ASTM D2812-95(2002)

(Test Method)Standard Test Method for Non-Lint Content of Cotton

Standard Test Method for Non-Lint Content of Cotton

SCOPE

1.1 This test method covers the determination of the non-lint content of cotton using the Shirley Analyzer. The cotton may be in the form of (1) raw stock, that is, cotton fiber that has been separated from the seed by ginning; (2) partially processed cotton, such as picker lap or sliver; or ( 3) ginning or processing waste, such as obtained from ginning, opening and cleaning, picking, carding, or combing machines.

1.2 This test method is especially adapted for determining non-lint content of cotton by use of the Shirley Analyser.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2812 – 95 (Reapproved 2002)

Standard Test Method for

Non-Lint Content of Cotton

This standard is issued under the fixed designation D 2812; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

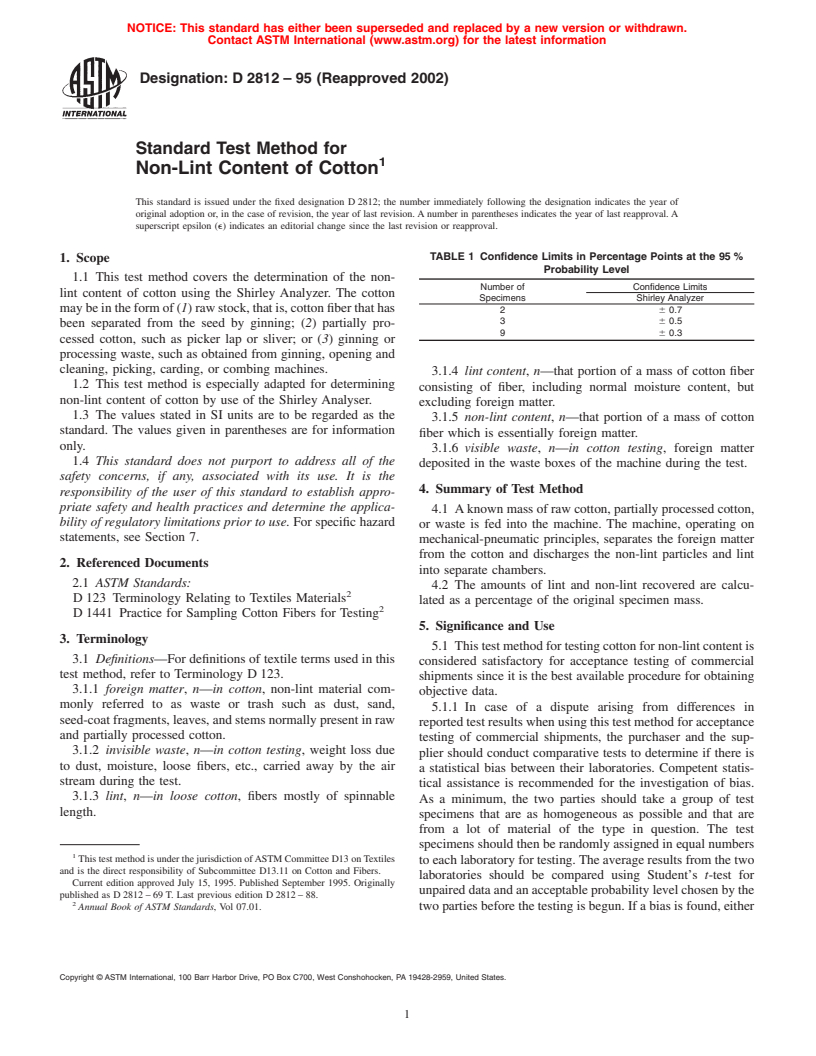

TABLE 1 Confidence Limits in Percentage Points at the 95 %

1. Scope

Probability Level

1.1 This test method covers the determination of the non-

Number of Confidence Limits

lint content of cotton using the Shirley Analyzer. The cotton

Specimens Shirley Analyzer

maybeintheformof(1)rawstock,thatis,cottonfiberthathas

2 6 0.7

3 6 0.5

been separated from the seed by ginning; (2) partially pro-

9 6 0.3

cessed cotton, such as picker lap or sliver; or (3) ginning or

processing waste, such as obtained from ginning, opening and

cleaning, picking, carding, or combing machines.

3.1.4 lint content, n—that portion of a mass of cotton fiber

1.2 This test method is especially adapted for determining

consisting of fiber, including normal moisture content, but

non-lint content of cotton by use of the Shirley Analyser.

excluding foreign matter.

1.3 The values stated in SI units are to be regarded as the

3.1.5 non-lint content, n—that portion of a mass of cotton

standard. The values given in parentheses are for information

fiber which is essentially foreign matter.

only.

3.1.6 visible waste, n—in cotton testing, foreign matter

1.4 This standard does not purport to address all of the

deposited in the waste boxes of the machine during the test.

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 Aknown mass of raw cotton, partially processed cotton,

bility of regulatory limitations prior to use. For specific hazard

or waste is fed into the machine. The machine, operating on

statements, see Section 7.

mechanical-pneumatic principles, separates the foreign matter

from the cotton and discharges the non-lint particles and lint

2. Referenced Documents

into separate chambers.

2.1 ASTM Standards:

4.2 The amounts of lint and non-lint recovered are calcu-

D 123 Terminology Relating to Textiles Materials

lated as a percentage of the original specimen mass.

D 1441 Practice for Sampling Cotton Fibers for Testing

5. Significance and Use

3. Terminology

5.1 Thistestmethodfortestingcottonfornon-lintcontentis

3.1 Definitions—For definitions of textile terms used in this

considered satisfactory for acceptance testing of commercial

test method, refer to Terminology D 123.

shipments since it is the best available procedure for obtaining

3.1.1 foreign matter, n—in cotton, non-lint material com-

objective data.

monly referred to as waste or trash such as dust, sand,

5.1.1 In case of a dispute arising from differences in

seed-coat fragments, leaves, and stems normally present in raw

reported test results when using this test method for acceptance

and partially processed cotton.

testing of commercial shipments, the purchaser and the sup-

3.1.2 invisible waste, n—in cotton testing, weight loss due

plier should conduct comparative tests to determine if there is

to dust, moisture, loose fibers, etc., carried away by the air

a statistical bias between their laboratories. Competent statis-

stream during the test.

tical assistance is recommended for the investigation of bias.

3.1.3 lint, n—in loose cotton, fibers mostly of spinnable

As a minimum, the two parties should take a group of test

length.

specimens that are as homogeneous as possible and that are

from a lot of material of the type in question. The test

specimens should then be randomly assigned in equal numbers

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

to each laboratory for testing.The average results from the two

and is the direct responsibility of Subcommittee D13.11 on Cotton and Fibers.

laboratories should be compared using Student’s t-test for

Current edition approved July 15, 1995. Published September 1995. Originally

unpaireddataandanacceptableprobabilitylevelchosenbythe

published as D 2812 – 69 T. Last previous edition D 2812 – 88.

Annual Book of ASTM Standards, Vol 07.01. two parties before the testing is begun. If a bias is found, either

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

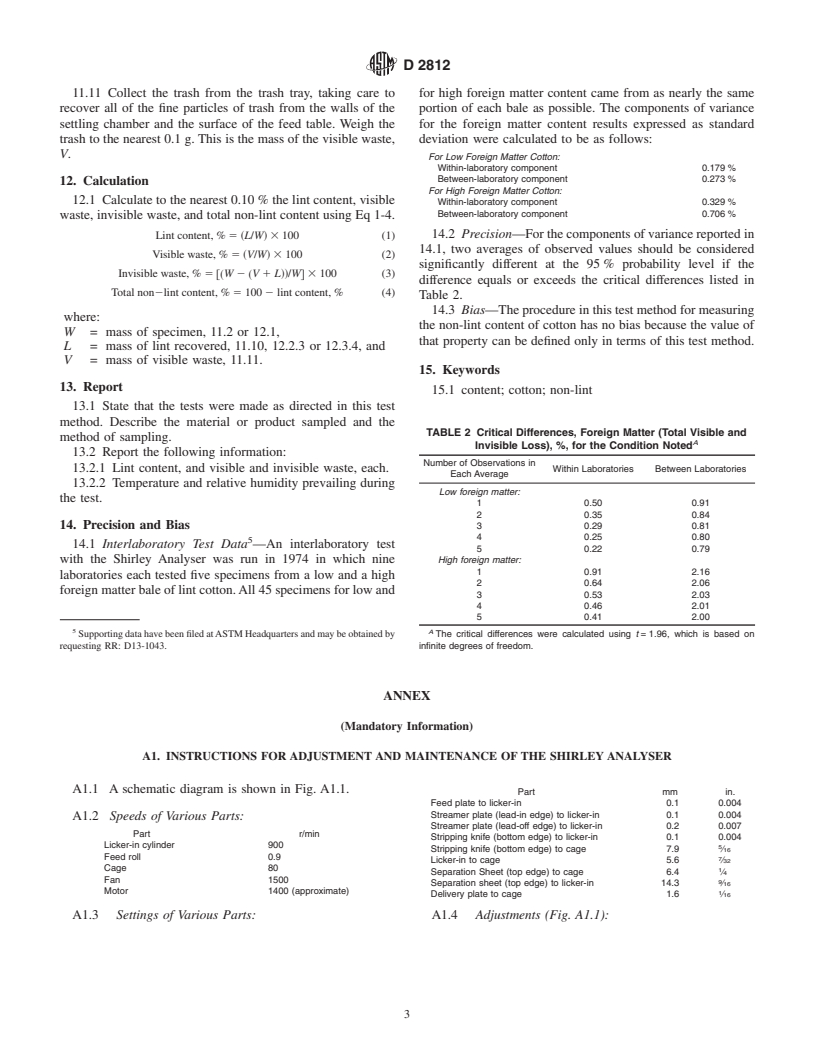

D 2812

its cause must be found and corrected or the purchaser and the 10. Conditioning

supplier must agree to interpret future test results with consid-

10.1 Do not precondition the test specimens.

eration to the known bias.

10.2 Bring the laboratory sample from the prevailing atmo-

5.2 This test method gives data on the non-lint content of

sphere to approximate moisture equilibrium with the air of the

raw cotton which can be used as a basis for: (1) estimating the

room in which the test will be performed by exposing the

net amount of manufactured textile product obtainable from

samples at least 24 h.

raw cotton; (2) predicting the quality of cotton textile products,

particularly their aesthetic properties; (3) assembling and

NOTE 1—Changes in relative humidity during the test will seriously

blending bales in a mix on a non-lint content basis; (4) affect test results.Although tests may be made in the standard atmosphere

for testing textiles as defined in Terminology D 123, studies have shown

adjusting ginning and textile processing machines for maxi-

that the most efficient separation of lint and foreign matter occurs at a

mum efficiency in cleaning lint; and (5) relating non-lint

relative humidity of 60 % or less. Temperature variations up to 6 1.1°C

content of cotton to end-product quality and processing effi-

(2°F) or variations up to 6 2 % relative humidity during the conditioning

ciency.

period do not introduce any significant errors, but atmospheric conditions

should be constant between the times of weighing the specimen and

6. Apparatus

weighing the clean lint or waste, or both.

6.1 Testing Instrument—Shirley Analyzer, commercially

11. Procedure

available non-lint testing machine operating on mechanical-

pneumatic principles, described in Annex A1.

11.1 Clean the delivery box, trash tray, and settling cham-

6.2 Laboratory Balance, with a capacity of 200 g, a sensi-

ber. If the machine has not been operated previously during the

tivity of 0.01 g, and a pan large enough to weigh a 100-g

day, start the motor and run the machine for 2 to 3 min with the

specimen of cotton.

clutch disengaged and the feed roller inoperative.

11.2 Weigh the specimen (see 8.2.1 and 8.2.2) to the nearest

7. Hazards

0.1 g. Record the mass, W.

7.1 Use care in running the specimen through the machine.

11.3 Placement of the Specimen on the Feed Table:

Spread the specimen uniformly on the feed plate so that fingers

11.3.1 For testing raw cotton or picker laps, arrange about

do not have to come into contact with the feed roll.

one third of the specimen in a uniform layer of small tufts on

7.2 In conducting tests, the machine should be completely

the feed table, tearing apart hard lumps where necessary.

stopped before cleaning any clumps of fiber or trash which

11.3.2 For testing slivers, spread short lengths on the feed

have adhered to the upper parts of the delivery box or trash

table perpendicular to the feed roller.

tray.

11.3.3 For testing ginning and processing waste, arrange

about one fourth of the specimen uniformly on the feed table.

8. Sampling, Selection, and Number of Specimens

11.4 Open the air control valve, engage the feed roller

8.1 Lot Sample—For acceptance testing, take as directed in

clutch and start feeding the specimen through the machine.

Practice D 1441.

Observe the character of the trash as it begins to fall into the

8.2 Laboratory Sample:

tray. Only small amounts of unopened lint should be falling

8.2.1 Unprocessed or Processed Cotton—Take the labora-

with the trash during the first passage. If there are hard tufts in

tory sample and the test specimen as directed in Practice

the specimen, it may be necessary to tighten the loading

D 1441. Do not blend the laboratory sample. Handle it in such

springs on the feed rollers.

a way as to prevent loss of foreign matter. Take a laboratory

11.5 As the specimen is fed into the machine, continue

sample large enough to provide two 100 6 5-g test specimens.

placing portions of it on the feed table to maintain a uniform

8.2.2 Ginning or Processing Waste—Take as a laboratory

feed rate until the whole specimen has been processed as

sample all the waste accumulated during the test run which

indicated by the absence of fibers under the streamer plate.

should last long enough to provide one specimen weighing not

11.6 When all of the specimen has passed under the feed

less than 45 g (1 lb).

8.3 Test Specimens—Test two 100 6 5-g specimens from roller, collect all lint-bearing trash from the settling chamber

and trash tray. Spread it over a small central area of the feed

each laboratory sampling unit.

plate and pass it through the analyser.

9. Preparation of Specimens

11.7 Disengage the clutch and close th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.