ASTM B801-07(2012)

(Specification)Standard Specification for Concentric-Lay-Stranded Conductors of 8000 Series Aluminum Alloy for Subsequent Covering or Insulation

Standard Specification for Concentric-Lay-Stranded Conductors of 8000 Series Aluminum Alloy for Subsequent Covering or Insulation

ABSTRACT

This specification covers aluminum alloys in the 8000 series in tempers �0� and H1X or H2X bare compact-round, compressed and conventional concentric-lay-stranded conductors made from round or shaped wires used as covered or insulated electrical conductors. These conductors shall be composed of a central core surrounded by one or more compacted, compressed or conventional layers of helically applied wires. Joints may be made in any of the wires of any stranding by electric-butt welding, cold-pressure welding, or electric-butt, cold-upset welding. The construction of the conductors shall conform to the construction requirements prescribed in this specification. Tests for the mechanical and electrical properties of wire composing the conductor shall be made before standing. Wires annealed before stranding shall meet the requirements of the prescribed specification. The tensile requirements shall be the same as those for round wires of equal nominal area.

SCOPE

1.1 This specification covers aluminum alloys in the 8000 series cited in B800 in tempers “0” and H1X or H2X bare compact-round, compressed and conventional concentric-lay-stranded conductors made from round or shaped wires used as covered or insulated electrical conductors. These conductors shall be composed of a central core surrounded by one or more compacted, compressed or conventional layers of helically applied wires (Explanatory Note 1 and Note 2).

1.2 The SI values for resistivity are regarded as standard. For all other properties, the inch-pound units are regarded as standard and the SI units may be approximate.

1.3 Sealed conductors that are intended to prevent longitudinal water propagation are also permitted within the guidelines of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B801 −07(Reapproved 2012)

Standard Specification for

Concentric-Lay-Stranded Conductors of 8000 Series

Aluminum Alloy for Subsequent Covering or Insulation

This standard is issued under the fixed designation B801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 ANSI Standard:

ANSI H35.1 Alloy and Temper Designation Systems for

1.1 This specification covers aluminum alloys in the 8000

Aluminum

series cited in B800 in tempers “0” and H1X or H2X bare

compact-round, compressed and conventional concentric-lay- 2.4 National Bureau of Standards:

NBS Handbook 100—Copper Wire Tables

stranded conductors made from round or shaped wires used as

covered or insulated electrical conductors. These conductors

3. Classification

shallbecomposedofacentralcoresurroundedbyoneormore

compacted, compressed or conventional layers of helically

3.1 For the purpose of this specification, conductors are

applied wires (Explanatory Note 1 and Note 2).

classified as follows:

1.2 The SI values for resistivity are regarded as standard. 3.1.1 Class A—For conductors to be covered with weather/

resistant materials.

For all other properties, the inch-pound units are regarded as

3.1.2 Class B—For conductors to be insulated with various

standard and the SI units may be approximate.

materials such as rubber, paper, varnished cloth, etc., and for

1.3 Sealed conductors that are intended to prevent longitu-

theconductorsindicatedunderClassAwheregreaterflexibility

dinal water propagation are also permitted within the guide-

is required.

lines of this specification.

3.1.3 Class C and D—For conductors where greater flex-

ibility is required than is provided by Class B conductors.

2. Referenced Documents

2.1 The following documents of the issue in effect on date

4. Ordering Information

of material purchase form a part of this specification to the

4.1 Ordersformaterialunderthisspecificationshallinclude

extent referenced herein.

the following information:

2.2 ASTM Standards:

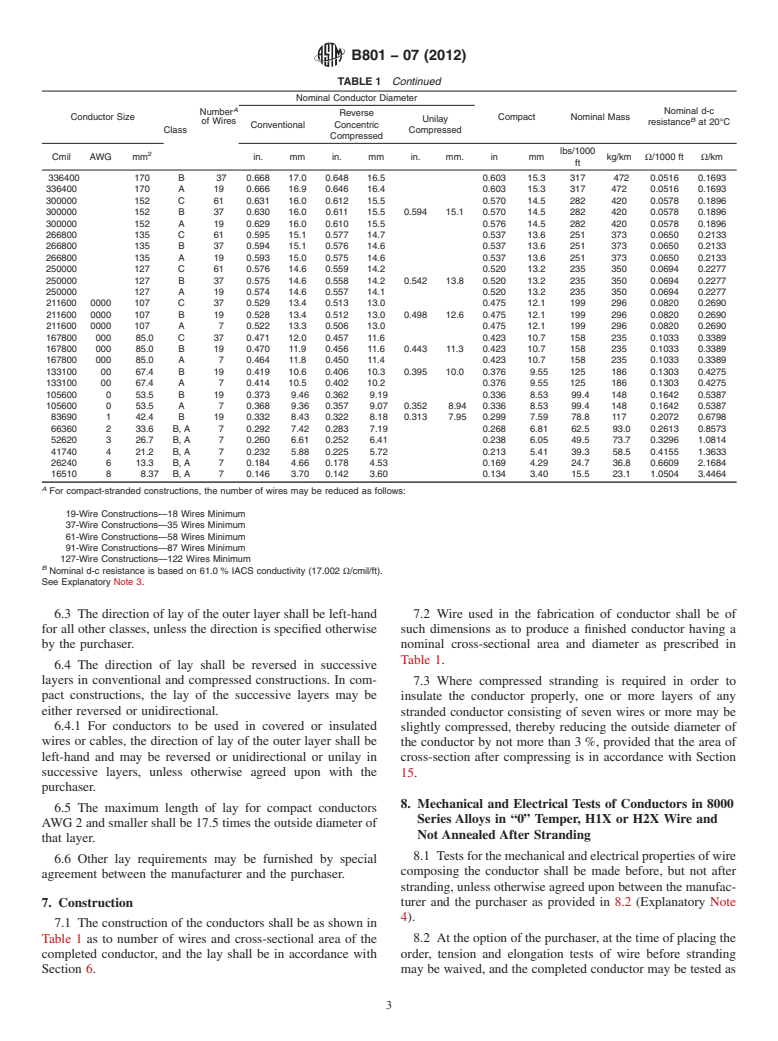

4.1.1 Quantity of each size and class (Table 1).

B193Test Method for Resistivity of Electrical Conductor

4.1.2 Conductor size; circular-mil area or Awg (Section 7),

Materials

4.1.3 Class (See 3.1),

B263Test Method for Determination of Cross-Sectional

4.1.4 Temper (Section 12),

Area of Stranded Conductors

4.1.5 Lay direction if nonstandard (See 6.3 and 6.4), re-

B354Terminology Relating to Uninsulated Metallic Electri-

versed or unidirectional (See 6.3) or special (See 6.4),

cal Conductors

4.1.6 Special tension test, if required (See 8.2),

B800Specification for 8000 Series Aluminum Alloy Wire

4.1.7 Packaging (Section 19),

forElectricalPurposes—AnnealedandIntermediateTem-

4.1.8 Special package marking (Section 19), and

pers

4.1.9 Place of inspection (Section 18).

E29Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

5. Joints

5.1 Jointsmaybemadeinanyof thewires of anystranding

This specification is under the jurisdiction of ASTM Committee B01 on

by electric-butt welding, cold-pressure welding, or electric-

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

butt, cold-upset welding.

Conductors of Light Metals.

Current edition approved Oct. 15, 2012. Published November 2012. Originally

approved in 1988. Last previous edition approved in 2007 as B801–07. DOI:

10.1520/B0801-07R12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from National Technical Information Service (NTIS), 5285 Port

the ASTM website. Royal Rd., Springfield, VA 22161, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B801−07 (2012)

5.2 Joints in the individual wires in a finished conductor the layers other than the two outer layers shall be at the option

shall be not closer together than 1 ft (0.3 m) for conductors of of the manufacturer, unless otherwise agreed upon.

19 wires or less, or closer than 1 ft (0.3 m) in a layer for

6.1.1 For conductors to be used in covered or insulated

conductors of more than 19 wires.

wiresorcables,thelaylengthofthewiresshallbenotlessthan

5.3 No joint or splice shall be made in a stranded conductor 8 nor more than 16 times the outer diameter of the finished

as a whole. conductor. For conductors of 37 wires or more, this require-

ment shall apply to the wires in the outer two layers. The lay

6. Lay

of the layers other than the two outer layers shall be at the

6.1 The length of lay for all classes shall be not less than 8

option of the manufacturer, unless otherwise agreed upon.

nor more than 16 times the outside diameter of that layer,

6.2 The direction of lay for Class A conductors shall be

except that for conductors composed of 37 wires or more, this

right-hand.

requirementshallapplyonlytothetwoouterlayers.Thelayof

TABLE 1 Construction Requirements for Aluminum Conductors in the 8000 Series Alloys

Nominal Conductor Diameter

A

Nominal d-c

Number

Reverse

Conductor Size Compact Nominal Mass

Unilay B

of Wires

resistance at 20°C

Conventional Concentric

Class Compressed

Compressed

lbs/1000

Cmil AWG mm in. mm in. mm in. mm. in mm kg/km Ω/1000 ft Ω/km

ft

1000000 507 D 127 1.153 29.3 1.119 28.4 1.060 26.9 941 1400 0.0173 0.0568

1000000 507 C 91 1.153 29.3 1.118 28.4 1.084 27.5 1.060 26.9 941 1400 0.0173 0.0568

1000000 507 B, A 61 1.152 29.3 1.117 28.4 1.060 26.9 941 1400 0.0173 0.0568

900000 456 D 127 1.095 27.8 1.062 27.0 0.999 25.4 847 1260 0.0193 0.0633

900000 456 C 91 1.093 27.8 1.060 26.9 1.028 26.1 0.999 25.4 847 1260 0.0193 0.0633

900000 456 B, A 61 1.093 27.8 1.060 26.9 0.999 25.4 847 1260 0.0193 0.0633

800000 405 D 127 1.032 26.2 1.001 25.4 0.938 23.8 753 1120 0.0217 0.0712

800000 405 C 91 1.032 26.2 1.001 25.4 0.969 24.6 0.938 23.8 753 1120 0.0217 0.0712

800000 405 B, A 61 1.031 26.2 1.000 25.4 0.938 23.8 753 1120 0.0217 0.0712

750000 380 D 127 0.998 25.3 0.968 24.6 0.908 23.1 706 1050 0.0231 0.0758

750000 380 C 91 0.999 25.4 0.969 24.6 0.939 23.9 0.908 23.1 706 1050 0.0231 0.0758

750000 380 B, A 61 0.998 25.3 0.968 24.6 0.908 23.1 706 1050 0.0231 0.0758

700000 355 D 127 0.965 24.5 0.936 23.8 0.877 22.3 659 981 0.0248 0.0814

700000 355 C 91 0.965 24.5 0.936 23.8 0.907 23.0 0.877 22.3 659 981 0.0248 0.0814

700000 355 B, A 61 0.964 24.5 0.935 23.7 0.877 22.3 659 981 0.0248 0.0814

650000 329 D 127 0.930 23.6 0.902 22.9 0.845 21.5 612 911 0.0267 0.0876

650000 329 C 91 0.930 23.6 0.902 22.9 0.874 22.2 0.845 21.5 612 911 0.0267 0.0876

650000 329 B 61 0.929 23.6 0.901 22.9 0.845 21.5 612 911 0.0267 0.0876

650000 329 A 37 0.928 23.6 0.900 22.9 0.845 21.5 612 911 0.0267 0.0876

600000 304 D 127 0.893 22.7 0.866 22.0 0.813 20.7 565 841 0.0289 0.0948

600000 304 C 91 0.893 22.7 0.866 22.0 0.840 21.3 0.813 20.7 565 841 0.0289 0.0948

600000 304 B 61 0.893 22.7 0.866 22.0 0.813 20.7 565 841 0.0289 0.0948

600000 304 A 37 0.891 22.6 0.864 21.9 0.813 20.7 565 841 0.0289 0.0948

556500 282 D 127 0.861 21.9 0.835 21.2 0.780 19.8 524 780 0.0312 0.1024

556500 282 C 91 0.860 21.8 0.834 21.2 0.780 19.8 524 780 0.0312 0.1024

556500 282 B 61 0.860 21.8 0.834 21.2 0.780 19.8 524 780 0.0312 0.1024

556500 282 A 37 0.858 21.8 0.832 21.1 0.780 19.8 524 780 0.0312 0.1024

550000 279 D 127 0.855 21.7 0.829 21.1 0.775 19.7 518 771 0.0315 0.1034

550000 279 C 91 0.855 21.7 0.829 21.1 0.775 19.7 518 771 0.0315 0.1034

550000 279 B 61 0.855 21.7 0.829 21.1 0.804 20.4 0.775 19.7 518 771 0.0315 0.1034

550000 279 A 37 0.853 21.7 0.827 21.0 0.775 19.7 518 771 0.0315 0.1034

500000 253 D 91 0.815 20.7 0.791 20.1 0.736 18.7 471 701 0.0347 0.1139

500000 253 C 61 0.815 20.7 0.791 20.1 0.766 19.5 0.736 18.7 471 701 0.0347 0.1139

500000 253 B, A 37 0.813 20.7 0.789 20.0 0.736 18.7 471 701 0.0347 0.1139

477000 242 D 91 0.796 20.2 0.772 19.6 0.722 18.3 449 668 0.0364 0.1194

477000 242 C 61 0.796 20.2 0.772 19.6 0.722 18.3 449 668 0.0364 0.1194

477000 242 B, A 37 0.795 20.2 0.771 19.6 0.722 18.3 449 668 0.0364 0.1194

450000 228 D 91 0.773 19.6 0.750 19.0 0.700 17.8 424 631 0.0385 0.1263

450000 228 C 61 0.773 19.6 0.750 19.0 0.727 18.5 0.700 17.8 424 631 0.0385 0.1263

450000 228 B, A 37 0.772 19.6 0.749 19.0 0.700 17.8 424 631 0.0385 0.1263

400000 203 D 91 0.729 18.5 0.707 18.0 0.659 16.7 376 559 0.0434 0.1424

400000 203 C 61 0.729 18.5 0.707 18.0 0.685 17.4 0.659 16.7 376 559 0.0434 0.1424

400000 203 B, A 37 0.728 18.5 0.706 17.9 0.659 16.7 376 559 0.0434 0.1424

397500 201 D 91 0.727 18.5 0.705 17.9 0.659 16.7 374 557 0.0436 0.1431

397500 201 C 61 0.726 18.4 0.704 17.9 0.659 16.7 374 557 0.0436 0.1431

397500 201 B 37 0.725 18.4 0.703 17.9 0.659 16.7 374 557 0.0436 0.1431

397500 201 A 19 0.724 18.4 0.702 17.8 0.659 16.7 374 557 0.0436 0.1431

350000 177 D 91 0.682 17.3 0.661 16.8 0.616 15.6 329 490 0.0495 0.1624

350000 177 C 61 0.681 17.3 0.661 16.8 0.641 16.3 0.616 15.6 329 490 0.0495 0.1624

350000 177 B 37 0.681 17.3 0.661 16.8 0.616 15.6 329 490 0.0495 0.1624

350000 177 A 19 0.679 17.2 0.659 16.7 0.616 15.6 329 490 0.0495 0.1624

336400 170 C 61 0.669 17.0 0.649 16.5 0.603 15.3 317 472 0.0516 0.1693

B801−07 (2012)

TABLE1 Continued

Nominal Conductor Diameter

A

Nominal d-c

Number

Reverse

Conductor Size Compact Nominal Mass

Unilay B

of Wires

resistance at 20°C

Conventional Concentric

Class Compressed

Compressed

lbs/1000

Cmil AWG mm in. mm in. mm in. mm. in mm kg/km Ω/1000 ft Ω/km

ft

336400 170 B 37 0.668 17.0 0.648 16.5 0.603 15.3 317 472 0.0516 0.1693

336400 170 A 19 0.666 16.9 0.646 16.4 0.603 15.3 317 472 0.0516 0.1693

300000 152 C 61 0.631 16.0 0.612 15.5 0.570 14.5 282 420 0.0578 0.1896

300000 152 B 37 0.630 16.0 0.611 15.5 0.594 15.1 0.570 14.5 282 420 0.0578 0.1896

300000 152 A 19 0.629 16.0 0.610 15.5 0.576 14.5 282 420 0.0578 0.1896

266800 135 C 61 0.595 15.1 0.577 14.7 0.537 13.6 251 373 0.0650 0.2133

266800 135 B 37 0.594 15.1 0.576 14.6 0.537 13.6 251 373 0.0650 0.2133

266800 135 A 19 0.593 15.0 0.575 14.6 0.537 13.6 251 373 0.0650 0.2133

250000 127 C 61 0.576 14.6 0.559 14.2 0.520 13.2 235 350 0.0694 0.2277

250000 127 B 37 0.575 14.6 0.558 14.2 0.542 13.8 0.520 13.2 235 350 0.0694 0.2277

250000 127 A 19 0.574 14.6 0.557 14.1 0.520 13.2 235 350 0.0694 0.2277

211600 0000 107 C 37 0.529 13.4 0.513 13.0 0.475 12.1 199 296 0.0820 0.2690

211600 0000 107 B 19 0.528 13.4 0.512 13.0 0.498 12.6 0.475 12.1 199 296 0.0820 0.2690

211600 0000 107 A 7 0.522 13.3 0.506 13.0 0.475 12.1 199 296 0.0820 0.2690

167800 000 85.0 C 37 0.471 12.0 0.457 11.6 0.423 10.7 158 235 0.1033 0.3389

167800 000 85.0 B 19 0.470 11.9 0.456 11.6 0.443 11.3 0.423 10.7 158 235 0.1033 0.3389

167800 000 85.0 A 7 0.464 11.8 0.450 11.4 0.423 10.7 158 235 0.1033 0.3389

133100 00 67.4 B 19 0.419 10.6 0.406 10.3 0.395 10.0 0.376 9.55 125 186 0.1303 0.4275

133100 00 67.4 A 7 0.414 10.5 0.402 10.2 0.376 9.55 125 186 0.1303 0.4275

105600 0 53.5 B 19 0.373 9.46 0.362 9.19 0.336 8.53 99.4 148 0.1642 0.5387

105600 0 53.5 A 7 0.368 9.36 0.357 9.07 0.352 8.94 0.336 8.53 99.4 148 0.1642 0.5387

83690 1 42.4 B 19 0.332 8.43 0.322 8.18 0.313 7.95 0.299 7.59 78.8 117 0.2072 0.6798

66360 2 33.6 B, A 7 0.292 7.42 0.283 7.19 0.268 6.81 62.5 93.0 0.2613 0.8573

52620 3 26.7 B, A 7 0.260 6.61 0.252 6.41 0.238 6.05 49.5 73.7 0.3296 1.0814

41740 4 21.2 B, A 7 0.232 5.88 0.225 5.72 0.213 5.41 39.3 58.5 0.4155 1.3633

26240 6 13.3 B, A 7 0.184 4.66 0.178 4.53 0.169 4.29 24.7 36.8 0.6609 2.1684

16510 8 8.37 B, A 7 0.146 3.70 0.142 3.60 0.134 3.40 15.5 23.1 1.0504 3.4464

A

For compact-stranded constructions, the number of wires may be reduced as follows:

19-Wire Constructions—18 Wires Minimum

37-Wire Constructions—35 Wires Minimum

61-Wire Constructions—58 Wires Minimum

91-Wire Constructions—87 Wires Minimum

127-Wire Constructions—122 Wires Minimum

B

Nominal d-c resistance is based on 61.0 % IACS conductivity (17.002 Ω/cmil/ft).

See Explanatory Note 3.

6.3 The direction of lay of the outer layer shall be left-hand 7.2 Wire used in the fabrication of conductor shall be of

for all other classes, unless the direction is specified otherwise such dimensions as to produce a finished conductor having a

by the purchaser. nominal cross-sectional area and diameter as prescribed in

Table 1.

6.4 The direction of lay shall be reversed in successive

layers in conventional and compressed constructions. In com-

7.3 Where compressed stranding is required in order to

pact constructions, the lay of the successive layers may be insulate the conductor properly, one or more layers of any

either reversed or unidirectional.

stranded conductor consisting of seven wires or more may be

6.4.1 For conductors to be used in covered or insulated slightly compressed, thereby reducing the outside diameter of

wires or cables, the direction of lay of the outer layer shall be

the conductor by not more than 3%, provided that the area of

left-hand and may be reversed or unidirectional or unilay in cross-section after compressing is in accordance with Section

successive layers, unless otherwise agreed upon with the

15.

purchaser.

8. Mechanical and Electrical Tests of Conductors in 8000

6.5 The maximum length of lay for compact conductors

Series Alloys in “0” Temper, H1X or H2X Wire and

AWG2andsmallershallbe17.5timestheoutsidediameterof

Not Annealed After Stranding

that layer.

8.1 Testsforthemechanicalandelectricalpropertiesofwire

6.6 Other lay requirements may be furnished by special

composing the conductor shall be made before, but not after

agreement between the manufacturer and the purchaser.

stranding, unless otherwise agreed upon between the manufac-

7. Construction turer and the purchaser as provided in 8.2 (Explanatory Note

4).

7.1 The construction of the conductors shall be as shown in

Table 1 as to number of wires and cross-sectional area of the 8.2 Attheoptionofthepurchaser,atthetimeofplacingthe

completed conductor, and the lay shall be in accordance with order, tension and elongation tests of wire before stranding

Section 6. may be waived, and the completed conductor may be tested as

B801−07 (2012)

aunit.Theminimumbreakingstrengthofconductorssotested 10.2 The maximum electrical resistance of a unit length of

shall be not less than the minimum rated strength of 8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.