ASTM D6448-14e1

(Specification)Standard Specification for Industrial Burner Fuels from Used Lubricating Oils

Standard Specification for Industrial Burner Fuels from Used Lubricating Oils

ABSTRACT

This specification covers four grades of fuel oil made in whole or in part with hydrocarbon-based used or reprocessed lubricating oil or functional fluids, such as preservative and hydraulic fluids. Grades RFO4, RFO5L, RFO5H, and RFO6 are of increasing viscosity and are intended for use in various types of fuel-oil-burning industrial equipment under various climatic and operating conditions, and are not intended for use in residential heaters, small commercial boilers, combustion engines, or marine applications. Detailed requirements for each grade of lubricating oil shall be tested accordingly, and are as follows: viscosity; flash point; water and sediment content; pour point; density; ash content; sulphur content; extracted pH; and gross heating value.

SCOPE

1.1 This specification covers four grades of fuel oil made in whole or in part with hydrocarbon-based used or reprocessed lubricating oil or functional fluids, such as preservative and hydraulic fluids. The four grades of fuel are intended for use in various types of fuel-oil-burning industrial equipment under various climatic and operating conditions. These fuels are not intended for use in residential heaters, small commercial boilers, combustion engines, or marine applications,

1.1.1 Grades RFO4, RFO5L, RFO5H, and RFO6 are used lubricating oil blends, with or without distillate or residual fuel oil, or both, of increasing viscosity and are intended for use in industrial burners equipped to handle these types of recycled fuels.

Note 1: For information on the significance of the terminology and test methods used in this specification, see Appendix X1.

1.2 This specification is for use in contracts for the purchase of fuel oils derived from used lubricating oil and for the guidance of consumers of such fuels. This specification does not address the frequency with which any particular test must be run.

1.3 Nothing in this specification shall preclude observance of national or local regulations, which can be more restrictive. In some jurisdictions, used oil is considered a hazardous waste and fuels from used oil are required to meet certain criteria before use as a fuel.

Note 2: For United States federal requirements imposed on used oil generators, transporters and transfer facilities, reprocessors, marketers, and burners, see 40 CFR 279.

Note 3: The generation and dissipation of static electricity can create problems in the handling of distillate burner fuel oils. For more information on the subject, see Guide D4865.

1.4 The values stated in SI units are to be regarded as standard; non-SI units, when given, are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D6448 −14

StandardSpecification for

Industrial Burner Fuels from Used Lubricating Oils

This standard is issued under the fixed designation D6448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes to SI units formatting were made throughout in December 2014.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers four grades of fuel oil made in

whole or in part with hydrocarbon-based used or reprocessed D56 Test Method for Flash Point by Tag Closed Cup Tester

D93 Test Methods for Flash Point by Pensky-Martens

lubricating oil or functional fluids, such as preservative and

hydraulic fluids.The four grades of fuel are intended for use in Closed Cup Tester

D95 Test Method for Water in Petroleum Products and

various types of fuel-oil-burning industrial equipment under

various climatic and operating conditions. These fuels are not Bituminous Materials by Distillation

D96 Test Method for Water and Sediment in Crude Oil by

intended for use in residential heaters, small commercial

boilers, combustion engines, or marine applications, Centrifuge Method (Field Procedure) (Withdrawn 2000)

D97 Test Method for Pour Point of Petroleum Products

1.1.1 Grades RFO4, RFO5L, RFO5H, and RFO6 are used

lubricating oil blends, with or without distillate or residual fuel D129 Test Method for Sulfur in Petroleum Products (Gen-

eral High Pressure Decomposition Device Method)

oil, or both, of increasing viscosity and are intended for use in

industrial burners equipped to handle these types of recycled D240 Test Method for Heat of Combustion of Liquid Hy-

drocarbon Fuels by Bomb Calorimeter

fuels.

D396 Specification for Fuel Oils

NOTE 1—For information on the significance of the terminology and

D445 Test Method for Kinematic Viscosity of Transparent

test methods used in this specification, see Appendix X1.

and Opaque Liquids (and Calculation of Dynamic Viscos-

1.2 This specification is for use in contracts for the purchase

ity)

of fuel oils derived from used lubricating oil and for the

D473 Test Method for Sediment in Crude Oils and Fuel Oils

guidance of consumers of such fuels. This specification does

by the Extraction Method

not address the frequency with which any particular test must

D482 Test Method for Ash from Petroleum Products

be run.

D1217 Test Method for Density and Relative Density (Spe-

cific Gravity) of Liquids by Bingham Pycnometer

1.3 Nothing in this specification shall preclude observance

of national or local regulations, which can be more restrictive. D1250 Guide for Use of the Petroleum Measurement Tables

In some jurisdictions, used oil is considered a hazardous waste D1266 Test Method for Sulfur in Petroleum Products (Lamp

and fuels from used oil are required to meet certain criteria Method)

before use as a fuel. D1298 Test Method for Density, Relative Density, or API

Gravity of Crude Petroleum and Liquid Petroleum Prod-

NOTE 2—For United States federal requirements imposed on used oil

ucts by Hydrometer Method

generators, transporters and transfer facilities, reprocessors, marketers,

D1480 Test Method for Density and Relative Density (Spe-

and burners, see 40 CFR 279.

NOTE 3—The generation and dissipation of static electricity can create cific Gravity) of Viscous Materials by Bingham Pycnom-

problems in the handling of distillate burner fuel oils. For more informa-

eter

tion on the subject, see Guide D4865.

D1481 Test Method for Density and Relative Density (Spe-

1.4 The values stated in SI units are to be regarded as

cific Gravity) of Viscous Materials by Lipkin Bicapillary

standard; non-SI units, when given, are for information only.

Pycnometer

1 2

This specification is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.P0 on Recycled Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2014. Published October 2014. Originally the ASTM website.

approved in 1999. Last previous edition approved in 2009 as D6448 – 09. DOI: The last approved version of this historical standard is referenced on

10.1520/D6448-14E01. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6448−14

D1552 Test Method for Sulfur in Petroleum Products (High- EPASW-846 Method 9000 Determination ofWater inWaste

Temperature Method) Materials by Karl Fisher Titration

D1796 Test Method for Water and Sediment in Fuel Oils by EPASW-846 Method 9001 Determination ofWater inWaste

the Centrifuge Method (Laboratory Procedure) Lubricants by Quantitative Calcium Hydride Reaction

D2622 Test Method for Sulfur in Petroleum Products by EPA SW-846 Method 9056 Determination of Inorganic An-

Wavelength Dispersive X-ray Fluorescence Spectrometry ions by Ion Chromatography

D2709 Test Method for Water and Sediment in Middle

2.3 Federal Code of Regulations Standards:

Distillate Fuels by Centrifuge

40 CFR 279 Standards for the Management of Used Oil

D2983 Test Method for Low-Temperature Viscosity of Lu-

bricants Measured by Brookfield Viscometer

3. Terminology

D3245 Test Method for Pumpability of Industrial Fuel Oils

3.1 Definitions:

(Withdrawn 2010)

3.1.1 burner fuel oil, n—any petroleum liquid suitable for

D3828 Test Methods for Flash Point by Small Scale Closed

the generation of heat by combustion in a furnace or firebox as

Cup Tester

a vapor or a spray, or a combination of both.

D4052 Test Method for Density, Relative Density, and API

3.1.1.1 Discussion—Different grades are characterized pri-

Gravity of Liquids by Digital Density Meter

marily by viscosity ranges.

D4057 Practice for Manual Sampling of Petroleum and

3.1.2 reclaiming, n—the use of cleaning methods during

Petroleum Products

recycling primarily to remove insoluble contaminants, thus

D4175 Terminology Relating to Petroleum, Petroleum

making the oil suitable for further use. The methods may

Products, and Lubricants

include settling, heating, dehydration, filtration, and centrifug-

D4177 Practice for Automatic Sampling of Petroleum and

ing.

Petroleum Products

D4294 Test Method for Sulfur in Petroleum and Petroleum 3.1.3 recycling, n—in petroleum technology, the acquisition

Products by Energy Dispersive X-ray Fluorescence Spec- of oil that has become unsuitable for its intended use, and

trometry processing it to regain useful materials.

D4377 Test Method forWater in Crude Oils by Potentiomet-

3.1.4 re-refining, n—the use of refining processes during

ric Karl Fischer Titration

recycling to produce high quality base stocks for lubricants or

D4865 Guide for Generation and Dissipation of Static Elec-

otherpetroleumproducts.Re-refiningmayincludeoneormore

tricity in Petroleum Fuel Systems

of the following: distillation, hydrotreating, or treatments

D4868 Test Method for Estimation of Net and Gross Heat of

employing acid, caustic, solvent, clay, or other chemicals, or

Combustion of Burner and Diesel Fuels

combination thereof.

D4980 Test Methods for Screening of pH in Waste (With-

3.1.5 used oil, n—in petroleum product recycling, oil whose

drawn 2009)

characteristics have changed since being originally

D5185 Test Method for Multielement Determination of

manufactured, and that is suitable for recycling.

Used and Unused Lubricating Oils and Base Oils by

3.1.6 waste oil, n—in petroleum technology, oil having

Inductively Coupled Plasma Atomic Emission Spectrom-

characteristics making it unsuitable either for further use or for

etry (ICP-AES)

economic recycling.

D5854 Practice for Mixing and Handling of Liquid Samples

of Petroleum and Petroleum Products

3.2 For definitions of other terms used in this specification,

D6304 Test Method for Determination of Water in Petro-

refer to Terminology D4175.

leum Products, Lubricating Oils, and Additives by Cou-

3.3 Definitions of Terms Specific to This Standard:

lometric Karl Fischer Titration

3.3.1 industrial burner, n—a device that produces heat for

D6450 Test Method for Flash Point by Continuously Closed

industrial use through the combustion of liquid hydrocarbon

Cup (CCCFP) Tester

fuels.

D6822 Test Method for Density, Relative Density, and API

3.3.1.1 Discussion—Industrial burners are typically de-

Gravity of Crude Petroleum and Liquid Petroleum Prod-

signed for one of two applications:

ucts by Thermohydrometer Method

(a) industrial furnaces—integral components of manufac-

D7042 Test Method for Dynamic Viscosity and Density of

turing processes that provide direct heating, for example, in

Liquids by Stabinger Viscometer (and the Calculation of

aggregate, cement, lime, or phosphate kilns; coke ovens; or

Kinematic Viscosity)

blast, smelting, melting, refining, or drying ovens.

D7094 Test Method for Flash Point by Modified Continu-

(b) industrial boilers—large indirect heating units that

ously Closed Cup (MCCCFP) Tester

transfer thermal energy to water or other fluids or gases for use

2.2 U.S. Environmental Protection Agency Standards:

in heating in industrial settings and in manufacturing processes

EPA 600/4-79-020 Determination of Inorganic Anions by

Ion Chromatography

National Archives and Records Administration, Code of Federal Regulations

Available from United States Environmental Protection Agency (US-EPA), (CFR), Available from U.S. Government Printing Office Superintendent of

Ariel Rios Bldg., PennsylvaniaAve., NW, Washington D.C. 20460. (www.epa.gov/ Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

epaoswer/hazwaste/test/main.htm. www.gpoaccess.gov/cfr/index.html.

´1

D6448−14

3.3.2 reprocessing, n— in petroleum product recycling, the 4.1.4 Grade RFO6—A high-viscosity used lubricating oil

preparation of used oil to be suitable as a fuel. and residual blend fuel, heavier than Grade RFO5H. It is

3.3.2.1 Discussion—Reprocessing includes procedures such intended for use in large industrial heaters and may require

as settling, filtration, blending, distillation, and chemical treat- preheating in the storage tank to permit pumping. Additional

ment. preheating at the burner may be necessary to permit satisfac-

tory atomization. The extra equipment and maintenance re-

4. Classification

quired to handle this fuel usually preclude its use in small

installations.

4.1 There are four grades of industrial burner fuel contain-

ing recycled lubricating oils covered by this specification.

5. General Requirements

These grades may or may not correlate directly with similar

grades in other ASTM standards. The RFO designation iden-

5.1 The fuel oils specified herein shall contain a minimum

tifies them as Reprocessed Fuel Oils.The usage descriptions of

volume of 25 % of used lubricating oil-derived products, the

each grade may not describe all the uses, but are included as

balance being a Specification D396 fuel oil or suitable refinery

general information. The four grades are described as follows:

stocks.

4.1.1 Grade RFO4—Primarily a blend of used lubricating

5.2 The fuel oils shall be homogeneous fluids consisting

oils and distillate or a reprocessed distillate product derived

primarily of hydrocarbons. Fuel oils containing residual com-

from used oil. It is intended for use in pressure atomizing

ponents shall remain uniform in storage and shall not separate

industrial burners with no preheating. This grade of recycled

by gravity or aging into layers in normal operating conditions.

oil fuel is used in many medium capacity industrial burners

whereeaseofhandlingjustifiesthehighercostovertheheavier

NOTE 4—Prolonged storage or equipment down time may necessitate

used oil fuels.

circulation of the fuel oil in-tank to prevent such separation.

4.1.2 Grade RFO5L—A straight (100 %) used lubricating

5.3 The fuel oil shall not contain excessive amounts of

oil blend or a used lubricating oil and distillate blend fuel of

organic or inorganic acids, or both, and shall be free of solid or

intermediate viscosity, heavier than Grade RFO4. It is intended

fibrousmatterthatcouldcausesystemhandlingormaintenance

for use both in pressure-atomizing industrial burners not

problems. The buyer and seller should agree on any require-

requiring higher cost distillates and in burners equipped to

ments for particle size.

atomize oils of higher viscosity with or without pre-heating. Its

NOTE5—Thefuelsdefinedbythisspecificationareappropriateonlyfor

permissible viscosity range allows it to be pumped and

burners capable of handling and combusting fuels with potentially higher

atomized at relatively low-storage temperatures.

metals and ash content.

4.1.3 Grade RFO5H—A straight (100 %) used lubricating

oil blend or a used lubricating oil and residual blend fuel,

6. Detailed Requirements

heavier than Grade RFO5L. It is intended for use in industrial

burners equipped with devices that atomize oil of higher 6.1 Grade RFO4—Therequirementsforthistypeoffuelare

viscosity than domestic burners can handle. Preheating may be presented in Table 1 and include fuels in the viscosity range

necessaryinsometypesofequipmentforburningandincolder below5mm /s(cSt)at100 °CinaccordancewithTestMethod

climates for handling. D445.

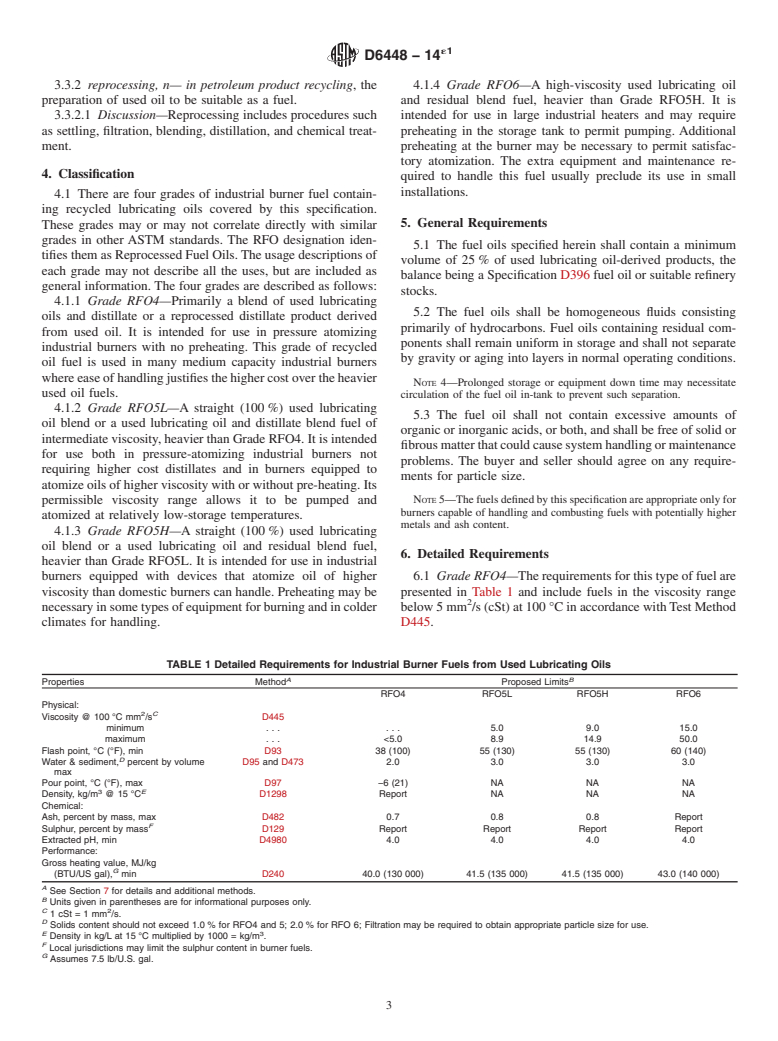

TABLE 1 Detailed Requirements for Industrial Burner Fuels from Used Lubricating Oils

A B

Properties Method Proposed Limits

RFO4 RFO5L RFO5H RFO6

Physical:

2 C

Viscosity @ 100 °C mm /s D445

minimum . . . . . . 5.0 9.0 15.0

maximum . . . <5.0 8.9 14.9 50.0

Flash point, °C (°F), min D93 38 (100) 55 (130) 55 (130) 60 (140)

D

Water & sediment, percent by volume D95 and D473 2.0 3.0 3.0 3.0

max

Pour point, °C (°F), max D97 −6 (21) NA NA NA

3 E

Density, kg/m @15°C D1298 Report NA NA NA

Chemical:

Ash, percent by mass, max D482 0.7 0.8 0.8 Report

F

Sulphur, percent by mass D129 Report Report Report Report

Extracted pH, min D4980 4.0 4.0 4.0 4.0

Performance:

Gross heating value, MJ/kg

G

(BTU/US gal), min D240 40.0 (130 000) 41.5 (135 000) 41.5 (135 000) 43.0 (140 000)

A

See Section 7 for details and additional methods.

B

Units given in parentheses are for informational purposes only.

C 2

1cSt =1mm /s.

D

Solids content should not exceed 1.0 % for RFO4 and 5; 2.0 % for RFO 6; Filtration may be required to obtain appropriate particle size for use.

E 3

Density in kg/L at 15 °C multiplied by 1000

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6448 − 14 D6448 − 14

Standard Specification for

Industrial Burner Fuels from Used Lubricating Oils

This standard is issued under the fixed designation D6448; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial changes to SI units formatting were made throughout in December 2014.

1. Scope*

1.1 This specification covers four grades of fuel oil made in whole or in part with hydrocarbon-based used or reprocessed

lubricating oil or functional fluids, such as preservative and hydraulic fluids. The four grades of fuel are intended for use in various

types of fuel-oil-burning industrial equipment under various climatic and operating conditions. These fuels are not intended for use

in residential heaters, small commercial boilers, combustion engines, or marine applications,

1.1.1 Grades RFO4, RFO5L, RFO5H, and RFO6 are used lubricating oil blends, with or without distillate or residual fuel oil,

or both, of increasing viscosity and are intended for use in industrial burners equipped to handle these types of recycled fuels.

NOTE 1—For information on the significance of the terminology and test methods used in this specification, see Appendix X1.

1.2 This specification is for use in contracts for the purchase of fuel oils derived from used lubricating oil and for the guidance

of consumers of such fuels. This specification does not address the frequency with which any particular test must be run.

1.3 Nothing in this specification shall preclude observance of national or local regulations, which can be more restrictive. In

some jurisdictions, used oil is considered a hazardous waste and fuels from used oil are required to meet certain criteria before

use as a fuel.

NOTE 2—For United States federal requirements imposed on used oil generators, transporters and transfer facilities, reprocessors, marketers, and

burners, see 40 CFR 279.

NOTE 3—The generation and dissipation of static electricity can create problems in the handling of distillate burner fuel oils. For more information

on the subject, see Guide D4865.

1.4 The values stated in SI units are to be regarded as standard; non-SI units, when given, are for information only.

2. Referenced Documents

2.1 ASTM Standards:

D56 Test Method for Flash Point by Tag Closed Cup Tester

D93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D95 Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

D96 Test Method for Water and Sediment in Crude Oil by Centrifuge Method (Field Procedure) (Withdrawn 2000)

D97 Test Method for Pour Point of Petroleum Products

D129 Test Method for Sulfur in Petroleum Products (General High Pressure Decomposition Device Method)

D240 Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter

D396 Specification for Fuel Oils

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D473 Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method

D482 Test Method for Ash from Petroleum Products

D1217 Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer

D1250 Guide for Use of the Petroleum Measurement Tables

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

This specification is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.P0 on Recycled Products.

Current edition approved Oct. 1, 2014. Published October 2014. Originally approved in 1999. Last previous edition approved in 2009 as D6448 – 09. DOI:

10.1520/D6448-14.10.1520/D6448-14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6448 − 14

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D1480 Test Method for Density and Relative Density (Specific Gravity) of Viscous Materials by Bingham Pycnometer

D1481 Test Method for Density and Relative Density (Specific Gravity) of Viscous Materials by Lipkin Bicapillary Pycnometer

D1552 Test Method for Sulfur in Petroleum Products (High-Temperature Method)

D1796 Test Method for Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedure)

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D2709 Test Method for Water and Sediment in Middle Distillate Fuels by Centrifuge

D2983 Test Method for Low-Temperature Viscosity of Lubricants Measured by Brookfield Viscometer

D3245 Test Method for Pumpability of Industrial Fuel Oils (Withdrawn 2010)

D3828 Test Methods for Flash Point by Small Scale Closed Cup Tester

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4294 Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry

D4377 Test Method for Water in Crude Oils by Potentiometric Karl Fischer Titration

D4865 Guide for Generation and Dissipation of Static Electricity in Petroleum Fuel Systems

D4868 Test Method for Estimation of Net and Gross Heat of Combustion of Burner and Diesel Fuels

D4980 Test Methods for Screening of pH in Waste (Withdrawn 2009)

D5185 Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively

Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D6304 Test Method for Determination of Water in Petroleum Products, Lubricating Oils, and Additives by Coulometric Karl

Fischer Titration

D6450 Test Method for Flash Point by Continuously Closed Cup (CCCFP) Tester

D6822 Test Method for Density, Relative Density, and API Gravity of Crude Petroleum and Liquid Petroleum Products by

Thermohydrometer Method

D7042 Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic

Viscosity)

D7094 Test Method for Flash Point by Modified Continuously Closed Cup (MCCCFP) Tester

2.2 U.S. Environmental Protection Agency Standards:

EPA 600/4-79-020 Determination of Inorganic Anions by Ion Chromatography

EPA SW-846 Method 9000 Determination of Water in Waste Materials by Karl Fisher Titration

EPA SW-846 Method 9001 Determination of Water in Waste Lubricants by Quantitative Calcium Hydride Reaction

EPA SW-846 Method 9056 Determination of Inorganic Anions by Ion Chromatography

2.3 Federal Code of Regulations Standards:

40 CFR 279 Standards for the Management of Used Oil

3. Terminology

3.1 Definitions:

3.1.1 burner fuel oil, n—any petroleum liquid suitable for the generation of heat by combustion in a furnace or firebox as a vapor

or a spray, or a combination of both.

Available from United States Environmental Protection Agency (US-EPA), Ariel Rios Bldg., Pennsylvania Ave., NW, Washington D.C. 20460. (www.epa.gov/epaoswer/

hazwaste/test/main.htm.

National Archives and Records Administration, Code of Federal Regulations (CFR), Available from U.S. Government Printing Office Superintendent of Documents, 732

N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401. www.gpoaccess.gov/cfr/index.html.

3.1.1.1 Discussion—

Different grades are characterized primarily by viscosity ranges.

3.1.2 reclaiming, n—the use of cleaning methods during recycling primarily to remove insoluble contaminants, thus making the

oil suitable for further use. The methods may include settling, heating, dehydration, filtration, and centrifuging.

3.1.3 recycling, n—in petroleum technology, the acquisition of oil that has become unsuitable for its intended use, and

processing it to regain useful materials.

´1

D6448 − 14

3.1.4 re-refining, n—the use of refining processes during recycling to produce high quality base stocks for lubricants or other

petroleum products. Re-refining may include one or more of the following: distillation, hydrotreating, or treatments employing

acid, caustic, solvent, clay, or other chemicals, or combination thereof.

3.1.5 used oil, n—in petroleum product recycling, oil whose characteristics have changed since being originally manufactured,

and that is suitable for recycling.

3.1.6 waste oil, n—in petroleum technology, oil having characteristics making it unsuitable either for further use or for economic

recycling.

3.2 For definitions of other terms used in this specification, refer to Terminology D4175.

3.3 Definitions of Terms Specific to This Standard:

3.3.1 industrial burner, n—a device that produces heat for industrial use through the combustion of liquid hydrocarbon fuels.

3.3.1.1 Discussion—

Industrial burners are typically designed for one of two applications:

(a) industrial furnaces—integral components of manufacturing processes that provide direct heating, for example, in

aggregate, cement, lime, or phosphate kilns; coke ovens; or blast, smelting, melting, refining, or drying ovens.

(b) industrial boilers—large indirect heating units that transfer thermal energy to water or other fluids or gases for use in

heating in industrial settings and in manufacturing processes

3.3.2 reprocessing, n— in petroleum product recycling, the preparation of used oil to be suitable as a fuel.

3.3.2.1 Discussion—

Reprocessing includes procedures such as settling, filtration, blending, distillation, and chemical treatment.

4. Classification

4.1 There are four grades of industrial burner fuel containing recycled lubricating oils covered by this specification. These

grades may or may not correlate directly with similar grades in other ASTM standards. The RFO designation identifies them as

Reprocessed Fuel Oils. The usage descriptions of each grade may not describe all the uses, but are included as general information.

The four grades are described as follows:

4.1.1 Grade RFO4—Primarily a blend of used lubricating oils and distillate or a reprocessed distillate product derived from used

oil. It is intended for use in pressure atomizing industrial burners with no preheating. This grade of recycled oil fuel is used in many

medium capacity industrial burners where ease of handling justifies the higher cost over the heavier used oil fuels.

4.1.2 Grade RFO5L—A straight (100 %) used lubricating oil blend or a used lubricating oil and distillate blend fuel of

intermediate viscosity, heavier than Grade RFO4. It is intended for use both in pressure-atomizing industrial burners not requiring

higher cost distillates and in burners equipped to atomize oils of higher viscosity with or without pre-heating. Its permissible

viscosity range allows it to be pumped and atomized at relatively low-storage temperatures.

4.1.3 Grade RFO5H—A straight (100 %) used lubricating oil blend or a used lubricating oil and residual blend fuel, heavier than

Grade RFO5L. It is intended for use in industrial burners equipped with devices that atomize oil of higher viscosity than domestic

burners can handle. Preheating may be necessary in some types of equipment for burning and in colder climates for handling.

4.1.4 Grade RFO6—A high-viscosity used lubricating oil and residual blend fuel, heavier than Grade RFO5H. It is intended for

use in large industrial heaters and may require preheating in the storage tank to permit pumping. Additional preheating at the burner

may be necessary to permit satisfactory atomization. The extra equipment and maintenance required to handle this fuel usually

preclude its use in small installations.

5. General Requirements

5.1 The fuel oils specified herein shall contain a minimum volume of 25 % (volume) of used lubricating oil-derived products,

the balance being a Specification D396 fuel oil or suitable refinery stocks.

5.2 The fuel oils shall be homogeneous fluids consisting primarily of hydrocarbons. Fuel oils containing residual components

shall remain uniform in storage and shall not separate by gravity or aging into layers in normal operating conditions.

NOTE 4—Prolonged storage or equipment down time may necessitate circulation of the fuel oil in-tank to prevent such separation.

5.3 The fuel oil shall not contain excessive amounts of organic or inorganic acids, or both, and shall be free of solid or fibrous

matter that could cause system handling or maintenance problems. The buyer and seller should agree on any requirements for

particle size.

NOTE 5—The fuels defined by this specification are appropriate only for burners capable of handling and combusting fuels with potentially higher

metals and ash content.

´1

D6448 − 14

6. Detailed Requirements

6.1 Grade RFO4—The requirements for this type of fuel are presented in Table 1 and include fuels in the viscosity range below

5 mm /s (cSt) at 100 °C in accordance with Test Method D445.

6.2 Grade RFO5L—The requirements for this type of fuel are presented in Table 1 and include fuels in the viscosity range

2 2

5.0 mm /s to 8.9 mm /s (cSt) at 100 °C in accordance with Test Method D445.

6.3 Grade RFO5H—The requirements for this type of fuel are presented in Table 1 and include fuels in the viscosity range

2 2

9.0 mm /s to 14.9 mm /s (cSt) at 100 °C in accordance with Test Method D445.

6.4 Grade RFO6—The requirements for this type of fuel are presented in Table 1 and include fuels in the viscosity range

2 2

15.0 mm /s to 50.0 mm /s (cSt) at 100 °C in accordance with Test Method D445.

NOTE 6—In the United States, fuel must also meet Environmental Protection Agency on-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.