ASTM D7577-12(2021)

(Test Method)Standard Test Method for Determining the Accelerated Iron Corrosion Rating of Denatured Fuel Ethanol and Ethanol Fuel Blends

Standard Test Method for Determining the Accelerated Iron Corrosion Rating of Denatured Fuel Ethanol and Ethanol Fuel Blends

SIGNIFICANCE AND USE

5.1 This test is designed to be used as a rapid measure of the overall relative corrosivity of Ethanol Fuel Blends (Specification D5798) and Denatured Fuel Ethanol (Specification D4806) to iron (steel).

5.2 The test can be used to compare corrosion inhibitor dosage levels and effectiveness of various corrosion inhibitors as they pertain to protecting iron (steel) materials from corrosion.

SCOPE

1.1 This test method measures the ability of inhibited and uninhibited Ethanol Fuel Blends defined by Specification D5798 and Denatured Fuel Ethanol defined by Specification D4806 to resist corrosion of iron should water become mixed with the fuel, using an accelerated laboratory test method. Corrosion ratings are reported based on a visual, numbered rating scale.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Sections 7 and 8.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7577 − 12 (Reapproved 2021)

Standard Test Method for

Determining the Accelerated Iron Corrosion Rating of

Denatured Fuel Ethanol and Ethanol Fuel Blends

This standard is issued under the fixed designation D7577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2699 Test Method for Research Octane Number of Spark-

Ignition Engine Fuel

1.1 This test method measures the ability of inhibited and

D4175 Terminology Relating to Petroleum Products, Liquid

uninhibited Ethanol Fuel Blends defined by Specification

Fuels, and Lubricants

D5798 and Denatured Fuel Ethanol defined by Specification

D4806 Specification for Denatured Fuel Ethanol for Blend-

D4806 to resist corrosion of iron should water become mixed

ing with Gasolines for Use as Automotive Spark-Ignition

with the fuel, using an accelerated laboratory test method.

Engine Fuel

Corrosion ratings are reported based on a visual, numbered

D5798 Specification for Ethanol Fuel Blends for Flexible-

rating scale.

Fuel Automotive Spark-Ignition Engines

1.2 The values stated in SI units are to be regarded as

E177 Practice for Use of the Terms Precision and Bias in

standard. The values in parentheses are for information only.

ASTM Test Methods

1.3 This standard does not purport to address all of the E2251 Specification for Liquid-in-Glass ASTM Thermom-

safety concerns, if any, associated with its use. It is the

eters with Low-Hazard Precision Liquids

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3. Terminology

mine the applicability of regulatory limitations prior to use.

3.1 Definitions:

Specific hazard statements are given in Sections 7 and 8.

3.1.1 For definitions of terms used in this test method, refer

1.4 This international standard was developed in accor-

to Terminology D4175.

dance with internationally recognized principles on standard-

3.1.2 Fuel C, n—a volumetric mixture of 50 volume percent

ization established in the Decision on Principles for the

reference fuel grade toluene and 50 volume percent reference

Development of International Standards, Guides and Recom-

fuel grade isooctane.

mendations issued by the World Trade Organization Technical

3.1.2.1 Discussion—Specifications for reference fuel grade

Barriers to Trade (TBT) Committee.

toluene and reference fuel grade isooctane can be found inTest

Method D2699.

2. Referenced Documents

3.2 Abbreviations:

2.1 ASTM Standards:

3.2.1 HDPE, n—high density polyethylene

A29/A29M SpecificationforGeneralRequirementsforSteel

3.2.2 PTFE, n—Polytetrafluoroethylene

Bars, Carbon and Alloy, Hot-Wrought

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

4. Summary of Test Method

Finished

D665 Test Method for Rust-Preventing Characteristics of

4.1 Apolished steel test rod is immersed in a mixture of the

Inhibited Mineral Oil in the Presence of Water

testsampleandwaterataratioof10partsfuelsampleto1part

D1193 Specification for Reagent Water

water and held at a temperature of 37 °C to 39 °C (98 °F to

102 °F) for 1 h.

4.2 At the end of 1 h, the test rod is removed, rinsed and

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of rated according to a numeric corrosion rating scale.

Subcommittee D02.14 on Stability, Cleanliness and Compatibility of Liquid Fuels.

Current edition approved May 1, 2021. Published June 2021. Originally

5. Significance and Use

approved in 2012. Last previous edition approved in 2016 as D7577 – 12 (2016).

DOI: 10.1520/D7577-12R21.

5.1 Thistestisdesignedtobeusedasarapidmeasureofthe

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

overall relative corrosivity of Ethanol Fuel Blends (Specifica-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion D5798) and Denatured Fuel Ethanol (Specification

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. D4806) to iron (steel).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7577 − 12 (2021)

FIG. 1 Recommended Small Volume Test Apparatus

5.2 The test can be used to compare corrosion inhibitor volumes of samples to improve the safety of the measurement.

dosage levels and effectiveness of various corrosion inhibitors Different apparatus and components that achieve the same

as they pertain to protecting iron (steel) materials from results may be used.

corrosion.

6.2.2 Hot plate/stir plate or water bath capable of maintain-

ing a temperature of 37 °C to 39 °C (98 °F to 102 °F) and

6. Apparatus

stirring at a rate of 900 r⁄min 6 100 r⁄min.

6.2.3 150 mL to 200 mL borosilicate glass beakers to hold

6.1 General—Two test apparatus have been evaluated and

water to serve as a water bath.

found to give comparable results.

6.1.1 Large sample volume (300 mL) apparatus specified in 6.2.4 50 mL to 150 mL borosilicate, flat bottom, glass test

Test Method D665. jar to hold test sample.

6.1.2 Small sample volume (30 mL to 75 mL) apparatus

6.2.5 JarcoversmadeofHDPEorothermaterialcompatible

specified in 6.2.

with ethanol, water and gasoline with three holes:

6.2.5.1 A hole to suspend the steel test rod into the test

6.2 Small Volume Test Apparatus (Fig. 1).

sample,

6.2.1 ComparedtoTestMethodD665,thesmallvolumetest

apparatus is lower in cost and allows for use of smaller 6.2.5.2 A hole for the thermometer,

D7577 − 12 (2021)

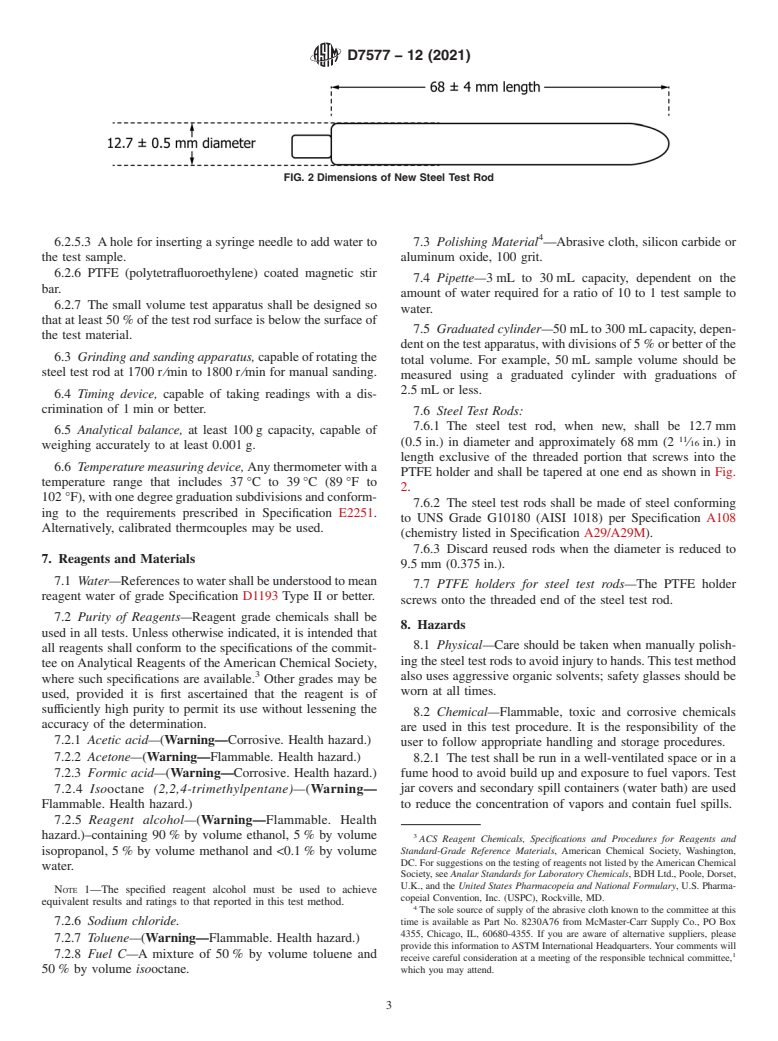

FIG. 2 Dimensions of New Steel Test Rod

6.2.5.3 Ahole for inserting a syringe needle to add water to 7.3 Polishing Material —Abrasive cloth, silicon carbide or

the test sample. aluminum oxide, 100 grit.

6.2.6 PTFE (polytetrafluoroethylene) coated magnetic stir

7.4 Pipette—3 mL to 30 mL capacity, dependent on the

bar.

amount of water required for a ratio of 10 to 1 test sample to

6.2.7 The small volume test apparatus shall be designed so

water.

that at least 50 % of the test rod surface is below the surface of

7.5 Graduated cylinder—50 mLto 300 mLcapacity, depen-

the test material.

dentonthetestapparatus,withdivisionsof5 %orbetterofthe

6.3 Grinding and sanding apparatus,capableofrotatingthe

total volume. For example, 50 mL sample volume should be

steel test rod at 1700 r⁄min to 1800 r⁄min for manual sanding.

measured using a graduated cylinder with graduations of

2.5 mL or less.

6.4 Timing device, capable of taking readings with a dis-

crimination of 1 min or better.

7.6 Steel Test Rods:

7.6.1 The steel test rod, when new, shall be 12.7 mm

6.5 Analytical balance, at least 100 g capacity, capable of

(0.5 in.) in diameter and approximately 68 mm (2 ⁄16 in.) in

weighing accurately to at least 0.001 g.

length exclusive of the threaded portion that screws into the

6.6 Temperature measuring device,Anythermometerwitha

PTFE holder and shall be tapered at one end as shown in Fig.

temperature range that includes 37 °C to 39 °C (89 °F to

2.

102 °F),withonedegreegraduationsubdivisionsandconform-

7.6.2 The steel test rods shall be made of steel conforming

ing to the requirements prescribed in Specification E2251.

to UNS Grade G10180 (AISI 1018) per Specification A108

Alternatively, calibrated thermcouples may be used.

(chemistry listed in Specification A29/A29M).

7.6.3 Discard reused rods when the diameter is reduced to

7. Reagents and Materials

9.5 mm (0.375 in.).

7.1 Water—Referencestowatershallbeunderstoodtomean

7.7 PTFE holders for steel test rods—The PTFE holder

reagent water of grade Specification D1193 Type II or better.

screws onto the threaded end of the steel test rod.

7.2 Purity of Reagents—Reagent grade chemicals shall be

8. Hazards

used in all tests. Unless otherwise indicated, it is intended that

8.1 Physical—Care should be taken when manually polish-

all reagents shall conform to the specifications of the commit-

ing the steel test rods to avoid injury to hands.This test method

tee onAnalytical Reagents of theAmerican Chemical Society,

also uses aggressive organic solvents; safety glasses should be

where such specifications are available. Other grades may be

worn at all times.

used, provided it is first ascertained that the reagent is of

sufficiently high purity to permit its use without lessening the

8.2 Chemical—Flammable, toxic and corrosive chemicals

accuracy of the determination.

are used in this test procedure. It is the responsibility of the

7.2.1 Acetic acid—(Warning—Corrosive. Health hazard.)

user to follow appropriate handling and storage procedures.

7.2.2 Acetone—(Warning—Flammable. Health hazard.) 8.2.1 The test shall be run in a well-ventilated space or in a

7.2.3 Formic acid—(Warning—Corrosive. Health hazard.) fume hood to avoid build up and exposure to fuel vapors. Test

jar covers and secondary spill containers (water bath) are used

7.2.4 Isooctane (2,2,4-trimethylpentane)—(Warning—

Flammable. Health hazard.) to reduce the concentration of vapors and contain fuel spills.

7.2.5 Reagent alcohol—(Warning—Flammable. Health

hazard.)–containing 90 % by volume ethanol, 5 % by volume

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

Standard-Grade Reference Materials, American Chemical Society, Washington,

isopropanol, 5 % by volume methanol and <0.1 % by volume

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

water.

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

NOTE 1—The specified reagent alcohol must be used to achieve

copeial Convention, Inc. (USPC), Rockville, MD.

equivalent results and ratings to that reported in this test method.

The sole source of supply of the abrasive cloth known to the committee at this

7.2.6 Sodium chloride. time is available as Part No. 8230A76 from McMaster-Carr Supply Co., PO Box

4355, Chicago, IL, 60680-4355. If you are aware of alternative suppliers, please

7.2.7 Toluene—(Warning—Flammable. Health hazard.)

provide this information toASTM International Headquarters. Your comments will

7.2.8 Fuel C—A mixture of 50 % by volume toluene and

receive careful consideration at a meeting of the responsible technical committee,

50 % by volume isooctane. which you may attend.

D7577 − 12 (2021)

TABLE 1 Concentration of Corrosive Components in 500 mL

11.4.1 Preliminary Sanding—Hold the 100 grit abrasive

Standard Solutions Containing 84 % by Volume Reagent Alcohol,

cloth strip perpendicular to the long-axis of the test rod so that

15 % by Volume Fuel C and 1 % by Volume Water

circular grooves are formed all along the length of the rod.

Standard Rating Chloride, Formic acid, Acetic acid,

Move the cloth along the axis of the test rod. All rust and

No. mg/kg±10% mg/kg±10% mg/kg±10%

irregularities must be removed.

1 1 000

11.4.2 Surface Marking—Rub a new piece of abrasive cloth

22 1.5 0 5

3 3 515

longitudinally over the static test rod until the entire surface

44 5 10 5

shows visible scratches.

5 5 15 10 20

11.4.3 Final Sanding—Using a new piece of abrasive cloth,

hold the 100 grit abrasive cloth strip perpendicular to the

long-axis of the test rod so that circular grooves are formed all

along the length of the rod. Move the cloth along the axis until

all visible surface scratches from 11.4.2 have been removed.

9. Standard Preparation

11.5 Using a clean cloth or wipe, remove the test-rod from

9.1 Standards 1, 2, 3, 4 and 5 in Table 1 shall be prepared

the chuck. Do not tough the surfaces with fingers.

and tested when the test method is initially set-up in the

laboratory or to demonstrate equivalency of test equipment. 11.6 Attach the PTFE rod holder.

9.2 It is required that one or more of the standards be 11.7 Wipe the rod with a clean, lintless cloth or tissue.

prepared and tested in the following instances:

11.8 Rinse the rod with acetone.

9.2.1 When new steel test rods are received.

11.9 Store cleaned and sanded test rods in isooctane until

9.2.2 When new operators are being trained on this proce-

use.Timebetweensandinganduseshouldnotexceed1hwhen

dure.

stored in isooctane and should not exceed 5 min when not

9.3 Testing of the standards in Table 1 provide the operator

stored in isooctane.

and individual laboratory with visual examples of the rating

scale.

12. Procedure

9.4 Standards are prepared by mixing 84 % by volume

12.1 Prepare the corrosion test-rod and test apparatus in

reagent alcohol, 15 % by volume Fuel C, and 1 % by volume

accordance with Sections 10 and 11.

water containing various concentrations of sodium chloride,

12.2 Transfer the test sample or standard into the test jar

formic acid and acetic acid. The final concentrations of

using a graduated cylinder.

chloride ion, formic acid and acetic acid are shown in Table 1.

12.2.1 Use 300 mL of test sample or standard for the large

Standard concentrations shall be prepared within 610 % of the

sample volume apparatus specified in Test Method D665.

stated values in Table 1.

12.2.2 Use 30 mL to 75 mL of test sample or standard for

9.5 Example standard preparations are shown in Table 2.

the small sample volume apparatus specified in 6.2.

Water or water solutions containing sodium chloride, formic

12.3 Place the stir bar or other stirring tool into the test jar

acid and acetic acid are added to a 500 mL volumetric flask

and cover with the jar cover.

containing approximately 300 mL of reagent alcohol. After

stirring to mix, 75 mL of Fuel C is added and reagent alcohol 12.4 It is very important that clean, oil-free gloves are used,

is added to reach the 500 mL volume mark on the flask. The

or similar precautions are taken, to avoid contamination of the

solutions are stirred until mixed adequately. test rod with fingerprints or other oils.

12.5 Insert the previously polished corrosion test rod with

10. Preparation of Apparatus

its holder down into the jar cover until at least half of the rod

10.1 Heat the water bath to a temperature of 37 °C to 39 °C is immersed in the test sample or standard. The test rod shall

(98 °F to 102 °F). not touch the bottom of the jar.

12.5.1 Do not let the clean test rod rub against the jar cover

11. Preparation of Corrosion Test Rod ifaplasticcoverisused.Transferofmaterialtothetestrodcan

affect test results.

11.1 It is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.