ASTM F2475-05

(Guide)Standard Guide for Biocompatibility Evaluation of Medical Device Packaging Materials

Standard Guide for Biocompatibility Evaluation of Medical Device Packaging Materials

SIGNIFICANCE AND USE

The compatibility of packaging materials with a medical device is a requirement of many regulatory bodies. Since most medical devices are used or implanted in, around or on the human body, these devices must do no harm. Therefore, the packaging materials that come in contact with the medical device must also be evaluated and determined to be safe for use with the human body in that they have no negative impact on the physical, chemical or biological properties of the device. . This evaluation may include both a study of relevant experience with and actual testing of packaging materials. Such an evaluation may result in the conclusion that no testing is needed if the material has a demonstrable history of safe use in the specific role that is the same as that of the package under design.

The medical device manufacturer determines the need for appropriate testing, with consideration of the device/package interactions, if any. The responsibility of the packaging supplier is typically limited to the performance of cytotoxicity testing.

SCOPE

1.1 This guide provides information to determine the appropriate testing for biocompatibility of packaging materials used to contain a medical device.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2475 – 05

Standard Guide for

Biocompatibility Evaluation of Medical Device Packaging

Materials

This standard is issued under the fixed designation F2475; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 biocompatibility—the inherent ability of a material to

remain biologically inert with the host in its intended applica-

1.1 This guide provides information to determine the appro-

tion.

priate testing for biocompatibility of packaging materials used

3.2.2 biocompatibility testing—the series of chemical and

to contain a medical device.

biological tests that a material is subjected to in order to

1.2 This standard does not purport to address all of the

determine the ability of the material to remain biologically

safety concerns, if any, associated with its use. It is the

inert with the host in its intended application.

responsibility of the user of this standard to establish appro-

3.2.3 extent of contact—the degree to which the packaged

priate safety and health practices and to determine the

device will contact the patient (refer to ISO 10993-1 for levels

applicability of regulatory limitations prior to use.

of contact of the device with the human body). When referring

2. Referenced Documents

tothepackaging,extentofcontactreferstothedegreetowhich

the packaging will interact with the device. Degree of packag-

2.1 ASTM Standards:

ing contact (interaction) is related to the physical-chemical

F1327 Terminology Relating to Barrier Materials for Medi-

nature of the packaging materials and the device, the intended

cal Packaging

use of the device (levels of contact with the body), and the

2.2 Other Standards:

extent to which the packaging may negatively impact the

ANSI/AAMI/ISO 11607 Packaging for Terminally Steril-

contained device.

ized Medical Devices

ISO 10993-1:2003 Biological Evaluation of Medical De-

4. Summary of Practice

vices – Part 1: Evaluation and Testing

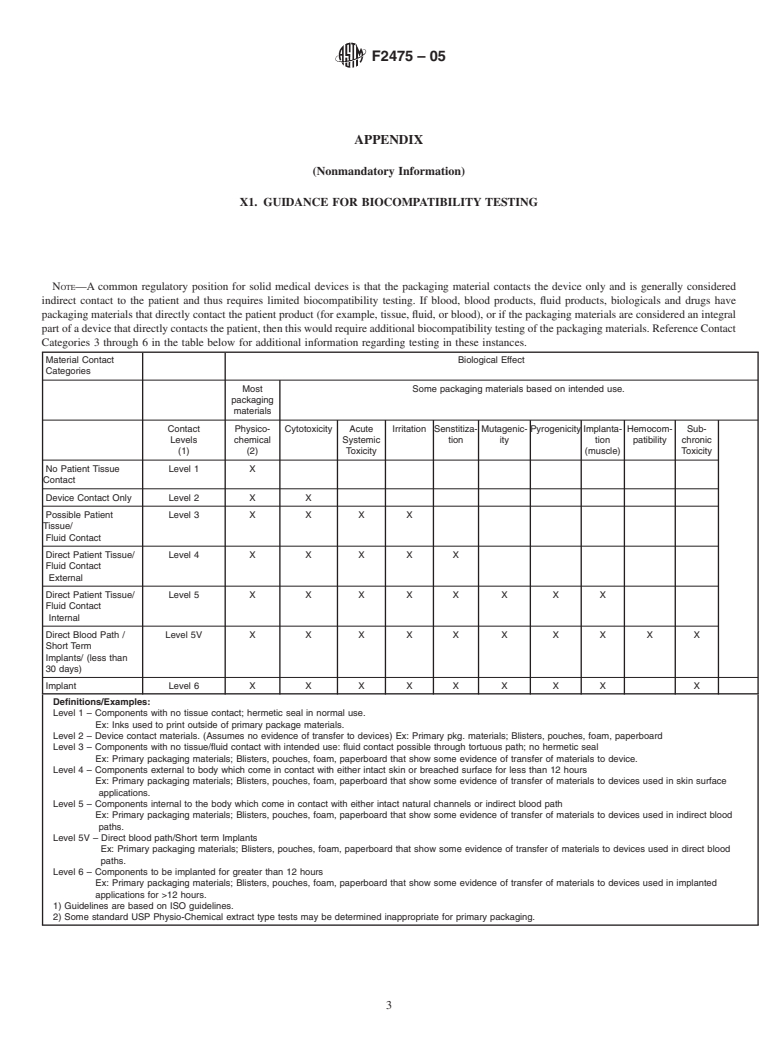

4.1 Materials used in packaging are to be evaluated per

USP <1031> The Biocompatibility of Materials Used in

defined guidelines, such as AAMI/ANSI/ISO 11607. Addi-

Drug Containers, Medical Devices, and Implants

tional biocompatibility testing for packaging materials may be

FDA – Center for Devices and Radiological Health: Re-

required based on the extent of material contact with the

quired Biocompatability Training and Toxicology Profiles

contained medical device, the subsequent degree to which the

for Evaluation of Medical Devices (#G95-1)

packaged device (product) will contact the patient, and the

3. Terminology intendeduseofthedevice.Whenselectingtheappropriatetests

for biological evaluation of medical devices, the chemical

3.1 Definitions—Forterminologyrelatedtobarriermaterials

characteristics of the device materials, as well as the nature,

for medical packaging see Terminology F1327.

degree, frequency and duration of the device’s exposure to the

3.2 Definitions of Terms Specific to This Standard:

body must be considered. Similar testing may be considered

for medical packaging, when there is not a history of safe use

of packaging materials for their intended sue or there may be

This guide is under the jurisdiction of ASTM Committee F02 on Flexible

Barrier Materials and is the direct responsibility of Subcommittee F02.15 on

a question as to whether the packaging may negatively impact

Chemical/Safety Properties.

the contained device. Guidelines for biocompatibility verifica-

Current edition approved April 1, 2005. Published May 2005. DOI: 10.1520/

tion of medical device packaging are based on FDA guidance

F2475-05.

(Memorandum #G-95), ANSI/AAMI/ISO 10993-1 and USP

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

<1031> The Biocompatibility of Materials Used in Drug

Standards volume information, refer to the standard’s Document Summary page on

Containers, Medical Devices, and Implants.While the scope of

the ASTM website.

these standards does not directly apply to medical device

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. packaging, use of them will address the intent of ISO 11607.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2475 – 05

The reader is advised to consult these standards in determin- Variations from standard testing plans may be justified to

ing which tests apply for a given packaging application. All either reduce or expand tests to be done based on 1) known

medicaldevicepackagesareconsideredtohaveindirectpatient potential contact levels of the device with the patient, 2) the

contact, at a minimum. Therefore, the tests selected will not extent of contact between the package and the device, and 3)

typically require more extensive testing than that required for the relative risk that the package may interact with the product,

medical devices intended for indirect patient contact. resulting in a change to the device’s physical, chemical, or

However, test selection should also be based on the extent of biological properties.

contact between the package and the device, and the probabil-

NOTE 1—For semi-solid and liquid device packaging, specific attention

itythatthepackagemaynegativelyimpactthepropertiesofthe

should be paid to the potential for indirect contact components such as

contained medical device. For example, a device that is a solid

inks, varnish and adhesive to volatilize and migrate through the primary

structure is less likely to interact with its packaging than a barrier into the product.

device composed of a semi-solid or liquid material.

The history of use of packages and package materials for

various medical device applications can also serve as a

5. Significance and Use

valuable resource in verifying the biocompatibility of a pack-

5.1 Thecompatibilityofpackagingmaterialswithamedical

age system.

device is a requirement of many regulatory bodies. Since most

6.2 Prepare samples for testing based on testing facilities

medical devices are used or implanted in, around or on the

requirements. Processing steps and labeling of packages can

human body, these devices must do no harm. Therefore, the

impact the biocompatibility of a package system. Therefore, it

packaging materials that come in contact with the medical

is important to test materials that have been manufactured and

devicemustalsobeevaluatedanddeterminedtobesafeforuse

processed under “nominal conditions” as well as worst case

with the human body in that they have no negative impact on

manufacturing conditions, including anti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.