, both in the 5.1 Bioabsorbable devices may be fabricated from one of

clockwise and counterclockwise rotation, to be encountered in the following materials:

the test method, shall be provided.

5.1.1 l-lactide, d-lactide, d,l-lactide, glycolide, or other

3.3.7 torsional displacement transducer—a transducer to

known hydrolytically degradable polymer resins or copoly-

translate the angle of twist into an electrical signal amenable to

mers. (See ISO 13781, ISO 15814, Test Method F1635, and

continuous recording, calibrated over the range of angles to be Specification F1925.)

encountered in the test and an accuracy of 61 % of reading,

5.2 The manufacturer is responsible to ensure that materials

both in the clockwise and counterclockwise rotation, shall be

used to manufacture bioabsorbable implants are suitable for

used.

implanting into the body. Methods to evaluate a material’s

3.4 Definitions for Screw Testing:

suitability are described in ISO 14630.

3.4.1 anchor—a bioabsorbable device or a component of a

bioabsorbable device that provides the attachment to the bone.

3.4.2 bone anchor—a bioabsorbable device that provides a

means to attach soft tissue to bone with a suture.

3.4.3 insertion depth (mm)—the linear advancement of the

bioabsorbabledeviceintothetestblockmeasuredrelativetoits

seated position at the test block’s surface prior to testing.

3.5 Definitions for Plate Testing:

3.5.1 bone plate—a device with two or more holes or slots,

or both, and a cross section that consists of at least two

dimensions (width and thickness), which generally are not the

same in magnitude. The device is intended to provide align- FIG. 1 Screw Parameters

F2502 – 05

5.3 All bioabsorbable devices made of materials that have 8. Performance Requirements

an ASTM committee F04 or D20 standard designation or an

8.1 Factors considered being important, but for which

ISO designation shall meet those requirements given in the

values and test methods have not been established, are shear

ASTM standards.

strength of the head of a screw, shear strength of the threaded

5.4 Soaking Solution—A phosphate buffered saline (PBS)

region of a screw, and enzymatically degradable polymer

solution shall be used. The pH of the solution shall be

resins.

maintained at 7.4 6 0.2 (see Test Method F1635, Section

9. Driving Instruments

X1.3). The pH should be monitored frequently and, if need be,

the solution should be changed periodically in order to main-

9.1 Specification F116 provides related dimensional infor-

tain the pH within the acceptable limits.

mation for several types of medical screwdrivers.

5.4.1 Other physiologic solutions may be substituted pro-

10. General Requirements and Performance

vided the solution is properly buffered. An anti-microbial

Considerations

additive should be used to inhibit the growth of microorgan-

isms in the solution during the test period. The investigator

10.1 The following properties may be important when

must demonstrate that the chosen antimicrobial does not affect

determining the suitability of a screw for a particular applica-

the degradation rate (see X1.3).

tion. However, the test methods referenced as follows may not

5.5 Sample Container—A self enclosed container capable

be appropriate for all types of implant applications. The user is

ofholdingthetestsampleandthesolution(seeX1.4).Multiple

cautionedtoconsidertheappropriatenessofthetestmethodsin

samples may be stored in the same container provided that

view of the devices being tested and their potential application.

suitable sample separation is maintained to allow fluid access

10.1.1 Offset Yield Strength is the stress at which the

to each sample surface and to preclude sample to sample

stress-strain curve departs from linearity by a specified percent

contact. Each container must be sealable against solution loss

of deformation (offset).

due to evaporation.

10.1.2 Torsional Strength is an important parameter to

5.6 Constant Temperature Bath or Oven—An aqueous bath

preventscrewbreakageduringinsertion.Thetorsionalstrength

or heated air oven capable of maintaining the samples and

shall be determined using the test methods described inAnnex

containers at physiologic temperatures (37 6 2°C) for the

A1.

specified testing periods.

10.1.3 Axial Pullout Strength is an important parameter if

5.7 pH Meter—A pH metering device sensitive in the

the screw is subjected to axial tensile forces, or if the screw is

physiological range (pH 6 to pH 8) with a precision of 0.02 or

fixed into poor quality or osteoporotic bone. The pullout

better.

strengthmaybedeterminedusingthetestmethodsdescribedin

5.8 Balance—Acalibratedweighingdevicecapableofmea-

Annex A3.

suring the weight of a sample to a precision of 0.1 % of its

10.1.4 Insertion Torque is an important parameter to avoid

initial weight.

failure of the screw during insertion and to ensure that the

screw may be easily inserted by the surgeon. The insertion

6. Conditioning

torque should be much less than the torsional yield strength of

6.1 Conditioning—Condition the test specimens in a suit-

thescrewaswellasthatoftheappropriatescrewdriverbit.The

ablesolution(forexample,PBSsolution)andtemperatureuntil

insertion torque may be determined using the test methods

it is time to be tested. Remove from solution and wipe off

described in Annex A2.

excess.The specimens must be tested within1hof rinsing (see

10.1.5 Geometric Considerations—Bone plates that are in-

Test Method F1635). In addition to conditioning the test

tended to be used with bone screws shall have design features

specimen in suitable solutions, if the test specimen is intended

(screw holes or slots) that conform or appropriately fit the

foruseinaloadedphysiologicalcondition,itmaybeimportant

corresponding bone screw.

to address the additional influence of conditioning static or

10.1.6 Bending Properties—Critical characteristics of bone

fatigue loads, or both, on the deterioration of the test specimen.

plates for orthopedic applications since the bone plate provides

Conditioning loads should be chosen that are representative of

the primary means of stabilizing the bone fragments.Addition-

anticipated physiological conditions.

ally, the bending stiffness of the bone plate may directly affect

6.1.1 Test Conditions—Conduct tests at 23 6 2ºC (73.4 6

the rate and ability of healing.

3.6ºF) and 50 6 5 % relative humidity, unless otherwise

10.1.6.1 The relevant bending properties (bending stiffness,

specified. (Remove from solution, wipe excess, and test within

bending structural stiffness, and bending strength) shall be

1 h of removal.)

determined using the standard test method of Annex A4.

7. Care and Handling 11. Keywords

7.1 Bioabsorbable devices should be cared for and handled 11.1 bend testing; bone plates; bone screw; dimensions;

in accor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.