ASTM D7577-12(2016)

(Test Method)Standard Test Method for Determining the Accelerated Iron Corrosion Rating of Denatured Fuel Ethanol and Ethanol Fuel Blends

Standard Test Method for Determining the Accelerated Iron Corrosion Rating of Denatured Fuel Ethanol and Ethanol Fuel Blends

SIGNIFICANCE AND USE

5.1 This test is designed to be used as a rapid measure of the overall relative corrosivity of Ethanol Fuel Blends (Specification D5798) and Denatured Fuel Ethanol (Specification D4806) to iron (steel).

5.2 The test can be used to compare corrosion inhibitor dosage levels and effectiveness of various corrosion inhibitors as they pertain to protecting iron (steel) materials from corrosion.

SCOPE

1.1 This test method measures the ability of inhibited and uninhibited Ethanol Fuel Blends defined by Specification D5798 and Denatured Fuel Ethanol defined by Specification D4806 to resist corrosion of iron should water become mixed with the fuel, using an accelerated laboratory test method. Corrosion ratings are reported based on a visual, numbered rating scale.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Sections 7 and 8.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7577 − 12 (Reapproved 2016)

Standard Test Method for

Determining the Accelerated Iron Corrosion Rating of

1

Denatured Fuel Ethanol and Ethanol Fuel Blends

This standard is issued under the fixed designation D7577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5798 Specification for Ethanol Fuel Blends for Flexible-

Fuel Automotive Spark-Ignition Engines

1.1 This test method measures the ability of inhibited and

E177 Practice for Use of the Terms Precision and Bias in

uninhibited Ethanol Fuel Blends defined by Specification

ASTM Test Methods

D5798 and Denatured Fuel Ethanol defined by Specification

E2251 Specification for Liquid-in-Glass ASTM Thermom-

D4806 to resist corrosion of iron should water become mixed

eters with Low-Hazard Precision Liquids

with the fuel, using an accelerated laboratory test method.

Corrosion ratings are reported based on a visual, numbered

3. Terminology

rating scale.

3.1 Definitions:

1.2 The values stated in SI units are to be regarded as

3.1.1 For definitions of terms used in this test method, refer

standard. The values in parentheses are for information only.

to Terminology D4175.

3.1.2 Fuel C, n—a volumetric mixture of 50 volume percent

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the reference fuel grade toluene and 50 volume percent reference

fuel grade isooctane.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.2.1 Discussion—Specifications for reference fuel grade

toluene and reference fuel grade isooctane can be found inTest

bility of regulatory limitations prior to use. Specific hazard

statements are given in Sections 7 and 8. Method D2699.

3.2 Abbreviations:

2. Referenced Documents

3.2.1 HDPE, n—high density polyethylene

2

2.1 ASTM Standards:

3.2.2 PTFE, n—Polytetrafluoroethylene

A29/A29M SpecificationforGeneralRequirementsforSteel

Bars, Carbon and Alloy, Hot-Wrought

4. Summary of Test Method

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

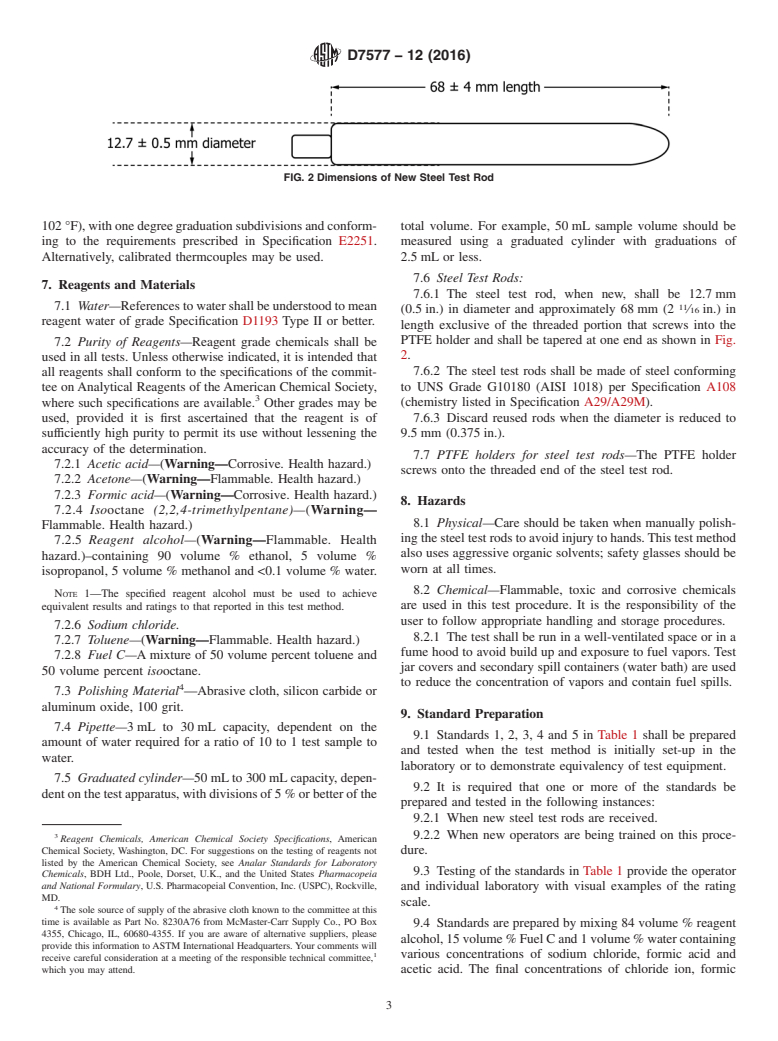

4.1 Apolished steel test rod is immersed in a mixture of the

Finished

testsampleandwaterataratioof10partsfuelsampleto1part

D665 Test Method for Rust-Preventing Characteristics of

water and held at a temperature of 37 °C to 39 °C (98 °F to

Inhibited Mineral Oil in the Presence of Water

102 °F) for 1 h.

D1193 Specification for Reagent Water

4.2 At the end of 1 h, the test rod is removed, rinsed and

D2699 Test Method for Research Octane Number of Spark-

rated according to a numeric corrosion rating scale.

Ignition Engine Fuel

D4175 Terminology Relating to Petroleum Products, Liquid

5. Significance and Use

Fuels, and Lubricants

5.1 Thistestisdesignedtobeusedasarapidmeasureofthe

D4806 Specification for Denatured Fuel Ethanol for Blend-

overall relative corrosivity of Ethanol Fuel Blends (Specifica-

ing with Gasolines for Use as Automotive Spark-Ignition

tion D5798) and Denatured Fuel Ethanol (Specification

Engine Fuel

D4806) to iron (steel).

1

This test method is under the jurisdiction of ASTM Committee D02 on

5.2 The test can be used to compare corrosion inhibitor

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

dosage levels and effectiveness of various corrosion inhibitors

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

as they pertain to protecting iron (steel) materials from

Current edition approved Oct. 1, 2016. Published November 2016. Originally

approved in 2012. Last previous edition approved in 2012 as D7577 – 12. DOI: corrosion.

10.1520/D7577-12R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Apparatus

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 General—Two test apparatus have been evaluated and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. found to give comparable results.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7577 − 12 (2016)

FIG. 1 Recommended Small Volume Test Apparatus

6.1.1 Large sample volume (300 mL) apparatus specified in 6.2.5.1 A hole to suspend the steel test rod into the test

Test Method D665. sample,

6.1.2 Small sample volume (30 mL to 75 mL) apparatus 6.2.5.2 A hole for the thermometer,

specified in 6.2. 6.2.5.3 Ahole for inserting a syringe needle to add water to

the test sample.

6.2 Small Volume Test Apparatus (Fig. 1).

6.2.6 PTFE (poly

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7577 − 12 D7577 − 12 (Reapproved 2016)

Standard Test Method for

Determining the Accelerated Iron Corrosion Rating of

1

Denatured Fuel Ethanol and Ethanol Fuel Blends

This standard is issued under the fixed designation D7577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method measures the ability of inhibited and uninhibited Ethanol Fuel Blends defined by Specification D5798 and

Denatured Fuel Ethanol defined by Specification D4806 to resist corrosion of iron should water become mixed with the fuel, using

an accelerated laboratory test method. Corrosion ratings are reported based on a visual, numbered rating scale.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazard statements are given in Sections 7 and 8.

2. Referenced Documents

2

2.1 ASTM Standards:

A29/A29M Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought

A108 Specification for Steel Bar, Carbon and Alloy, Cold-Finished

D665 Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

D1193 Specification for Reagent Water

D2699 Test Method for Research Octane Number of Spark-Ignition Engine Fuel

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4806 Specification for Denatured Fuel Ethanol for Blending with Gasolines for Use as Automotive Spark-Ignition Engine Fuel

D5798 Specification for Ethanol Fuel Blends for Flexible-Fuel Automotive Spark-Ignition Engines

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4175.

3.1.2 Fuel C, n—a volumetric mixture of 50 volume percent reference fuel grade toluene and 50 volume percent reference fuel

grade isooctane.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved Dec. 15, 2012Oct. 1, 2016. Published January 2013November 2016. Originally approved in 2012. Last previous edition approved in 2012 as

D7577 – 12. DOI: 10.1520/D7577-12.10.1520/D7577-12R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.2.1 Discussion—

Specifications for reference fuel grade toluene and reference fuel grade isooctane can be found in Test Method D2699.

3.2 Abbreviations:

3.2.1 HDPE, n—high density polyethylene

3.2.2 PTFE, n—Polytetrafluoroethylene

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7577 − 12 (2016)

FIG. 1 Recommended Small Volume Test Apparatus

4. Summary of Test Method

4.1 A polished steel test rod is immersed in a mixture of the test sample and water at a ratio of 10 parts fuel sample to 1 part

water and held at a temperature of 3737 °C to 39°C (9839 °C (98 °F to 102°F)102 °F) for 1 h.1 h.

4.2 At the end of 1 h, 1 h, the test rod is removed, rinsed and rated according to a numeric corrosion rating scale.

5. Significance and Use

5.1 This test is designed to be used as a rapid measure of the overall relative corrosivity of Ethanol Fuel Blends (Specification

D5798) and Denatured Fuel Ethanol (Specification D4806) to iron (steel).

5.2 The test can be used to compare corrosion inhibitor dosage levels and effectiveness of various corrosion inhibitors as they

pertain to protecting iron (steel) materials from corrosion.

6. Apparatus

6.1 General—Two test apparatus have been evaluated and found to give comparable results.

6.1.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.