ASTM E2189-02

(Test Method)Standard Test Method for Testing Resistance to Fogging in Insulating Glass Units

Standard Test Method for Testing Resistance to Fogging in Insulating Glass Units

SCOPE

1.1 This test method covers procedures for testing the resistance to fogging of preassembled permanently sealed insulating glass units or insulating glass units with capillary tubes intentionally left open.

1.2 This test method is applicable only to sealed insulating glass units that are constructed with glass.

1.3 The unit construction used in this test method contains construction details that are essential components of the test. Different types of glass, different glass thicknesses and different airspace sizes may affect the test results.

1.4 This test method is not applicable to sealed insulating glass units containing a spandrel glass coating due to testing limitations.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2189–02

Standard Test Method for

Testing Resistance to Fogging in Insulating Glass Units

This standard is issued under the fixed designation E2189; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2190 Specification for Insulating Glass Unit Performance

and Evaluation

1.1 This test method covers procedures for testing the

resistance to fogging of preassembled permanently sealed

3. Terminology

insulating glass units or insulating glass units with capillary

3.1 Definition of Terms:

tubes intentionally left open.

3.1.1 For definitions of terms found in the standard, refer to

1.2 This test method is applicable only to sealed insulating

Terminology C717,Terminology C162 andTerminology E631.

glass units that are constructed with glass.

3.2 Definitions of Terms Specific to This Standard:

1.3 The unit construction used in this test method contains

3.2.1 fog, n—visible deposits present after testing in accor-

construction details that are essential components of the test.

dance with Section 8.

Different types of glass, different glass thicknesses and differ-

ent airspace sizes may affect the test results.

4. Significance and Use

1.4 This test method is not applicable to sealed insulating

4.1 This test method is intended to provide a means for

glass units containing a spandrel glass coating due to testing

testingtheresistancetofogginginsealedinsulatingglassunits.

limitations.

4.2 This test method is also intended to provide a means for

1.5 The values stated in SI units are to be regarded as the

testing the resistance to fogging caused by components in the

standard. The values given in parentheses are for information

interior of the unit. These interior components include, but are

only.

not limited to, suspended or applied films, decorative compo-

1.6 This standard does not purport to address all of the

nents, muntins, and coatings.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Test Specimens

priate safety and health practices and determine the applica-

5.1 Each test specimen shall be manufactured in accordance

bility of regulatory limitations prior to use.

with Test Method E2188, Section 5 or Specification E2190,

Section 5, or both.

2. Referenced Documents

2 5.2 For double-glazed units, at least three specimens of

2.1 ASTM Standards:

identical component materials and construction shall be sub-

C162 Terminology of Glass and Glass Products

4 mitted.

C717 Terminology of Building Seals and Sealants

5.3 For triple-glazed units, at least five specimens of iden-

E631 Terminology of Building Constructions

5 tical component materials and construction shall be submitted.

E2188 Test Method for Insulating Glass Unit Performance

For these units, the manufacturer must specify the exterior

surface.

This test method is under the jurisdiction of ASTM Committee E06 on

NOTE 1—Certain reflective coatings may interfere with the ability to

Performance of Buildings and is the direct responsibility of Subcommittee E06.22

view fog.

on Durability Performance of Building Constructions.

5.4 During all stages of storage and handling, the units shall

Current edition approved March 10, 2002. Published May 2002. DOI: 10.1520/

E2189-02.

beheldinaverticalpositionwithequalsupporttoallpanesand

Annual Book of ASTM Standards, Vol 15.02.

no compression loading.

Annual Book of ASTM Standards, Vol 04.07.

5.5 Two units shall be randomly selected for this test.

Annual Book of ASTM Standards, Vol 04.11.

Annual Book of ASTM Standards, Vol 04.12. Damaged units shall not be tested.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2189–02

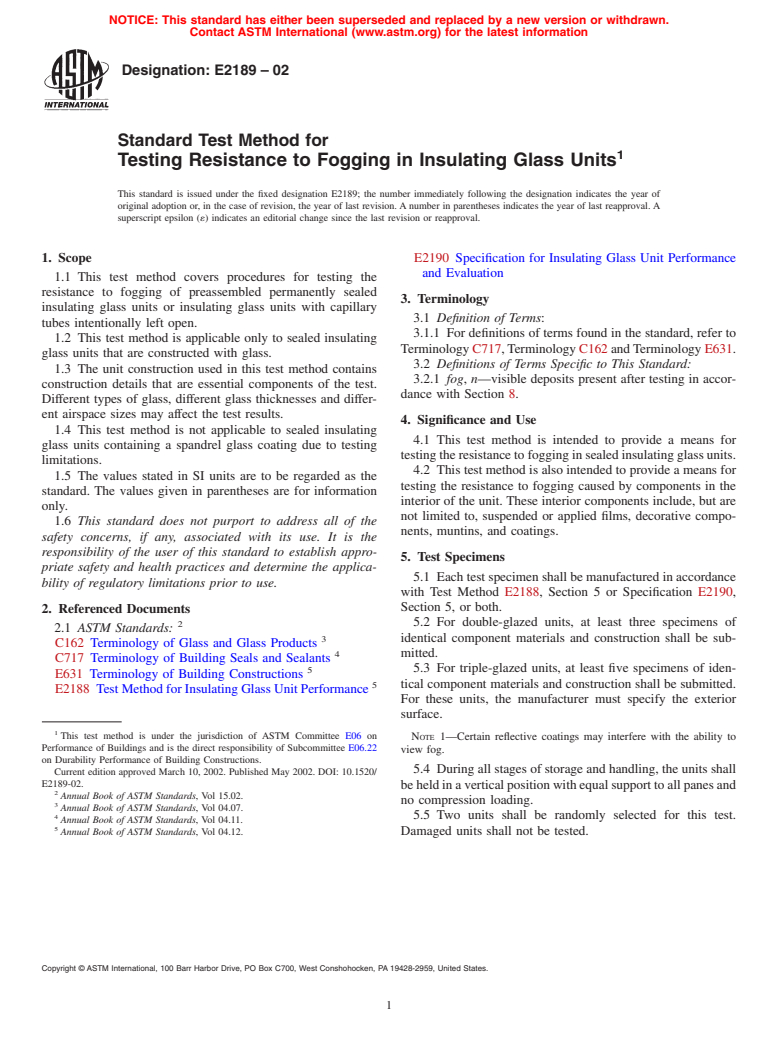

6. Apparatus 6.1.4 The test specimen supports are located as shown in

Fig. 1.

6.1 Volatile Fog Test Apparatus:

6.1.5 The cooling plates are constructed of a conductive

6.1.1 The dimensions and components are found in Fig. 1.

material such as copper or brass. The cooling plates shall be

The construction of the apparatus shall be capable of maintain-

nominally 150 6 5 mm (5.91 6 0.20 in.) diameter and shall be

ing 50 6 3°C (122 6 5°F). In order to maintain this

placed directly in complete contact with the glass surface for

temperature, a fan shall be mounted in the box. The fan shall

the duration of the test. Alternatively, a rectangular cooling

run continuously.

2 2

plate shall be 0.0177 6 0.0006 m (27.4 6 1.0 in. ) in area.

6.1.2 The apparatus shall be constructed from sturdy, solid

6.1.6 The cooling water temperature is determined as the

materials that minimize the escape of ultraviolet light into the

1 3 water immediately exits the apparatus from each cooling plate

surrounding area. ⁄2 or ⁄4 in. plywood has been found suitable

as shown in Figure 1. The cooling water temperature at these

for this purpose. Stainless steel construction is also acceptable.

locations shall be 21 6 2°C.

6.1.3 The interior of the apparatus shall have a reflective

6.2 Ultraviolet Light Source:

surface. If plywood is used to construct the apparatus, then line

the entire interior of the apparatus with aluminum foil or other

NOTE 2—Warning: Ultraviolet light sources used in this test method

reflective material. are harmful to the human body, especially to the eyes. Appropriate

FIG. 1 Volatile Fogging Exposure Box

E2189–02

protective measures must be observed.

8.3 Remove the test specimens from the test apparatus.

Examine them carefully for fog by holding at arm’s length

6.2.1 The source shall consist of one ultraviolet lamp. This

(appro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.