ASTM D4963-04

(Test Method)Standard Test Method for Ignition Loss of Glass Strands and Fabrics

Standard Test Method for Ignition Loss of Glass Strands and Fabrics

SIGNIFICANCE AND USE

This test method is considered satisfactory for acceptance testing of commercial shipments because current estimates of between-laboratory precision are acceptable.

5.1.1 In cases of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student’t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing begins. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in the view of the known bias.

Glass textiles are provided with various sizings or coatings. These provide a protection for the individual fibers, yarns, or fabric that may compose the glass textile as well as compatibility with further finishing requirements. The amount of sizing or coating on glass textiles as determined by this procedure is used for process control.

SCOPE

1.1 This test method covers primarily the determination of ignition loss of glass textiles. This method applies to glass fiber strands, twisted or untwisted, coated or uncoated; and fabrics, woven, nonwoven, knitted, coated, and uncoated, and chopped strand. This procedure may be applied to other glass textiles where the amount of organic content obtained by ignition loss is required.

Note 1—This test method may be used with other glass fiber classifications, such as C or D, but a different ignition temperature and exposure time may be required. In these cases the manufacturer should be consulted for the appropriate ignition conditions.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4963–04

Standard Test Method for

1

Ignition Loss of Glass Strands and Fabrics

This standard is issued under the fixed designation D4963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers primarily the determination of 3.1 Definitions—For all terminology related to Subcommit-

ignition loss of glass textiles.This method applies to glass fiber tee D13.18 on Glass Fibers, see Terminology D7018.

strands, twisted or untwisted, coated or uncoated; and fabrics, 3.2 For definitions of other textile terms used in this test

woven, nonwoven, knitted, coated, and uncoated, and chopped method, refer to Terminology D123. For information on the

strand. This procedure may be applied to other glass textiles designation of construction of glass strands, refer to Specifi-

where the amount of organic content obtained by ignition loss cation D578.

is required.

4. Summary of Test Method

NOTE 1—This test method may be used with other glass fiber classifi-

4.1 The organic content on glass textiles is determined by

cations, such as C or D, but a different ignition temperature and exposure

weighing the specimen before and after ignition. The amount

time may be required. In these cases the manufacturer should be consulted

of ignition loss on a sample is reported as a percentage of the

for the appropriate ignition conditions.

mass before ignition.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

5. Significance and Use

each system may not be exact equivalents; therefore, each

5.1 This test method is considered satisfactory for accep-

system shall be used independently of the other. Combining

tance testing of commercial shipments because current esti-

values from the two systems may result in nonconformance

mates of between-laboratory precision are acceptable.

with the standard.

5.1.1 In cases of a dispute arising from differences in

1.3 This standard does not purport to address all of the

reported test results when using this test method for acceptance

safety concerns, if any, associated with its use. It is the

testing of commercial shipments, the purchaser and the sup-

responsibility of the user of this standard to establish appro-

plier should conduct comparative tests to determine if there is

priate safety and health practices and determine the applica-

a statistical bias between their laboratories. Competent statis-

bility of regulatory limitations prior to use.

tical assistance is recommended for the investigation of bias.

As a minimum, the two parties should take a group of test

2. Referenced Documents

specimens which are as homogeneous as possible and which

2

2.1 ASTM Standards:

are from a lot of material of the type in question. The test

D123 Terminology Relating to Textiles

specimens should then be randomly assigned in equal numbers

D578 Specification for Glass Fiber Strands

to each laboratory for testing.The average results from the two

D7018 Terminology Relating to Glass Fiber and Its Prod-

laboratories should be compared using Student’s t-test for

ucts

unpaireddataandanacceptableprobabilitylevelchosenbythe

two parties before the testing begins. If a bias is found, either

its cause must be found and corrected or the purchaser and the

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

suppliermustagreetointerpretfuturetestresultsintheviewof

and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and its

the known bias.

Products.

5.2 Glass textiles are provided with various sizings or

Current edition approved Dec. 1, 2004. Published January 2005. Originally

coatings. These provide a protection for the individual fibers,

approved in 1989. Last previous edition approved in 1999 as D4963 – 99. DOI:

10.1520/D4963-04.

yarns, or fabric that may compose the glass textile as well as

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

compatibility with further finishing requirements. The amount

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of sizing or coating on glass textiles as determined by this

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. procedure is used for process control.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

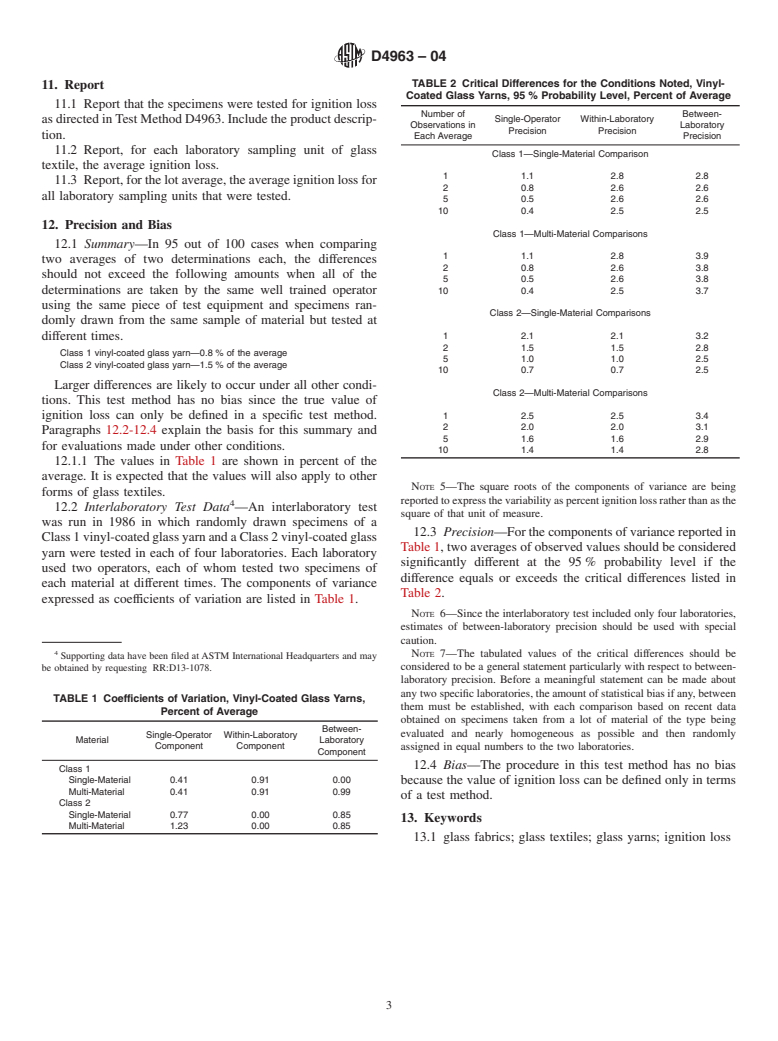

D4963–04

6. Apparatus and Materials different part of the width of the swatches, with no specimen

being ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.