ASTM G108-23

(Test Method)Standard Test Methods for Electrochemical Reactivation (EPR) for Detecting Sensitization of AISI Type 304 and 304L Stainless Steels

Standard Test Methods for Electrochemical Reactivation (EPR) for Detecting Sensitization of AISI Type 304 and 304L Stainless Steels

SIGNIFICANCE AND USE

5.1 This test method describes an EPR test method for quantitatively determining the relative degree of sensitization in AISI Type 304 and 304L stainless steels. The EPR test has found wide use as a means to provide a numerical level of sensitization in studies of the effects of sensitization on intergranular corrosion and intergranular stress corrosion cracking behavior. The results of this test method correlate with other test methods (for example, Practices A262 and Test Methods G28) that are commonly used to assess sensitization in stainless steels.

5.2 The EPR test can also be used for product acceptance, service evaluation, regulatory statutes, and manufacturing controls providing that both the supplier and user have agreed upon appropriate acceptance criteria and a sensitizing treatment. The test is not intended for design purposes since the test conditions accelerate corrosion in a manner that does not simulate any actual service environment.

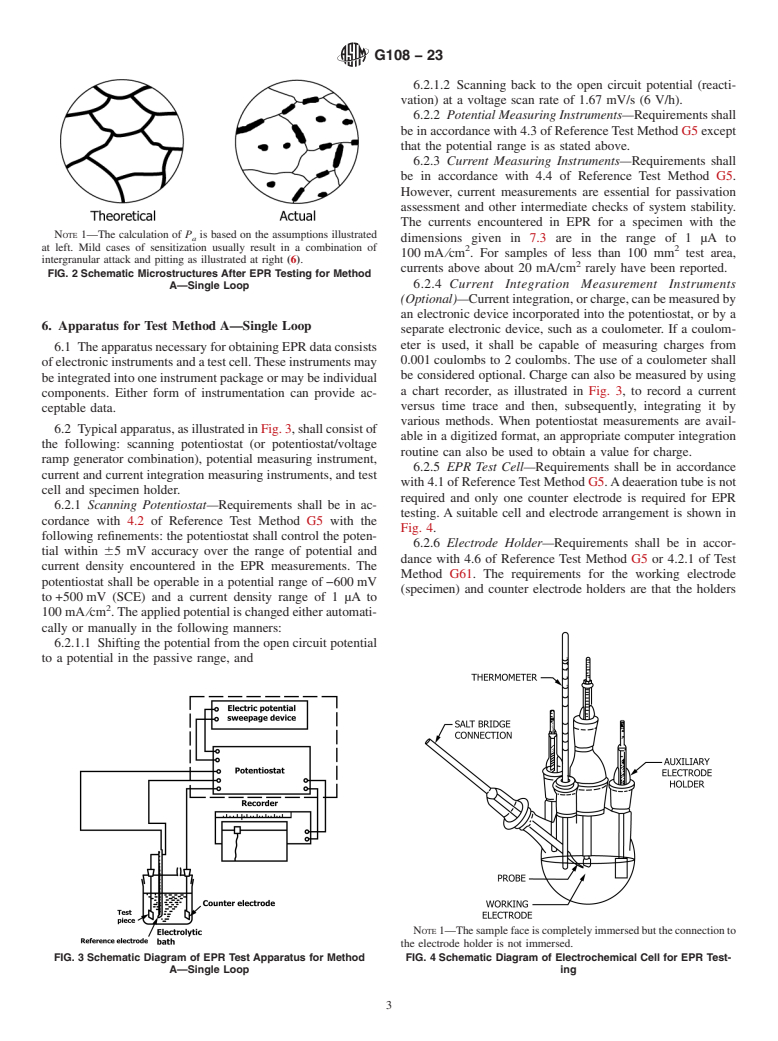

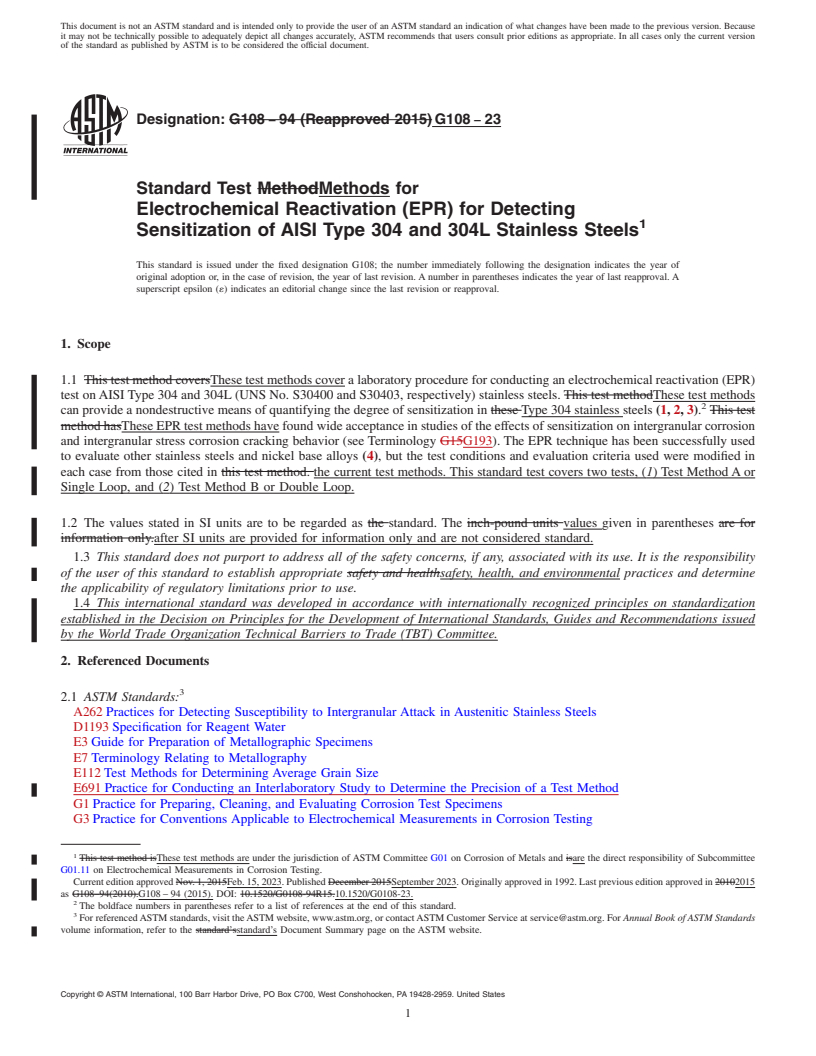

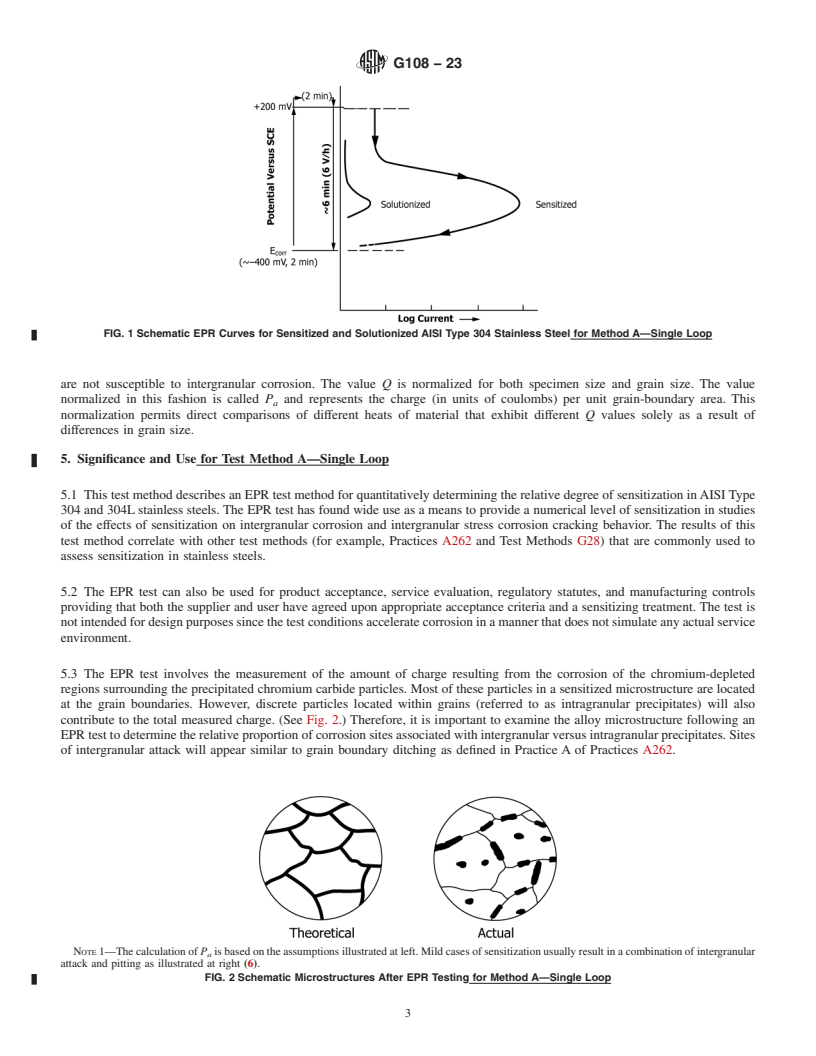

5.3 The EPR test involves the measurement of the amount of charge resulting from the corrosion of the chromium-depleted regions surrounding the precipitated chromium carbide particles. Most of these particles in a sensitized microstructure are located at the grain boundaries. However, discrete particles located within grains (referred to as intragranular precipitates) will also contribute to the total measured charge. (See Fig. 2.) Therefore, it is important to examine the alloy microstructure following an EPR test to determine the relative proportion of corrosion sites associated with intergranular versus intragranular precipitates. Sites of intergranular attack will appear similar to grain boundary ditching as defined in Practice A of Practices A262.

FIG. 2 Schematic Microstructures After EPR Testing for Method A—Single Loop

Note 1: The calculation of Pa is based on the assumptions illustrated at left. Mild cases of sensitization usually result in a combination of intergranular attack and pitting as illustr...

SCOPE

1.1 These test methods cover a laboratory procedure for conducting an electrochemical reactivation (EPR) test on AISI Type 304 and 304L (UNS No. S30400 and S30403, respectively) stainless steels. These test methods can provide a nondestructive means of quantifying the degree of sensitization in Type 304 stainless steels (1, 2, 3).2 These EPR test methods have found wide acceptance in studies of the effects of sensitization on intergranular corrosion and intergranular stress corrosion cracking behavior (see Terminology G193). The EPR technique has been successfully used to evaluate other stainless steels and nickel base alloys (4), but the test conditions and evaluation criteria used were modified in each case from those cited in the current test methods. This standard test covers two tests, (1) Test Method A or Single Loop, and (2) Test Method B or Double Loop.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G108 − 23

Standard Test Methods for

Electrochemical Reactivation (EPR) for Detecting

1

Sensitization of AISI Type 304 and 304L Stainless Steels

This standard is issued under the fixed designation G108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 These test methods cover a laboratory procedure for 2.1 ASTM Standards:

conducting an electrochemical reactivation (EPR) test on AISI A262 Practices for Detecting Susceptibility to Intergranular

Type 304 and 304L (UNS No. S30400 and S30403, respec- Attack in Austenitic Stainless Steels

tively) stainless steels. These test methods can provide a D1193 Specification for Reagent Water

nondestructive means of quantifying the degree of sensitization E3 Guide for Preparation of Metallographic Specimens

2

in Type 304 stainless steels (1, 2, 3). These EPR test methods E7 Terminology Relating to Metallography

have found wide acceptance in studies of the effects of E112 Test Methods for Determining Average Grain Size

sensitization on intergranular corrosion and intergranular stress E691 Practice for Conducting an Interlaboratory Study to

corrosion cracking behavior (see Terminology G193). The EPR Determine the Precision of a Test Method

technique has been successfully used to evaluate other stainless G1 Practice for Preparing, Cleaning, and Evaluating Corro-

steels and nickel base alloys (4), but the test conditions and sion Test Specimens

evaluation criteria used were modified in each case from those G3 Practice for Conventions Applicable to Electrochemical

cited in the current test methods. This standard test covers two Measurements in Corrosion Testing

tests, (1) Test Method A or Single Loop, and (2) Test Method G5 Reference Test Method for Making Potentiodynamic

B or Double Loop. Anodic Polarization Measurements

G28 Test Methods for Detecting Susceptibility to Inter-

1.2 The values stated in SI units are to be regarded as

granular Corrosion in Wrought, Nickel-Rich, Chromium-

standard. The values given in parentheses after SI units are

Bearing Alloys

provided for information only and are not considered standard.

G61 Test Method for Conducting Cyclic Potentiodynamic

1.3 This standard does not purport to address all of the

Polarization Measurements for Localized Corrosion Sus-

safety concerns, if any, associated with its use. It is the

ceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

responsibility of the user of this standard to establish appro-

G193 Terminology and Acronyms Relating to Corrosion

priate safety, health, and environmental practices and deter-

G215 Guide for Electrode Potential Measurement

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Definitions of Terms Specific to This Standard:

ization established in the Decision on Principles for the

3.1.1 integrated charge (Q), n—charge measured, in

Development of International Standards, Guides and Recom-

coulombs, during reactivation as given by the time integral of

mendations issued by the World Trade Organization Technical

current below the reactivation peak of the curve.

Barriers to Trade (TBT) Committee.

3.1.2 maximum anodic current density (i ), n—current den-

r

sity measured at the peak of the anodic curve during reactiva-

1

These test methods are under the jurisdiction of ASTM Committee G01 on

tion.

Corrosion of Metals and are the direct responsibility of Subcommittee G01.11 on

Electrochemical Measurements in Corrosion Testing.

Current edition approved Feb. 15, 2023. Published September 2023. Originally

3

approved in 1992. Last previous edition approved in 2015 as G108 – 94 (2015). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/G0108-23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G108 − 23

3.1.3 normalized charge (P ), n—integrated current normal- 4.4 The EPR test results are readily reproducible, as long as

a

i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G108 − 94 (Reapproved 2015) G108 − 23

Standard Test MethodMethods for

Electrochemical Reactivation (EPR) for Detecting

1

Sensitization of AISI Type 304 and 304L Stainless Steels

This standard is issued under the fixed designation G108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method coversThese test methods cover a laboratory procedure for conducting an electrochemical reactivation (EPR)

test on AISI Type 304 and 304L (UNS No. S30400 and S30403, respectively) stainless steels. This test methodThese test methods

2

can provide a nondestructive means of quantifying the degree of sensitization in these Type 304 stainless steels (1, 2, 3). This test

method hasThese EPR test methods have found wide acceptance in studies of the effects of sensitization on intergranular corrosion

and intergranular stress corrosion cracking behavior (see Terminology G15G193). The EPR technique has been successfully used

to evaluate other stainless steels and nickel base alloys (4), but the test conditions and evaluation criteria used were modified in

each case from those cited in this test method. the current test methods. This standard test covers two tests, (1) Test Method A or

Single Loop, and (2) Test Method B or Double Loop.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units values given in parentheses are for

information only.after SI units are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

D1193 Specification for Reagent Water

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E112 Test Methods for Determining Average Grain Size

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing

1

This test method isThese test methods are under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and isare the direct responsibility of Subcommittee

G01.11 on Electrochemical Measurements in Corrosion Testing.

Current edition approved Nov. 1, 2015Feb. 15, 2023. Published December 2015September 2023. Originally approved in 1992. Last previous edition approved in 20102015

as G108–94(2010).G108 – 94 (2015). DOI: 10.1520/G0108-94R15.10.1520/G0108-23.

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G108 − 23

G5 Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements

4

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

G28 Test Methods for Detecting Susceptibility to Intergranular Corrosion in Wrought, Nickel-Rich, Chromium-Bearing Alloys

G61 Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements for Localized Corrosion Susceptibility of

Iron-, Nickel-, or Cobalt-Based Alloys

G193 Terminology and Acronyms Relating to Corrosion

G215 Guide for Electrode Potential Measurement

3. Terminology

3.1 Defin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.