ASTM E2461-12

(Practice)Standard Practice for Determining the Thickness of Glass in Airport Traffic Control Tower Cabs

Standard Practice for Determining the Thickness of Glass in Airport Traffic Control Tower Cabs

SIGNIFICANCE AND USE

This standard procedure facilitates determination of the thickness of a glass construction required to resist a specified design load with a selected probability of breakage.

This standard procedure addresses the following glass constructions: annealed monolithic, annealed laminated, and insulating glass fabricated with annealed monolithic or annealed laminated glass, or both.

Use of these procedures assume:

The glass is free of edge damage and is properly glazed,

The glass has not been subjected to abuse,

The surface condition of the glass is typical of glass that has been in service for several years, and is significantly weaker than freshly manufactured glass due to minor abrasions on exposed surfaces,

The glass edge support system is sufficiently stiff to limit the lateral deflections of the supported glass edges to less than 1/175 of their lengths. The specified design load shall be used for this calculation, and

The center of glass deflection shall not result in loss of edge support. Typically maintaining center of glass deflection at or below the magnitude of three times the nominal glass thickness assures that no loss of edge support will occur.

Many other factors affect the selection of glass type and thickness. These factors include but are not limited to: thermal stresses, the effects of windborne debris, excessive deflections, behavior of glass fragments after breakage, seismic effects, heat flow, edge bite, noise abatement, potential post-breakage consequences, and so forth. In addition, considerations set forth in federal, state, and local building codes along with criteria presented in safety glazing standards and site specific concerns may control the ultimate glass type and thickness selection.

SCOPE

1.1 This practice covers the determination of the thickness of glass installed in airport traffic control towers (ATCT) to resist a specified design loading with a selected probability of breakage less than or equal to either 1 lite per 1000 or 4 lites per 1000 at the first occurrence of the design wind loading.

1.2 The procedures apply to common outward sloping cab glass designs for which the specified loads do not exceed 10 kPa (210 psf).

1.3 The procedures assume control tower cab glass has an aspect ratio no greater than 2.

1.4 The procedures assume control tower cab glass has an area no less than 1.86 square metres (20 square feet).

1.5 The procedures apply only to annealed monolithic, annealed laminated, or annealed insulating glass having a rectangular or trapezoidal shape.

1.6 The use of the procedures assumes the following:

1.6.1 Annealed monolithic and annealed laminated glass installed in ATCTs shall have continuous lateral support along two parallel edges, along any three edges, or along all four edges;

1.6.2 Insulating glass shall have continuous lateral support along all four edges; and

1.6.3 Supported glass edges are simply supported and free to slip in plane.

1.7 The procedures do not apply to any form of wired, patterned, etched, sandblasted, or glass types with surface treatments that reduce the glass strength.

1.8 The procedures do not apply to any form of heat treated glass, chemically strengthened glass, or any type of glass with surface treatments intended to increase the glass strength.

1.9 The procedures address the determination of thickness and construction type to resist a specified design wind load at a selected probability of breakage. The final glass thickness and construction determined also depends upon a variety of other factors (see 5.3).

1.10 These procedures do not address blast loading on glass.

1.11 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.12 This standard does not purport to address all of the safety concerns, if ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2461 − 12

Standard Practice for

Determining the Thickness of Glass in Airport Traffic

1

Control Tower Cabs

This standard is issued under the fixed designation E2461; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope a selected probability of breakage. The final glass thickness

and construction determined also depends upon a variety of

1.1 This practice covers the determination of the thickness

other factors (see 5.3).

of glass installed in airport traffic control towers (ATCT) to

resist a specified design loading with a selected probability of 1.10 Theseproceduresdonotaddressblastloadingonglass.

breakage less than or equal to either 1 lite per 1000 or 4 lites

1.11 The values stated in SI units are to be regarded as

per 1000 at the first occurrence of the design wind loading.

standard. The values given in parentheses are mathematical

1.2 The procedures apply to common outward sloping cab conversions to inch-pound units that are provided for informa-

glass designs for which the specified loads do not exceed 10 tion only and are not considered standard.

kPa (210 psf).

1.12 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.3 The procedures assume control tower cab glass has an

responsibility of the user of this standard to establish appro-

aspect ratio no greater than 2.

priate safety and health practices and to determine the

1.4 The procedures assume control tower cab glass has an

applicability of regulatory limitations prior to use.

area no less than 1.86 square metres (20 square feet).

1.5 The procedures apply only to annealed monolithic, 2. Referenced Documents

annealed laminated, or annealed insulating glass having a 2

2.1 ASTM Standards:

rectangular or trapezoidal shape.

C162 Terminology of Glass and Glass Products

1.6 The use of the procedures assumes the following: C1036 Specification for Flat Glass

1.6.1 Annealed monolithic and annealed laminated glass E631 Terminology of Building Constructions

installed in ATCTs shall have continuous lateral support along E1300 Practice for Determining Load Resistance of Glass in

two parallel edges, along any three edges, or along all four Buildings

3

edges;

2.2 American Society of Civil Engineers Standard:

1.6.2 Insulating glass shall have continuous lateral support

ASCE 7 Minimum Design Loads for Buildings and Other

along all four edges; and

Structures

1.6.3 Supported glass edges are simply supported and free

3. Terminology

to slip in plane.

3.1 Definitions:

1.7 The procedures do not apply to any form of wired,

3.1.1 For definitions of general terms related to building

patterned, etched, sandblasted, or glass types with surface

construction used in this test method refer to Terminology

treatments that reduce the glass strength.

E631, and for general terms related to glass and glass products,

1.8 The procedures do not apply to any form of heat treated

refer to Terminology E1300.

glass, chemically strengthened glass, or any type of glass with

3.2 Definitions of Terms Specific to This Standard:

surface treatments intended to increase the glass strength.

3.2.1 annealed(AN)glass,n—aflat,monolithic,glassliteof

1.9 The procedures address the determination of thickness

uniform thickness; it is formed by a process whereby the

and construction type to resist a specified design wind load at

magnitudes of the residual stresses are nearly zero.

1 2

This practice is under the jurisdiction of ASTM Committee E06 on Perfor- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mance of Buildings and is the direct responsibility of Subcommittee E06.52 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Glass Use in Buildings. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2012. Published May 2012. Originally the ASTM website.

3

approved in 2005. Last previous edition in 2011 as E2421 – 05 (2011). DOI: Available from American Society of Civil Engineers (ASCE), 1801 Alexander

10.1520/E2461-12. Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

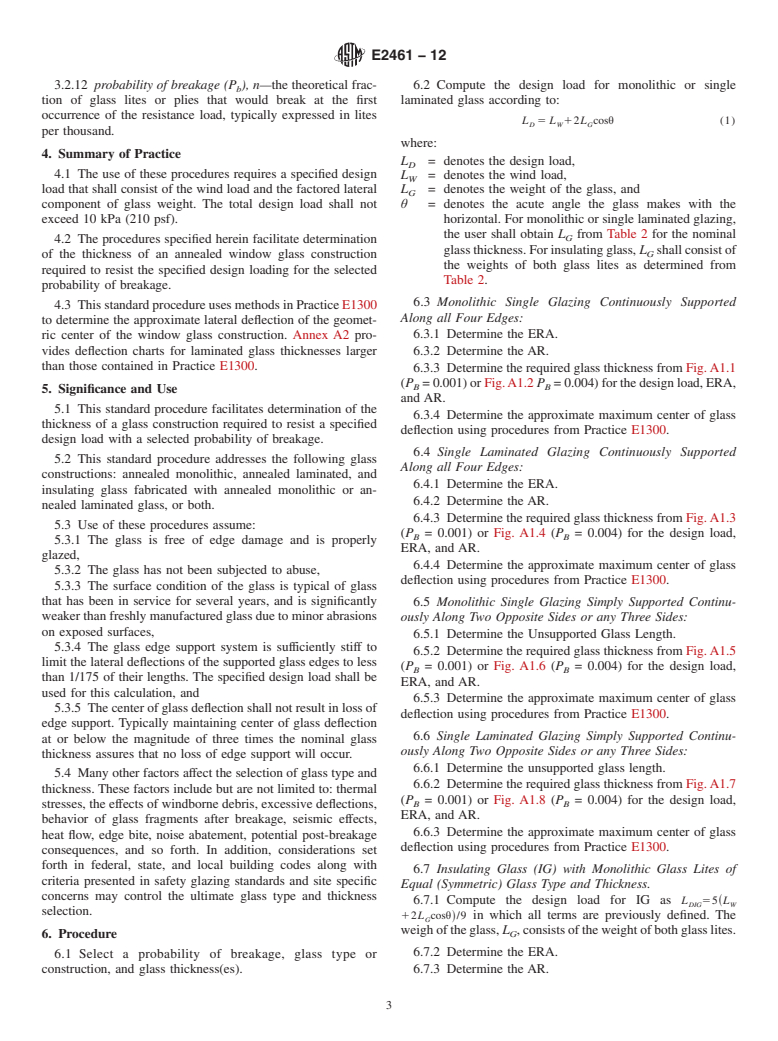

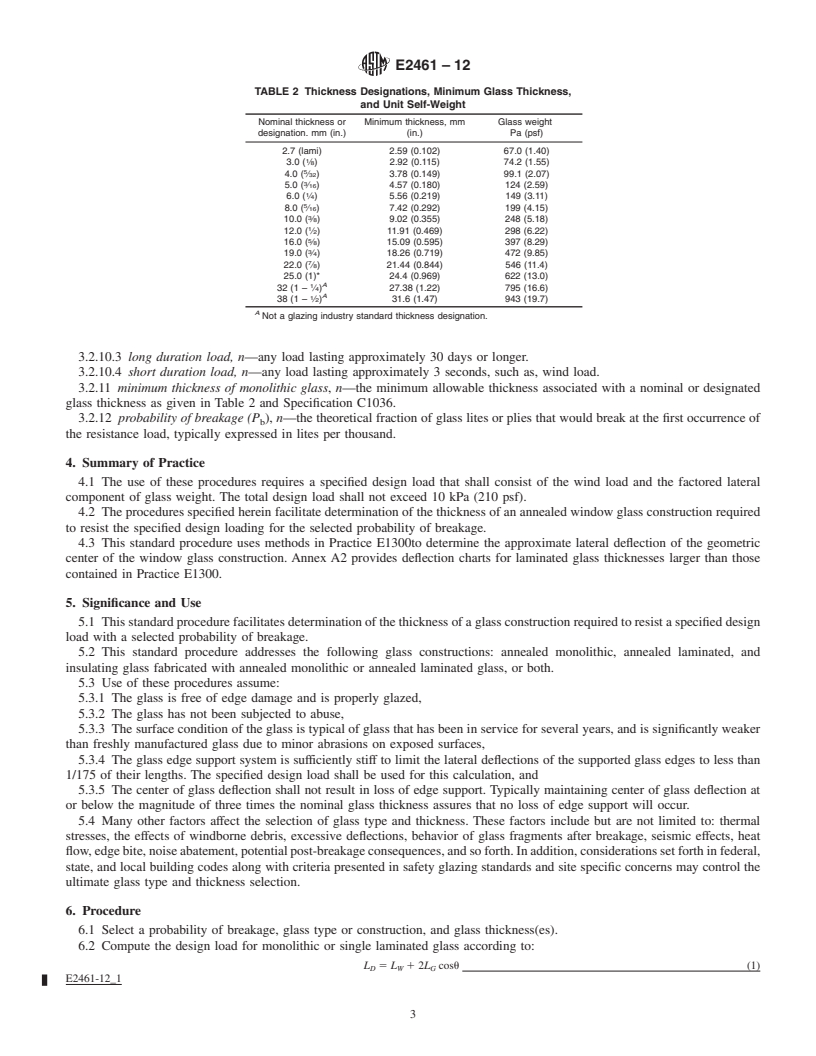

E2461 − 12

TABLE 2 Thickness Designations, Minimum Glass Thickness,

3.2.2 aspect ratio (AR), n—the ratio of the long dimension

and Unit Self-Weight

to the short dimension for rectangular glass or the ratio of the

Nominal thickness or Minimum thickness, mm Glass weight

long dimension to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2461–05 (Reapproved 2011) Designation: E2461 – 12

Standard Practice for

Determining the Thickness of Glass in Airport Traffic

1

Control Tower Cabs

This standard is issued under the fixed designation E2461; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the determination of the thickness of glass installed in airport traffic control towers (ATCT) to resist

a specified design loading with a selected probability of breakage less than or equal to either 1 lite per 1000 or 4 lites per 1000

at the first occurrence of the design wind loading.

1.2 Theproceduresapplytocommonoutwardslopingcabglassdesignsforwhichthespecifiedloadsdonotexceed10kPa(210

psf).

1.3 The procedures assume control tower cab glass has an aspect ratio no greater than 2.

1.4 The procedures assume control tower cab glass has an area no less than 1.86 square metres (20 square feet).

1.5 The procedures apply only to annealed monolithic, annealed laminated, or annealed insulating glass having a rectangular

or trapezoidal shape.

1.6 The use of the procedures assumes the following:

1.6.1 Annealed monolithic and annealed laminated glass installed in ATCTs shall have continuous lateral support along two

parallel edges, along any three edges, or along all four edges;

1.6.2 Insulating glass shall have continuous lateral support along all four edges; and

1.6.3 Supported glass edges are simply supported and free to slip in plane.

1.7 The procedures do not apply to any form of wired, patterned, etched, sandblasted, or glass types with surface treatments that

reduce the glass strength.

1.8 The procedures do not apply to any form of heat treated glass, chemically strengthened glass, or any type of glass with

surface treatments intended to increase the glass strength.

1.9 The procedures address the determination of thickness and construction type to resist a specified design wind load at a

selected probability of breakage.The final glass thickness and construction determined also depends upon a variety of other factors

(see 5.3).

1.10 These procedures do not address blast loading on glass.

1.11 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.12 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C162 Terminology of Glass and Glass Products

C1036 Specification for Flat Glass

E631 Terminology of Building Constructions

E1300 Practice for Determining Load Resistance of Glass in Buildings

3

2.2 American Society of Civil Engineers Standard:

ASCE 7 Minimum Design Loads for Buildings and Other Structures

1

This practice is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.51 on Performance

of Windows, Doors, Skylights and Curtain Walls.

Current edition approved Oct.April 1, 2011.2012. Published November 2011.May 2012. Originally approved in 2005. Last previous edition in 20052011 as

E2421 – 05 (2011). DOI: 10.1520/E2461-05R11.10.1520/E2461-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Civil Engineers (ASCE), 1801 Alexander Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2461 – 12

3. Terminology

3.1 Definitions:

3.1.1Refer to Terminology

3.1.1 For definitions of general terms related to building construction used in this test method refer to Terminology E631for

additional terms used in these procedures. , and for general terms related to glass and glass products, refer to Terminology E1300.

3.2 Definitions of Terms Specific to T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.