ASTM D3275-97

(Classification)Standard Classification for E-CTFE-Fluoroplastic Molding, Extrusion, and Coating Materials

Standard Classification for E-CTFE-Fluoroplastic Molding, Extrusion, and Coating Materials

SCOPE

1.1 This classification covers melt processible molding, extrusion, and coating materials of ethylene-chlorotrifluoroethylene (E-CTFE) fluoroplastics. The resin is a copolymer of ethylene and chlorotrifluoroethylene containing approximately 80 weight % of chlorotrifluoroethylene.

1.2 The values stated in SI units, as detailed in IEEE/ASTM SI 10, are to be regarded as the standard.

1.3 The following precautionary statement pertains only to the test methods portion, Section 11 of this specification.This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1--Although this specification and ISO 12086-1 (1995) and ISO 12086-2 (1995) differ in approach or detail, data obtained using either are technically equivalent.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3275 – 97 An American National Standard

Standard Specification for

E-CTFE-Fluoroplastic Molding, Extrusion, and Coating

1

Materials

This standard is issued under the fixed designation D 3275; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope * Use of Microtensile Specimens

3

D 1898 Practice for Sampling of Plastics

1.1 This specification covers melt processible molding,

D 2863 Test Method for Measuring the Minimum Oxygen

extrusion, and coating materials of ethylene-

Concentration to Support Candle-Like Combustion of

chlorotrifluoroethylene (E-CTFE) fluoroplastics. The resin is a

4

Plastics (Oxygen Index)

copolymer of ethylene and chlorotrifluoroethylene containing

4

D 3892 Practice for Packaging/Packing of Plastics

approximately 80 weight % of chlorotrifluoroethylene.

D 4591 Test Method for Determining Temperature and

1.2 The values stated in SI units, as detailed in Practice

Heats of Transitions of Fluoropolymer is by Differential

E 380, are to be regarded as the standard.

5

Scanning Calorimetry

1.3 The following precautionary statement pertains only to

E 380 Practice for Use of the International System of Units

the test methods portion, Section 11 of this specification. This

6

(SI) (The Modernized Metric System)

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

3.1 Definitions: Definitions of terms used in this specifica-

practices and determine the applicability of regulatory limita-

tion shall be in accordance with Terminology D 883.

tions prior to use.

NOTE 1—Although this specification and ISO 12086-1 (1994) and ISO 4. Classification

12086-2 (1994) differ in approach or detail, data obtained using either are

4.1 This specification covers three types of E-CTFE-

technically equivalent.

fluoroplastic supplied in pellet or powder forms for molding,

extrusion, and coatings:

2. Referenced Documents

4.1.1 Type I—Low melt flow rate.

2.1 ASTM Standards:

4.1.2 Type II—Medium melt flow rate.

D 150 Test Methods for A-C Loss Characteristics and

4.1.3 Type III—High melt flow rate.

Permittivity (Dielectric Constant) of Solid Electrical Insu-

4.2 A one-line system may be used to specify materials

2

lating Materials

covered by this specification. The system uses predefined cells

D 618 Practice for Conditioning Plastics and Electrical

to refer to specific aspects of this specification, as illustrated

3

Insulating Materials for Testing

below.

3

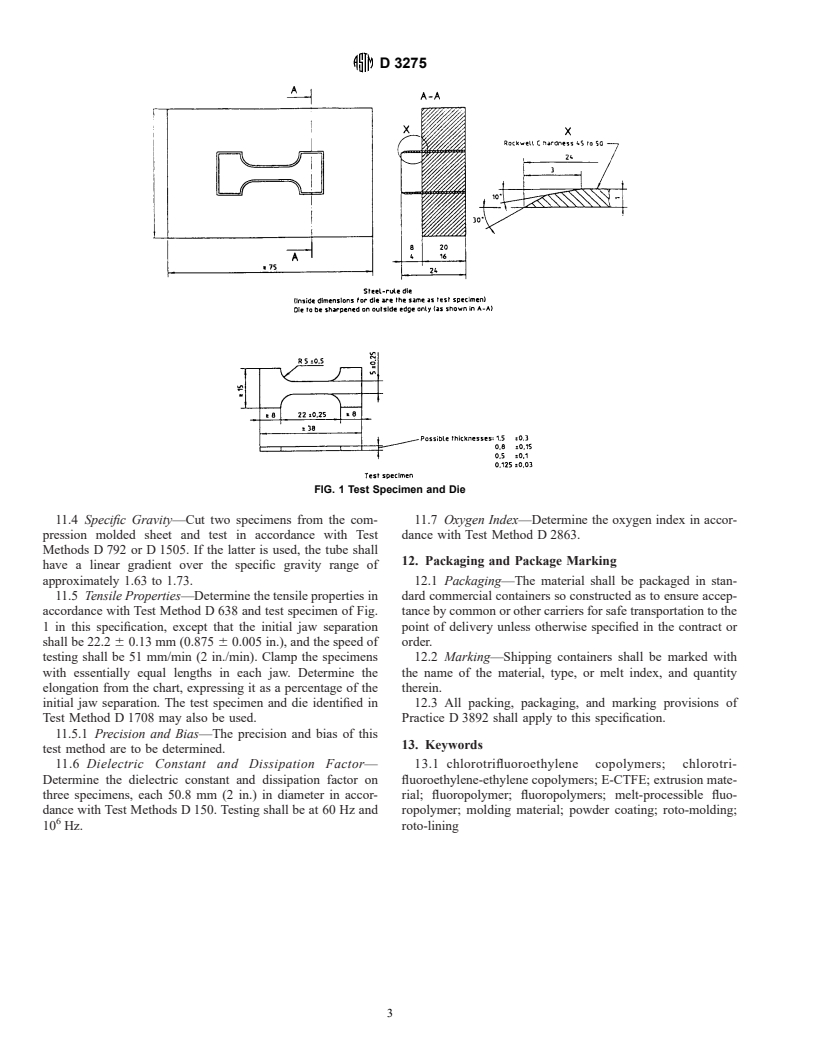

D 638 Test Method for Tensile Properties of Plastics

Specification

D 792 Test Methods for Specific Gravity (Relative Density)

Standard Number : Type :

3

and Density of Plastics by Displacement

Block : :

3

D 883 Terminology Relating to Plastics ::

––––––––––––––––– –––

D 1238 Test Method for Flow Rates of Thermoplastics by

Example: Specification I

3

Extrusion Plastometer

D 3275 – 97,

D 1505 Test Method for Density of Plastics by the Density-

3 For this example, the line callout would be Specification

Gradient Technique

D 3275 and would specify a low melt flow rate extrusion and

D 1708 Test Method for Tensile Properties of Plastics By

molding grade of E-CTFE that has all of the properties listed

for that Type in the appropriate tables, or both, in the

1

This specification is under the jurisdiction of ASTM Committee D-20 on

specification identified. A comma is used as the separator

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

Materials (Section 20.15.12).

Current edition approved April 10, 1997. Published April 1998. Originally

4

published as D 3275 – 73. Last previous edition D 3275 – 91a. Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 10.01. Annual Book of ASTM Standards, Vol 08.03.

3 6

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3275

TABLE 2 Detail Requirements for Molded Test Specimens of

between the Standard Number and the Type.

Types I, II, and III Resins

5. Ordering Information

Specific gravity, 23/23°C (73.4/73.4°F):

min 1.65

5.1 The purchase order or inquiry for these materials shall

max 1.71

state the specification number and type. For example, D 3275

Ultimate Tensile strength, 23°C

(73.4°F), min:

Type I.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.