ASTM D914-00(2006)

(Test Method)Standard Test Methods for Ethylcellulose

Standard Test Methods for Ethylcellulose

SIGNIFICANCE AND USE

The results of this test are used for calculating the total solids in the sample and, by common usage, all materials volatile at this test temperature are designated as moisture.

Moisture analysis (along with sulfated ash) is used to calculate the amount of active polymer in the material and shall be considered when determining the amount of ethylcellulose in various functions.

SCOPE

1.1 These test methods cover the testing of ethylcellulose.

1.2 The test procedures appear in the following order: SectionsMoisture to Sulfated Ash to Chlorides (as Sodium Chloride) to Ethoxyl Content to Viscosity to

1.3The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This test method covers the determination of the volatile content of ethylcellulose.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D914 − 00 (Reapproved 2006)

StandardTest Methods for

Ethylcellulose

This standard is issued under the fixed designation D914; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope conform to the specifications of the Committee on Analytical

Reagents of the American Chemical Society, where such

1.1 These test methods cover the testing of ethylcellulose.

specifications are available. Where such specifications have

1.2 The test procedures appear in the following order:

not been established, reagents of the best grade available shall

Sections

be used. References to water shall be understood to mean

Moisture 4 to 6

distilled water.

Sulfated Ash 7 to 11

Chlorides (as Sodium Chloride) 12 to 16

Ethoxyl Content 20 to 24 MOISTURE

Viscosity 25 to 39

1.3 The values stated in SI units are to be regarded as

4. Scope

standard. The values given in parentheses are for information

4.1 Thistestmethodcoversthedeterminationofthevolatile

only.

content of ethylcellulose.

1.4 This standard may involve hazardous materials,

operations, and equipment. This standard does not purport to

5. Significance and Use

address all of the safety concerns, if any, associated with its

5.1 The results of this test are used for calculating the total

use. It is the responsibility of the user of this standard to

solids in the sample and, by common usage, all materials

establish appropriate safety and health practices and deter-

volatile at this test temperature are designated as moisture.

mine the applicability of regulatory limitations prior to use.

5.2 Moisture analysis (along with sulfated ash) is used to

2. Referenced Documents

calculatetheamountofactivepolymerinthematerialandshall

2.1 ASTM Standards:

be considered when determining the amount of ethylcellulose

D362 Specification for Industrial Grade Toluene

in various functions.

D446 Specifications and Operating Instructions for Glass

Capillary Kinematic Viscometers

6. Apparatus

D841 Specification for Nitration Grade Toluene

6.1 Oven, gravity convection, capable of maintaining a

D4794 Test Method for Determination of Ethoxyl or Hy-

temperature of 105 6 3°C.

droxyethoxyl Substitution in Cellulose Ether Products by

Gas Chromatography

6.2 Weighing Bottles.

E1 Specification for ASTM Liquid-in-Glass Thermometers

6.3 Analytical Balance.

3. Purity of Reagents and Materials

7. Procedure

3.1 Reagent grade chemicals shall be used in all tests.

Unless otherwise indicated, all of the reagents used shall

7.1 Weigh accurately 2 to5gofthe sample to the nearest

0.001 g into a tared dish (fitted with a lid) and dry for2hinan

These test methods are under the jurisdiction of ASTM Committee D01 on

oven at 100 to 105°C. Remove the dish from the oven, cover

Paint and Related Coatings, Materials, and Applications and are the direct

with a lid, cool in a desiccator, and weigh.

responsibility of Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved April 1, 2006. Published April 2006. Originally

approved in 1947. Last previous edition approved in 2000 as D914 – 00. DOI:

10.1520/D0914-00R06.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Reagent Chemicals, American Chemical Society Specifications, American

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Standards volume information, refer to the standard’s Document Summary page on listed by the American Chemical Society, see Analar Standards for Laboratory

the ASTM website. Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Withdrawn. The last approved version of this historical standard is referenced and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

on www.astm.org. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D914 − 00 (Reapproved 2006)

8. Calculation 16. Precision and Bias

8.1 Calculate the percent moisture, M as follows: 16.1 Precision—Statistical analysis of interlaboratory (re-

producibility) test results indicates a precision of 610 % at the

M 5 A/B 3100 (1)

~ !

95 % confidence level.

where:

16.2 Bias—No statement of bias can be made as no suitable

A = mass loss on heating, g, and

reference material is available as a standard.

B = sample used, g.

CHLORIDES (as Sodium Chloride)

9. Precision and Bias

17. Scope

9.1 Precision—Statistical analysis of intralaboratory (re-

peatability) test results indicates a precision of 65 % at the

17.1 This test method covers the determination of the

95 % confidence level.

chloride content of ethylcellulose.

9.2 Bias—No statement of bias can be made as no suitable

18. Significance and Use

reference material is available as a standard.

18.1 Sodium chloride is a major by-product of the ethylcel-

SULFATED ASH

lulose manufacturing process. This test is a measure of the

purity of ethylcellulose. Chlorides may also affect solution

10. Scope

properties.

10.1 This test method covers the determination of the

residue on ignition of ethylcellulose after a specimen has been

19. Apparatus

treated with sulfuric acid.

19.1 Titration pH Meter.

11. Significance and Use

19.2 Mercury-Mercurous Sulfate Reference Electrode—The

11.1 This test method (along with moisture) is used to electrode uses a potassium sulfate electrolyte to avoid chloride

contamination from a chloride electrolyte.

calculate the active polymer in the material. It shall be used

when testing ethylcellulose in United States government regu-

19.3 Silver-Silver Chloride Electrode—The electrode is

lated applications. Excessive ash may also affect solution

coated with silver chloride periodically. Prepare the electrode

clarity and film properties.

by polishing with fine steel wool, briefly soaking it in 5 %

potassium cyanide solution, and rinsing it with water. Coat the

12. Apparatus

electrode with silver chloride by electrodeposition from 0.1 N

12.1 Muffle Furnace.

potassiumchloridesolutionusinga3-Vdrycellandaplatinum

wire electrode. Connect the silver electrode to the positive pole

12.2 Crucibles, either porcelain, 30–mLhigh, form cracked,

of the battery and electrolyze for 20 s; then reverse the

platinum.

connections for 5 s. Repeat these operations twice, and finally,

13. Reagent

chloridize the silver electrode for 20 s at the positive terminal.

Store the silver electrode in 0.1 N potassium chloride solution.

13.1 Sulfuric Acid (sp gr 1.84)—Concentrated sulfuric acid

Rinse the electrode with water and wipe it with a soft tissue

(H SO ).

2 4

before each titration.

14. Procedure

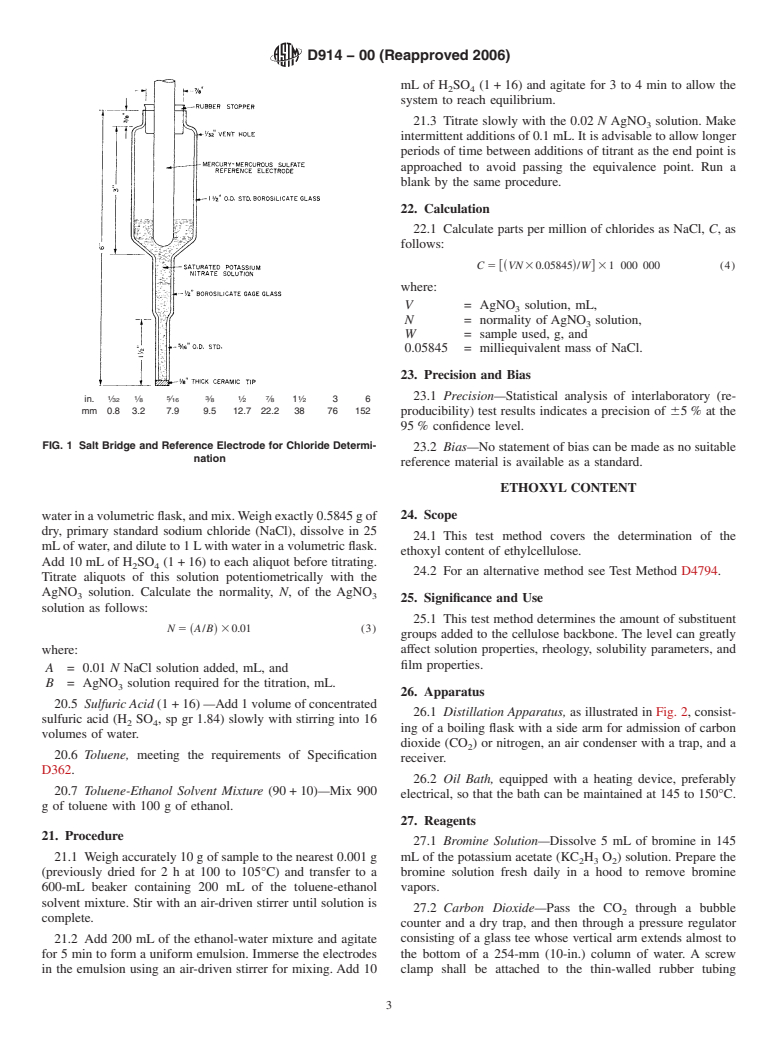

19.4 Salt Bridge for Reference Electrode—Fig. 1 shows one

14.1 Ignite a crucible for 10 to 15 min at 800 6 25°C, cool

configuration in use. Exact dimensions are not important. The

in a desiccator, and weigh to the nearest 0.001 g.

salt bridge is used to keep the reference electrode from

plugging with the ethylcellulose slurry.

14.2 Weigh about5gof sample to the nearest 0.001 g

(previously dried for3hat 105°C) into the crucible. Burn off

19.5 Air-Driven Stirrer.

the bulk of the carbonaceous material directly over a flame.

After cooling, add 1 mLof H SO in such a way as to moisten 20. Reagents

2 4

the entire ash; then cautiously heat with the burner to dense

20.1 Ethanol (95 volume %), undenatured or specially

white fumes. Ignite in a muffle furnace at 800 6 25°C until all

denatured conforming to Formula 2B of the U.S. Bureau of

signs of carbon are gone. Cool in a desiccator and reweigh to

Internal Revenue.

the nearest 0.001 g.

20.2 Ethanol-Distilled Water Solvent Mixture (80 + 20)—

15. Calculation Mix 800 g of 2B ethanol with 200 g of water. Add 7.5 g of

aerosol OT 100 % surface-active agent per 3000 g of ethanol-

15.1 Calculate the percent ash (as sulfate), C, as follows:

water mixture.

C 5 ~A/B! 3100 (2)

20.3 Potassium Nitrate (KNO ) Solution (saturated) for salt

where:

bridge (Fig. 1).

A = ash, g, and

20.4 Silver Nitrate, Standard Solution (0.02 N)—Dissolve

B = sample used, g.

3.4 g of silver nitrate (AgNO ) in water, dilute to 1 L with

D914 − 00 (Reapproved 2006)

mL of H SO (1 + 16) and agitate for 3 to 4 min to allow the

2 4

system to reach equilibrium.

21.3 Titrate slowly with the 0.02 N AgNO solution. Make

intermittent additions of 0.1 mL. It is advisable to allow longer

periods of time between additions of titrant as the end point is

approached to avoid passing the equivalence point. Run a

blank by the same procedure.

22. Calculation

22.1 Calculate parts per million of chlorides as NaCl, C,as

follows:

C 5 VN 30.05845 /W 31 000 000 (4)

@~ ! #

where:

V = AgNO solution, mL,

N = normality of AgNO solution,

W = sample used, g, and

0.05845 = milliequivalent mass of NaCl.

23. Precision and Bias

1 1 5 3 1 7 1 23.1 Precision—Statistical analysis of interlaboratory (re-

in. ⁄32 ⁄8 ⁄16 ⁄8 ⁄2 ⁄8 1 ⁄2 3 6

mm 0.8 3.2 7.9 9.5 12.7 22.2 38 76 152

producibility) test results indicates a precision of 65 % at the

95 % confidence level.

FIG. 1 Salt Bridge and Reference Electrode for Chloride Determi-

23.2 Bias—No statement of bias can be made as no suitable

nation

reference material is available as a standard.

ETHOXYL CONTENT

24. Scope

waterinavolumetricflask,andmix.Weighexactly0.5845gof

dry, primary standard sodium chloride (NaCl), dissolve in 25

24.1 This test method covers the determination of the

mLof water, and dilute to 1 Lwith water in a volumetric flask.

ethoxyl content of ethylcellulose.

Add 10 mL of H SO (1 + 16) to each aliquot before titrating.

2 4

24.2 For an alternative method see Test Method D4794.

Titrate aliquots of this solution potentiometrically with the

AgNO solution. Calculate the normality, N, of the AgNO

3 3

25. Significance and Use

solution as follows:

25.1 This test method determines the amount of substituent

N 5 ~A/B! 30.01 (3)

groups added to the cellulose backbone. The level can greatly

affect solution properties, rheology, solubility parameters, and

where:

film properties.

A = 0.01 N NaCl solution added, mL, and

B = AgNO solution required for the titration, mL.

26. Apparatus

20.5 Sulfuric Acid (1 + 16) —Add 1 volume of concentrated

26.1 Distillation Apparatus, as illustrated in Fig. 2, consist-

sulfuric acid (H SO , sp gr 1.84) slowly with stirring into 16

2 4

ing of a boiling flask with a side arm for admission of carbon

volumes of water.

dioxide (CO ) or nitrogen, an air condenser with a trap, and a

20.6 Toluene, meeting the requirements of Specification

receiver.

D362.

26.2 Oil Bath, equipped with a heating device, preferably

20.7 Toluene-Ethanol Solvent Mixture (90 + 10)—Mix 900

electrical, so that the bath can be maintained at 145 to 150°C.

g of toluene with 100 g of ethanol.

27. Reagents

21. Procedure

27.1 Bromine Solution—Dissolve 5 mL of bromine in 145

21.1 Weigh accurately 10 g of sample to the nearest 0.001 g mL of the potassium acetate (KC H O ) solution. Prepare the

2 3 2

(previously dried for2hat100to 105°C) and transfer to a bromine solution fresh daily in a hood to remove bromine

600-mL beaker containing 200 mL of the toluene-ethanol vapors.

solvent mixture. Stir with an air-driven stirrer until solution is

27.2 Carbon Dioxide—Pass the CO through a bubble

complete.

counter and a dry trap, and then through a pressure regulator

21.2 Add 200 mL of the ethanol-water mixture and agitate consisting of a glass tee whose vertical arm extends almost to

for 5 min to form a uniform emulsion. Immerse the electrodes the bottom of a 254-mm (10-in.) column of water. A screw

in the emulsion using an air-driven stirrer for mixing. Add 10 clamp shall be attached to the thin-walled rubber tubing

D914 − 00 (Reapproved 2006)

keepthecurrentofCO goingafterthedistillationisendedand

until the apparatus has cooled; this will prevent air from being

sucked into the apparatus. Put the purified HI in small, brown,

glass-stoppered bottles, previously swept out with CO , and

seal the stoppers with molten paraffin. Store in a dark place.To

minimize decomposition of HI due to contact with air, run CO

into the bottle while withdrawing portions of the acid for use.

27.6 PhosphorusSlurry(0.06g/100mL)—Addabout0.06g

ofredphosphorusto100mLofwater.Shakewellbeforeusing.

27.7 Potassium Acetate Solution (100 g/L)—Dissolve 100 g

of anhydrous potassium acetate (KC H O ) crystal in 1 L of a

2 3 2

solution containing 900 mL of glacial acetic acid and 100 mL

of acetic anhydride.

27.8 Potassium Iodide (KI).

27.9 Sodium Acetate Solution (220 g/L)—Dissolve 220 g of

anhydrous sodium acetate in water and dilute to 1 L.

27.10 Sodium Thiosulfate, Standard Solution (0.1 N)—

Dissolve 25 g of sodium thiosulfate (Na S O ·5H O) in 200

2 2 3 2

mL of water and dilute to 1 L. Use freshly boiled and cooled

water. It is preferable to allow the solution to stand for a few

days before standardization. Standardize the solution against

0.1000 N potassium dichromate (K Cr O ) solution prepared

2 2 7

by dissolving exactly 4.9037 g of K Cr O (National Institute

2 2 7

of Standards and Technology Standard Sample No. 136) in

water and diluting to 1 L in a volumetric flask. By means of a

buret, measure accurately 35 to 45 mLof the K Cr O solution

2 2 7

into a 250-mL Erlenmeyer flask. Add2gofKIand50mLof

FIG. 2 Distillation Apparatus for Ethoxyl Determination

sulfuricacid(H SO ,1 + 9)andallowtostandforabout5min.

2 4

Titrate the liberated iodine with the Na S O solution, using

2 2 3

starch indicator solution near the end point. At the end point,

connecting the horizontal arm of the tee with the boiling flask.

This arrangement permits regulation of the flow of gas and the blue color of the starch indicator will be destroyed, leaving

the pale green color of the chromate ion. The normality of the

allowsanyexcessgastoescape.Nitrogenmaybeusedinplace

Na S O , solution should be checked at least once a week.

of CO .

2 2 3

Calculate the normality, N, of the Na S O solution as follows:

2 2 3

27.3 Formic Acid (90 %).

N 5 A/B 30.1 (5)

~ !

27.4 Gelatin Capsules—Gelatin capsules of a suitable size

to hold from 50 to 60 mg of the dried sample will be required. where:

A = 0.1000 N K Cr O solution added, mL, and

27.5 Hydriodic Acid (sp gr 1.70) —Hydriodic acid (HI)

2 2 7

B =Na S O solution required for the titration, mL.

forms with water a constant-boiling mixture (boiling point 126 2 2 3

to127°C)thatc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.