ASTM D4122-02

(Practice)Standard Practice for Carbon Black—Evaluation of an Industry Reference Black

Standard Practice for Carbon Black—Evaluation of an Industry Reference Black

SCOPE

1.1 This practice offers guidelines for the production and testing for uniformity of a lot of carbon black to be used as an Industry Reference Black (IRB).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4122–02

Standard Practice for

1

Carbon Black—Evaluation of an Industry Reference Black

This standard is issued under the fixed designation D4122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

2

1. Scope D3265 Test Method for Carbon Black—Tint Strength

D3493 Test Method for Carbon Black—Oil Absorption

1.1 This practice offers guidelines for the production and

2

Number of Compressed Sample

testing for uniformity of a lot of carbon black to be used as an

D5230 Test Method for Carbon Black—Automated Indi-

Industry Reference Black (IRB).

2

vidual Pellet Hardness

1.2 The values stated in SI units are to be regarded as the

D6556 Test Methods for Carbon Black—Total and Exter-

standard. The values given in parentheses are for information

2

nal Surface Area by Nitrogen Adsorption

only.

1.3 This standard does not purport to address all of the

3. Significance and Use

safety concerns, if any, associated with its use. It is the

3.1 These guidelines are intended to ensure that IRBs are

responsibility of the user of this standard to establish appro-

evaluated by a standard procedure.

priate safety and health practices and determine the applica-

3.2 These guidelines are to be used to establish the average

bility of regulatory limitations prior to use.

physicochemical and physical rubber properties of a lot of

2. Referenced Documents carbon black to be used as an IRB.

2.1 ASTM Standards:

4. Production, Quality Control, and Quality Assurance

D412 Test Methods for Vulcanized Rubber and Thermo-

2

4.1 It is assumed that the manufacturer of the IRB will use

plastic Elastomers—Tension

2 state-of-the-art techniques to ensure maximum uniformity

D1506 Test Methods for Carbon Black—Ash Content

throughouttheentireproductionrun.Theproductionshouldbe

D1508 Test Method for Carbon Black, Pelleted Fines and

2 made in one continuous production lot run. The testing called

Attrition

2

for in this practice is not intended to be a substitute for

D1509 Test Methods for Carbon Black—Heating Loss

in-process quality control. This interlaboratory study is only

D1510 Test Method for Carbon Black—IodineAdsorption

2 adequate to verify the quality of a homogeneous lot.

Number

4.2 Thesizeofthelotisdeterminedbyhistoricalrecordson

D1513 Test Method for Carbon Black, Pelleted—Pour

2 the rate of use. The lot should have an expected life of 8 to 10

Density

2 years at the most recent rate of use.

D1514 Test Method for Carbon Black—Sieve Residue

4.3 The black should be bagged in 50–lb polyethylene bags

D 1618 Test Method for Carbon Extractables—

2 to reduce moisture incursion. Each pallet of bagged black

Transmittance of Toluene Extract

should be wrapped in plastic to reduce environmental expo-

D1765 Classification System for Carbon Blacks Used in

2 sure. The bagged black will be segregated into at least twelve

Rubber Products

equal sized sublots for uniformity testing.

D2414 Test Method for Carbon Black—Oil Absorption

2

Number

5. Sampling

D3191 Test Methods for Carbon Black Evaluation in SBR

5.1 Afterasuitabletimetoallowtheblacktostabilize,abag

(Styrene-Butadiene Rubber)—Recipe and Evaluation Pro-

2 will be selected from the approximate middle of each of the

cedures

sublots; the bags selected will be numbered from one through

D3192 Test Methods for Carbon Black Evaluation in NR

2 n, where n is the total number of sublots, in order to represent

(Natural Rubber)

the corresponding production lot.

3

5.2 n 4-dm (1-gal)samples,numberedfromonethroughn,

1

and taken from the corresponding bags, will be sent to each

This practice is under the jurisdiction of ASTM Committee D24 on Carbon

Black and is the direct responsibility of Subcommittee D24.61 on Carbon Black

participant in the interlaboratory study to evaluate the new

Sampling and Statistical Analysis.

IRB.

Current edition approved Nov. 10, 2002. Published December 2002. Originally

e1

approved in 1982. Last previous edition approved in 1996 as D4122–96a .

2

Annual Book of ASTM Standards, Vol 09.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4122–02

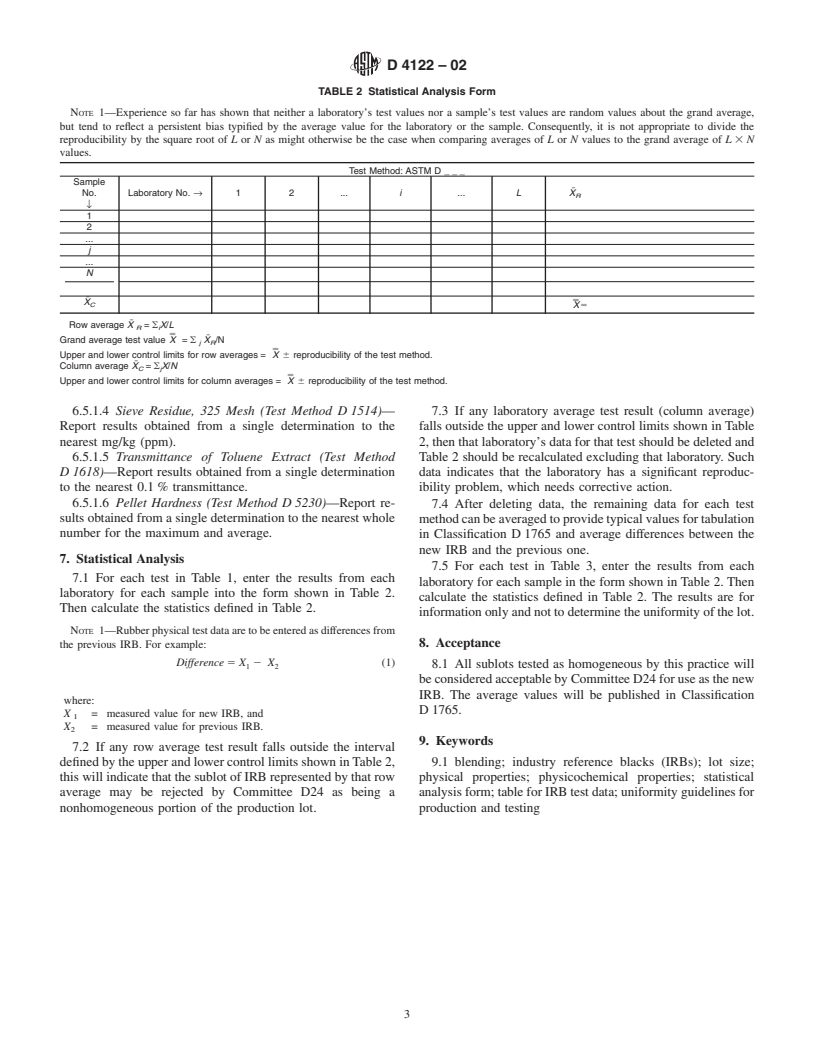

TABLE 1 Industry Reference Black Test Data

Laboratory Number __

Com-

NSA Oil Ab-

pressed

Tensile Multi- sorption, Pour

Day of Tensile 300 % Oil No.,

−5

Tensile Stress at Elonga- Elonga- Iodine STSA point No., 10 Tint Density,

−5

Mix- Strength, Modulus, 10

3 2 3 3

Sample No. Strength, 300 %, tion, % tion, % No., g/kg 10 m /kg Adsorption mg /kg Strength, kg/m

3

ing and MPa MPa mg /kg

3 3 3

MPa D 3191 MPa D 3191 D 3192A D 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.