ASTM D2812-07

(Test Method)Standard Test Method for Non-Lint Content of Cotton

Standard Test Method for Non-Lint Content of Cotton

SIGNIFICANCE AND USE

This test method for testing cotton for non-lint content is considered satisfactory for acceptance testing of commercial shipments since it is the best available procedure for obtaining objective data.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, ensure the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results were obtained, and are randomly assigned in equal numbers to each laboratory for testing. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

This test method gives data on the non-lint content of raw cotton which can be used as a basis for: (1) estimating the net amount of manufactured textile product obtainable from raw cotton; (2) predicting the quality of cotton textile products, particularly their aesthetic properties; (3) assembling and blending bales in a mix on a non-lint content basis; (4) adjusting ginning and textile processing machines for maximum efficiency in cleaning lint; and (5) relating non-lint content of cotton to end-product quality and processing efficiency.

SCOPE

1.1 This test method covers the determination of the non-lint content of cotton using the Shirley Analyzer. The cotton may be in the form of (1) raw stock, that is, cotton fiber that has been separated from the seed by ginning; (2) partially processed cotton, such as picker lap or sliver; or ( 3) ginning or processing waste, such as obtained from ginning, opening and cleaning, picking, carding, or combing machines.

1.2 This test method is especially adapted for determining non-lint content of cotton by use of the Shirley Analyser.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2812 – 07

Standard Test Method for

1

Non-Lint Content of Cotton

This standard is issued under the fixed designation D2812; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 For all other terminology related to textiles, refer to

Terminology D123.

1.1 This test method covers the determination of the non-

lint content of cotton using the Shirley Analyzer. The cotton

4. Summary of Test Method

maybeintheformof(1)rawstock,thatis,cottonfiberthathas

4.1 Aknown mass of raw cotton, partially processed cotton,

been separated from the seed by ginning; (2) partially pro-

or waste is fed into the machine. The machine, operating on

cessed cotton, such as picker lap or sliver; or (3) ginning or

mechanical-pneumatic principles, separates the foreign matter

processing waste, such as obtained from ginning, opening and

from the cotton and discharges the non-lint particles and lint

cleaning, picking, carding, or combing machines.

into separate chambers.

1.2 This test method is especially adapted for determining

4.2 The amounts of lint and non-lint recovered are calcu-

non-lint content of cotton by use of the Shirley Analyser.

lated as a percentage of the original specimen mass.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

5. Significance and Use

only.

5.1 Thistestmethodfortestingcottonfornon-lintcontentis

1.4 This standard does not purport to address all of the

considered satisfactory for acceptance testing of commercial

safety concerns, if any, associated with its use. It is the

shipments since it is the best available procedure for obtaining

responsibility of the user of this standard to establish appro-

objective data.

priate safety and health practices and determine the applica-

5.1.1 If there are differences of practical significance be-

bility of regulatory limitations prior to use. For specific hazard

tween reported test results for two laboratories (or more),

statements, see Section 7.

comparative tests should be performed to determine if there is

2. Referenced Documents a statistical bias between them, using competent statistical

2 assistance. As a minimum, ensure the test samples to be used

2.1 ASTM Standards:

are as homogeneous as possible, are drawn from the material

D123 Terminology Relating to Textiles

from which the disparate test results were obtained, and are

D1441 Practice for Sampling Cotton Fibers for Testing

randomly assigned in equal numbers to each laboratory for

D7139 Terminology for Cotton Fibers

testing. The test results from the two laboratories should be

3. Terminology compared using a statistical test for unpaired data, at a

probability level chosen prior to the testing series. If a bias is

3.1 For all terminology relating to D13.11, Cotton Fibers,

found, either its cause must be found and corrected, or future

refer to Terminology D7139.

test results for that material must be adjusted in consideration

3.1.1 The following terms are relevant to this standard:

of the known bias.

foreign matter, invisible waste, lint, lint content, non-lint

5.2 This test method gives data on the non-lint content of

content, visible waste.

raw cotton which can be used as a basis for: (1) estimating the

net amount of manufactured textile product obtainable from

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

raw cotton; (2) predicting the quality of cotton textile products,

and is the direct responsibility of Subcommittee D13.11 on Cotton Fibers.

particularly their aesthetic properties; (3) assembling and

Current edition approved Jan. 1, 2007. Published April 2007. Originally

blending bales in a mix on a non-lint content basis; (4)

approved in 1969. Last previous edition approved in 2002 as D2812 – 95(2002).

DOI: 10.1520/D2812-07.

adjusting ginning and textile processing machines for maxi-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mum efficiency in cleaning lint; and (5) relating non-lint

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

content of cotton to end-product quality and processing effi-

Standards volume information, refer to the standard’s Document Summary page on

ciency.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

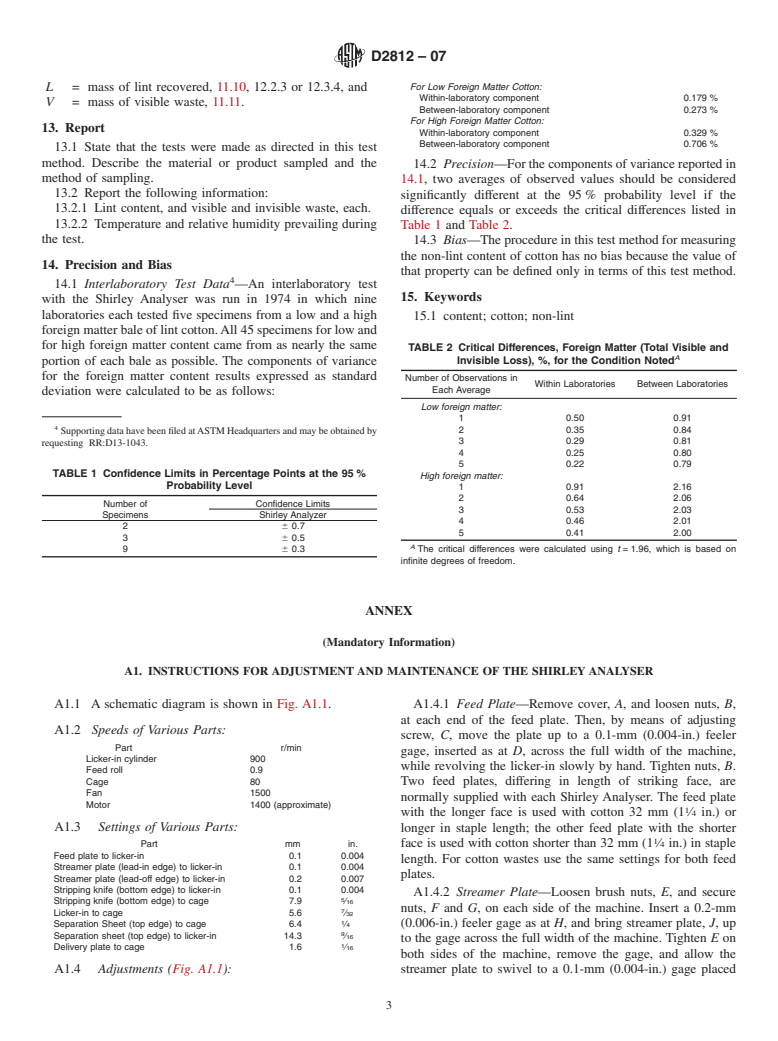

D2812 – 07

6. Apparatus 11. Procedure

6.1 Testing Instrument—Shirley Analyzer, commercially 11.1 Clean the delivery box, trash tray, and settling cham-

availab

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.