ASTM F1273-91(1996)e1

(Specification)Standard Specification for Tank Vent Flame Arresters

Standard Specification for Tank Vent Flame Arresters

SCOPE

1.1 This specification provides the minimum requirements for design, construction, performance, and testing of tank vent flame arresters.

1.2 This specification is intended for flame arresters protecting systems containing vapors of flammable or combustible liquids where vapor temperatures do not exceed 60°C. The test media defined in 9.1.1 can be used except where arresters protect systems handling vapors with a maximum experimental safe gap (MESG) below 0.9 mm. Flame arresters protecting such systems must be tested with appropriate media (the same vapor or a media having a MESG no greater than the vapor). Various gases and their respective MESG are listed in Table 1. Note 1-Flame arresters meeting this specification also comply with the minimum requirements of the International Maritime Organization, Maritime Safety Committee Circular No. 373 (MSC/Circ. 373/Rev. 1).

1.3 The values stated in either inch-pound or SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test methods portions, Sections 8 and 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

General Information

Standards Content (Sample)

e1

Designation: F 1273 – 91 (Reapproved 1996) An American National Standard

Standard Specification for

Tank Vent Flame Arresters

This standard is issued under the fixed designation F 1273; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in November 1996.

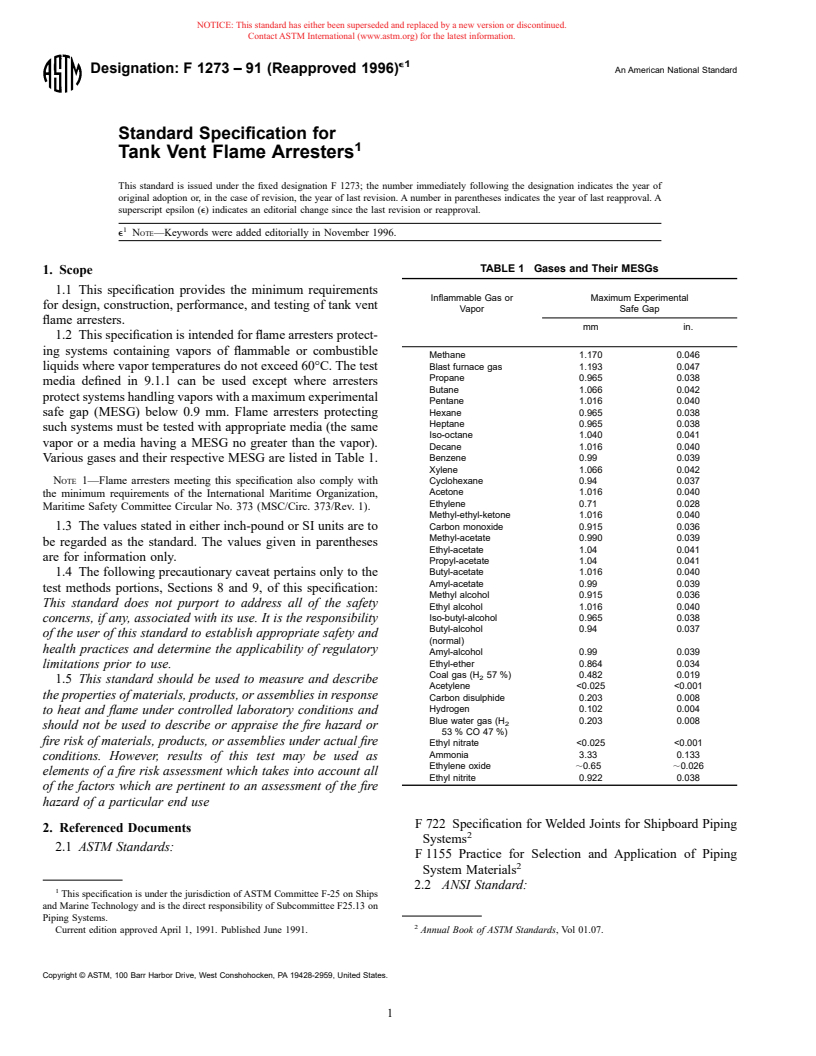

TABLE 1 Gases and Their MESGs

1. Scope

1.1 This specification provides the minimum requirements

Inflammable Gas or Maximum Experimental

for design, construction, performance, and testing of tank vent

Vapor Safe Gap

flame arresters.

mm in.

1.2 This specification is intended for flame arresters protect-

ing systems containing vapors of flammable or combustible

Methane 1.170 0.046

liquids where vapor temperatures do not exceed 60°C. The test Blast furnace gas 1.193 0.047

Propane 0.965 0.038

media defined in 9.1.1 can be used except where arresters

Butane 1.066 0.042

protect systems handling vapors with a maximum experimental

Pentane 1.016 0.040

safe gap (MESG) below 0.9 mm. Flame arresters protecting Hexane 0.965 0.038

Heptane 0.965 0.038

such systems must be tested with appropriate media (the same

Iso-octane 1.040 0.041

vapor or a media having a MESG no greater than the vapor).

Decane 1.016 0.040

Benzene 0.99 0.039

Various gases and their respective MESG are listed in Table 1.

Xylene 1.066 0.042

NOTE 1—Flame arresters meeting this specification also comply with

Cyclohexane 0.94 0.037

Acetone 1.016 0.040

the minimum requirements of the International Maritime Organization,

Ethylene 0.71 0.028

Maritime Safety Committee Circular No. 373 (MSC/Circ. 373/Rev. 1).

Methyl-ethyl-ketone 1.016 0.040

1.3 The values stated in either inch-pound or SI units are to Carbon monoxide 0.915 0.036

Methyl-acetate 0.990 0.039

be regarded as the standard. The values given in parentheses

Ethyl-acetate 1.04 0.041

are for information only.

Propyl-acetate 1.04 0.041

Butyl-acetate 1.016 0.040

1.4 The following precautionary caveat pertains only to the

Amyl-acetate 0.99 0.039

test methods portions, Sections 8 and 9, of this specification:

Methyl alcohol 0.915 0.036

This standard does not purport to address all of the safety

Ethyl alcohol 1.016 0.040

Iso-butyl-alcohol 0.965 0.038

concerns, if any, associated with its use. It is the responsibility

Butyl-alcohol 0.94 0.037

of the user of this standard to establish appropriate safety and

(normal)

health practices and determine the applicability of regulatory

Amyl-alcohol 0.99 0.039

Ethyl-ether 0.864 0.034

limitations prior to use.

Coal gas (H 57 %) 0.482 0.019

1.5 This standard should be used to measure and describe

Acetylene <0.025 <0.001

the properties of materials, products, or assemblies in response

Carbon disulphide 0.203 0.008

Hydrogen 0.102 0.004

to heat and flame under controlled laboratory conditions and

Blue water gas (H 0.203 0.008

should not be used to describe or appraise the fire hazard or

53%CO47%)

fire risk of materials, products, or assemblies under actual fire

Ethyl nitrate <0.025 <0.001

Ammonia 3.33 0.133

conditions. However, results of this test may be used as

Ethylene oxide ;0.65 ;0.026

elements of a fire risk assessment which takes into account all

Ethyl nitrite 0.922 0.038

of the factors which are pertinent to an assessment of the fire

hazard of a particular end use

F 722 Specification for Welded Joints for Shipboard Piping

2. Referenced Documents

Systems

2.1 ASTM Standards:

F 1155 Practice for Selection and Application of Piping

System Materials

2.2 ANSI Standard:

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.13 on

Piping Systems.

Current edition approved April 1, 1991. Published June 1991. Annual Book of ASTM Standards, Vol 01.07.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1273

B16.5 Pipe Flanges and Flanged Fittings 6. Materials

2.3 Other Documents:

6.1 The flame arrester housing, and other parts or bolting

ASME Boiler and Pressure Vessel Code: Section VIII,

used for pressure retention, shall be constructed of materials

Division 1, Pressure Vessels;

listed in Practice F 1155, or Section VIII, Division 1 of the

ASME Boiler and Pressure Vessel Code: Section IX,

ASME Boiler and Pressure Vessel Code.

Welding and Brazing Qualifications

6.1.1 Arrester, elements, gaskets, and seals shall be of

International Maritime Organization, Maritime Safety Com-

materials resistant to attack by seawater and the liquids and

mittee: MSC/Circ. 373/Rev. 1 Revised Standards for the

vapors contained in the tank being protected (see 5.1.3).

Design, Testing and Locating of Devices to Prevent the

6.2 Nonmetallic materials, other than gaskets and seals,

Passage of Flame into Cargo Tanks in Tankers

shall not be used in the construction of pressure-retaining

International Electrotechnical Commission: Publication 79-

components of the flame arrester.

1 Electrical Apparatus for Explosive Gas Atmospheres

6.2.1 Nonmetallic gaskets and seals shall be noncombus-

tible and suitable for the service intended.

3. Terminology

6.3 Bolting materials, other than those in 6.1, shall be at

3.1 Definitions:

least equal to those listed in Table 1 of ANSI B16.5.

3.1.1 flame arrester—a device to prevent the passage of

6.4 The possibility of galvanic corrosion shall be considered

flame in accordance with a specified performance standard. Its

in the selection of materials.

flame arresting element is based on the principle of quenching.

6.5 All other parts shall be constructed of materials suitable

3.1.2 flame passage—the transmission of a flame through a

for the service intended.

flame arrester.

3.1.3 flame speed—the speed at which a flame propagates

7. Other Requirements

along a pipe or other system.

7.1 Flame arrester housings shall be gastight to prevent the

3.1.4 gasoline vapors—a nonleaded petroleum distillate

escape of vapors.

consisting essentially of aliphatic hydrocarbon compounds

7.2 Flame arrester elements shall fit in the housing in a

with a boiling range of approximately 65 to 75°C.

manner that will ensure tightness of metal-to-metal contacts in

4. Classification

such a way that flame cannot pass between the element and the

housing.

4.1 The two types of flame arresters covered in this speci-

7.2.1 The net free area through flame arrester elements shall

fication are classified as follows:

be at least 1.5 times the cross-sectional area of the arrester

4.1.1 Type I—Flame arresters acceptable for end-of-line

inlet.

applications.

7.3 Housings and elements shall be of substantial construc-

4.1.2 Type II—Flame arresters acceptable for in-line appli-

tion and designed for the mechanical and other loads intended

cations.

during service. In addition, they shall be capable of withstand-

5. Ordering Information

ing the maximum and minimum pressures and temperatures to

which the device may be exposed under both normal and the

5.1 Orders for flame arresters under this specification shall

specified fire test conditions in Section 9.

include the following information, as applicable:

5.1.1 Type (I or II), 7.4 Threaded or flanged pipe connections shall comply with

the applicable B–16 standards in Practice F 1155. Welded

5.1.2 Nominal pipe size,

5.1.3 Each gas or vapor in the tank being protected by the joints shall comply with Specification F 722.

7.5 All flat joints of the housing shall be machined true and

flame arrester and the corresponding MESG,

5.1.4 Inspection and tests other than those specified by this shall provide for a joint having adequate metal-to-metal

contact.

specification,

5.1.5 Anticipated ambient air temperature range, 7.6 Where welded construction is used for pressure-

5.1.6 Purchaser’s inspection requirements (see 10.1), retaining components, welded joint design details, welding,

5.1.7 Description of installation (distance and configuration and nondestructive testing shall be in accordance with Section

of pipe between the arrester and the atmosphere or potential VIII, Division 1 of the ASME Code and Specification F 722.

ignition source) (see 8.2.4.2), Welders and weld procedures shall be qualified in accordance

5.1.8 Materials of construction (see Section 6), and with Section IX of the ASME Code.

5.1.9 Maximum flow rate and the design pressure drop for 7.7 The design of flame arresters shall allow for ease of

that maximum flow rate. inspection and removal of internal elements for replacement,

cleaning, or repair without removal of the entire device from

the system.

Available from American National Standards Institute, 11 W. 42nd St., 13th

7.8 Flame arresters shall allow for efficient drainage of

Floor, New York, NY 10036.

condensate without impairing their efficiency to prevent the

Available from American Society of Mechanical Engineers, 345 E. 47th St.,

New York, NY 10017.

passage of flame.

Available from International Maritime Organization, 4 Albert Embankment,

7.8.1 Where the design does not permit complete drainage

London SE1 7SR, England.

of condensate through its connection to the tank, the housing

Available from International Electrotechnical Commission, 1 rue de Varembe,

Geneva, Switzerland. shall be fitted with a plugged drain opening on the side of the

F 1273

atmospheric outlet of not less than ⁄2-in. nominal pipe size burn and flashback in accordance with the test procedures in

(NPS ⁄2). Section 9. The following constraints apply:

7.9 All fastenings shall be protected against loosening. 8.2.4.1 Where a Type I flame arrester is provided with

7.10 Flame arresters shall be designed and constructed to cowls, weather hoods, deflectors, etc., it shall be tested in each

minimize the effect of fouling under normal operating condi- configuration in which it is provided.

tions. 8.2.4.2 Type II arresters shall be specifically tested with the

7.11 Flame arresters shall be capable of operating over the inclusion of all pipes, tees, bends, cowls, weather hoods, and so

full range of ambient air temperatures anticipated. forth, which may be fitted between the arrester and the

7.12 End-of-line flame arresters shall be so constructed as to atmosphere.

direct the efflux vertically upward. 8.2.5 Devices that are provided with a heating arrangement

7.13 Flame arresters shall be of first class workmanship and shall pass the required tests at the heat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.