ASTM D5910-05(2019)

(Test Method)Standard Test Method for Determination of Free Formaldehyde in Emulsion Polymers by Liquid Chromatography

Standard Test Method for Determination of Free Formaldehyde in Emulsion Polymers by Liquid Chromatography

SIGNIFICANCE AND USE

4.1 With the need to calculate free formaldehyde levels in emulsion polymers, it is necessary to make the determination without upsetting any equilibria that might generate or deplete formaldehyde. This test method provides a means for determining ppm levels of free formaldehyde in emulsion polymers without upsetting existing equilibria.

SCOPE

1.1 This test method is used for the determination of free formaldehyde (HCHO) in emulsion polymers without upsetting existing formaldehyde equilibria. The procedure has been evaluated using acrylic, acrylonitrile-butadiene, carboxylated styrene-butadiene and polyvinyl acetate emulsion polymers. This test method may also be applicable for emulsion polymers of other compositions. The established working range of this test method is from 0.05 to 15 ppm formaldehyde. Emulsion polymers must be diluted to meet the working range.

1.2 This test method minimizes changes in free formaldehyde concentration that can result from changes in the physical or chemical properties of an emulsion polymer.

1.3 There are no known limitations to this test method when used in the manner described. The emulsion polymer test specimen must be prepared with a diluent that has a pH similar to that of the emulsion. Use of an inappropriate pH may upset formaldehyde equilibria and result in incorrect formaldehyde levels.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5910 − 05 (Reapproved 2019)

Standard Test Method for

Determination of Free Formaldehyde in Emulsion Polymers

by Liquid Chromatography

This standard is issued under the fixed designation D5910; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method is used for the determination of free

D1193 Specification for Reagent Water

formaldehyde (HCHO) in emulsion polymers without upset-

D2194 Test Method for Concentration of Formaldehyde

ting existing formaldehyde equilibria. The procedure has been

Solutions

evaluated using acrylic, acrylonitrile-butadiene, carboxylated

E180 Practice for Determining the Precision of ASTM

styrene-butadiene and polyvinyl acetate emulsion polymers.

Methods for Analysis and Testing of Industrial and Spe-

Thistestmethodmayalsobeapplicableforemulsionpolymers

cialty Chemicals (Withdrawn 2009)

of other compositions. The established working range of this

E682 Practice for Liquid Chromatography Terms and Rela-

test method is from 0.05 to 15 ppm formaldehyde. Emulsion

tionships

polymers must be diluted to meet the working range.

3. Summary of Test Method

1.2 This test method minimizes changes in free formalde-

hyde concentration that can result from changes in the physical

3.1 The aqueous phase of an emulsion polymer is diluted

or chemical properties of an emulsion polymer.

and chromatographed on a reversed-phase octadecyl silane

(ODS) column using an aqueous mobile phase and a visible-

1.3 There are no known limitations to this test method when

light detector at 410 nm. Formaldehyde is separated from other

used in the manner described. The emulsion polymer test

species in the matrix on a chromatographic column. The

specimen must be prepared with a diluent that has a pH similar

detection system includes a post-column reactor that produces

to that of the emulsion. Use of an inappropriate pH may upset

a lutidine derivative when formaldehyde reacts with the

formaldehyde equilibria and result in incorrect formaldehyde

2,4-pentanedione reagent (Nash Reagent). The concentration

levels.

offreeformaldehydeinemulsionpolymersisdeterminedusing

1.4 The values stated in SI units are to be regarded as

peak areas from the standard and sample chromatograms. This

standard. No other units of measurement are included in this

test method is specific for formaldehyde.

standard.

4. Significance and Use

1.5 This standard does not purport to address all of the

4.1 With the need to calculate free formaldehyde levels in

safety concerns, if any, associated with its use. It is the

emulsion polymers, it is necessary to make the determination

responsibility of the user of this standard to establish appro-

without upsetting any equilibria that might generate or deplete

priate safety, health, and environmental practices and deter-

formaldehyde. This test method provides a means for deter-

mine the applicability of regulatory limitations prior to use.

mining ppm levels of free formaldehyde in emulsion polymers

1.6 This international standard was developed in accor-

without upsetting existing equilibria.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 5. Interferences

Development of International Standards, Guides and Recom-

5.1 This test method is very selective for formaldehyde.

mendations issued by the World Trade Organization Technical

Potential interferants are either chromatographically separated

Barriers to Trade (TBT) Committee.

from formaldehyde or do not react with the post-column

reagent.

1 2

This test method is under the jurisdiction of ASTM Committee D01 on Paint For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Related Coatings, Materials, andApplications and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D01.33 on Polymers and Resins. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 1, 2019. Published June 2019. Originally the ASTM website.

approved in 1996. Last previous edition approved in 2012 as D5910 – 05 (2012). The last approved version of this historical standard is referenced on

DOI: 10.1520/D5910-05R19. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5910 − 05 (2019)

NOTE 1—The following species were identified as possible interfer-

ences for the method: acetaldehyde, acetone, benzaldehyde, formamide,

formic acid, glyoxylic acid and propionaldehyde. These species, when

chromatographed using this test method, did not interfere with the

formaldehyde peak at the 1000 ppm level or lower.

5.2 Because emulsion polymers vary in composition, the

method run time may need to be extended to allow for late

eluting compounds. Compounds that remain on the column

after an analysis may interfere with the formaldehyde peak in

subsequent runs.

6. Apparatus

6.1 Liquid Chromatograph—Any liquid chromatographic

instrument having an injection valve, a post-column reactor, a

410-nm UV-Vis detector, and an isocratic solvent delivery

system may be used. The solvent delivery system must deliver

a mobile phase flow of 0.6 mL/min.

NOTE 2—The UV-Vis detector may incorporate either a tungsten lamp

or a deuterium lamp with a second order visible filter that filters out light

below 400 nm.

6.2 Post-Column Reactor—Any post-column reactor that

can deliver a reagent flow at 0.5 mL/min, contains a Knitted

Reaction Coil thatcanbeheatedto95°Candcontainsastatic

5,6

mixing tee.

6.3 Chromatographic Column—Column should be 250 by

4.6 mm inside diameter packed with a reversed-phase pH

stable C18, 5-µm particles.

6.4 Chromatographic Guard Column—The column should

be 10 by 4.6 mm inside diameter packed with a reversed-phase

pH stable C18 5-µm particles.

6.5 Data System, that can collect data at 1 point/s from a

1-V output detector.

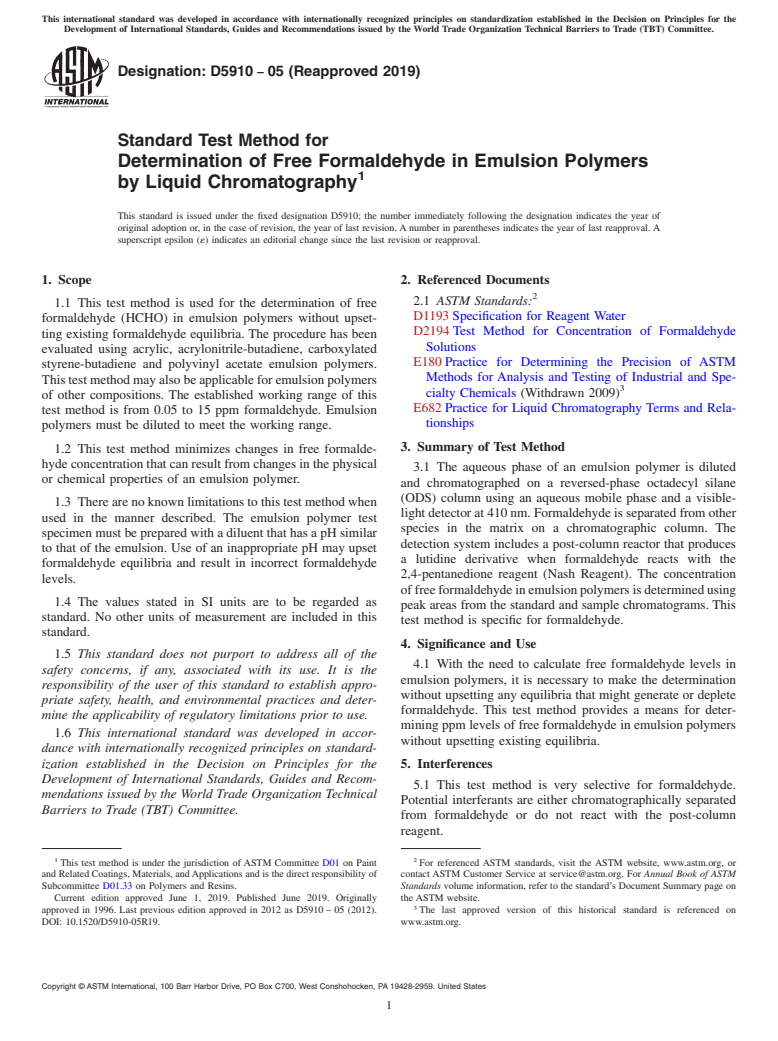

FIG. 1 Schematic of Liquid Chromatograph and Post-Column Re-

6.6 Syringe—100 µL capacity.

action Systems

6.7 Sample Filter—The filter should consist of a 5-mL

sample syringe and a 0.1-µm-filter assembly to remove micro

particulate matter from the prepared sample solution.

the injector.The outlet of the analytical column is connected to

6.8 Centrifuge—Any high speed centrifuge that can gener-

the mixing tee as described in 8.1.

ate 50 000 r/min (274 980 g) or greater (Procedure 2).

6.9 Centrifuge—Any centrifuge that can generate 1000

8. Configuration of Post-Column Reactor (PCR)

r/min or greater (Procedure 3).

8.1 The post-column reagent passes through a pulse damp-

9 8

ener and an in-line check valve prior to the mixing tee. The

7. Configuration of Liquid Chromatograph

outlet of the analytical column is connected to one side of a

7.1 An in-line check valve is placed between the pump and

mixing tee. The reaction coil is connected to the outlet of the

theinjector.Theguardandanalyticalcolumnsareconnectedto

mixing tee. Stainless steel tubing with 0.25-mm inside diam-

eter is used to make the connections. Tubing lengths should be

kepttoaminimum.Themixingteeandreactioncoilareplaced

Knitted capillary delay tube such as Supelco No. 5-9206 available from

inside a 95°C oven. A 40 cm-length of 0.25-mm inside

Supelco Inc., Supelco Park, Bellefonte, PA 16823 has been found satisfactory for

this purpose. diameter stainless steel tubing is connected to the outlet of the

Staticmixingtee,availablefromUpchurchScientific,619W.OakSt.,P.O.Box

reaction coil and is placed in an ambient-temperature stirred

1529, Oak Harbor, WA 98277-1529, Catalog No. U-466, has been found to be

water bath. (This configuration acts as a heat exchanger.) The

satisfactory for this purpose.

exit of the stainless steel tubing is connected to the UV/Vis

Timberline RDR-1, available from Alltech Associates, Inc., 2051 Waukegan

Rd., Deerfield, IL 60015, with two 0.4-mL serpentine reaction coils in series, has

detector. Fig. 1 shows a schematic of the system.

been found to be satisfactory for this purpose.

Filter such as Anotop 25 Plus Syringe Filter, 0.1 µm, Catalog No. 2270,

available from Alltech Assoc., has been found to be satisfactory for this purpose.

8 9

In-line check valve CV-3001 and U-469, Catalog No. 2270, from Upchurch Pulse dampener, SSI LO, Catalog No. 20-0218, available fromAlltechAssoc.,

Scientific has been found to be satisfactory for this purpose. has been found to be satisfactory for this purpose.

D5910 − 05 (2019)

9. Reagents and Materials 10.1.3 Transfer the post-column reagent to the post-column

reactor reservoir. The reservoir should be protected from light.

9.1 Purity of Reagents—Reagent grade chemicals shall be

10.1.4 Degas the post-column reagent with a helium sparge.

used with this test method. Unless otherwise indicated, it is

intended that all reagents shall conform to the specification of 10.2 Mobile Phase and Standard Diluent:

theCommitteeonAnalyticalReagentsoftheAmericanChemi- 10.2.1 Transfer1.78gofsodiumphosphate,dibasictoa2-L

cal Society, where such specifications are available. Other mobilephasereservoirthatcontainsastirbar.Add2Lofwater

grades may be used, provided it is first ascertained that the and mix on a stir plate until the sodium phosphate, dibasic has

reagent is of sufficiently high purity to permit its use without completely dissolved.

lessening the accuracy of the determination. 10.2.2 Adjust the pH of the solution to 7.0 with 0.1 N

phosphoric acid.

9.2 Water—Unless otherwise indicated, references to water

10.2.3 Degas the mobile phase with a helium sparge.

shall be understood to mean reagent water minimally conform-

ing to Type II of Specification D1193, or distilled deionized

NOTE 5—Water may also be used as the mobile phase without the

addition of a buffer.Awater mobile phase should be used when the Carrez

water. High-performance liquid chromatography (HPLC)

reagents are used in the sample preparation (see section 12.2.3).

grade water from chromatography suppliers is also acceptable.

10.3 Sample Diluent:

9.3 Acetic Acid, glacial (CH CO H).

3 2

10.3.1 Transfer0.89gofsodiumphosphate,dibasictoa1-L

9.4 Ammonium Acetate—(CH CO NH ).

3 2 4

bottle that contains a stir bar. Add 1 L of water and mix on a

stir plate until the sodium phosphate, dibasic has completely

9.5 Formaldehyde, 37 % (HCHO).

11 dissolved.

9.6 2,4-Pentanedione, 99 % (CH COCH COCH ).

3 2 3

10.3.2 ThefinalstepofthediluentpreparationrequiresapH

9.7 Phosphoric Acid Solution (0.1 N)—Dissolve 2.3 mL of

adjustment. Before that step can occur the pH of the emulsion

phosphoric acid 85 % (H PO ) in water and dilute to 1 L with

3 4 polymers must be measured to 0.1 pH unit. The emulsion

water.

polymers must be diluted with a buffer that is 60.1 pH unit of

the emulsion polymer.

9.8 Potassium Ferrocyanide Trihydrate Solution (36 g/L)

10.3.3 Divide the 1-L solution into the number of separate

[Carrez Solution I]—Dissolve 26 g of potassium ferrocyanide

diluents required as mentioned in 10.3.2.

trihydrate, 99 % (K Fe(CN) ·3H O) in water and dilute to 1 L

4 6 2

10.3.4 Adjust the pH of the diluents to 0.1 pH unit using

with water.

either 0.1 N NaOH or 0.1 N H PO .

3 4

9.9 Zinc Sulfate Heptahydrate (72 g/L) [Carrez Solution

II]—Dissolve 72 g of zinc sulfate heptahydrate, 99.9 %

11. Operating Conditions for Analysis

(ZnSO ·7H O) in water and dilute to 1 L with water.

4 2

11.1 Adjust the liquid chromatograph in accordance with

9.10 Sodium Hydroxide (0.1 N)—Dissolve8gof sodium

the manufacturers’ directions and the following parameters.

hydroxide 50 % (NaOH) in water and dilute to 1 L with water.

Allow the instrument to equilibrate until a stable base line is

obtained on the data system.

9.11 Sodium Phosphate, dibasic, 98 % (Na HPO ).

2 4

Column temperature: ambient

10. Preparation Mobile phase: 6.3 mM Na HPO (pH = 7) or water

2 4

Flow rate: 0.6 mL/min

10.1 Post-Column Reagent (Nash Reagent):

Injection volume: 50 µL

PCR temperature: 95°C

10.1.1 Transfer 62.5 g of ammonium acetate to a 1-Lamber

PCR flow rate: 0.5 mL/min

bottle that contains a stir bar. Add 600 mL of water to the

Detector: UV/Vis, 410 nm

bottle and mix on a stir plate until the ammonium acetate has

11.2 Determine whether the system is working properly by

completed dissolved.

injecting 50 µLof a 10 ppm formaldehyde standard solution.A

10.1.2 Pipet 7.5 mL of glacial acetic acid into the bottle.

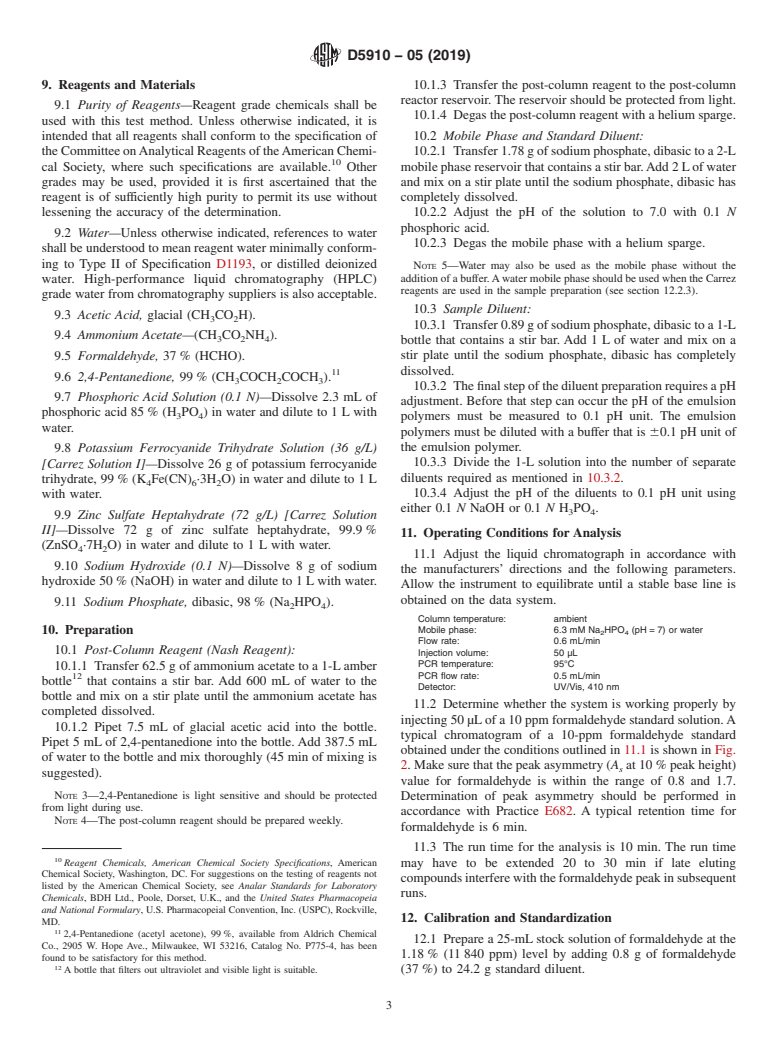

typical chromatogram of a 10-ppm formaldehyde standard

Pipet 5 mL of 2,4-pentanedione into the bottle. Add 387.5 mL

obtained under the conditions outlined in 11.1 is shown in Fig.

of water to the bottle and mix thoroughly (45 min of mixing is

2. Make sure that the peak asymmetry (A at 10 % peak height)

s

suggested).

value for formaldehyde is within the range of 0.8 and 1.7.

NOTE 3—2,4-Pentanedione is light sensitive and should be protected

Determination of peak asymmetry should be performed in

from light during use.

accordance with Practice E682. A typical retention time for

NOTE 4—The post-column reagent should be prepared weekly.

formaldehyde is 6 min.

11.3 The run time for the analysis is 10 min. The run time

Reagent Chemicals, American Chemical Society Specifications, American

may have to be extended 20 to 30 min if late eluting

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

compoundsinterferewiththeformaldehydepeakinsubsequent

listed by the American Chemical Society, see Analar Standards for Laboratory

runs.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

12. Calibration and Standardization

MD.

2,4-Pentanedione (acetyl acetone), 99 %, available from Aldrich Chemical

12.1 Prepare a 25-mLstock solution of formaldehyde at the

Co., 2905 W. Hope Ave., Milwaukee, WI 53216, Catalog No. P775-4, has been

1.18 % (11 840 ppm) level by adding 0.8 g of formaldehyde

found to be satisfactory for this method.

A bottle that filters out ultraviolet and visible light is suitable. (37 %) to 24.2 g standard diluent.

D5910 − 05 (2019)

FIG. 2 Chromatogram of 10 ppm Formaldehyde Standard

NOTE 6—Reagent grade formaldehyde is nominally 37 %. Perform the NOTE 7—Store stock and s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.