ASTM D5503-94(2008)

(Practice)Standard Practice for Natural Gas Sample-Handling and Conditioning Systems for Pipeline Instrumentation (Withdrawn 2017)

Standard Practice for Natural Gas Sample-Handling and Conditioning Systems for Pipeline Instrumentation (Withdrawn 2017)

SIGNIFICANCE AND USE

A well-designed sample-handling and conditioning system is essential to the accuracy and reliability of pipeline instruments. Approximately 70 % of the problems encountered are associated with the sampling system.

SCOPE

1.1 This practice covers sample-handling and conditioning systems for typical pipeline monitoring instrumentation (gas chromatographs, moisture analyzers, and so forth). The selection of the sample-handling and conditioning system depends upon the operating conditions and stream composition.

1.2 This practice is intended for single-phase mixtures that vary in composition. A representative sample cannot be obtained from a two-phase stream.

1.3 The values stated in SI units are to regarded as standard. The values stated in English units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee D03 on Gaseous Fuels, this practice was withdrawn in January 2017 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5503 − 94 (Reapproved 2008)

Standard Practice for

Natural Gas Sample-Handling and Conditioning Systems for

1

Pipeline Instrumentation

This standard is issued under the fixed designation D5503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers sample-handling and conditioning 3.1 Definitions:

systems for typical pipeline monitoring instrumentation (gas 3.1.1 compressed natural gas—natural gas compressed to

chromatographs, moisture analyzers, and so forth). The selec- approximately 3600 psi.

tion of the sample-handling and conditioning system depends

3.1.2 density—mass per unit volume of the substance being

upon the operating conditions and stream composition.

considered.

1.2 This practice is intended for single-phase mixtures that

3.1.3 dew point—the temperature and pressure at which the

vary in composition. A representative sample cannot be ob-

first droplet of liquid forms from a vapor.

tained from a two-phase stream.

3.1.4 lag time—time required to transport the sample to the

1.3 The values stated in SI units are to regarded as standard.

analyzer.

The values stated in English units are for information only.

3.1.5 natural gas—mixture of low molecular weight hydro-

1.4 This standard does not purport to address all of the

carbons obtained from petroleum-bearing regions.

safety concerns, if any, associated with its use. It is the

3.1.6 sample probe—device to extract a representative

responsibility of the user of this standard to establish appro-

sample from the pipeline.

priate safety and health practices and determine the applica-

3.1.7 system turnaround time—the time required to trans-

bility of regulatory limitations prior to use.

port the sample to the analyzer and to measure the desired

components.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Significance and Use

D1142 Test Method for Water Vapor Content of Gaseous

4.1 Awell-designed sample-handling and conditioning sys-

Fuels by Measurement of Dew-Point Temperature

tem is essential to the accuracy and reliability of pipeline

D3764 Practice forValidation of the Performance of Process

instruments.Approximately 70 % of the problems encountered

Stream Analyzer Systems

are associated with the sampling system.

2.2 Other Standards:

3

ANSI/API 2530 (AGA Report Number 3)

5. Selection of Sample-Handling and Conditioning

4

AGA Report Number 8

System

5

NACE Standard MR-01-75

5.1 The sample-handling and conditioning system must

extract a representative sample from a flowing pipeline, trans-

1

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous

port the sample to the analyzer, condition the sample to be

Fuels and is the direct responsibility of Subcommittee D03.01 on Collection and

compatible with the analyzer, switch sample streams and

Measurement of Gaseous Samples.

calibration gases, transport excess sample to recovery (or

CurrenteditionapprovedDec.1,2008.PublishedJuly2009.Originallyapproved

disposal), and resist corrosion by the sample.

in 1994. Last previous edition approved in 2003 as D5503 – 94 (2003). DOI:

10.1520/D5503-94R08.

5.2 The sample probe should be located in a flowing

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pipeline where the flow is fully developed (little turbulence)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

and where the composition is representative. In areas of high

the ASTM website.

turbulence, the contaminates that normally flow along the

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

bottom or the wall of the pipeline will form aerosols.

4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from American Gas Association, 1515 Wilson Blvd., Arlington, VA

5.3 The purpose of the sample probe is to extract a repre-

22209.

5

sentative sample by obtaining it near the center of the pipeline

Available from NACE International (NACE), 1440 South Creek Dr., Houston,

TX 77084-4906, http://www.nace.org. where changes in stream composition can be quickly detected.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5503 − 94 (2008)

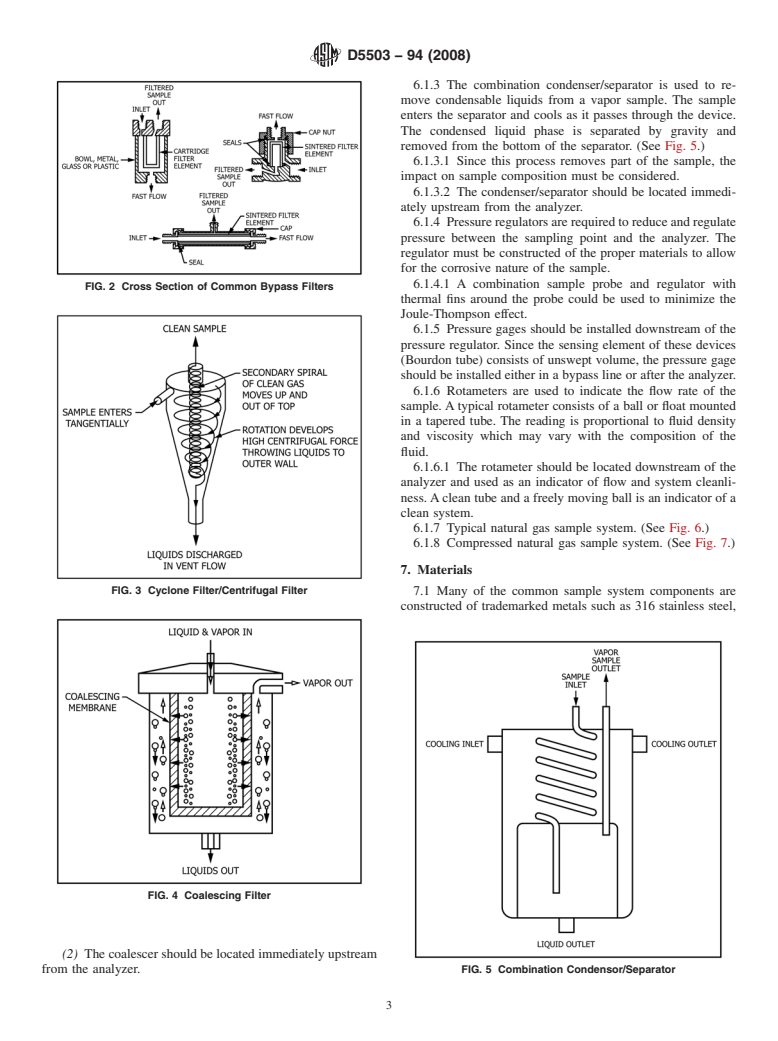

5.3.1 Thetipinthesampleprobeshouldbepositionedinthe 6. Apparatus

center one third of the pipeline, away from the pipeline wall

6.1 The following are common components of a sample-

where large particles accumulate. 6

handling and condit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.