ASTM D671-93

(Test Method)Standard Test Method for Flexural Fatigue of Plastics by Constant-Amplitude-of-Force (Withdrawn 2002)

Standard Test Method for Flexural Fatigue of Plastics by Constant-Amplitude-of-Force (Withdrawn 2002)

SCOPE

1.1 This test method covers the determination of the effect of repetitions of the same magnitude of flexural stress on plastics by fixed-cantilever type testing machines, designed to produce a constant-amplitude-of-force on the test specimen each cycle.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 671 – 93

Standard Test Method for

Flexural Fatigue of Plastics by Constant-Amplitude-of-

Force

This standard is issued under the fixed designation D 671; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 This test method is useful to determine the effect of

variations in material, stress, and environmental conditions on

1.1 This test method covers the determination of the effect

the ability of a material to resist deterioration resulting from

of repetitions of the same magnitude of flexural stress on

repeated stress. It may also be used to provide data for use as

plastics by fixed-cantilever type testing machines, designed to

a guide to design and selection of materials for service under

produce a constant-amplitude-of-force on the test specimen

conditions of repeated stress.

each cycle.

4.3 The results are suitable for direct application in design

1.2 The values stated in SI units are to be regarded as the

only when all design factors including magnitude and mode of

standard. The values given in parentheses are for information

stress, size and shape of part, ambient and part temperature,

only.

heat transfer conditions, cyclic frequency, and environmental

1.3 This standard does not purport to address all of the

conditions are comparable to the test conditions.

safety problems, if any, associated with its use. It is the

4.4 The results obtained from testing machines other than

responsibility of the user of this standard to establish appro-

the type described here may not agree due to differences in

priate safety and health practices and determine the applica-

specimen size and geometry, testing machine speeds, heat

bility of regulatory limitations prior to use.

transfer, material fabrication, etc.

2. Referenced Documents 4.5 The type of machine covered in this test method is

suitable for determining the fatigue strength for a range of

2.1 ASTM Standards:

mean stress in flexure. However, for plastic materials, which

D 618 Practice for Conditioning Plastics and Electrical

creep and stress relax, the effect of a mean stress other than

Insulating Materials for Testing

zero is to cause relaxation so that the stress cycle tends to

D 4000 Classification System for Specifying Plastic Mate-

approach the condition of complete reversal of stress.

rials

4.6 Tests of thin sheet yield results which vary with the

3. Summary of Test Method

thickness of the sheet (Note 1). Because of this fact the

thickness of the sheet shall be specified when reporting results

3.1 This test method measures the ability of a material to

of tests of thin sheet; and all comparisons of different materials,

resist deterioration from cyclic stress. The test results provide

or selection of materials on the basis of fatigue strength, shall

data on the number of cycles of stress to produce specimen

be made from results of tests of standard specimens or tests in

failure by fracture, softening, or reduction in stiffness by

which the same thickness of sheet is used for all materials.

heating as a result of internal friction (damping).

NOTE 1—For the purposes of this test a thin sheet shall be defined as a

4. Significance and Use

sheet less than 7.6 mm (0.3 in.) in thickness or a material for which the

4.1 The flexural fatigue test provides information on the ratio of the modulus of elasticity to the fatigue limit is less than 100. The

reason for these restrictions is that thin sheets and materials having a low

ability of rigid plastics to resist the development of cracks or

modulus of elasticity are bent so much under the required loads that the

general mechanical deterioration of the material as a result of

fatigue specimen cannot (in the deflected position) be considered a straight

a relatively large number of cycles of constant amplitude of

beam and hence the following equation is not accurate:

force.

S 5 Mc/I

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

where:

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

S = stress in outer fiber,

Current edition approved Oct. 15, 1993. Published December 1993. Originally

M = bending moment (PL),

published as D 671 – 42 T. Last previous edition D 671 – 90.

c = distance from neutral axis to outer fiber, and

Annual Book of ASTM Standards, Vol 08.01.

I = moment of inertia.

Annual Book of ASTM Standards, Vol 08.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D671–93

4.7 In any plastic part fatigue may be frequency dependent.

Data should not be extrapolated to other frequencies unless the

frequency response is known.

4.8 In any plastic having appreciable damping, fatigue is

dependent on the heat transfer of the specimen or part to the

surroundings. Changes in testing temperature, test frequency,

rate of removal of heat (as by current of air from a fan) will

affect test results. It may be desirable to measure the effect of

these variables or combinations thereof to more closely simu-

late end-use conditions for some specific application.

4.9 The nominal stress or strain resulting from the applied

load does not always represent the actual magnitude of the

applied stress or strain at the test section of the specimen. The

elementary beam formula will not yield precise results for

materials whose: (a) stress-strain relationship is not linear, (b)

stress-strain curve in tension is not identical to that in com-

pression, or (c) internal damping is large. Most plastics have

one or more of these characteristics. No generally satisfactory

method of taking these factors into account is yet available.

4.10 For many materials, there may be a specification that

requires the use of this test method, but with some procedural

modifications that take precedence when adhering to the

specification. Therefore, it is advisable to refer to that material

specification before using this test method. Table 1 of Classi-

fication System D 4000 lists the ASTM materials standards that

currently exist.

5. Apparatus (Fig. 1)

5.1 Testing Machine—A fatigue testing machine of the

fixed-cantilever, repeated-constant-force type (see Appendix

X1). In this machine the specimen, A, shall be held as a

cantilever beam in a vise, B, at one end, and bent by a

concentrated load applied through a yoke, C, fastened to the

opposite end. The alternating force shall be produced by an

unbalanced, variable eccentric, D, mounted on a shaft. The

FIG. 1 Fixed-Cantilever, Repeated-Constant-Load Type Fatigue

Testing Machine

shaft shall be rotated at constant speed by a motor.

5.2 Counter—A counter, E, to record the number of cycles.

the stress range over which the measurements are to be made.

5.3 Cut-off Switch—A suitable mechanically or electrically

operated cut-off switch, F, shall be provided to stop the The triangular form of these specimen types provides for

uniform stress distribution over their respective test spans.

machine when the specimens fail.

5.4 Thermometer—A suitable means of measuring the 6.2 Machining of each specimen shall be accomplished with

a very sharp cutting tool, using such combination of speed and

specimen temperature during the fatigue test such that the

fatigue stress is not disturbed. One approach which has been feed as will give a good finish with a minimum of heating of

the specimen. The test specimen shall be polished with

successful utilized a radiation thermometer to measure the

specimen surface temperature. Other approaches such as ad- successively finer emery paper, finishing with No. 00 to

remove all scratches and tool marks. The final polishing shall

hering thermocouples to the specimen surface may be adequate

provided the stress distribution in the fatigue experiments is not be lengthwise of the specimen, since even small scratches

disturbed. transverse to the direction of tensile stress tend to lower the

fatigue strength. In order to avoid heating, all polishing shall be

6. Test Specimens

done either by hand or with light pressure on a slowly

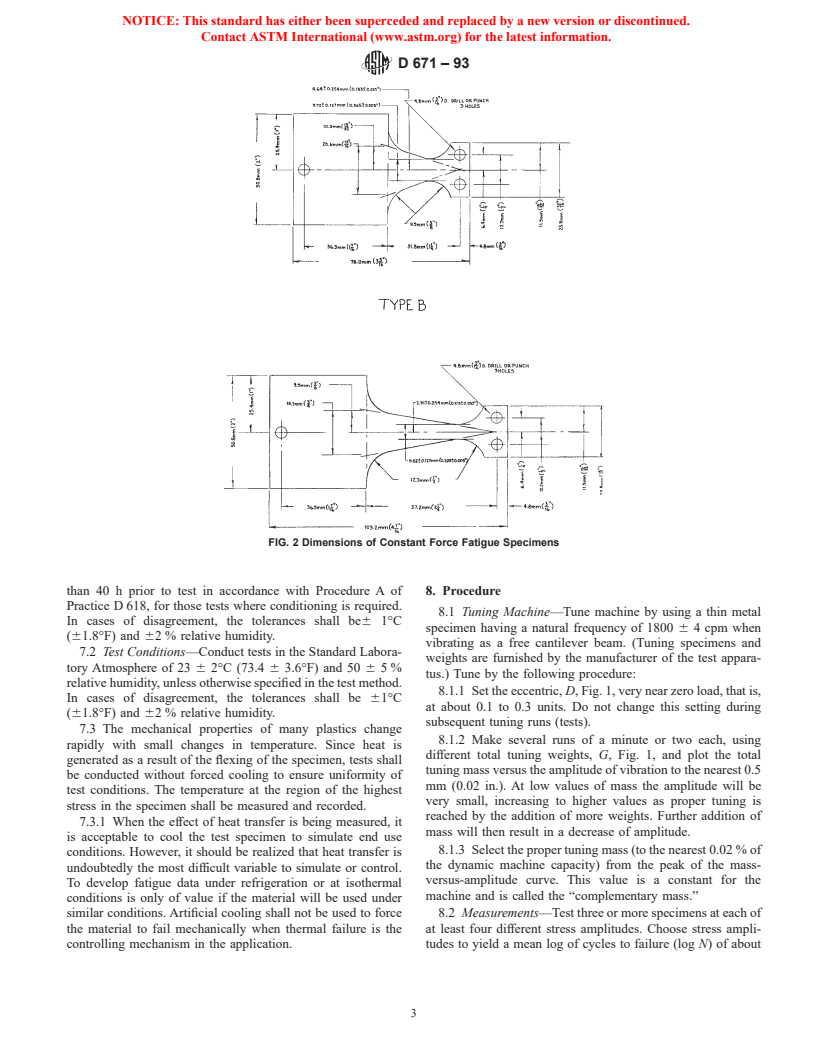

6.1 The test specimens shall conform to one of the two revolving sanding drum. Care shall be taken to avoid rounding

geometries (Type A or Type B) shown in Fig. 2. Selection of a the edges and corners of the specimen.

particular specimen will depend upon specimen thickness and 6.3 Specimens may be molded to the dimensions specified

in Fig. 2, but care should be taken to stress relieve internal

stress unless the effect of molded-in stress is to be measured.

Model SF-2U Constant-Amplitude-of-Force Fatigue Machine, available from

Satec Systems, Inc., Liberty St. Extension, Grove City, PA 16127, has been found

7. Conditioning

satisfactory for this purpose.

7.1 Conditioning—Condition the test specimens at 23 6

Ircon Radiation Thermometer Series 700, available from Ircon Inc., 207

Lawrence Rd., Niles, IL, has been found satisfactory for this purpose. 2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D671–93

FIG. 2 Dimensions of Constant Force Fatigue Specimens

than 40 h prior to test in accordance with Procedure A of 8. Procedure

Practice D 618, for those tests where conditioning is required.

8.1 Tuning Machine—Tune machine by using a thin metal

In cases of disagreement, the tolerances shall be6 1°C

specimen having a natural frequency of 1800 6 4 cpm when

(61.8°F) and 62 % relative humidity.

vibrating as a free cantilever beam. (Tuning specimens and

7.2 Test Conditions—Conduct tests in the Standard Labora-

weights are furnished by the manufacturer of the test appara-

tory Atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

tus.) Tune by the following procedure:

relative humidity, unless otherwise specified in the test method.

8.1.1 Set the eccentric, D, Fig. 1, very near zero load, that is,

In cases of disagreement, the tolerances shall be 61°C

at about 0.1 to 0.3 units. Do not change this setting during

(61.8°F) and 62 % relative humidity.

subsequent tuning runs (tests).

7.3 The mechanical properties of many plastics change

8.1.2 Make several runs of a minute or two each, using

rapidly with small changes in temperature. Since heat is

different total tuning weights, G, Fig. 1, and plot the total

generated as a result of the flexing of the specimen, tests shall

tuning mass versus the amplitude of vibration to the nearest 0.5

be conducted without forced cooling to ensure uniformity of

mm (0.02 in.). At low values of mass the amplitude will be

test conditions. The temperature at the region of the highest

very small, increasing to higher values as proper tuning is

stress in the specimen shall be measured and recorded.

reached by the addition of more weights. Further addition of

7.3.1 When the effect of heat transfer is being measured, it

mass will then result in a decrease of amplitude.

is acceptable to cool the test specimen to simulate end use

8.1.3 Select the proper tuning mass (to the nearest 0.02 % of

conditions. However, it should be realized that heat transfer is

the dynamic machine capacity) from the peak of the mass-

undoubtedly the most difficult variable to simulate or control.

versus-amplitude curve. This value is a constant for the

To develop fatigue data under refrigeration or at isothermal

machine and is called the “complementary mass.”

conditions is only of value if the material will be used under

similar conditions. Artificial cooling shall not be used to force 8.2 Measurements—Test three or more specimens at each of

the material to fail mechanically when thermal failure is the at least four different stress amplitudes. Choose stress ampli-

controlling mechanism in the application. tudes to yield a mean log of cycles to failure (log N) of about

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D671–93

4, 5, 6, and 7. Measure the minimum thickness of the triangular mass system so that tuning (see 8.1) can be achieved. When

portion of each specimen to the nearest 0.03 mm (0.001 in.). frequency is not specified, tests shall be conducted at 30 Hz 6

Clamp the specimen snugly in the vise, B, Fig. 1, with its 5%.

smaller end screwed securely to the vibrating yoke, C. Measure 8.7 Readings—Set the revolution counter at zero before

the test span, L, to the nearest 0.5 mm (0.02 in.) from the starting a test. Upon failure of the test specimen, read the

leading edge of the vise, B, along the principal axis of the counter to determine the number of cycles to failure.

specimen to the line-of-centers of the mounting screws in the 8.8 Temperature Measurement—Measure the steady-state

yoke, C. Measure the width, b, of the specimen defined by the temperature. If steady-state conditions do not occur, measure

intersection of the leading edge of the vise with the sides (or the temperature throughout the fatigue test. In all fatigue tests,

projections thereof) of the triangular portion of the specimen, measure the temperature at failure unless it can be shown that

to the nearest 0.3 mm (0.01 in.). the heat rise is insignificant for the specific material and test

8.3 Calculation of Effective Mass of Test Specimen— condition. Focus the radiation thermometer on the expected

Calculate the effective mass (Note 2) of the standard specimen failure area of specimen. Temperature measurements should be

Types A and B (Fig. 2) as follows: measured over small areas, such as over a 1-mm (0.040-in.)

For Type A Specimen: diameter spot, and the specimen should be periodically

scanned to ensure that the maximum localized heating is being

W 5 kDd

measured.

For Type B Specimen:

9. Plotting and Interpreting Results

W 5 k8Dd

9.1 Plotting Results—Plot an S-N (stress versus cycles-to-

where: failure) diagram with the alternating stress amplitude as the

W = effective mass, g (or lb),

ordinate against the common logarithm of the number of cycles

3 3

D = density of the specimen (material), Gg/m (or lb/in. ),

required for failure (see X3.21) as the abscissa. Plot all test data

d = average specimen thickness, mm (or in.),

and define the S-N diag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.