ASTM E1816-12

(Practice)Standard Practice for Ultrasonic Testing Using Electromagnetic Acoustic Transducer (EMAT) Techniques

Standard Practice for Ultrasonic Testing Using Electromagnetic Acoustic Transducer (EMAT) Techniques

SIGNIFICANCE AND USE

5.1 Since EMAT techniques are noncontacting, they should be considered for ultrasonic examinations in which applications involve automation, high-speed examinations, moving objects, applications in remote or hazardous locations, and applications to objects at elevated temperatures or objects with rough surfaces. This practice describes procedures for using EMAT techniques as associated with the ultrasonic method to detect flaws for both surface and volumetric examinations as well as to measure thickness.

5.2 The uniqueness of the electromagnetic acoustic transducer technique for ultrasonic examination basically lies in the generation and reception of the ultrasonic waves. Otherwise, conventional ultrasonic techniques and methodologies generally apply.

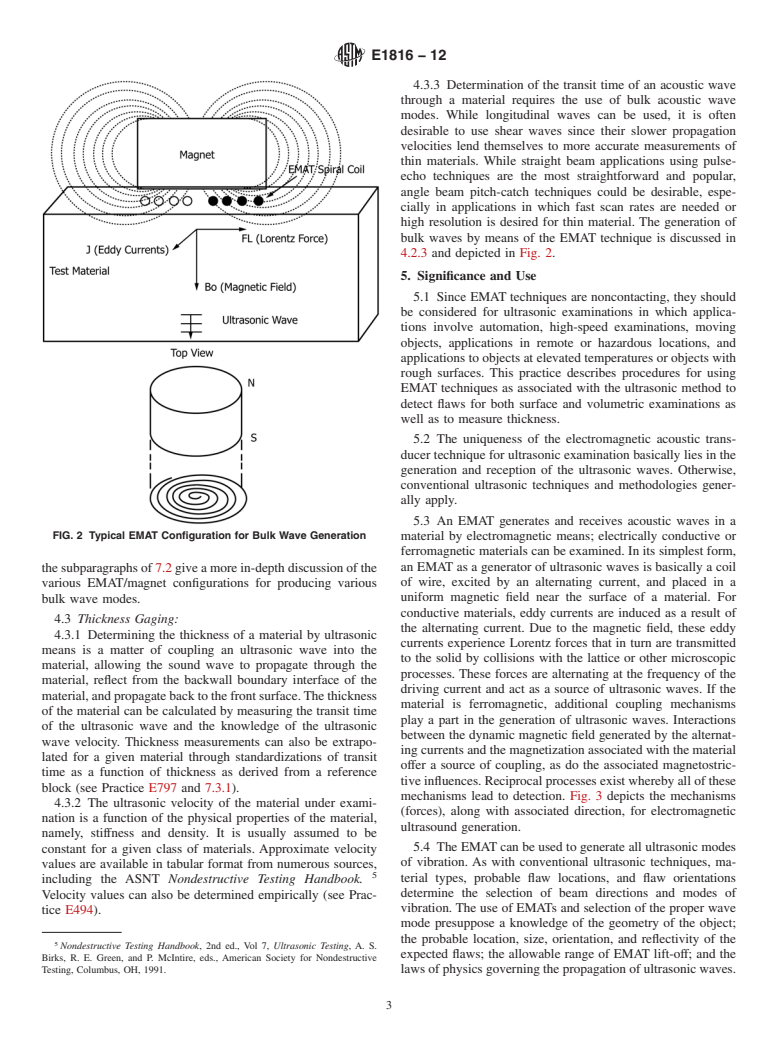

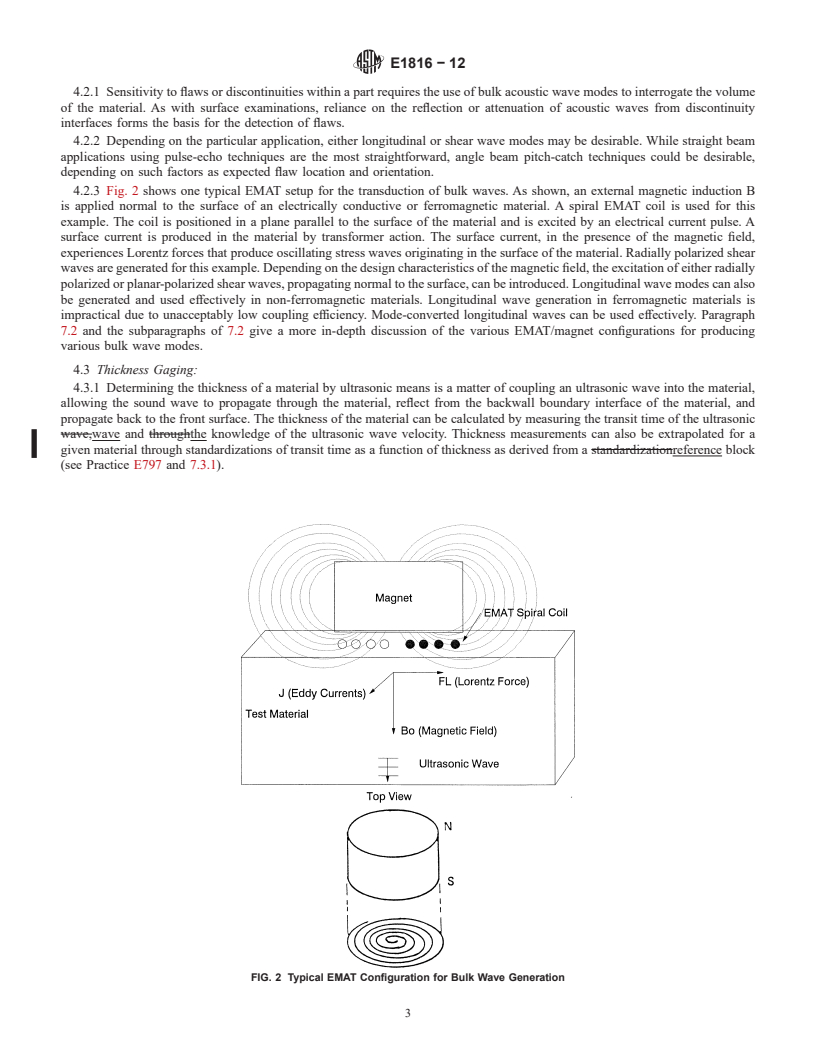

5.3 An EMAT generates and receives acoustic waves in a material by electromagnetic means; electrically conductive or ferromagnetic materials can be examined. In its simplest form, an EMAT as a generator of ultrasonic waves is basically a coil of wire, excited by an alternating current, and placed in a uniform magnetic field near the surface of a material. For conductive materials, eddy currents are induced as a result of the alternating current. Due to the magnetic field, these eddy currents experience Lorentz forces that in turn are transmitted to the solid by collisions with the lattice or other microscopic processes. These forces are alternating at the frequency of the driving current and act as a source of ultrasonic waves. If the material is ferromagnetic, additional coupling mechanisms play a part in the generation of ultrasonic waves. Interactions between the dynamic magnetic field generated by the alternating currents and the magnetization associated with the material offer a source of coupling, as do the associated magnetostrictive influences. Reciprocal processes exist whereby all of these mechanisms lead to detection. Fig. 3 depicts the mechanisms (forces), along with associated direction, for electrom...

SCOPE

1.1 This practice covers procedures for the use of electromagnetic acoustic transducers (EMATs) for specific ultrasonic examination applications. Recommendations are given for specific applications for using EMAT techniques to detect flaws through both surface and volumetric examinations as well as to measure thickness.

1.2 These procedures recommend technical details and guidelines for the reliable and reproducible ultrasonic detection of flaws and thickness measurements using electromagnetic acoustic transducers for both the pulsing and receiving of ultrasonic waves. The EMAT techniques described herein can be used as a basis for assessing the serviceability of various components nondestructively, as well as for process control in manufacturing.

1.3 These procedures cover noncontact techniques for coupling ultrasonic energy into materials through the use of electromagnetic fields. Surface, Lamb, longitudinal, and shear wave modes are discussed.

1.4 These procedures are intended to describe specific EMAT applications. These procedures are intended for applications in which the user has determined that the use of EMAT techniques can offer substantial benefits over conventional piezoelectric search units. It is not intended that EMAT techniques should be used in applications in which conventional techniques and applications offer superior benefits (refer to Guide E1774).

1.5 These procedures are applicable to any material in which acoustic waves can be introduced electromagnetically. This includes any material that is either electrically conductive or ferromagnetic.

1.6 The procedures outlined in this practice address proven EMAT techniques for specific applications; they do not purport to address the only variation or all variations of EMAT techniques to address the given applications. Latitude in application techniques is offered where options are considered appropriate.

1.7 The values stated in inch-...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1816 −12

Standard Practice for

Ultrasonic Testing Using Electromagnetic Acoustic

1

Transducer (EMAT) Techniques

This standard is issued under the fixed designation E1816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* techniques to address the given applications. Latitude in

application techniques is offered where options are considered

1.1 This practice covers procedures for the use of electro-

appropriate.

magnetic acoustic transducers (EMATs) for specific ultrasonic

examination applications. Recommendations are given for 1.7 The values stated in inch-pound units are to be regarded

specific applications for using EMAT techniques to detect as the standard. The values given in parentheses are for

flaws through both surface and volumetric examinations as information only.

well as to measure thickness.

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.2 These procedures recommend technical details and

responsibility of the user of this standard to establish appro-

guidelinesforthereliableandreproducibleultrasonicdetection

priate safety and health practices and determine the applica-

of flaws and thickness measurements using electromagnetic

bility of regulatory limitations prior to use.

acoustic transducers for both the pulsing and receiving of

ultrasonic waves. The EMAT techniques described herein can

2. Referenced Documents

be used as a basis for assessing the serviceability of various

2

components nondestructively, as well as for process control in 2.1 ASTM Standards:

manufacturing. E114 Practice for Ultrasonic Pulse-Echo Straight-Beam

Contact Testing

1.3 These procedures cover noncontact techniques for cou-

E494 Practice for Measuring Ultrasonic Velocity in Materi-

pling ultrasonic energy into materials through the use of

als

electromagnetic fields. Surface, Lamb, longitudinal, and shear

E543 Specification forAgencies Performing Nondestructive

wave modes are discussed.

Testing

1.4 These procedures are intended to describe specific

E587 Practice for Ultrasonic Angle-Beam Contact Testing

EMAT applications. These procedures are intended for appli-

E797 Practice for Measuring Thickness by Manual Ultra-

cations in which the user has determined that the use of EMAT

sonic Pulse-Echo Contact Method

techniques can offer substantial benefits over conventional

E1316 Terminology for Nondestructive Examinations

piezoelectric search units. It is not intended that EMAT

E1774 Guide for Electromagnetic Acoustic Transducers

techniques should be used in applications in which conven-

(EMATs)

tional techniques and applications offer superior benefits (refer 3

2.2 ASNT Standards:

to Guide E1774).

SNT-TC-1A Recommended Practice for Personnel Qualifi-

1.5 These procedures are applicable to any material in cations and Certification in Nondestructive Testing

which acoustic waves can be introduced electromagnetically.

ANSI/ASNT CP-189 Standard for Qualification and Certifi-

This includes any material that is either electrically conductive cation of Nondestructive Testing Personnel

or ferromagnetic.

2.3 Aerospace Industries Association Standard:

NAS 410 Certification and Qualification of Nondestructive

1.6 The procedures outlined in this practice address proven

4

Test Personnel

EMATtechniques for specific applications; they do not purport

to address the only variation or all variations of EMAT

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- Standards volume information, refer to the standard’s Document Summary page on

structive Testing and is the direct responsibility of Subcommittee E07.06 on the ASTM website.

3

Ultrasonic Method. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Current edition approved Nov. 1, 2012. Published November 2012. Originally 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

4

approved in 1996. Last previous edition approved in 2007 as E1816 - 07. DOI: Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

10.1520/E1816-12. WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1816−12

3. Terminology produceoscillatingstresswavesperp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1816 − 07 E1816 − 12

Standard Practice for

Ultrasonic Testing Using Electromagnetic Acoustic

1

Transducer (EMAT) Techniques

This standard is issued under the fixed designation E1816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice covers procedures for the use of electromagnetic acoustic transducers (EMATs) for specific ultrasonic

examination applications. Recommendations are given for specific applications for using EMAT techniques to detect flaws through

both surface and volumetric examinations as well as to measure thickness.

1.2 These procedures recommend technical details and guidelines for the reliable and reproducible ultrasonic detection of flaws

and thickness measurements using electromagnetic acoustic transducers for both the pulsing and receiving of ultrasonic waves. The

EMAT techniques described herein can be used as a basis for assessing the serviceability of various components nondestructively,

as well as for process control in manufacturing.

1.3 These procedures cover noncontact techniques for coupling ultrasonic energy into materials through the use of

electromagnetic fields. Surface, Lamb, longitudinal, and shear wave modes are discussed.

1.4 These procedures are intended to describe specific EMAT applications. These procedures are intended for applications in

which the user has determined that the use of EMAT techniques can offer substantial benefits over conventional piezoelectric

search units. It is not intended that EMAT techniques should be used in applications in which conventional techniques and

applications offer superior benefits (refer to Guide E1774).

1.5 These procedures are applicable to any material in which acoustic waves can be introduced electromagnetically. This

includes any material that is either electrically conductive or ferromagnetic.

1.6 The procedures outlined in this practice address proven EMAT techniques for specific applications; they do not purport to

address the only variation or all variations of EMAT techniques to address the given applications. Latitude in application

techniques is offered where options are considered appropriate.

1.7 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing

E494 Practice for Measuring Ultrasonic Velocity in Materials

E543 Specification for Agencies Performing Nondestructive Testing

E587 Practice for Ultrasonic Angle-Beam Contact Testing

E797 Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method

E1316 Terminology for Nondestructive Examinations

E1774 Guide for Electromagnetic Acoustic Transducers (EMATs)

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic Method.

Current edition approved July 1, 2007Nov. 1, 2012. Published July 2007November 2012. Originally approved in 1996. Last previous edition approved in 20022007 as

E1816 - 96E1816 - 07.(2002). DOI: 10.1520/E1816-07.10.1520/E1816-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1816 − 12

3

2.2 ASNT Standards:

SNT-TC-1A Recommended Practice for Personnel Qualifications and Certification in Nondestructive Testing

ANSI/ASNT CP-189 Standard for Qualification and Certification of Nondestructive Testing Personnel

2.3 Military Aerospace Industries Association Standard:

MIL-STD-410NAS 410 Nondestructive Testing Personnel Qualific

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.