ASTM B786/B786M-08(2018)

(Specification)Standard Specification for 19 Wire Combination Unilay-Stranded Aluminum Conductors for Subsequent Insulation

Standard Specification for 19 Wire Combination Unilay-Stranded Aluminum Conductors for Subsequent Insulation

ABSTRACT

This specification covers the standard requirements for bare combination unilay-stranded conductors made from round wires of aluminum 1350 and 8000 series of aluminum alloys, for insulated conductors to be used for electrical purposes. Aluminum 1350 wires in tempers -H19, -H16 or -H26, -H14 or -H24, and -H142 or -H242 and 8000 series aluminum alloy wires in tempers “0” and H1X or H2X are permitted. These conductors shall be constructed with a central core wire surrounded by two layers of helically laid wires, resulting in an outer diameter equal to the compressed-stranded equivalent conductors. Electric-butt welds, cold pressure welds, or electric-butt cold-upset welds may be made in the finished individual wires composing the conductor. Mechanical (tension) and electrical tests shall be performed on the wires composing the conductors that are annealed and not annealed after stranding. The mass and electrical resistance of a unit length of stranded conductor shall be determined as a function of the length of lay. The conductors shall meet the breaking strength, tensile strength, and bending strength requirements.

SCOPE

1.1 This specification covers bare combination unilay-stranded conductors made from round wires of aluminum 1350 and 8000 series of aluminum alloys, for insulated conductors for electrical purposes. Aluminum 1350 wires in tempers -H19 (extra hard), -H16 or -H26 (3/4 hard), -H14 or -H24 (1/2 hard), and -H142 or -H242 (1/2 hard) and 8000 series aluminum alloys wires in tempers “0” and H1X or H2X are permitted. These conductors shall be constructed with a central core wire surrounded by two layers of helically laid wires, resulting in an outer diameter equal to the compressed-stranded equivalent conductors.

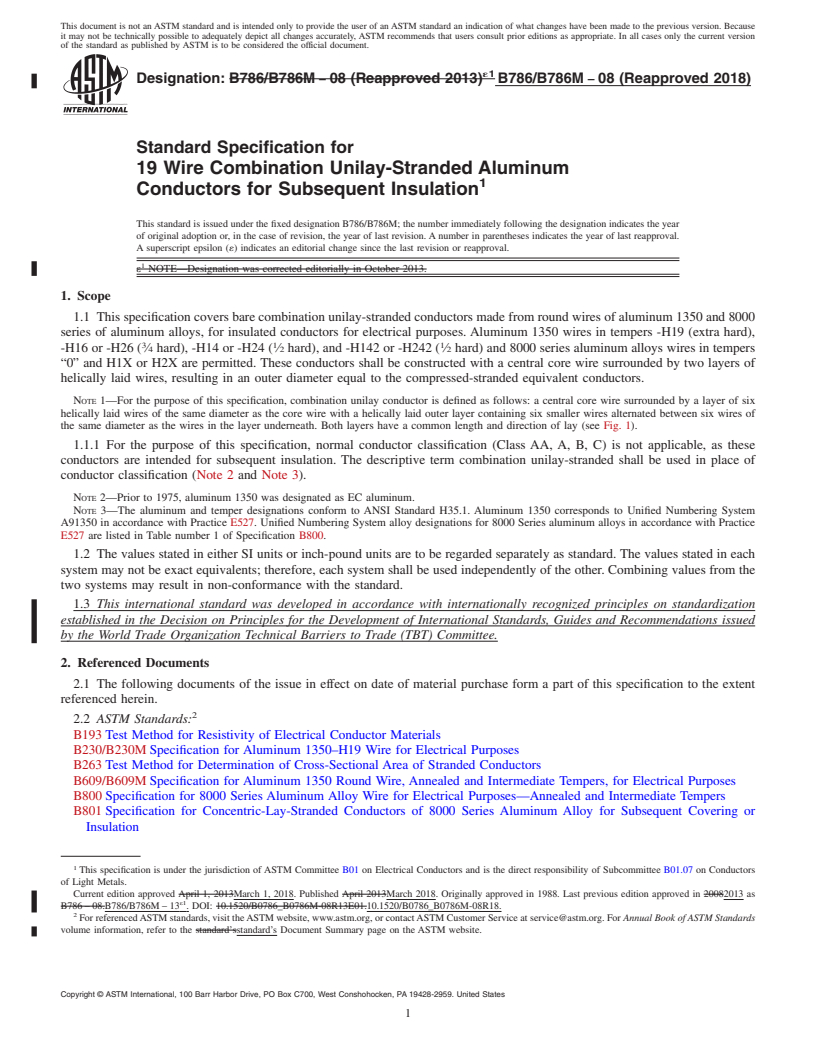

Note 1: For the purpose of this specification, combination unilay conductor is defined as follows: a central core wire surrounded by a layer of six helically laid wires of the same diameter as the core wire with a helically laid outer layer containing six smaller wires alternated between six wires of the same diameter as the wires in the layer underneath. Both layers have a common length and direction of lay (see Fig. 1).

FIG. 1 Cross Section of Conductor

1.1.1 For the purpose of this specification, normal conductor classification (Class AA, A, B, C) is not applicable, as these conductors are intended for subsequent insulation. The descriptive term combination unilay-stranded shall be used in place of conductor classification (Note 2 and Note 3).

Note 2: Prior to 1975, aluminum 1350 was designated as EC aluminum.

Note 3: The aluminum and temper designations conform to ANSI Standard H35.1. Aluminum 1350 corresponds to Unified Numbering System A91350 in accordance with Practice E527. Unified Numbering System alloy designations for 8000 Series aluminum alloys in accordance with Practice E527 are listed in Table number 1 of Specification B800.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B786/B786M −08 (Reapproved 2018)

Standard Specification for

19 Wire Combination Unilay-Stranded Aluminum

Conductors for Subsequent Insulation

This standard is issued under the fixed designation B786/B786M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This specification covers bare combination unilay-

ization established in the Decision on Principles for the

strandedconductorsmadefromroundwiresofaluminum1350

Development of International Standards, Guides and Recom-

and 8000 series of aluminum alloys, for insulated conductors

mendations issued by the World Trade Organization Technical

for electrical purposes.Aluminum 1350 wires in tempers -H19

Barriers to Trade (TBT) Committee.

3 1

(extra hard), -H16 or -H26 ( ⁄4 hard), -H14 or -H24 ( ⁄2 hard),

and-H142or-H242( ⁄2hard)and8000seriesaluminumalloys

2. Referenced Documents

wires in tempers “0” and H1X or H2X are permitted. These

conductors shall be constructed with a central core wire

2.1 The following documents of the issue in effect on date

surroundedbytwolayersofhelicallylaidwires,resultinginan

of material purchase form a part of this specification to the

outer diameter equal to the compressed-stranded equivalent

extent referenced herein.

conductors.

2.2 ASTM Standards:

NOTE 1—For the purpose of this specification, combination unilay

B193Test Method for Resistivity of Electrical Conductor

conductor is defined as follows: a central core wire surrounded by a layer

Materials

of six helically laid wires of the same diameter as the core wire with a

B230/B230MSpecification for Aluminum 1350–H19 Wire

helically laid outer layer containing six smaller wires alternated between

six wires of the same diameter as the wires in the layer underneath. Both

for Electrical Purposes

layers have a common length and direction of lay (see Fig. 1).

B263Test Method for Determination of Cross-Sectional

1.1.1 Forthepurposeofthisspecification,normalconductor Area of Stranded Conductors

classification (Class AA, A, B, C) is not applicable, as these

B609/B609M Specification for Aluminum 1350 Round

conductorsareintendedforsubsequentinsulation.Thedescrip- Wire, Annealed and Intermediate Tempers, for Electrical

tivetermcombinationunilay-strandedshallbeusedinplaceof

Purposes

conductor classification (Note 2 and Note 3).

B800Specification for 8000 Series Aluminum Alloy Wire

forElectricalPurposes—AnnealedandIntermediateTem-

NOTE 2—Prior to 1975, aluminum 1350 was designated as EC

pers

aluminum.

NOTE 3—The aluminum and temper designations conform to ANSI B801SpecificationforConcentric-Lay-StrandedConductors

Standard H35.1. Aluminum 1350 corresponds to Unified Numbering

of 8000 SeriesAluminumAlloy for Subsequent Covering

System A91350 in accordance with Practice E527. Unified Numbering

or Insulation

System alloy designations for 8000 Series aluminum alloys in accordance

E29Practice for Using Significant Digits in Test Data to

with Practice E527 are listed in Table number 1 of Specification B800.

Determine Conformance with Specifications

1.2 The values stated in either SI units or inch-pound units

E527Practice for Numbering Metals and Alloys in the

are to be regarded separately as standard. The values stated in

Unified Numbering System (UNS)

each system may not be exact equivalents; therefore, each

2.3 ANSI Standard:

system shall be used independently of the other. Combining

ANSI H35.1/H35.1(M)Alloy and Temper Designation Sys-

values from the two systems may result in non-conformance

tems for Aluminum

with the standard.

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Conductors of Light Metals. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2018. Published March 2018. Originally the ASTM website.

ε1 3

approved in 1988. Last previous edition approved in 2013 as B786/B786M–13 . Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/B0786_B0786M-08R18. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B786/B786M − 08 (2018)

3.1.7 Whenphysicaltestsshallbemade(seeSections7and

8),

3.1.8 Package size (see 16.1),

3.1.9 Heavy wood lagging, if required (see 17.2),

3.1.10 Special package marking, if required (Section 17),

and

3.1.11 Place of inspection (Section 15).

4. Joints

FIG. 1 Cross Section of Conductor

4.1 Electric-butt welds, cold pressure welds, or electric-butt

TABLE 1 Construction Requirements for 19-Wire Combination

cold-upset welds may be made in the finished individual wires

Unilay Stranded Aluminum Conductors

composing the conductor but shall not be closer together than

A B

Wire D Wire D

Area of Size, American (or

1 2

1 ft (Explanatory Note 2).

Diameter Diameter

Cross-Section, Brown and Sharpe)

cmil Wire Gage

mils mm mils mm

5. Lay

556 500 185.3 4.71 135.6 3.44

500 000 175.6 4.46 128.5 3.26 5.1 For combination unilay conductors the lay of a layer of

477 000 171.5 4.36 125.5 3.19

wires shall be not less than 8 nor more than 16 times the

450 000 166.6 4.23 121.9 3.10

outside diameter of the outer layer.

397 500 156.6 3.98 114.6 2.91

350 000 146.9 3.73 107.5 2.73

5.2 Other lays for special purposes shall be furnished by

336 400 144.0 3.66 105.4 2.68

specialagreementbetweenthemanufacturerandthepurchaser.

300 000 136.0 3.45 99.6 2.53

266 800 128.3 3.26 93.9 2.38

NOTE4—Certaintypesofinsulationconductorsmayrequireshorterlay

250 000 124.2 3.15 90.9 2.31

than other conductors. It is expected that special requirements regarding

211 600 0000 114.2 2.90 83.6 2.12

length of lay will be specified by the purchaser in such instances.

167 800 000 101.7 2.58 74.5 1.89

133 100 00 90.6 2.30 66.3 1.68

5.3 The direction of lay shall be left-hand unless the

105 600 0 80.7 2.05 59.1 1.50

83 690 1 71.8 1.82 52.6 1.34 direction of lay is specified otherwise by the purchaser.

66 360 2 64.0 1.63 46.8 1.19

52 620 3 57.0 1.45 41.7 1.06

6. Construction (Explanatory Note 1)

41 740 4 50.7 1.29 37.1 0.94

33 090 5 45.2 1.15 33.1 0.84 6.1 The areas of cross section, numbers, and diameters of

26 240 6 40.2 1.02 29.4 0.75

wires in the various conductors shall conform to the require-

20 820 7 35.8 0.91 26.2 0.67

ments prescribed in Table 1 (Note 3) (see Fig. 1).

16 510 8 31.9 0.81 23.4 0.59

13 090 9 28.4 0.72 20.8 0.53

6.2 ThediametersofthewireslistedinTable2arenominal.

10 380 10 25.3 0.64 18.5 0.47

In order to produce an essentially round 19-wire construction,

6 530 12 20.1 0.51 14.7 0.37

A the outer 12-wire layer in the combination unilay product is

Equation to calculate D :

comprised of 6 wires of the same diameter as the wires in the

Cross2Sectional Area

D 5

Π7-wire core, and 6 wires approximately 25% smaller. The

16.2149

2-wire sizes are alternated around the 7-wire core.

B

Equation to calculate D :

D 5 D 30.732.

7. Mechanical and Electrical Tests of Conductors not

2 1

Annealed after Stranding

7.1 Wires composing the conductors shall be tested prior to

stranding in accordance with the applicable specification (see

2.4 NIST Standard:

11.1.2), and tests on the completed conductor are not required.

NBS Handbook 100—Copper Wire Tables

However, when requested by the purchaser and agreed to by

the manufacturer at time of ordering, the tension tests of wires

3. Ordering Information

before stranding may be waived and the completed conductor

3.1 Orders for materials under this specification shall in-

tested in accordance with 7.2, or wires removed from the

clude the following information:

completed conductor tested in accordance with 7.5.

3.1.1 Conductor alloy,

7.2 When the completed conductor is tested as a unit, the

3.1.2 Quantity of each size,

breaking strength shall be not less than the rated strength of

3.1.3 Conductor size: Circular-mil area or American Wire

1350-H19 conductors or the minimum rated strength of 1350-

Gage, AWG (Section 6 and Table 1),

H16, -H26, -H14, -H24, -H142, and -H242 conductors if

3.1.4 Stranding (see Explanatory Note 1),

failure occurs in the free length at least 1 in. [25 mm] beyond

3.1.5 Temper (see Section 11),

theendofeithergrippingdevice.Thestrengthshallbenotless

3.1.6 Details of special-purpose lays, if required (see 5.2),

than 95% of the rated or minimum rated strength if failure

occurs inside, or within 1 in. of the end of either gripping

device.Thebreakingstrengthof1350-H16,-H26,-H14,-H24,

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. -H142, and -H242 conductors shall be not greater than their

B786/B786M − 08 (2018)

A

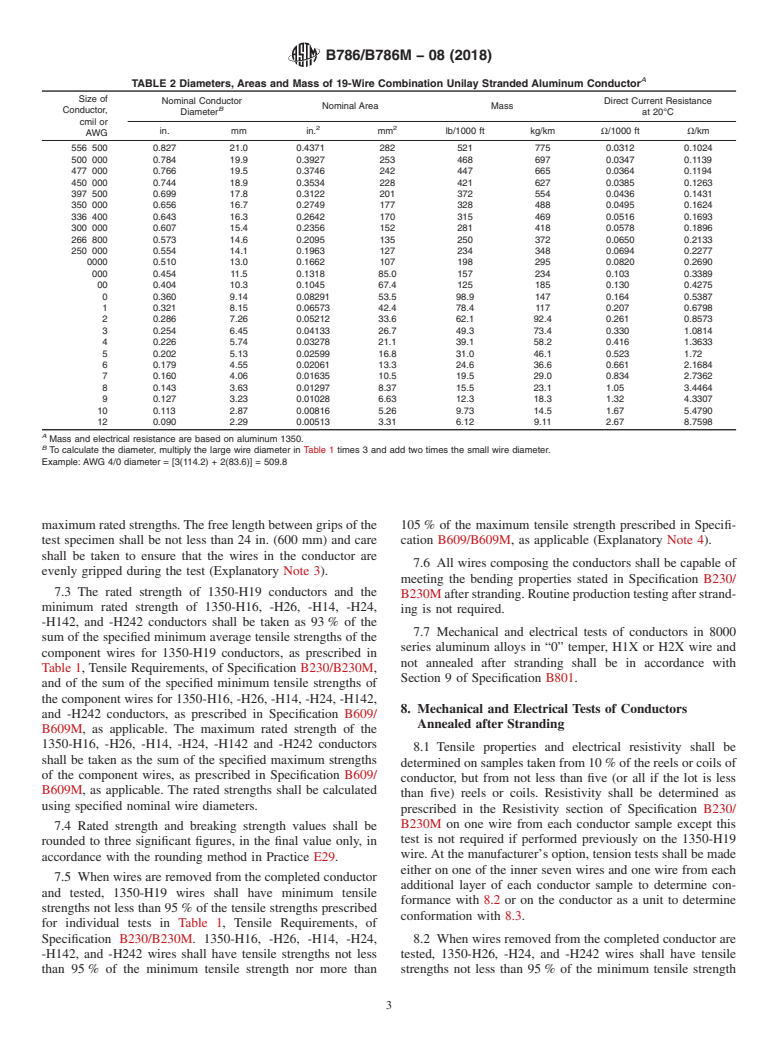

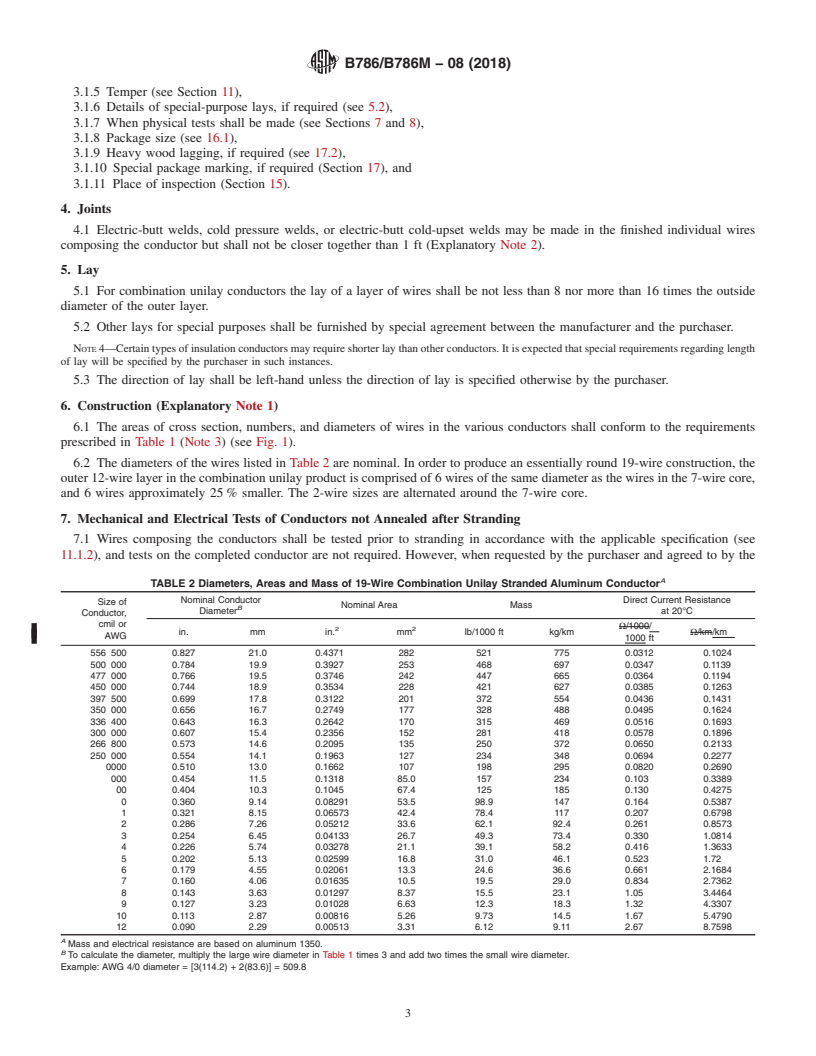

TABLE 2 Diameters, Areas and Mass of 19-Wire Combination Unilay Stranded Aluminum Conductor

Size of

Nominal Conductor Direct Current Resistance

Nominal Area Mass

B

Conductor,

Diameter at 20°C

cmil or

2 2

in. mm in. mm lb/1000 ft kg/km Ω/1000 ft Ω/km

AWG

556 500 0.827 21.0 0.4371 282 521 775 0.0312 0.1024

500 000 0.784 19.9 0.3927 253 468 697 0.0347 0.1139

477 000 0.766 19.5 0.3746 242 447 665 0.0364 0.1194

450 000 0.744 18.9 0.3534 228 421 627 0.0385 0.1263

397 500 0.699 17.8 0.3122 201 372 554 0.0436 0.1431

350 000 0.656 16.7 0.2749 177 328 488 0.0495 0.1624

336 400 0.643 16.3 0.2642 170 315 469 0.0516 0.1693

300 000 0.607 15.4 0.2356 152 281 418 0.0578 0.1896

266 800 0.573 14.6 0.2095 135 250 372 0.0650 0.2133

250 000 0.554 14.1 0.1963 127 234 348 0.0694 0.2277

0000 0.510 13.0 0.1662 107 198 295 0.0820 0.2690

000 0.454 11.5 0.1318 85.0 157 234 0.103 0.3389

00 0.404 10.3 0.1045 67.4 125 185 0.130 0.4275

0 0.360 9.14 0.08291 53.5 98.9 147 0.164 0.5387

1 0.321 8.15 0.06573 42.4 78.4 117 0.207 0.6798

2 0.286 7.26 0.05212 33.6 62.1 92.4 0.261 0.8573

3 0.254 6.45 0.04133 26.7 49.3 73.4 0.330 1.0814

4 0.226 5.74 0.03278 21.1 39.1 58.2 0.416 1.3633

5 0.202 5.13 0.02599 16.8 31.0 46.1 0.523 1.72

6 0.179 4.55 0.02061 13.3 24.6 36.6 0.661 2.1684

7 0.160 4.06 0.01635 10.5 19.5 29.0 0.834 2.7362

8 0.143 3.63 0.01297 8.37 15.5 23.1 1.05 3.4464

9 0.127 3.23 0.01028 6.63 12.3 18.3 1.32 4.3307

10 0.113 2.87 0.00816 5.26 9.73 14.5 1.67 5.4790

12 0.090 2.29 0.00513 3.31 6.12 9.11 2.67 8.7598

A

Mass and electrical resistance are based on aluminum 1350.

B

To calculate the diameter, multiply the large wire diameter in Table 1 times 3 and add two times the small wire diameter.

Example: AWG 4/0 diameter = [3(114.2) + 2(83.6)] = 509.8

maximumratedstrengths.Thefreelengthbetweengripsofthe 105% of the maximum tensile strength prescribed in Specifi-

test specimen shall be not less than 24 in. (600 mm) and care cation B609/B609M, as applicable (Explanatory Note 4).

shall be taken to ensure that the wires in the conductor are

7.6 All wires composing the conductors shall be capable of

evenly gripped during the test (Explanatory Note 3).

meeting the bending properties stated in Specification B230/

7.3 The rated strength of 1350-H19 conductors and the

B230Mafterstranding.Routineproductiontestingafterstrand-

minimum rated strength of 1350-H16, -H26, -H14, -H24,

ing is not required.

-H142, and -H242 conductors shall be taken as 93% of the

7.7 Mechanical and electrical tests of conductors in 8000

sum of the specified minimum average tensile strengths of the

series aluminum alloys in “0” temper, H1X or H2X wire and

component wires for 1350-H19 conductors, as prescribed in

not annealed after stranding shall be in accordance with

Table 1, Tensile Requirements, of Specification B230/B230M,

Section 9 of Specification B801.

and of the sum of the specified minimum tensile strengths of

the component wires for 1350-H16, -H26, -H14, -H24, -H142,

8. Mechanical and Electrical Tests of Conductors

and -H242 conductors, as prescribed in Specification B609/

Annealed after Stranding

B609M, as applicable. The maximum rated strength of the

1350-H16, -H26, -H14, -H24, -H142 and -H242 conductors

8.1 Tensile properties and electrical resistivity shall be

shall be taken as the sum of the specified maximum strengths

determinedonsamplestakenfrom10%ofthereelsorcoilsof

of the component wires, as prescribed in Specification B609/

conductor, but from not less than five (or all if the lot is less

B609M, as applicable. The rated strengths shall be calculated

than five) reels or coils. Resistivity shall be determined as

using specified nominal wire diameters.

prescribed in the Resistivity section of Specification B230/

B230M on one wire from each conductor sample except this

7.4 Rated strength and breaking strength values shall be

test is not required if performed previously on the 1350-H19

rounded to three significant figures, in the final value only, in

wire.At the manufacturer’s option, tension tests shall be made

accordance with the rounding method in Practice E29.

either on one of the inner seven wires and one wire from each

7.5 When wires are removed from the completed conductor

additional layer of each conductor sample to determine con-

and tested, 1350-H19 wires shall have minimum tensile

formance with 8.2 or on the conductor as a unit to determine

strengths not less than 95% of the tensile strengths prescribed

conformation with 8.3.

for individual tests in Table 1, Tensile Requirements, of

Specification B230/B230M. 1350-H16, -H26, -H14, -H24, 8.2 When wires removed from the completed conductor are

-H142, and -H242 wires shall have tensile strengths not less tested, 1350-H26, -H24, and -H242 wires shall have tensile

than 95% of the minimum tensile strength nor more than strengths not less than 95% of the minimum tensile strength

B786/B786M − 08 (2018)

nor more than 105% of the maximum tensile strength pre- 11. Requirements for Wires

scribed in Specification B609/B609M, as applicable (Explana-

11.1 Thepurchasershalldesignatethetemperofwirestobe

tory Note 4).

used in the conductor.

8.3 When the completed conductor is tested as a unit, the 11.1.1 Forconductorsofaluminum1350withtempersother

breaking strengths of 1350-H26, -H24, a

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B786/B786M − 08 (Reapproved 2018)

Standard Specification for

19 Wire Combination Unilay-Stranded Aluminum

Conductors for Subsequent Insulation

This standard is issued under the fixed designation B786/B786M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This specification covers bare combination unilay-

ization established in the Decision on Principles for the

stranded conductors made from round wires of aluminum 1350

Development of International Standards, Guides and Recom-

and 8000 series of aluminum alloys, for insulated conductors

mendations issued by the World Trade Organization Technical

for electrical purposes. Aluminum 1350 wires in tempers -H19

Barriers to Trade (TBT) Committee.

3 1

(extra hard), -H16 or -H26 ( ⁄4 hard), -H14 or -H24 ( ⁄2 hard),

and -H142 or -H242 ( ⁄2 hard) and 8000 series aluminum alloys

2. Referenced Documents

wires in tempers “0” and H1X or H2X are permitted. These

conductors shall be constructed with a central core wire

2.1 The following documents of the issue in effect on date

surrounded by two layers of helically laid wires, resulting in an

of material purchase form a part of this specification to the

outer diameter equal to the compressed-stranded equivalent

extent referenced herein.

conductors.

2.2 ASTM Standards:

NOTE 1—For the purpose of this specification, combination unilay

B193 Test Method for Resistivity of Electrical Conductor

conductor is defined as follows: a central core wire surrounded by a layer

Materials

of six helically laid wires of the same diameter as the core wire with a

B230/B230M Specification for Aluminum 1350–H19 Wire

helically laid outer layer containing six smaller wires alternated between

six wires of the same diameter as the wires in the layer underneath. Both

for Electrical Purposes

layers have a common length and direction of lay (see Fig. 1).

B263 Test Method for Determination of Cross-Sectional

1.1.1 For the purpose of this specification, normal conductor

Area of Stranded Conductors

classification (Class AA, A, B, C) is not applicable, as these B609/B609M Specification for Aluminum 1350 Round

conductors are intended for subsequent insulation. The descrip-

Wire, Annealed and Intermediate Tempers, for Electrical

tive term combination unilay-stranded shall be used in place of

Purposes

conductor classification (Note 2 and Note 3).

B800 Specification for 8000 Series Aluminum Alloy Wire

for Electrical Purposes—Annealed and Intermediate Tem-

NOTE 2—Prior to 1975, aluminum 1350 was designated as EC

pers

aluminum.

NOTE 3—The aluminum and temper designations conform to ANSI

B801 Specification for Concentric-Lay-Stranded Conductors

Standard H35.1. Aluminum 1350 corresponds to Unified Numbering

of 8000 Series Aluminum Alloy for Subsequent Covering

System A91350 in accordance with Practice E527. Unified Numbering

or Insulation

System alloy designations for 8000 Series aluminum alloys in accordance

E29 Practice for Using Significant Digits in Test Data to

with Practice E527 are listed in Table number 1 of Specification B800.

Determine Conformance with Specifications

1.2 The values stated in either SI units or inch-pound units

E527 Practice for Numbering Metals and Alloys in the

are to be regarded separately as standard. The values stated in

Unified Numbering System (UNS)

each system may not be exact equivalents; therefore, each

2.3 ANSI Standard:

system shall be used independently of the other. Combining

ANSI H35.1/H35.1(M) Alloy and Temper Designation Sys-

values from the two systems may result in non-conformance

tems for Aluminum

with the standard.

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Conductors of Light Metals. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2018. Published March 2018. Originally the ASTM website.

ε1 3

approved in 1988. Last previous edition approved in 2013 as B786/B786M – 13 . Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/B0786_B0786M-08R18. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B786/B786M − 08 (2018)

3.1.7 When physical tests shall be made (see Sections 7 and

8),

3.1.8 Package size (see 16.1),

3.1.9 Heavy wood lagging, if required (see 17.2),

3.1.10 Special package marking, if required (Section 17),

and

3.1.11 Place of inspection (Section 15).

4. Joints

FIG. 1 Cross Section of Conductor

4.1 Electric-butt welds, cold pressure welds, or electric-butt

TABLE 1 Construction Requirements for 19-Wire Combination

cold-upset welds may be made in the finished individual wires

Unilay Stranded Aluminum Conductors

composing the conductor but shall not be closer together than

A B

Wire D Wire D

Area of Size, American (or 1 2

1 ft (Explanatory Note 2).

Diameter Diameter

Cross-Section, Brown and Sharpe)

cmil Wire Gage mils mm mils mm

5. Lay

556 500 185.3 4.71 135.6 3.44

500 000 175.6 4.46 128.5 3.26 5.1 For combination unilay conductors the lay of a layer of

477 000 171.5 4.36 125.5 3.19

wires shall be not less than 8 nor more than 16 times the

450 000 166.6 4.23 121.9 3.10

outside diameter of the outer layer.

397 500 156.6 3.98 114.6 2.91

350 000 146.9 3.73 107.5 2.73

5.2 Other lays for special purposes shall be furnished by

336 400 144.0 3.66 105.4 2.68

special agreement between the manufacturer and the purchaser.

300 000 136.0 3.45 99.6 2.53

266 800 128.3 3.26 93.9 2.38

NOTE 4—Certain types of insulation conductors may require shorter lay

250 000 124.2 3.15 90.9 2.31

than other conductors. It is expected that special requirements regarding

211 600 0000 114.2 2.90 83.6 2.12

length of lay will be specified by the purchaser in such instances.

167 800 000 101.7 2.58 74.5 1.89

133 100 00 90.6 2.30 66.3 1.68

5.3 The direction of lay shall be left-hand unless the

105 600 0 80.7 2.05 59.1 1.50

direction of lay is specified otherwise by the purchaser.

83 690 1 71.8 1.82 52.6 1.34

66 360 2 64.0 1.63 46.8 1.19

52 620 3 57.0 1.45 41.7 1.06

6. Construction (Explanatory Note 1)

41 740 4 50.7 1.29 37.1 0.94

33 090 5 45.2 1.15 33.1 0.84 6.1 The areas of cross section, numbers, and diameters of

26 240 6 40.2 1.02 29.4 0.75

wires in the various conductors shall conform to the require-

20 820 7 35.8 0.91 26.2 0.67

ments prescribed in Table 1 (Note 3) (see Fig. 1).

16 510 8 31.9 0.81 23.4 0.59

13 090 9 28.4 0.72 20.8 0.53

6.2 The diameters of the wires listed in Table 2 are nominal.

10 380 10 25.3 0.64 18.5 0.47

In order to produce an essentially round 19-wire construction,

6 530 12 20.1 0.51 14.7 0.37

A

the outer 12-wire layer in the combination unilay product is

Equation to calculate D :

comprised of 6 wires of the same diameter as the wires in the

Cross 2 Sectional Area

D 5

Π7-wire core, and 6 wires approximately 25 % smaller. The

16.2149

2-wire sizes are alternated around the 7-wire core.

B

Equation to calculate D :

D 5 D 3 0.732.

2 1 7. Mechanical and Electrical Tests of Conductors not

Annealed after Stranding

7.1 Wires composing the conductors shall be tested prior to

stranding in accordance with the applicable specification (see

2.4 NIST Standard:

11.1.2), and tests on the completed conductor are not required.

NBS Handbook 100 —Copper Wire Tables

However, when requested by the purchaser and agreed to by

the manufacturer at time of ordering, the tension tests of wires

3. Ordering Information

before stranding may be waived and the completed conductor

3.1 Orders for materials under this specification shall in-

tested in accordance with 7.2, or wires removed from the

clude the following information:

completed conductor tested in accordance with 7.5.

3.1.1 Conductor alloy,

7.2 When the completed conductor is tested as a unit, the

3.1.2 Quantity of each size,

breaking strength shall be not less than the rated strength of

3.1.3 Conductor size: Circular-mil area or American Wire

1350-H19 conductors or the minimum rated strength of 1350-

Gage, AWG (Section 6 and Table 1),

H16, -H26, -H14, -H24, -H142, and -H242 conductors if

3.1.4 Stranding (see Explanatory Note 1),

failure occurs in the free length at least 1 in. [25 mm] beyond

3.1.5 Temper (see Section 11),

the end of either gripping device. The strength shall be not less

3.1.6 Details of special-purpose lays, if required (see 5.2),

than 95 % of the rated or minimum rated strength if failure

occurs inside, or within 1 in. of the end of either gripping

4 device. The breaking strength of 1350-H16, -H26, -H14, -H24,

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. -H142, and -H242 conductors shall be not greater than their

B786/B786M − 08 (2018)

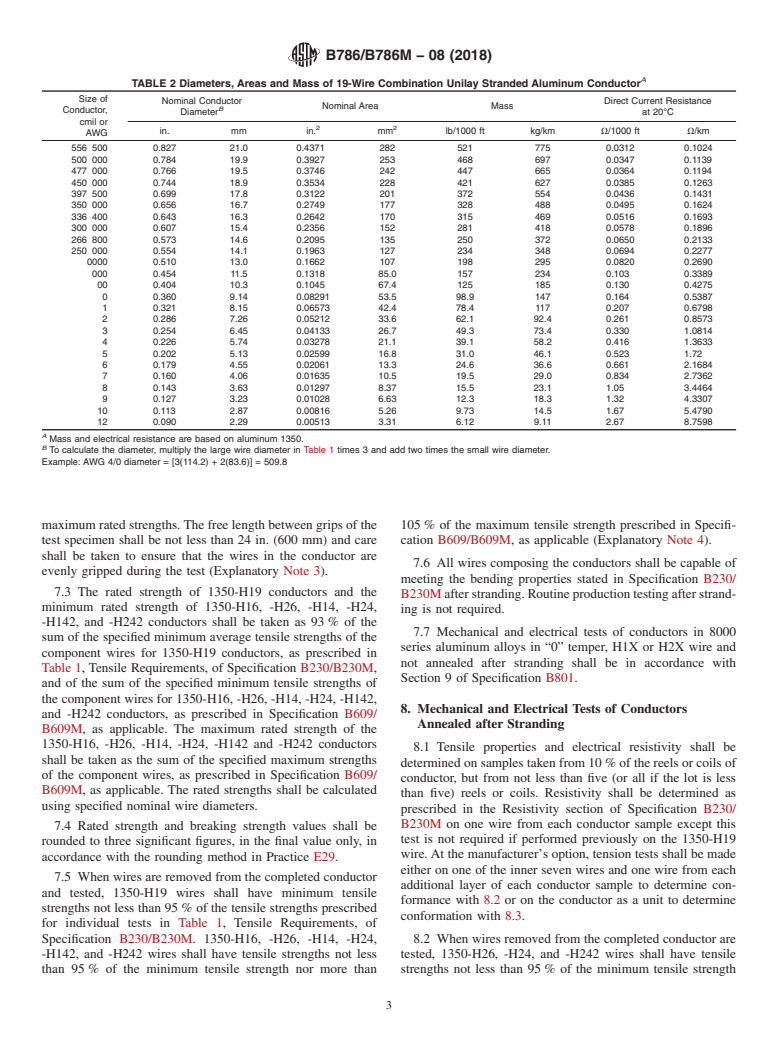

A

TABLE 2 Diameters, Areas and Mass of 19-Wire Combination Unilay Stranded Aluminum Conductor

Size of

Nominal Conductor Direct Current Resistance

Nominal Area Mass

B

Conductor,

Diameter at 20°C

cmil or

2 2

in. mm in. mm lb/1000 ft kg/km Ω/1000 ft Ω/km

AWG

556 500 0.827 21.0 0.4371 282 521 775 0.0312 0.1024

500 000 0.784 19.9 0.3927 253 468 697 0.0347 0.1139

477 000 0.766 19.5 0.3746 242 447 665 0.0364 0.1194

450 000 0.744 18.9 0.3534 228 421 627 0.0385 0.1263

397 500 0.699 17.8 0.3122 201 372 554 0.0436 0.1431

350 000 0.656 16.7 0.2749 177 328 488 0.0495 0.1624

336 400 0.643 16.3 0.2642 170 315 469 0.0516 0.1693

300 000 0.607 15.4 0.2356 152 281 418 0.0578 0.1896

266 800 0.573 14.6 0.2095 135 250 372 0.0650 0.2133

250 000 0.554 14.1 0.1963 127 234 348 0.0694 0.2277

0000 0.510 13.0 0.1662 107 198 295 0.0820 0.2690

000 0.454 11.5 0.1318 85.0 157 234 0.103 0.3389

00 0.404 10.3 0.1045 67.4 125 185 0.130 0.4275

0 0.360 9.14 0.08291 53.5 98.9 147 0.164 0.5387

1 0.321 8.15 0.06573 42.4 78.4 117 0.207 0.6798

2 0.286 7.26 0.05212 33.6 62.1 92.4 0.261 0.8573

3 0.254 6.45 0.04133 26.7 49.3 73.4 0.330 1.0814

4 0.226 5.74 0.03278 21.1 39.1 58.2 0.416 1.3633

5 0.202 5.13 0.02599 16.8 31.0 46.1 0.523 1.72

6 0.179 4.55 0.02061 13.3 24.6 36.6 0.661 2.1684

7 0.160 4.06 0.01635 10.5 19.5 29.0 0.834 2.7362

8 0.143 3.63 0.01297 8.37 15.5 23.1 1.05 3.4464

9 0.127 3.23 0.01028 6.63 12.3 18.3 1.32 4.3307

10 0.113 2.87 0.00816 5.26 9.73 14.5 1.67 5.4790

12 0.090 2.29 0.00513 3.31 6.12 9.11 2.67 8.7598

A

Mass and electrical resistance are based on aluminum 1350.

B

To calculate the diameter, multiply the large wire diameter in Table 1 times 3 and add two times the small wire diameter.

Example: AWG 4/0 diameter = [3(114.2) + 2(83.6)] = 509.8

maximum rated strengths. The free length between grips of the 105 % of the maximum tensile strength prescribed in Specifi-

test specimen shall be not less than 24 in. (600 mm) and care cation B609/B609M, as applicable (Explanatory Note 4).

shall be taken to ensure that the wires in the conductor are

7.6 All wires composing the conductors shall be capable of

evenly gripped during the test (Explanatory Note 3).

meeting the bending properties stated in Specification B230/

7.3 The rated strength of 1350-H19 conductors and the

B230M after stranding. Routine production testing after strand-

minimum rated strength of 1350-H16, -H26, -H14, -H24,

ing is not required.

-H142, and -H242 conductors shall be taken as 93 % of the

7.7 Mechanical and electrical tests of conductors in 8000

sum of the specified minimum average tensile strengths of the

series aluminum alloys in “0” temper, H1X or H2X wire and

component wires for 1350-H19 conductors, as prescribed in

not annealed after stranding shall be in accordance with

Table 1, Tensile Requirements, of Specification B230/B230M,

Section 9 of Specification B801.

and of the sum of the specified minimum tensile strengths of

the component wires for 1350-H16, -H26, -H14, -H24, -H142,

8. Mechanical and Electrical Tests of Conductors

and -H242 conductors, as prescribed in Specification B609/

Annealed after Stranding

B609M, as applicable. The maximum rated strength of the

1350-H16, -H26, -H14, -H24, -H142 and -H242 conductors

8.1 Tensile properties and electrical resistivity shall be

shall be taken as the sum of the specified maximum strengths

determined on samples taken from 10 % of the reels or coils of

of the component wires, as prescribed in Specification B609/

conductor, but from not less than five (or all if the lot is less

B609M, as applicable. The rated strengths shall be calculated

than five) reels or coils. Resistivity shall be determined as

using specified nominal wire diameters.

prescribed in the Resistivity section of Specification B230/

B230M on one wire from each conductor sample except this

7.4 Rated strength and breaking strength values shall be

test is not required if performed previously on the 1350-H19

rounded to three significant figures, in the final value only, in

wire. At the manufacturer’s option, tension tests shall be made

accordance with the rounding method in Practice E29.

either on one of the inner seven wires and one wire from each

7.5 When wires are removed from the completed conductor

additional layer of each conductor sample to determine con-

and tested, 1350-H19 wires shall have minimum tensile

formance with 8.2 or on the conductor as a unit to determine

strengths not less than 95 % of the tensile strengths prescribed

conformation with 8.3.

for individual tests in Table 1, Tensile Requirements, of

Specification B230/B230M. 1350-H16, -H26, -H14, -H24, 8.2 When wires removed from the completed conductor are

-H142, and -H242 wires shall have tensile strengths not less tested, 1350-H26, -H24, and -H242 wires shall have tensile

than 95 % of the minimum tensile strength nor more than strengths not less than 95 % of the minimum tensile strength

B786/B786M − 08 (2018)

nor more than 105 % of the maximum tensile strength pre- 11. Requirements for Wires

scribed in Specification B609/B609M, as applicable (Explana-

11.1 The purchaser shall designate the temper of wires to be

tory Note 4).

used in the conductor.

8.3 When the completed conductor is tested as a unit, the 11.1.1 For conductors o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B786/B786M − 08 (Reapproved 2013) B786/B786M − 08 (Reapproved 2018)

Standard Specification for

19 Wire Combination Unilay-Stranded Aluminum

Conductors for Subsequent Insulation

This standard is issued under the fixed designation B786/B786M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Designation was corrected editorially in October 2013.

1. Scope

1.1 This specification covers bare combination unilay-stranded conductors made from round wires of aluminum 1350 and 8000

series of aluminum alloys, for insulated conductors for electrical purposes. Aluminum 1350 wires in tempers -H19 (extra hard),

3 1 1

-H16 or -H26 ( ⁄4 hard), -H14 or -H24 ( ⁄2 hard), and -H142 or -H242 ( ⁄2 hard) and 8000 series aluminum alloys wires in tempers

“0” and H1X or H2X are permitted. These conductors shall be constructed with a central core wire surrounded by two layers of

helically laid wires, resulting in an outer diameter equal to the compressed-stranded equivalent conductors.

NOTE 1—For the purpose of this specification, combination unilay conductor is defined as follows: a central core wire surrounded by a layer of six

helically laid wires of the same diameter as the core wire with a helically laid outer layer containing six smaller wires alternated between six wires of

the same diameter as the wires in the layer underneath. Both layers have a common length and direction of lay (see Fig. 1).

1.1.1 For the purpose of this specification, normal conductor classification (Class AA, A, B, C) is not applicable, as these

conductors are intended for subsequent insulation. The descriptive term combination unilay-stranded shall be used in place of

conductor classification (Note 2 and Note 3).

NOTE 2—Prior to 1975, aluminum 1350 was designated as EC aluminum.

NOTE 3—The aluminum and temper designations conform to ANSI Standard H35.1. Aluminum 1350 corresponds to Unified Numbering System

A91350 in accordance with Practice E527. Unified Numbering System alloy designations for 8000 Series aluminum alloys in accordance with Practice

E527 are listed in Table number 1 of Specification B800.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein.

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B230/B230M Specification for Aluminum 1350–H19 Wire for Electrical Purposes

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B609/B609M Specification for Aluminum 1350 Round Wire, Annealed and Intermediate Tempers, for Electrical Purposes

B800 Specification for 8000 Series Aluminum Alloy Wire for Electrical Purposes—Annealed and Intermediate Tempers

B801 Specification for Concentric-Lay-Stranded Conductors of 8000 Series Aluminum Alloy for Subsequent Covering or

Insulation

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved April 1, 2013March 1, 2018. Published April 2013March 2018. Originally approved in 1988. Last previous edition approved in 20082013 as

ε1

B786 – 08.B786/B786M – 13 . DOI: 10.1520/B0786_B0786M-08R13E01.10.1520/B0786_B0786M-08R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B786/B786M − 08 (2018)

FIG. 1 Cross Section of Conductor

TABLE 1 Construction Requirements for 19-Wire Combination

Unilay Stranded Aluminum Conductors

A B

Wire D Wire D

Area of Size, American (or

1 2

Diameter Diameter

Cross-Section, Brown and Sharpe)

cmil Wire Gage

mils mm mils mm

556 500 185.3 4.71 135.6 3.44

500 000 175.6 4.46 128.5 3.26

477 000 171.5 4.36 125.5 3.19

450 000 166.6 4.23 121.9 3.10

397 500 156.6 3.98 114.6 2.91

350 000 146.9 3.73 107.5 2.73

336 400 144.0 3.66 105.4 2.68

300 000 136.0 3.45 99.6 2.53

266 800 128.3 3.26 93.9 2.38

250 000 124.2 3.15 90.9 2.31

211 600 0000 114.2 2.90 83.6 2.12

167 800 000 101.7 2.58 74.5 1.89

133 100 00 90.6 2.30 66.3 1.68

105 600 0 80.7 2.05 59.1 1.50

83 690 1 71.8 1.82 52.6 1.34

66 360 2 64.0 1.63 46.8 1.19

52 620 3 57.0 1.45 41.7 1.06

41 740 4 50.7 1.29 37.1 0.94

33 090 5 45.2 1.15 33.1 0.84

26 240 6 40.2 1.02 29.4 0.75

20 820 7 35.8 0.91 26.2 0.67

16 510 8 31.9 0.81 23.4 0.59

13 090 9 28.4 0.72 20.8 0.53

10 380 10 25.3 0.64 18.5 0.47

6 530 12 20.1 0.51 14.7 0.37

A

Equation to calculate D :

Cross 2Sectional Area

D 5

Œ

16.2149

B

Equation to calculate D :

D 5D 30.732.

2 1

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.3 ANSI Standard:

ANSI H35.1/H35.1(M) Alloy and Temper Designation Systems for Aluminum

2.4 NIST Standard:

NBS Handbook 100 — NBS Handbook 100Copper Wire Tables

3. Ordering Information

3.1 Orders for materials under this specification shall include the following information:

3.1.1 Conductor alloy,

3.1.2 Quantity of each size,

3.1.3 Conductor size: Circular-mil area or American Wire Gage, AWG (Section 6 and Table 1),

3.1.4 Stranding (see Explanatory Note 1),

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

B786/B786M − 08 (2018)

3.1.5 Temper (see Section 11),

3.1.6 Details of special-purpose lays, if required (see 5.2),

3.1.7 When physical tests shall be made (see Sections 7 and 8),

3.1.8 Package size (see 16.1),

3.1.9 Heavy wood lagging, if required (see 17.2),

3.1.10 Special package marking, if required (Section 17), and

3.1.11 Place of inspection (Section 15).

4. Joints

4.1 Electric-butt welds, cold pressure welds, or electric-butt cold-upset welds may be made in the finished individual wires

composing the conductor but shall not be closer together than 1 ft (Explanatory Note 2).

5. Lay

5.1 For combination unilay conductors the lay of a layer of wires shall be not less than 8 nor more than 16 times the outside

diameter of the outer layer.

5.2 Other lays for special purposes shall be furnished by special agreement between the manufacturer and the purchaser.

NOTE 4—Certain types of insulation conductors may require shorter lay than other conductors. It is expected that special requirements regarding length

of lay will be specified by the purchaser in such instances.

5.3 The direction of lay shall be left-hand unless the direction of lay is specified otherwise by the purchaser.

6. Construction (Explanatory Note 1)

6.1 The areas of cross section, numbers, and diameters of wires in the various conductors shall conform to the requirements

prescribed in Table 1 (Note 3) (see Fig. 1).

6.2 The diameters of the wires listed in Table 2 are nominal. In order to produce an essentially round 19-wire construction, the

outer 12-wire layer in the combination unilay product is comprised of 6 wires of the same diameter as the wires in the 7-wire core,

and 6 wires approximately 25 % smaller. The 2-wire sizes are alternated around the 7-wire core.

7. Mechanical and Electrical Tests of Conductors not Annealed after Stranding

7.1 Wires composing the conductors shall be tested prior to stranding in accordance with the applicable specification (see

11.1.2), and tests on the completed conductor are not required. However, when requested by the purchaser and agreed to by the

A

TABLE 2 Diameters, Areas and Mass of 19-Wire Combination Unilay Stranded Aluminum Conductor

Nominal Conductor Direct Current Resistance

Size of

Nominal Area Mass

B

Diameter at 20°C

Conductor,

cmil or

Ω/1000/

2 2

in. mm in. mm lb/1000 ft kg/km Ω/km/km

AWG

1000 ft

556 500 0.827 21.0 0.4371 282 521 775 0.0312 0.1024

500 000 0.784 19.9 0.3927 253 468 697 0.0347 0.1139

477 000 0.766 19.5 0.3746 242 447 665 0.0364 0.1194

450 000 0.744 18.9 0.3534 228 421 627 0.0385 0.1263

397 500 0.699 17.8 0.3122 201 372 554 0.0436 0.1431

350 000 0.656 16.7 0.2749 177 328 488 0.0495 0.1624

336 400 0.643 16.3 0.2642 170 315 469 0.0516 0.1693

300 000 0.607 15.4 0.2356 152 281 418 0.0578 0.1896

266 800 0.573 14.6 0.2095 135 250 372 0.0650 0.2133

250 000 0.554 14.1 0.1963 127 234 348 0.0694 0.2277

0000 0.510 13.0 0.1662 107 198 295 0.0820 0.2690

000 0.454 11.5 0.1318 85.0 157 234 0.103 0.3389

00 0.404 10.3 0.1045 67.4 125 185 0.130 0.4275

0 0.360 9.14 0.08291 53.5 98.9 147 0.164 0.5387

1 0.321 8.15 0.06573 42.4 78.4 117 0.207 0.6798

2 0.286 7.26 0.05212 33.6 62.1 92.4 0.261 0.8573

3 0.254 6.45 0.04133 26.7 49.3 73.4 0.330 1.0814

4 0.226 5.74 0.03278 21.1 39.1 58.2 0.416 1.3633

5 0.202 5.13 0.02599 16.8 31.0 46.1 0.523 1.72

6 0.179 4.55 0.02061 13.3 24.6 36.6 0.661 2.1684

7 0.160 4.06 0.01635 10.5 19.5 29.0 0.834 2.7362

8 0.143 3.63 0.01297 8.37 15.5 23.1 1.05 3.4464

9 0.127 3.23 0.01028 6.63 12.3 18.3 1.32 4.3307

10 0.113 2.87 0.00816 5.26 9.73 14.5 1.67 5.4790

12 0.090 2.29 0.00513 3.31 6.12 9.11 2.67 8.7598

A

Mass and electrical resistance are based on aluminum 1350.

B

To calculate the diameter, multiply the large wire diameter in Table 1 times 3 and add two times the small wire diameter.

Example: AWG 4/0 diameter = [3(114.2) + 2(83.6)] = 509.8

B786/B786M − 08 (2018)

manufacturer at time of ordering, the tension tests of wires before stranding may be waived and the completed conductor tested

in accordance with 7.2, or wires removed from the completed conductor tested in accordance with 7.5.

7.2 When the completed conductor is tested as a unit, the breaking strength shall be not less than the rated strength of 1350-H19

conductors or the minimum rated strength of 1350-H16, -H26, -H14, -H24, -H142, and -H242 conductors if failure occurs in the

free length at least 1 in. [25 mm] beyond the end of either gripping device. The strength shall be not less than 95 % of the rated

or minimum rated strength if failure occurs inside, or within 1 in. of the end of either gripping device. The breaking strength of

1350-H16, -H26, -H14, -H24, -H142, and -H242 conductors shall be not greater than their maximum rated strengths. The free

length between grips of the test specimen shall be not less than 24 in. (600 mm) and care shall be taken to ensure that the wires

in the conductor are evenly gripped during the test (Explanatory Note 3).

7.3 The rated strength of 1350-H19 conductors and the minimum rated strength of 1350-H16, -H26, -H14, -H24, -H142, and

-H242 conductors shall be taken as 93 % of the sum of the specified minimum average tensile strengths of the component wires

for 1350-H19 conductors, as prescribed in Table 1, Tensile Requirements, of Specification B230/B230M, and of the sum of the

specified minimum tensile strengths of the component wires for 1350-H16, -H26, -H14, -H24, -H142, and -H242 conductors, as

prescribed in Specification B609/B609M, as applicable. The maximum rated strength of the 1350-H16, -H26, -H14, -H24, -H142

and -H242 conductors shall be taken as the sum of the specified maximum strengths of the component wires, as prescribed in

Specification B609/B609M, as applicable. The rated strengths shall be calculated using specified nominal wire diameters.

7.4 Rated strength and breaking strength values shall be rounded to three significant figures, in the final value only, in

accordance with the rounding method in Practice E29.

7.5 When wires are removed from the completed conductor and tested, 1350-H19 wires shall have minimum tensile strengths

not less than 95 % of the tensile strengths prescribed for individual tests in Table 1, Tensile Requirements, of Specification

B230/B230M. 1350-H16, -H26, -H14, -H24, -H142, and -H242 wires shall have tensile strengths not less than 95 % of the

minimum tensile strength nor more than 105 % of the maximum tensile strength prescribed in Specification B609/B609M, as

applicable (Explanatory Note 4).

7.6 All wires composing the conductors shall be capable of meeting the bending properties stated in Specification B230/B230M

after stranding. Routine production testing after stranding is not required.

7.7 Mechanical and electrical tests of conductors in 8000 series aluminum alloys in “0” temper, H1X or H2X wire and not

annealed after stranding shall be in accordance with Section 9 of Specification B801.

8. Mechanical and Electrical Tests of Conductors Annealed after Stranding

8.1 Tensile properties and electrical resistivity shall be determined on samples taken from 10 % of the reels or coils of

conductor, but from not less than five (or all if the lot is less than five) reels or coils. Resistivity shall be determined as prescribed

in the Resistivity section of Specification B230/B230M on one wire from each conductor sample except this test is not required

if performed previously on the 1350-H19 wire. At the manufacturer’s option, tension tests shall be made either on one of the inner

seven wires and one wire from each additional layer of each conductor sample to determine conformance with 8.2 or on the

conductor as a unit to determine conformation with 8.3.

8.2 When wires removed from the completed conductor are tested, 1350-H26, -H24, and -H242 w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.