ASTM D5399-95(2000)

(Test Method)Standard Test Method for Boiling Point Distribution of Hydrocarbon Solvents by Gas Chromatography

Standard Test Method for Boiling Point Distribution of Hydrocarbon Solvents by Gas Chromatography

SCOPE

1.1 This test method covers the determination of the boiling point distribution of hydrocarbon solvents by capillary gas chromatography. This test method is limited to samples having a minimum initial boiling point of 37°C (99°F), a maximum final boiling point of 285°C (545°F), and a boiling range of 5 to 150°C (9 to 270°F) as measured by this test method.

1.2 The values stated in SI units are standard. The values given in parentheses are for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5399 – 95 (Reapproved 2000)

Standard Test Method for

Boiling Point Distribution of Hydrocarbon Solvents by Gas

Chromatography

This standard is issued under the fixed designation D 5399; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the boiling 3.1 Definitions:

point distribution of hydrocarbon solvents by capillary gas 3.1.1 initial boiling point (IBP)—the point at which a

chromatography. This test method is limited to samples having cumulative area count equal to 0.5 % of the total area under the

a minimum initial boiling point of 37°C (99°F), a maximum chromatogram is obtained.

final boiling point of 285°C (545°F), and a boiling range of 5 3.1.2 final boiling point (FBP)—the point at which a cumu-

to 150°C (9 to 270°F) as measured by this test method. lative area count equal to 99.5 % of the total area under the

1.2 The values stated in SI units are standard. The values chromatogram is obtained.

given in parentheses are for information purposes only.

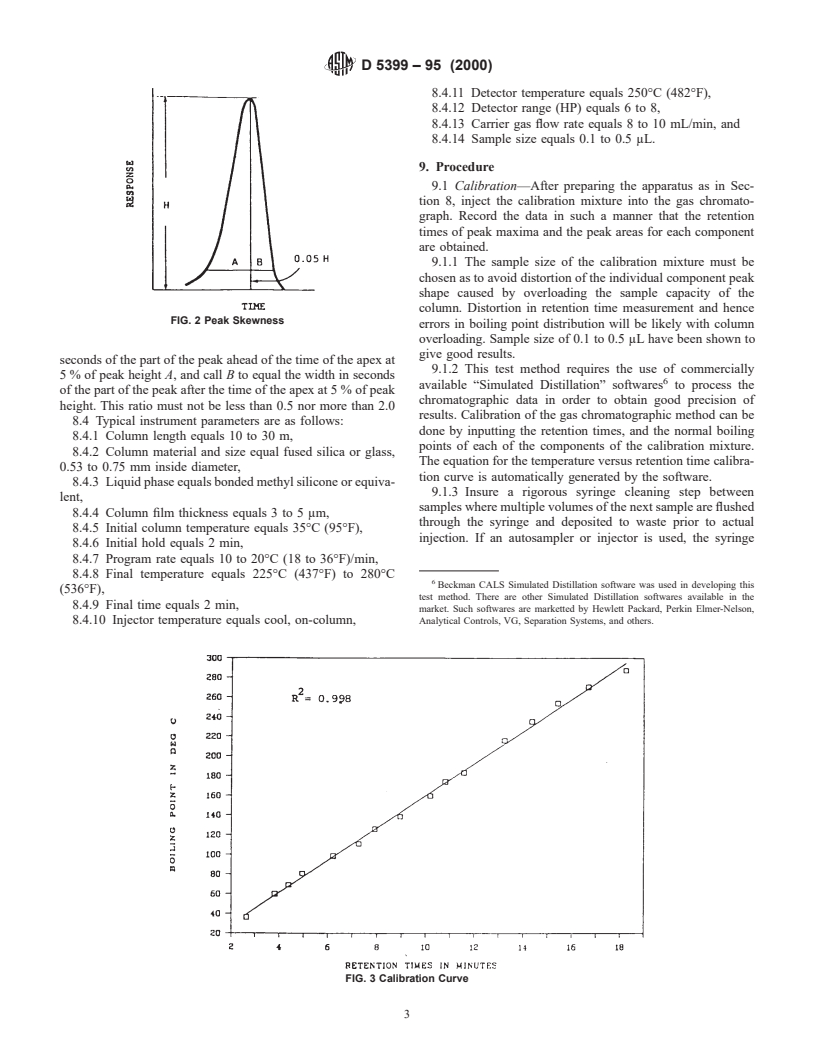

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 The sample is introduced into a capillary gas chromato-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- graphic column that separates hydrocarbons in the order of

increasing boiling point. The column temperature is raised at a

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. reproducible rate and the area under the chromatogram is

recorded throughout the run. Boiling points are assigned from

2. Referenced Documents

a calibration curve obtained under the same conditions by

2.1 ASTM Standards: running a known mixture of hydrocarbons covering the boiling

D 86 Test Method for Distillation of Petroleum Products at range expected in the sample. From these data, the boiling

Atmospheric Pressure point distribution of the sample is obtained.

D 850 Test Method for Distillation of Industrial Aromatic

3 5. Significance and Use

Hydrocarbons and Related Materials

D 1078 Test Method for Distillation Range of Volatile 5.1 The gas chromatographic determination of the boiling

point distribution of hydrocarbon solvents can be used as an

Organic Liquids

D 2887 Test Method for Boiling Range Distribution of alternative to conventional distillation methods for control of

solvents quality during manufacture, and specification testing.

Petroleum Fractions by Gas Chromatography

D 2892 Test Method for Distillation of Crude Petroleum 5.2 Boiling point distribution data can be used to monitor

the presence of product contaminants and compositional varia-

(15-Theoretical Plate Column)

D 3710 Test Method for Boiling Range Distribution of tion during the manufacture of hydrocarbon solvents.

5.3 Boiling point distribution data obtained by this test

Gasoline and Gasoline Fractions by Gas Chromatography

E 691 Practice for Conducting an Interlaboratory Study to method are not equivalent to those obtained by Test Methods

D 86, D 850, D 1078, D 2887, D 2892, and D 3710.

Determine the Precision of a Test Method

6. Apparatus

6.1 Chromatograph—Any gas chromatograph that can

This test method is under the jurisdiction of ASTM Committee D01 on Paint

handle capillary column and has the following characteristics:

and Related Coatings, Materials, and Applications and is the direct responsibility of

6.1.1 Detector—A flame ionization detector (FID) capable

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

of continuous operation at a temperature equivalent to the

Current edition approved Nov. 10, 1995. Published January 1996. Originally

published as D 5399 – 93. Last previous edition D 5399 – 93.

maximum column temperature employed.

Annual Book of ASTM Standards, Vol 05.01.

6.1.2 Column Temperature Programmer—The chromato-

Annual Book of ASTM Standards, Vol 06.04.

graph must be capable of reproducible linear temperature

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 14.02. programming over a range sufficient to establish a retention

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5399 – 95 (2000)

time of 1 min for n-pentane and to allow elution of entire 7.3 Carrier Gas, helium (high purity)—Additional purifica-

sample within a reasonable time period. tion is recommended by the use of molecular sieves or other

6.1.3 Sample Inlet System—The sample inlet system must suitable agents to remove water, oxygen, and hydrocarbons.

be capable of operating continuously at a temperature up to the 7.3.1 Warning: Helium is a compressed gas under high

maximum column temperature employed, or provide on- pressure.

column injection. 7.4 Detector Gases, air, hydrogen (high purity)—Additional

purification for air and hydrogen is recommended by the use of

NOTE 1—The use of cool, on-column injection using an automatic

molecular sieves, activated carbons, or other suitable agents to

injector or sampler has been shown to provide better precision relative to

remove water and organics.

manual injection.

7.4.1 Warning: Air and hydrogen are compressed gases

6.1.4 Column—A 10 to 30 m by 0.53 mm inside diameter

under high pressure. Hydrogen is an extremely flammable gas.

by 3-μm bonded methyl silicone, fused silica, or equivalent

column that elutes components in order of boiling points, and

8. Preparation of Apparatus

meets the resolution criteria specified in 8.2 must be used (see

8.1 Column Preparation—The column must be conditioned

8.4).

at the maximum operating temperature to reduce baseline shifts

6.1.5 Integrator—Means must be provided for determining

due to bleeding of column substrate.

the accumulated area under the chromatogram. This can be

done by means of a computer or electronic integrator. A timing

NOTE 2—The column can be conditioned using the following proce-

dure:

device can be used to record the area at set time intervals. The

same basis for measuring time must be used to determine the

(a) Disconnect the column from the detector,

retention times in the calibration, and the sample. The maxi-

(b) Purge the column at ambient temperature with carrier

mum signal measured must be within the linear range of the

gas for at least 30 min,

measuring system used.

(c) With carrier gas flowing through the column, raise the

6.1.6 Flow Controller—The chromatograph must be

column temperature to the maximum operating temperature

equipped with a constant-flow device capable of maintaining

and maintain the temperature at this level for 12 to 16 h,

the carrier gas at a constant flow rate throughout the tempera-

(d) Cool the column to ambient temperature,

ture program.

(e) Reconnect the column to the detector,

6.1.7 Sample Introduction—A microsyringe is required for

(f) Set the detector temperature to at least 5°C higher than

the introduction of the sample to the gas chromatograph (see

the maximum column temperature, and

Note 1).

(g) Program the column temperature up to the maximum

several times with normal carrier flow until a stable, flat

7. Reagents and Materials

baseline is obtained.

7.1 Purity of Reagents—Reagent grade chemicals shall be 8.2 Column Resolution—To test column resolution, inject

used in the preparation of the calibration mixture. the same volume of the calibration mixture as used during

7.2 Calibration Mixture—A synthetic blend of pure liquid normal sample analysis and obtain the chromatogram by the

hydrocarbons of known boiling points. The components of the procedure described in Section 9. Using the n-dodecane (C )

calibration mixture are listed in Table 1 and prepared by and n-tridecane (C ) peaks, and Fig. 1, calculate the resolu-

tion, R, as calculated from the equation:

mixing equivolume quantities of the components. At least one

component in the mixture must have a boiling point equal to or

R 5 2D/~Y 1 Y ! (1)

1 2

lower than the initial boiling point of the sample, and one

where:

component must have a retention time greater than any

D = time, s, between n-C and n-C apexes,

component in the sample. 12 13

Y = peak width of n-C ,s,and

1 12

Y = peak width of n-C ,s.

2 13

The resolution, R, thus calculated must be between eight and

TABLE 1 Calibration Mixture

twelve to be acceptable.

Peak Number Compound Identification Normal Boiling Point, °C

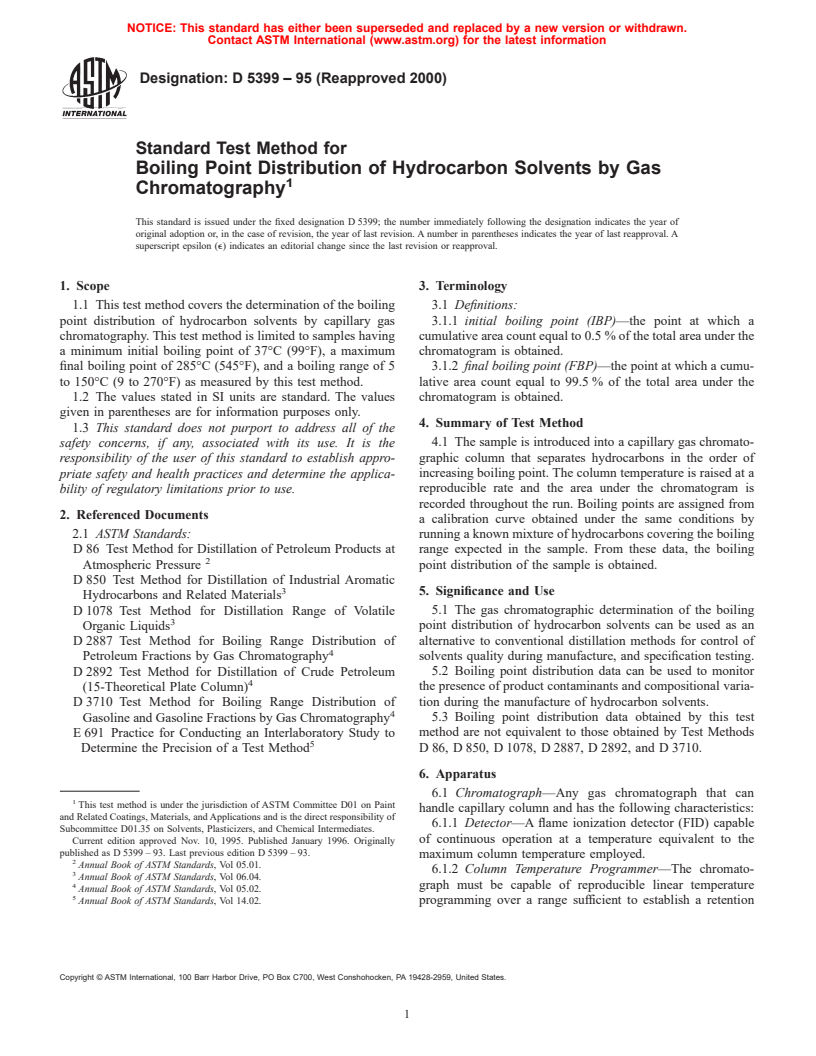

8.3 Skewing of Peaks—Calculate the ratio A/B on peaks in

1 n-Pentane 36.1

the calibration mixture as shown in Fig. 2. Call the width in

2 2-Methyl Pentane 60.0

3 n-Hexane 68.9

4 2,4-Dimethyl Pentane 80.6

5 n-Heptane 98.3

6 Toluene 110.6

7 n-Octane 125.6

8 p-Xylene 138.3

9 n-Propyl Benzene 159.4

10 n-Decane 173.9

11 n-Butyl Benzene 183.3

12 n-Dodecane 216.1

13 n-Tridecane 235.6

14 n-Tetradecane 253.9

15 n-Pentadecane 270.6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.