ASTM G61-86(2014)

(Test Method)Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements for Localized Corrosion Susceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements for Localized Corrosion Susceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

SIGNIFICANCE AND USE

3.1 An indication of the susceptibility to initiation of localized corrosion in this test method is given by the potential at which the anodic current increases rapidly. The more noble this potential, obtained at a fixed scan rate in this test, the less susceptible is the alloy to initiation of localized corrosion. The results of this test are not intended to correlate in a quantitative manner with the rate of propagation that one might observe in service when localized corrosion occurs.

3.2 In general, once initiated, localized corrosion can propagate at some potential more electropositive than that at which the hysteresis loop is completed. In this test method, the potential at which the hysteresis loop is completed is determined at a fixed scan rate. In these cases, the more electropositive the potential at which the hysteresis loop is completed the less likely it is that localized corrosion will occur.

3.3 If followed, this test method will provide cyclic potentiodynamic anodic polarization measurements that will reproduce data developed at other times in other laboratories using this test method for the two specified alloys discussed in 3.4. The procedure is used for iron-, nickel-, or cobalt-based alloys in a chloride environment.

3.4 A standard potentiodynamic polarization plot is included. These reference data are based on the results from five different laboratories that followed the standard procedure, using specific alloys of Type 304 stainless steel, UNS S30400 and Alloy C-276, UNS N10276.3 Curves are included which have been constructed using statistical analysis to indicate the acceptable range of polarization curves.

3.5 The availability of a standard test method, standard material, and standard plots should make it easy for an investigator to check his techniques to evaluate susceptibility to localized corrosion.

SCOPE

1.1 This test method covers a procedure for conducting cyclic potentiodynamic polarization measurements to determine relative susceptibility to localized corrosion (pitting and crevice corrosion) for iron-, nickel-, or cobalt-based alloys in a chloride environment. This test method also describes an experimental procedure which can be used to check one's experimental technique and instrumentation.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G61 − 86 (Reapproved 2014)

Standard Test Method for

Conducting Cyclic Potentiodynamic Polarization

Measurements for Localized Corrosion Susceptibility of

Iron-, Nickel-, or Cobalt-Based Alloys

ThisstandardisissuedunderthefixeddesignationG61;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope whichtheanodiccurrentincreasesrapidly.Themorenoblethis

potential, obtained at a fixed scan rate in this test, the less

1.1 This test method covers a procedure for conducting

susceptible is the alloy to initiation of localized corrosion.The

cyclic potentiodynamic polarization measurements to deter-

resultsofthistestarenotintendedtocorrelateinaquantitative

mine relative susceptibility to localized corrosion (pitting and

manner with the rate of propagation that one might observe in

crevicecorrosion)foriron-,nickel-,orcobalt-basedalloysina

service when localized corrosion occurs.

chloride environment. This test method also describes an

experimental procedure which can be used to check one’s 3.2 Ingeneral,onceinitiated,localizedcorrosioncanpropa-

experimental technique and instrumentation. gate at some potential more electropositive than that at which

the hysteresis loop is completed. In this test method, the

1.2 The values stated in SI units are to be regarded as

potential at which the hysteresis loop is completed is deter-

standard. No other units of measurement are included in this

mined at a fixed scan rate. In these cases, the more electro-

standard.

positive the potential at which the hysteresis loop is completed

1.3 This standard does not purport to address all of the

the less likely it is that localized corrosion will occur.

safety concerns, if any, associated with its use. It is the

3.3 If followed, this test method will provide cyclic poten-

responsibility of the user of this standard to establish appro-

tiodynamic anodic polarization measurements that will repro-

priate safety and health practices and determine the applica-

duce data developed at other times in other laboratories using

bility of regulatory limitations prior to use.

this test method for the two specified alloys discussed in 3.4.

2. Referenced Documents

The procedure is used for iron-, nickel-, or cobalt-based alloys

in a chloride environment.

2.1 ASTM Standards:

D1193Specification for Reagent Water

3.4 A standard potentiodynamic polarization plot is in-

G3Practice for Conventions Applicable to Electrochemical

cluded.These reference data are based on the results from five

Measurements in Corrosion Testing

different laboratories that followed the standard procedure,

G5Reference Test Method for Making Potentiodynamic

using specific alloys of Type 304 stainless steel, UNS S30400

Anodic Polarization Measurements

and Alloy C-276, UNS N10276. Curves are included which

2.2 ASTM Adjuncts:

have been constructed using statistical analysis to indicate the

Standard Samples (set of two)

acceptable range of polarization curves.

3.5 The availability of a standard test method, standard

3. Significance and Use

material, and standard plots should make it easy for an

3.1 An indication of the susceptibility to initiation of local-

investigator to check his techniques to evaluate susceptibility

ized corrosion in this test method is given by the potential at

to localized corrosion.

This test method is under the jurisdiction of ASTM Committee G01 on

4. Apparatus

Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on

Electrochemical Measurements in Corrosion Testing.

4.1 The polarization cell should be similar to the one

Current edition approved May 1, 2014. Published May 2014. Originally

described in Reference Test Method G5. Other polarization

approvedin1986.Lastpreviouseditionapprovedin2009asG61–86(2009).DOI:

cells may be equally suitable.

10.1520/G0061-86R14.

4.1.1 The cell should have a capacity of about 1 L and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

should have suitable necks or seals to permit the introduction

Standards volume information, refer to the standard’s Document Summary page on

of electrodes, gas inlet and outlet tubes, and a thermometer.

the ASTM website.

3 The Luggin probe-salt bridge separates the bulk solution from

Available from ASTM International Headquarters. Order Adjunct No.

ADJG0061. Original adjunct produced before 1995. thesaturatedcalomelreferenceelectrode.Theprobetipshould

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G61 − 86 (2014)

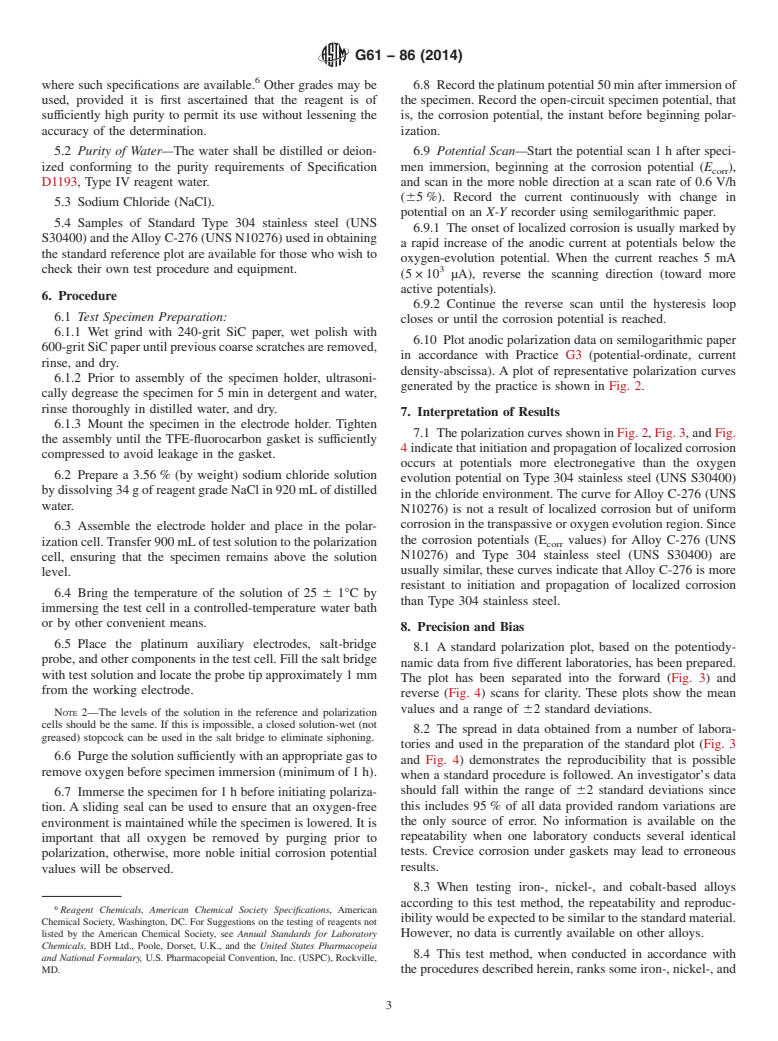

TABLE 1 Chemical Composition of Alloys Used in the Round

Robin, Weight %

Type 304

Alloy C-276

Element Stainless Steel

(UNS N10276)

(UNS S30400)

Carbon 0.003 0.060

Chromium 15.29 18.46

Cobalt 2.05 .

Columbium . 0.11

Copper . 0.17

Iron 5.78 balance

Manganese 0.48 1.43

Molybdenum 16.03 0.17

Nickel balance 8.74

Phosphorus 0.018 0.029

Silicon 0.05 0.60

Sulfur 0.006 0.014

Vanadium 0.20 .

Tungsten 3.62 .

4.5 Current-Measuring Instruments (Note 1)—An instru-

mentthatiscapableofmeasuringacurrentaccuratelytowithin

1%oftheabsolutevalueoveracurrentrangebetween1.0and

10 µAshouldbeused.Manycommercialunitshaveabuild-in

instrument with an output as a voltage, which is preferred for

recording purposes. For the purpose of the present test a

FIG. 1 Schematic Diagram of Specimen Holder (see Footnotes 3

logarithmic output is desirable.

and 4)

4.6 Anodic Polarization Circuit—Ascanning potentiostat is

used for potentiodynamic measurements. Potential and current

are plotted continuously using an X-Y recorder and a logarith-

beadjustablesothatitcanbebroughtintocloseproximitywith

the working electrode. mic converter (contained in the potentiostat or incorporated

into the circuit) for the current. Commercially available units

4.2 Specimen Holder:

are suitable.

4.2.1 Specimens should be mounted in a suitable holder

4.7 Electrodes:

designed for flat strip, exposing 1 cm to the test solution (Fig.

1). Such specimen holders have been described in the litera- 4.7.1 The standard Type 304 stainless steel (UNS S30400)

andAlloy C-276 (UNS N10276) should be machined into flat

ture. It is important that the circular TFE-fluorocarbon gasket

0.625-in. (14-mm) diameter disks. The chemical compositions

be drilled and machined flat in order to minimize crevices.

of the alloys used in the round robin are listed in Table 1.

4.3 Potentiostat (Note 1)—Apotentiostat that will maintain

4.7.2 Counter Electrodes—The counter electrodes may be

an electrode potential within 1 mV of a preset value over a

prepared as described in ReferenceTest Method G5 or may be

widerangeofappliedcurrentsshouldbeused.Forthetypeand

prepared from high-purity platinum flat stock and wire. A

size of standard specimen supplied, the potentiostat should

suitable method would be to seal the platinum wire in glass

have a potential range of−1.0 to+1.6 V and an anodic current

tubing and introduce the platinum electrode assembly through

output range of 1.0 to 10 µA. Most commercial potentiostats

a sliding seal. Counter electrodes should have an area at least

meet the specific requirements for these types of measure-

twice as large as the test electrode.

ments.

4.7.3 Reference Electrode —A saturated calomel electrode

NOTE 1—These instrumental requirements are based upon values

with a controlled rate of leakage (about 3 µL/h) is recom-

typical of the instruments in the five laboratories that have provided the

mended. This type of electrode is durable, reliable, and

data used in determining the standard polarization plot.

commercially available. Precautions should be taken to ensure

4.4 Potential-Measuring Instruments (Note 1)—The

that it is maintained in the proper condition. The potential of

potential-measuring circuit should have a high input imped-

thecalomelelectrodeshouldbecheckedatperiodicintervalsto

11 14

ance on the order of 10 to 10 Ω to minimize current drawn

ensure the accuracy of the electrode.

from the system during measurements. Instruments should

5. Reagents and Materials

have sufficient sensitivity and accuracy to detect a change in

potential of 61 mV, usually included in commercial poten-

5.1 Purity of Reagents—Reagent grade chemicals shall be

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G61 − 86 (Reapproved 2009) G61 − 86 (Reapproved 2014)

Standard Test Method for

Conducting Cyclic Potentiodynamic Polarization

Measurements for Localized Corrosion Susceptibility of

Iron-, Nickel-, or Cobalt-Based Alloys

This standard is issued under the fixed designation G61; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for conducting cyclic potentiodynamic polarization measurements to determine relative

susceptibility to localized corrosion (pitting and crevice corrosion) for iron-, nickel-, or cobalt-based alloys in a chloride

environment. This test method also describes an experimental procedure which can be used to check one’s experimental technique

and instrumentation.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1193 Specification for Reagent Water

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing

G5 Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements

2.2 ASTM Adjuncts:

Standard Samples (set of two)

3. Significance and Use

3.1 An indication of the susceptibility to initiation of localized corrosion in this test method is given by the potential at which

the anodic current increases rapidly. The more noble this potential, obtained at a fixed scan rate in this test, the less susceptible

is the alloy to initiation of localized corrosion. The results of this test are not intended to correlate in a quantitative manner with

the rate of propagation that one might observe in service when localized corrosion occurs.

3.2 In general, once initiated, localized corrosion can propagate at some potential more electropositive than that at which the

hysteresis loop is completed. In this test method, the potential at which the hysteresis loop is completed is determined at a fixed

scan rate. In these cases, the more electropositive the potential at which the hysteresis loop is completed the less likely it is that

localized corrosion will occur.

3.3 If followed, this test method will provide cyclic potentiodynamic anodic polarization measurements that will reproduce data

developed at other times in other laboratories using this test method for the two specified alloys discussed in 3.4. The procedure

is used for iron-, nickel-, or cobalt-based alloys in a chloride environment.

3.4 A standard potentiodynamic polarization plot is included. These reference data are based on the results from five different

laboratories that followed the standard procedure, using specific alloys of Type 304 stainless steel, UNS S30400 and Alloy C-276,

UNS N10276. Curves are included which have been constructed using statistical analysis to indicate the acceptable range of

polarization curves.

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical

Measurements in Corrosion Testing.

Current edition approved May 1, 2009May 1, 2014. Published May 2009May 2014. Originally approved in 1986. Last previous edition approved in 20032009 as

ε1

G61–86(2003)G61 . DOI: 10.1520/G0061-86R09.– 86 (2009). DOI: 10.1520/G0061-86R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from ASTM International Headquarters. Order Adjunct No. ADJG0061. Original adjunct produced before 1995.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G61 − 86 (2014)

FIG. 1 Schematic Diagram of Specimen Holder (see Footnotes 3 and 4)

3.5 The availability of a standard test method, standard material, and standard plots should make it easy for an investigator to

check his techniques to evaluate susceptibility to localized corrosion.

4. Apparatus

4.1 The polarization cell should be similar to the one described in Reference Test Method G5. Other polarization cells may be

equally suitable.

4.1.1 The cell should have a capacity of about 1 L and should have suitable necks or seals to permit the introduction of

electrodes, gas inlet and outlet tubes, and a thermometer. The Luggin probe-salt bridge separates the bulk solution from the

saturated calomel reference electrode. The probe tip should be adjustable so that it can be brought into close proximity with the

working electrode.

4.2 Specimen Holder:

4.2.1 Specimens should be mounted in a suitable holder designed for flat strip, exposing 1 cm to the test solution (Fig. 1). Such

specimen holders have been described in the literature. It is important that the circular TFE-fluorocarbon gasket be drilled and

machined flat in order to minimize crevices.

4.3 Potentiostat (Note 1) —A potentiostat that will maintain an electrode potential within 1 mV of a preset value over a wide

range of applied currents should be used. For the type and size of standard specimen supplied, the potentiostat should have a

potential range of −1.0 to +1.6 V and an anodic current output range of 1.0 to 10 μA. Most commercial potentiostats meet the

specific requirements for these types of measurements.

NOTE 1—These instrumental requirements are based upon values typical of the instruments in the five laboratories that have provided the data used

in determining the standard polarization plot.

4.4 Potential-Measuring Instruments (Note 1)—The potential-measuring circuit should have a high input impedance on the

11 14

order of 10 to 10 Ω to minimize current drawn from the system during measurements. Instruments should have sufficient

sensitivity and accuracy to detect a change in potential of 61 mV, usually included in commercial potentiostats. An output as a

voltage is preferred for recording purposes.

4.5 Current-Measuring Instruments (Note 1)—An instrument that is capable of measuring a current accurately to within 1 %

of the absolute value over a current range between 1.0 and 10 μA should be used. Many commercial units have a build-in

instrument with an output as a voltage, which is preferred for recording purposes. For the purpose of the present test a logarithmic

output is desirable.

France, W. D., Jr., Journal of the Electrochemical Society, Vol 114, 1967, p. 818; and Myers, J. R., Gruewlar, F. G., and Smulezenski, L. A., Corrosion, Vol 24, 1968,

p. 352.

G61 − 86 (2014)

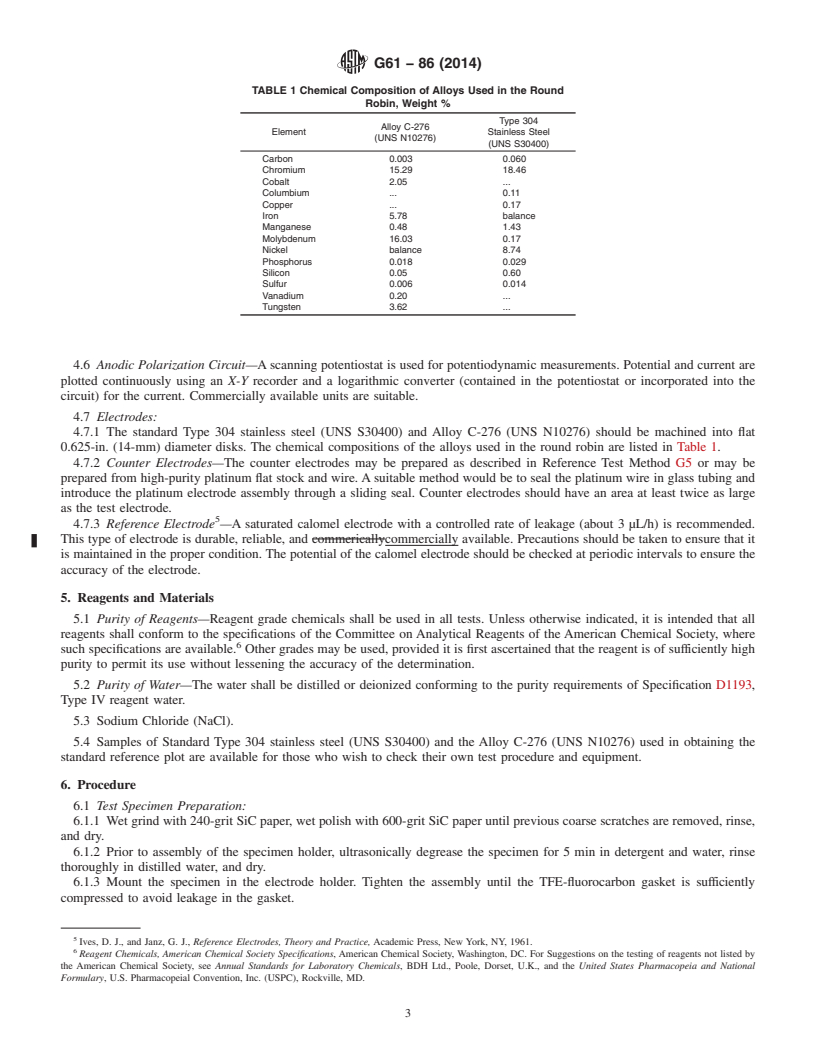

TABLE 1 Chemical Composition of Alloys Used in the Round

Robin, Weight %

Type 304

Alloy C-276

Element Stainless Steel

(UNS N10276)

(UNS S30400)

Carbon 0.003 0.060

Chromium 15.29 18.46

Cobalt 2.05 .

Columbium . 0.11

Copper . 0.17

Iron 5.78 balance

Manganese 0.48 1.43

Molybdenum 16.03 0.17

Nickel balance 8.74

Phosphorus 0.018 0.029

Silicon 0.05 0.60

Sulfur 0.006 0.014

Vanadium 0.20 .

Tungsten 3.62 .

4.6 Anodic Polarization Circuit—A scanning potentiostat is used for potentiodynamic measurements. Potential and current are

plotted continuously using an X-Y recorder and a logarithmic converter (contained in the potentiostat or incorporated into the

circuit) for the current. Commercially available units are suitable.

4.7 Electrodes:

4.7.1 The standard Type 304 stainless steel (UNS S30400) and Alloy C-276 (UNS N10276) should be machined into flat

0.625-in. (14-mm) diameter disks. The chemical compositions of the alloys used in the round robin are listed in Table 1.

4.7.2 Counter Electrodes—The counter electrodes may be prepared as described in Reference Test Method G5 or may be

prepared from high-purity platinum flat stock and wire. A suitable method would be to seal the platinum wire in glass tubing and

introduce the platinum electrode assembly through a sliding seal. Counter electrodes should have an area at least twice as large

as the test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.