ASTM F1980-99e1

(Guide)Standard Guide for Accelerated Aging of Sterile Medical Device Packages

Standard Guide for Accelerated Aging of Sterile Medical Device Packages

SCOPE

1.1 This guide provides information for developing accelerated aging protocols to rapidly determine the effects, if any, due to the passage of time and environmental effects on the sterile integrity of packages and the physical properties of their component packaging materials.

1.2 Information obtained using this guide may be used to support expiration date claims for medical device packages.

1.3 The accelerated aging guideline addresses the primary medical package in whole and does not address the package and product interaction or compatibility that may be required for new product development. Package and product compatibility and interactions should be addressed as a material analysis process before package design.

1.4 Real-time aging protocols are not addressed in this guide; however, it is essential that real-time aging studies be performed to confirm the accelerated aging test results using the same methods of evaluation.

1.5 Methods used for package process validation, which include the machine process, the effects of the sterilization process, distribution, handling, and shipping events, are beyond the scope of this guide.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 1980 – 99

Standard Guide for

Accelerated Aging of Sterile Medical Device Packages

This standard is issued under the fixed designation F 1980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout in February 2000.

1. Scope F 1140 Test Methods for Failure Resistance of Unrestrained

and Nonrigid Packages for Medical Applications

1.1 This guide provides information for developing accel-

F 1327 Terminology Relating to Barrier Materials for Medi-

erated aging protocols to rapidly determine the effects, if any,

cal Packaging

due to the passage of time and environmental effects on the

F 1585 Guide for Integrity Testing of Porous Barrier Medi-

sterile integrity of packages and the physical properties of their

cal Packages

component packaging materials.

F 1608 Test Method for Microbial Ranking of Porous Pack-

1.2 Information obtained using this guide may be used to

aging Materials (Exposure Chamber Method)

support expiration date claims for medical device packages.

F 1929 Test Method for Detecting Seal Leaks in Porous

1.3 The accelerated aging guideline addresses the primary

Medical Packaging by Dye Penetration

medical package in whole and does not address the package

2.2 ISO Standard:

and product interaction or compatibility that may be required

ANSI/AAMI/ISO 11607, Packaging for Terminally Steril-

for new product development. Package and product compat-

ized Medical Devices

ibility and interactions should be addressed as a material

analysis process before package design.

3. Terminology

1.4 Real-time aging protocols are not addressed in this

3.1 Definitions—For general definitions of packaging for

guide; however, it is essential that real-time aging studies be

medical devices see ANSI/AAMI/ISO 11607. For terminology

performed to confirm the accelerated aging test results using

related to barrier materials for medical packaging see Termi-

the same methods of evaluation.

nology F 1327.

1.5 Methods used for package process validation, which

3.2 Definitions of Terms Specific to This Standard:

include the machine process, the effects of the sterilization

3.2.1 accelerated aging (AA), n—storage of samples at an

process, distribution, handling, and shipping events, are be-

elevated temperature (T ) in order to simulate real time aging

AA

yond the scope of this guide.

in a reduced amount of time.

1.6 This standard does not purport to address all of the

3.2.2 accelerated aging factor (AAF), n—an estimated or

safety concerns, if any, associated with its use. It is the

calculated ratio of the time to achieve the same level of

responsibility of the user of this standard to establish appro-

physical property change as a package stored at real time (RT)

priate safety and health practices and determine the applica-

conditions.

bility of regulatory limitations prior to use.

3.2.3 accelerated aging temperature (T ), n—the elevated

AA

2. Referenced Documents temperature used to conduct the aging studies, and it is based

on the ambient temperature or the estimated temperature of

2.1 ASTM Standards:

usage, or storage of this package, or both.

D 3078 Test Method for Determination of Leaks in Flexible

3.2.4 accelerated aging time (AAT), n—the length of time at

Packaging by Bubble Emission

which the accelerated aging is conducted.

D 4169 Practice for Performance Testing of Shipping Con-

3.2.5 ambient temperature (T ), n—storage temperature

RT

tainers and Systems

for real-time aging (RT) samples that represents storage con-

D 4332 Practice for Conditioning Containers, Packages, or

ditions.

Packaging Components for Testing

3.2.6 package shelf life, n—the amount of real time that a

F 88 Test Method for Seal Strength of Flexible Barrier

package can be expected to remain in storage at ambient

Materials

conditions, or under specified conditions of storage, and

maintain its critical performance properties.

This guide is under the jurisdiction of ASTM Committee F-2 on Flexible

Barrier Materials and is the direct responsibility of Subcommittee F02.60 on

Medical Packaging.

Current edition approved May 10, 1999. Published July 1999. Available from the American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 15.09. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1980

3.2.7 real-time aging (RT), n—storage time of samples at applied than the normal environmental stress, for a relatively

ambient conditions. short period of time.

3.2.8 real-time equivalent (RTE), n—amount of real-time 5.3 Accelerated aging techniques are based on the assump-

aging to which given accelerated aging conditions are esti- tion that the chemical reactions involved in the deterioration of

mated to be equivalent. materials follow the Arrhenius reaction rate function. This

3.2.9 zero time (t ), n—the beginning of an aging study. function states that a 10°C increase or decrease in temperature

3.3 Symbols: of a homogeneous process results in approximately, a two

times or ⁄2-time change in the rate of a chemical reaction

(Q ) .

Q = an aging factor for 10°C increase or decrease in

5.4 Determining the Q involves testing products at various

temperature.

temperatures and defining the differences in reaction rate for a

T = temperature at which a material melts.

m

10° change in temperature. Modeling the kinetics of material

T = glass transition temperature.

g

deterioration is complex and difficult and is beyond the scope

T = alpha temperature; heat distortion temperature.

a 5

of this guide. For more details on modeling kinetics of

materials.

4. Significance and Use

6. Accelerated Aging Plan

4.1 As package components and adhesives age, they may

break down, become brittle, or lose their bonding capabilities.

6.1 Characterization of Materials—In order to apply AA

This aging characteristic may result in the potential loss of

theory, an understanding of the materials of the package under

package integrity.

investigation is necessary. Items to be considered include the

4.2 The ANSI/AAMI/ISO 11607 states that, “the manufac-

following:

turer shall demonstrate that, under the rigors of distribution,

6.1.1 Processing history;

storage, handling, and aging, the integrity of the final package

6.1.2 Morphology (glassy, amorphous, semi-crystalline,

is maintained at least for the claimed shelf-life of the medical

highly crystalline, % crystallinity, etc.);

device under storage conditions specified by the manufacturer,

6.1.3 Thermal transitions (T ,T ,T );

m g a

as long as the package is undamaged or unopened.”

6.1.4 Chemical structure (aliphatic, aromatic, repeating

4.3 The most valid aging program is to age the package

units, repeating unit sequence, end groups, side chains);

under real-life (ambient) storage conditions for the intended

6.1.5 Molecular weight and molecular weight distribution;

shelf-life. Since such testing would be completed prior to

and,

market release, this approach would delay, unnecessarily in

6.1.6 Additives, processing agents, catalysts, lubricants,

many cases, the introduction of potentially valuable technology

residual solvents, and fillers.

to the market with a loss of benefit to the patient. Avoiding

6.2 Accelerated Aging Plan-Design Guidelines:

unnecessary delays in bringing technology to the market is the

6.2.1 Temperature boundaries, based on the characterization

reason for developing and utilizing accelerated aging pro-

of the device and package materials, must be considered in

grams.

order to assure that initial, conservative aging factors are

4.4 Due to the complexity of aging processes, the use of

applied appropriately.

accelerated aging programs do involve some risk. The manu-

6.2.2 Ambient Temperature (T )—Select an ambient stor-

RT

facturer is exposed to risk of unnecessary product obsolescence

age temperature representative of actual product storage and

from conservative aging programs that predict shelf lives

use conditions.

shorter than reality. In addition, since accelerated aging often is

NOTE 2—This temperature normally is between 20–25°C for normal

on the critical path for market release, overly conservative

hospital type storage. A temperature of 25°C is conservative and may be

aging programs increase the time required to collect aging data,

appropriate when detailed information about the storage environment is

and thereby delay the release of products to the patient.

not available; however, any temperature that represents the normal storage

4.5 Conservative accelerated aging factors (AAFs) must be conditions for the product can be selected, for example, 22°C.

used if little information is known about the package under

6.2.3 Accelerated Aging Temperature (T )—Considering

AA

investigation. With more information about the system under

the characterization of the materials under investigation, select

investigation and with information demonstrating the correla-

a temperature for the accelerated aging testing. As the aging

tion between real time performance and accelerated aging

temperature increases, the aging factor also increases and the

performance, more aggressive and accurate AAFs may be

aging duration decreases; however, the benefits in efficiency

defined.

from raising the aging temperature must be balanced by the

risks involved with extrapolating increasingly high aging

NOTE 1—AAF methods are beyond the scope of this guide.

temperature properties to room temperature properties (see

5. Accelerated Aging Theory

Appendix X1). Guidelines for selecting an aging temperature

are as follows:

5.1 Accelerated aging of materials refers to the accelerated

variation of their properties over time, the properties of interest

Hemmerich, Karl J., “General Aging Theory and Simplified Protocol for

being those related to safety and function of the material or

Accelerated Aging of Medical Devices,” Medical Plastics and Biomaterials,

package.

July/August 1998, pp. 16–23.

5.2 In an aging study, the material or package is subjected to 5

Nelson, Wayne, “Accelerated Testing Statistical Models, Test Plans, and Data

an external stress, which is more severe, or more frequently Analyses,” John Wiley and Sons, New York, 1999.

F 1980

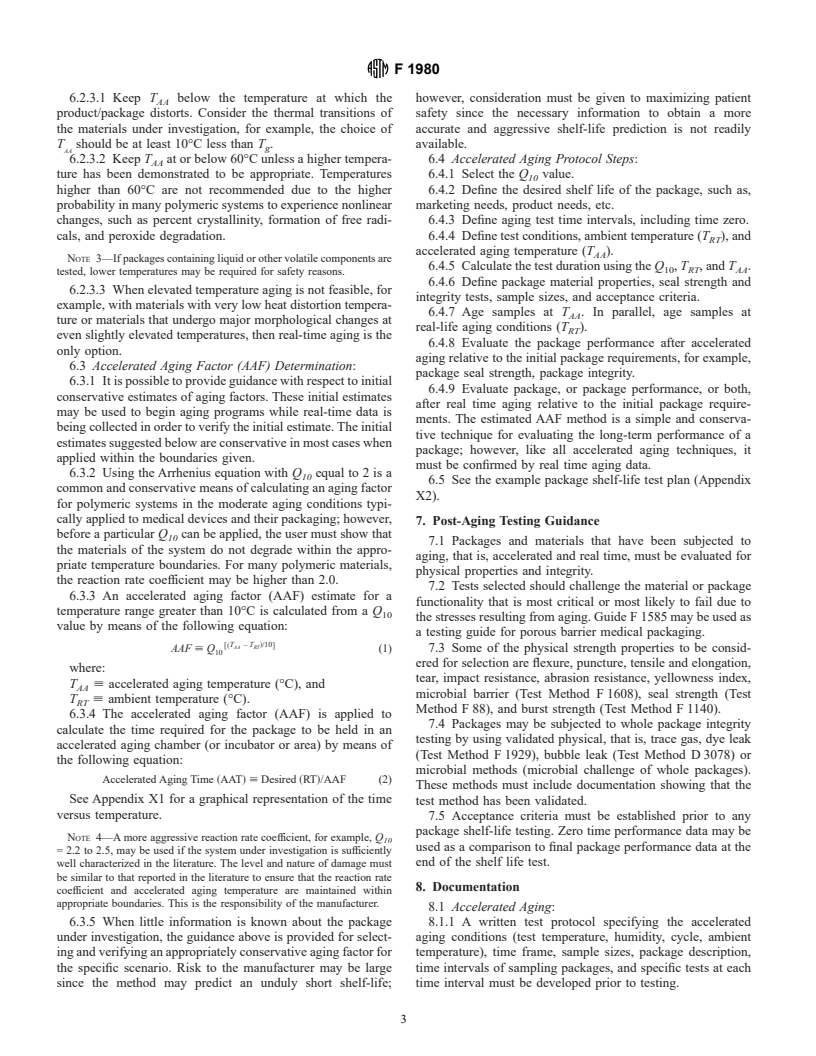

6.2.3.1 Keep T below the temperature at which the however, consideration must be given to maximizing patient

AA

product/package distorts. Consider the thermal transitions of safety since the necessary information to obtain a more

the materials under investigation, for example, the choice of accurate and aggressive shelf-life prediction is not readily

T should be at least 10°C less than T . available.

g

AA

6.2.3.2 Keep T at or below 60°C unless a higher tempera- 6.4 Accelerated Aging Protocol Steps:

AA

ture has been demonstrated to be appropriate. Temperatures 6.4.1 Select the Q value.

higher than 60°C are not recommended due to the higher 6.4.2 Define the desired shelf life of the package, such as,

probability in many polymeric systems to experience nonlinear marketing needs, product needs, etc.

changes, such as percent crystallinity, formation of free radi- 6.4.3 Define aging test time intervals, including time zero.

cals, and peroxide degradation. 6.4.4 Define test conditions, ambient temperature (T ), and

RT

accelerated aging temperature (T ).

AA

NOTE 3—If packages containing liquid or other volatile components are

6.4.5 Calculate the test duration using the Q , T , and T .

10 RT AA

tested, lower temperatures may be required for safety reasons.

6.4.6 Define package material properties, seal strength and

6.2.3.3 When elevated temperature aging is not feasible, for

integrity tests, sample sizes, and acceptance criteria.

example, with materials with very low heat distortion tempera-

6.4.7 Age samples at T . In parallel, age samples at

AA

ture or materials that undergo major morphological changes at

real-life aging conditions (T ).

RT

even slightly elevated temperatures, then real-time aging is the

6.4.8 Evaluate the package performance after accelerated

only option.

aging relative to the initial package requirements, for example,

6.3 Accelerated Aging Factor (AAF) Determination:

package seal strength, package integrity.

6.3.1 It is possible to provide guidance with respect to initial

6.4.9 Evaluate package, or package performance, or both,

conservative estimates of aging factors. These initial estimates

after real time aging relative to the initial package require-

may be used to begin aging programs while real-time data is

ments. The estimated AAF method is a simple and conserva-

being collected in order to verify the initial estimate. The initial

tive technique for evaluating the long-term performance of a

estimates suggested below are conservative in most cases when

package; however, like all accelerated aging techniques, it

applied within the boundaries given.

must be confirmed by real time aging data.

6.3.2 Using the Arrhenius equation with Q equal to 2 is a

6.5 See the example package shelf-life test plan (Appendix

common and conservative means of calculating an aging factor

X2).

for polymeric systems in the moderate aging conditions typi-

cally applied to medical devices and their packaging; however,

7. Post-Aging Testing Guidance

before a particular Q can be applied, the user must show that

7.1 Packages and materials that have been subjected to

the materials of the system do not degrade within the appro-

aging, that is, accelerated and real time, must be evaluated for

priate temperature boundaries. For many polymeric materials,

physical properties and integrity.

the reaction rate coefficient may be higher than 2.0.

7.2 Tests selected should challenge the material or package

6.3.3 An accelerated aging factor (AAF) estimate for a

functionality that is most critical or most likely to fail due to

temperature range greater than 10°C is calculated from a Q

the stresses resulting from aging. Guide F 1585 may be used as

value by means of the following equation:

a testing guide for porous barrier medical packaging.

@~T – T !/10#

AA RT

7.3 Some of the physical strength properties to be consid-

AAF [ Q (1)

ered for selection are flexure, puncture, tensile and elongation,

where:

tear, impact resistance, abrasion resistance, yellowness index,

T [ accelerated aging temperature (°C), and

AA

microbial barrier (Test Method F 1608), seal strength (Test

T [ ambient temperature (°C).

RT

Method F 88), and burst strength (Test Method F 11

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.