ASTM F1875-98(2022)

(Practice)Standard Practice for Fretting Corrosion Testing of Modular Implant Interfaces: Hip Femoral Head-Bore and Cone Taper Interface

Standard Practice for Fretting Corrosion Testing of Modular Implant Interfaces: Hip Femoral Head-Bore and Cone Taper Interface

SIGNIFICANCE AND USE

5.1 The modular interfaces of total joint prostheses are subjected to micromotion that could result in fretting and corrosion. The release of corrosion products and particulate debris could stimulate adverse biological reactions, as well as lead to accelerated wear at the articulation interface. Methods to assess the stability and corrosion resistance of the modular interfaces, therefore, are an essential component of device testing.

5.2 Long-term in-vitro testing is essential to produce damage and debris from fretting of a modular interface (4, 5). The use of proteinaceous solutions is recommended to best simulate the in-vivo environment.

5.3 Short-term tests often can be useful in evaluations of differences in design during device development (1-4). The electrochemical methods provide semiquantitative measures of fretting corrosion rates. The relative contributions of mechanical and electrochemical processes to the total corrosion and particulate release phenomena, however, have not been established; therefore, these tests should not be utilized to compare the effects of changes in material combinations, but rather be utilized to evaluate design changes of bore (head) and cone (stem) components.

5.4 These tests are recommended for evaluating the fretting wear and corrosion of modular interfaces of hip femoral head and stem components. Similar methods may be applied to other modular interfaces where fretting corrosion is of concern.

5.5 These methods are recommended for comparative evaluation of the fretting wear and corrosion of new materials, coatings, or designs, or a combination thereof, under consideration for hip femoral head and neck modular interfaces. Components for testing may be those of a manufactured modular hip device (finished product) or sample coupons, which are designed and manufactured for simulation of the head, taper, and neck region of a modular hip device.

SCOPE

1.1 This practice describes the testing, analytical, and characterization methods for evaluating the mechanical stability of the bore and cone interface of the head and stem junction of modular hip implants subjected to cyclic loading by measurements of fretting corrosion (1-5).2 Two test methods described are as follows:

1.1.1 Method I—The primary purpose of this method is to provide a uniform set of guidelines for long-term testing to determine the amount of damage by measurement of the production of corrosion products and particulate debris from fretting and fretting corrosion. Damage is also assessed by characterization of the damage to the bore and cone surfaces (4, 5).

1.1.2 Method II—This method provides for short-term electrochemical evaluation of the fretting corrosion of the modular interface. It is not the intent of this method to produce damage nor particulate debris but rather to provide a rapid method for qualitative assessment of design changes which do not include material changes (1-4).

1.2 This practice does not provide for judgment or prediction of in-vivo implant performance, but rather provides for a uniform set of guidelines for evaluating relative differences in performance between differing implant designs, constructs, or materials with performance defined in the context of the amount of fretting and fretting corrosion. Also, this practice should permit direct comparison of fretting corrosion data between independent research groups, and thus provide for building of a data base on modular implant performance.

1.3 This practice provides for comparative testing of manufactured hip femoral heads and stems and for coupon-type specimen testing where the male taper portion of the modular junction does not include the entire hip implant, with the taper portion of the coupon identical in design, manufacturing, and materials to the taper of the final hip implant (4, 5).

1.4 Method I of this practice permits simultaneous evaluation of the fatigue strength of a femoral ...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1875 − 98 (Reapproved 2022)

Standard Practice for

Fretting Corrosion Testing of Modular Implant Interfaces:

Hip Femoral Head-Bore and Cone Taper Interface

This standard is issued under the fixed designation F1875; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope portion of the coupon identical in design, manufacturing, and

materials to the taper of the final hip implant (4, 5).

1.1 This practice describes the testing, analytical, and char-

acterization methods for evaluating the mechanical stability of 1.4 Method I of this practice permits simultaneous evalua-

the bore and cone interface of the head and stem junction of tionofthefatiguestrengthofafemoralhipstem(inaccordance

modular hip implants subjected to cyclic loading by measure- with Practice F1440) and the mechanical stability and debris

ments of fretting corrosion (1-5). Two test methods described generated by fretting and fretting corrosion of the modular

are as follows: interface.

1.1.1 Method I—The primary purpose of this method is to

1.5 The general concepts and methodologies described in

provide a uniform set of guidelines for long-term testing to

this practice could be applied to the study of other modular

determine the amount of damage by measurement of the

interfaces in total joint prostheses.

production of corrosion products and particulate debris from

1.6 The values stated in SI units are to be regarded as

fretting and fretting corrosion. Damage is also assessed by

standard. No other units of measurement are included in this

characterization of the damage to the bore and cone surfaces

standard.

(4, 5).

1.7 This standard does not purport to address all of the

1.1.2 Method II—This method provides for short-term elec-

trochemical evaluation of the fretting corrosion of the modular safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

interface. It is not the intent of this method to produce damage

nor particulate debris but rather to provide a rapid method for priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

qualitative assessment of design changes which do not include

material changes (1-4). 1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.2 This practice does not provide for judgment or predic-

ization established in the Decision on Principles for the

tion of in-vivo implant performance, but rather provides for a

Development of International Standards, Guides and Recom-

uniform set of guidelines for evaluating relative differences in

mendations issued by the World Trade Organization Technical

performance between differing implant designs, constructs, or

Barriers to Trade (TBT) Committee.

materials with performance defined in the context of the

amount of fretting and fretting corrosion. Also, this practice

2. Referenced Documents

should permit direct comparison of fretting corrosion data

2.1 ASTM Standards:

between independent research groups, and thus provide for

E4 Practices for Force Calibration and Verification of Test-

building of a data base on modular implant performance.

ing Machines

1.3 This practice provides for comparative testing of manu-

E466 Practice for Conducting Force Controlled Constant

factured hip femoral heads and stems and for coupon-type

Amplitude Axial Fatigue Tests of Metallic Materials

specimen testing where the male taper portion of the modular

E467 Practice for Verification of Constant Amplitude Dy-

junction does not include the entire hip implant, with the taper

namic Forces in an Axial Fatigue Testing System

F561 Practice for Retrieval and Analysis of Medical

Devices, and Associated Tissues and Fluids

ThispracticeisunderthejurisdictionofASTMCommitteeF04onMedicaland

F746 Test Method for Pitting or Crevice Corrosion of

Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved Oct. 1, 2022. Published October 2022. Originally

approved in 1998. Last previous edition approved in 2014 as F1875 – 98 (2014). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/F1875-98R22. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The bold face numbers in parentheses refers to the list of references at the end Standards volume information, refer to the standard’s Document Summary page on

of this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1875 − 98 (2022)

Metallic Surgical Implant Materials 3.1.9 total elemental level, n—the total weight of particulate

F897 Test Method for Measuring Fretting Corrosion of matter and corrosion ions generated by fretting wear and

Osteosynthesis Plates and Screws fretting corrosion. Most analytical techniques are unable to

F1440 Practice for Cyclic Fatigue Testing of Metallic accurately differentiate between ions and particulates, and

Stemmed HipArthroplasty Femoral Components Without therefore, total elemental level refers to all matter and corro-

Torsion (Withdrawn 2012) sion products released by fretting wear and corrosion.

F1636 SpecificationforBoresandConesforModularFemo-

3.1.10 wear, n—damage to a solid surface, generally involv-

ral Heads (Withdrawn 2001)

ingprogressivelossofmaterial,duetorelativemotionbetween

G3 Practice for Conventions Applicable to Electrochemical

that surface and a contacting substance or substances.

Measurements in Corrosion Testing

G5 Reference Test Method for Making Potentiodynamic

4. Summary of Test Method

Anodic Polarization Measurements

4.1 Method I—The femoral stem and head components, or

G15 Terminology Relating to Corrosion and CorrosionTest-

coupons to simulate head-taper-neck geometry, are loaded

ing (Withdrawn 2010)

cyclically in a manner similar to that described in Practice

G40 Terminology Relating to Wear and Erosion

F1440. The head neck junction is exposed to a saline or

G61 Test Method for Conducting Cyclic Potentiodynamic

proteinaceous solution, either by immersion of the entire

Polarization Measurements for Localized Corrosion Sus-

device, or with a fluid-containing envelope. The cyclic load is

ceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

applied for a minimum of 10 million cycles.At the conclusion

G102 Practice for Calculation of Corrosion Rates and Re-

of testing, the isolated fluid is withdrawn for chemical analysis

lated Information from Electrochemical Measurements

for total elemental level, and characterization of particulate

2.2 ISO Standards:

debris. The taper interface is subsequently disengaged and the

ISO 7206-7 Endurance Performance of Stemmed Femoral

surfaces inspected for fretting wear and corrosion using optical

Components Without Application of Torsion

microscopy and scanning electron microscopy. The output of

3. Terminology thesemethodsisaquantitativemeasureoftotalelementallevel

andaqualitativeevaluationofdamageofthemodularinterface

3.1 Definitions:

caused by fretting wear and corrosion.

3.1.1 corrosive wear, n—wear in which chemical or electro-

chemical reaction with the environment is significant.

4.2 Method II—A coupon similar to that used in Method I,

or an entire femoral stem and head construct, may be mounted

3.1.2 coverage, n—the length, parallel to the taper surface,

in an inverted position in a test chamber. The chamber is filled

that the bore and cone interfaces are in contact.

withanelectrolytesolutiontoalevelsufficienttosubmergethe

3.1.3 crevice corrosion, n—localized corrosion of a metal

bore and cone interface and a small portion of the exposed

surface at, or immediately adjacent to, an area that is shielded

neck. The area of contact and articulation between the ball and

from full exposure to the environment because of close

the test apparatus is isolated from the electrolyte, either by

proximity between the metal and the surface of another

being above the fill level, or with an elastomeric seal used to

material.

isolate the bottom of the test chamber.

3.1.4 external circuit, n—the wires, connectors, measuring

4.2.1 Procedure A—A saturated calomel electrode with a

devices, current sources, and so forth that are used to bring

luggin probe is used as a reference electrode to measure

about or measure the desired electrical conditions within the

changes in the corrosion potential with an electrometer. A

test cell.

counter electrode also may be employed and the polarization

3.1.5 femoral head neck extension, n—a distance parallel to

characteristics measured with a potentiostat.

the taper axis, from the nominal neck offset length (k)as

4.2.2 Procedure B—Alargesurfaceareacounterelectrodeis

defined in Specification F1636, and the center of the head.

immersed in the solution to simulate the area of the stem. A

Such variants from the nominal length are used to adjust for

zero-resistance ammeter is connected between the test device

resection level, leg length, and so forth. A positive neck

and the counter electrode. The difference in current, thus

extension equates to the center of the head being located

measured prior to and during cyclic loading, represents the

further away from the stem.

fretting corrosion current flowing between the modular inter-

face (anode) and the metal sheet (cathode).

3.1.6 fretting, n—small amplitude oscillatory motion, usu-

ally tangential, between two solid surfaces in contact.

5. Significance and Use

3.1.7 fretting corrosion, n—the deterioration at the interface

between contacting surfaces as the result of corrosion and

5.1 The modular interfaces of total joint prostheses are

slight oscillatory slip between the two surfaces.

subjected to micromotion that could result in fretting and

corrosion. The release of corrosion products and particulate

3.1.8 fretting wear, n—wear arising as a result of fretting.

debris could stimulate adverse biological reactions, as well as

lead to accelerated wear at the articulation interface. Methods

The last approved version of this historical standard is referenced on

to assess the stability and corrosion resistance of the modular

www.astm.org.

interfaces, therefore, are an essential component of device

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. testing.

F1875 − 98 (2022)

5.2 Long-term in-vitro testing is essential to produce dam-

age and debris from fretting of a modular interface (4, 5). The

useofproteinaceoussolutionsisrecommendedtobestsimulate

the in-vivo environment.

5.3 Short-term tests often can be useful in evaluations of

differences in design during device development (1-4). The

electrochemical methods provide semiquantitative measures of

fretting corrosion rates. The relative contributions of mechani-

cal and electrochemical processes to the total corrosion and

particulate release phenomena, however, have not been estab-

lished; therefore, these tests should not be utilized to compare

the effects of changes in material combinations, but rather be

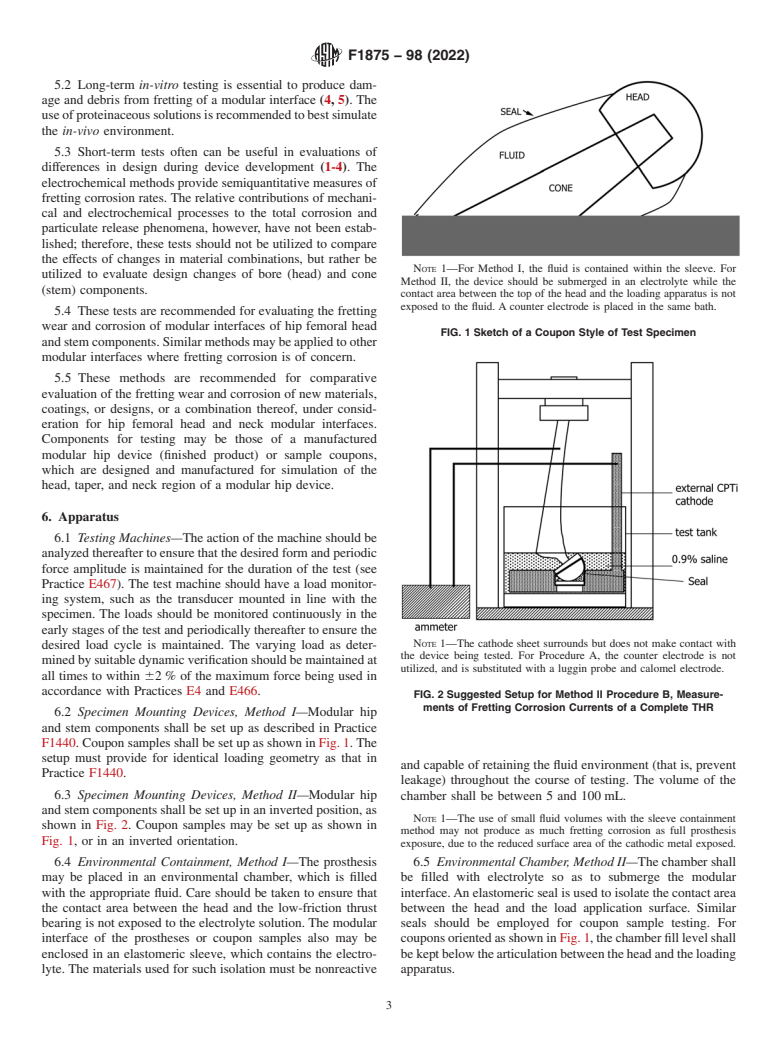

NOTE 1—For Method I, the fluid is contained within the sleeve. For

utilized to evaluate design changes of bore (head) and cone

Method II, the device should be submerged in an electrolyte while the

(stem) components.

contact area between the top of the head and the loading apparatus is not

exposed to the fluid. A counter electrode is placed in the same bath.

5.4 These tests are recommended for evaluating the fretting

wear and corrosion of modular interfaces of hip femoral head

FIG. 1 Sketch of a Coupon Style of Test Specimen

andstemcomponents.Similarmethodsmaybeappliedtoother

modular interfaces where fretting corrosion is of concern.

5.5 These methods are recommended for comparative

evaluation of the fretting wear and corrosion of new materials,

coatings, or designs, or a combination thereof, under consid-

eration for hip femoral head and neck modular interfaces.

Components for testing may be those of a manufactured

modular hip device (finished product) or sample coupons,

which are designed and manufactured for simulation of the

head, taper, and neck region of a modular hip device.

6. Apparatus

6.1 Testing Machines—The action of the machine should be

analyzedthereaftertoensurethatthedesiredformandperiodic

force amplitude is maintained for the duration of the test (see

Practice E467). The test machine should have a load monitor-

ing system, such as the transducer mounted in line with the

specimen. The loads should be monitored continuously in the

early stages of the test and periodically thereafter to ensure the

NOTE 1—The cathode sheet surrounds but does not make contact with

desired load cycle is maintained. The varying load as deter-

the device being tested. For Procedure A, the counter electrode is not

minedbysuitabledynamicverificationshouldbemaintainedat

utilized, and is substituted with a luggin probe and calomel electrode.

all times to within 62 % of the maximum force being used in

accordance with Practices E4 and E466.

FIG. 2 Suggested Setup for Method II Procedure B, Measure-

ments of Fretting Corrosion Currents of a Complete THR

6.2 Specimen Mounting Devices, Method I—Modular hip

and stem components shall be set up as described in Practice

F1440. Coupon samples shall be set up as shown in Fig. 1.The

setup must provide for identical loading geometry as that in

and capable of retaining the fluid environment (that is, prevent

Practice F1440.

leakage) throughout the course of testing. The volume of the

6.3 Specimen Mounting Devices, Method II—Modular hip

chamber shall be between 5 and 100 mL.

and stem components shall be set up in an inverted position, as

NOTE 1—The use of small fluid volumes with the sleeve containment

shown in Fig. 2. Coupon samples may be set up as shown in

method may not produce as much fretting corrosion as full prosthesis

Fig. 1, or in an inverted orientation.

exposure, due to the reduced surface area of the cathodic metal exposed.

6.4 Environmental Containment, Method I—The prosthesis 6.5 Environmental Chamber, Method II—The chamber shall

may be placed in an environmental chamber, which is filled be filled with electrolyte so as to submerge the modular

with the appropriate fluid. Care sho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.