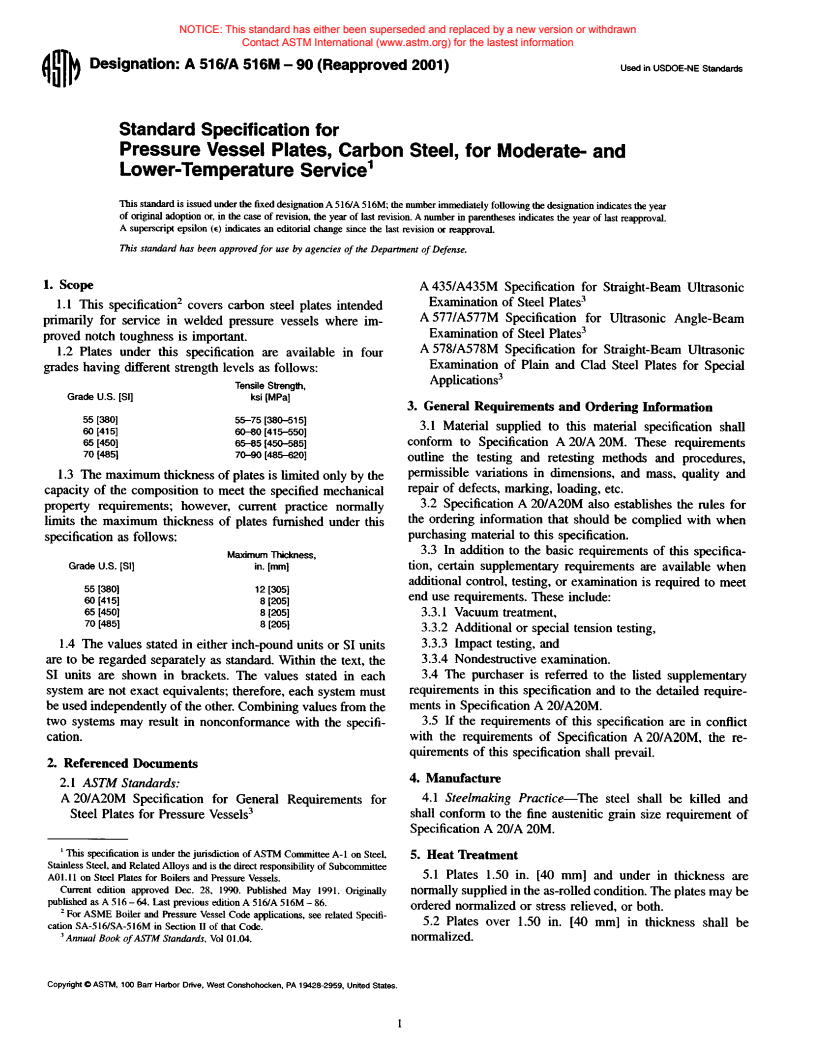

ASTM A516/A516M-90(2001)

(Specification)Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service

Standard Specification for Pressure Vessel Plates, Carbon Steel, for Moderate- and Lower-Temperature Service

SCOPE

1.1 This specification covers carbon steel plates intended primarily for service in welded pressure vessels where improved notch toughness is important.

1.2 Plates under this specification are available in four grades having different strength levels as follows:Tensile Strength,Grade U.S. [SI]ksi [MPa]55 [380]55-75 [380-515]60 [415]60-80 [415-550]65 [450]65-85 [450-585]70 [485]70-90 [485-620]

1.3 The maximum thickness of plates is limited only by the capacity of the composition to meet the specified mechanical property requirements; however, current practice normally limits the maximum thickness of plates furnished under this specification as follows: Maximum Thickness,Grade U.S. [SI]in. [mm] 55 [380]12 [305]60 [415]8 [205]65 [450]8 [205]70 [485]8 [205]

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn

Contact ASTM Int

...

This May Also Interest You

ABSTRACT

This specification covers high-tensile strength carbon-manganese steel plates intended for welded pressure vessels. Plates are normally supplied in the as-rolled condition. The plates may be ordered normalized or stress relieved, or both. The steel shall conform to the chemical composition requirements. The plates, as represented by the tension test specimens, shall conform to the mechanical property requirements.

SCOPE

1.1 This specification2 covers high-tensile strength carbon-manganese steel plates intended for welded pressure vessels.

1.2 This steel is usually made to a semi-killed or capped deoxidation practice; however, at the purchaser's or the steel producer's option, the steel may be made silicon-killed or aluminum-killed.

1.3 The maximum thickness of plates furnished under this specification shall be 3/4 in. [20 mm].

1.4 For plates produced from coil and furnished without heat treatment or with stress relieving only, the additional requirements, including additional testing requirements and the reporting of additional test results, of Specification A20/A20M apply.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers standard requirements for three grades of carbon-manganese-silicon steel, designated Grades A, B, and C. Grade C may be produced with a boron addition. The plates shall be quenched and tempered and shall be intended for welded-layered pressure vessels. The steel shall be killed and shall conform to the fine austenitic grain size requirement. Heat and product analyses shall be performed wherein the material shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, vanadium, and boron. The steel plate shall undergo tension test and shall conform to tensile requirements such as tensile strength, yield strength, and elongation.

SCOPE

1.1 This specification2 covers three grades of carbon-manganese-silicon steel, designated Grades A, B, and C. Grade C may be produced with a boron addition. The plates are quenched and tempered and are intended for welded-layered pressure vessels.

1.2 The maximum thickness of plates supplied under this specification is limited only by the capability of the chemical composition to meet the specified mechanical requirements. However, current practice normally limits the maximum thickness to 7/8 in. [22 mm] for Grades A and B, and to 2 in. [50 mm] for Grade C.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification2 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers standard requirements for high-strength quenched and tempered alloy steel plates intended for use in fusion welded boilers and other pressure vessels. The steel shall be killed and shall conform to the fine austenitic grain size requirement. Heat and product analyses shall be conducted wherein the material shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, boron, vanadium, titanium, zirconium, copper, and columbium. Tensile properties of the steel plate shall meet the specified values for tensile strength, yield strength, and elongation. The material shall undergo mechanical tests such as tension test and transverse Charpy V-notch impact test.

SCOPE

1.1 This specification2 covers high-strength quenched and tempered alloy steel plates intended for use in fusion welded boilers and other pressure vessels.

1.2 This specification includes a number of grades as manufactured by different producers, but all having the same mechanical properties and general characteristics.

1.3 The maximum thickness of plates furnished under this specification shall be as follows:

Grade

Thickness

A, B

1.25 in. [32 mm]

H, S

2 in. [50 mm]

P

4 in. [100 mm]

F

2.50 in. [65 mm]

E, Q

6 in. [150 mm]

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other without combining values in any way.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers the standard requirements for low-carbon age-hardened nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components. Materials shall be manufactured to a killed fine austenitic grain size, by vacuum degas melting process. Heat treatment shall be conducted, according to class, by: normalizing and precipitation hardening (Grade A, Class 1); liquid quenching and precipitation hardening (Grade A, Class 2); or double liquid-quenching, tempering, double austenitizing, and precipitation hardening (Grade B). Heat and product analyses shall be used to evaluate the conformance of forgings to required chemical compositions. Tensile, notch toughness, and Charpy impact requirements shall be examined, for which one of four sampling methods may be employed. One tension test and one impact test (for three samples) shall be made for each forging. Dimensions and finishes of the forgings shall conform to that specified by the purchaser. Repair welding shall also be performed only if permitted by the purchaser.

SCOPE

1.1 This specification covers requirements for low-carbon age-hardening nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components.

1.2 Forgings under this specification are available as Grades A or B. Grade A may be ordered in one or two classes as follows:

1.2.1 Grade A Class 1—Normalized-and-precipitation-heat-treated, providing a minimum yield strength of 55 ksi [380 MPa] and a minimum tensile strength of 65 ksi [450 MPa].

1.2.2 Grade A Class 2—Quenched-and-precipitation-heat-treated, providing a minimum yield strength of 65 ksi [450 MPa] and a minimum tensile strength of 75 ksi [515 MPa].

1.2.3 Grade A was the original steel composition in this specification.

1.3 Although the material is readily weldable, welding procedures are of fundamental importance and must be such as not to affect adversely the properties of the material, especially in the heat-affected zone. It is presupposed that welding procedures will be suitable for the material being welded.

1.4 Supplementary requirements, including those applicable in Specification A788/A788M, are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other and values from the two systems shall not be combined.

1.6 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M” specification designation [SI units], the material shall be furnished to inch-pound units.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications. The steel shall conform to the requirements as to chemical composition specified. The material shall conform to the mechanical properties specified.

SCOPE

1.1 This specification2 covers chromium, chromium-nickel, and chromium-manganese-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications including architectural, building, construction, and aesthetic applications.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished in inch-pound units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification12 pagesEnglish languagesale 15% off

- Technical specification12 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers quenched and tempered vacuum-treated carbon and alloy steel forgings for pressure vessels, such as those used in reactor systems, specifically, vessel closures, shells, flanges, tube sheets, rings, heads, and similar parts. Steels shall be manufactured by basic electric-furnace process except when secondary ladle refining or remelting process is employed, and shall be vacuum treated prior to or during the pouring of the ingot. Materials shall also go through preliminary heat treatment and quenching for mechanical properties. Heat and product analyses shall be executed to evaluate the conformance of the forgings with specified chemical requirements. Tension and Charpy impact tests shall also be performed to examine the conformance of steel specimens with the following mechanical properties: tensile strength, yield strength, elongation, and reduction of area. Nondestructive inspection procedures, such as magnetic particle examination, and longitudinal wave and angle beam ultrasonic examination, shall also be carried out. Repair welding may be permitted at the option of the purchaser.

SCOPE

1.1 This specification2 covers quenched and tempered vacuum-treated carbon and alloy steel forgings for pressure vessels such as those used in reactor systems. Specifically, it covers forgings for vessel closures, shells, flanges, tube sheets, rings, heads, and similar parts.

1.2 All grades are considered weldable under proper conditions. Welding technique is of fundamental importance, and it is presupposed that welding procedure and inspection will be in accordance with approved methods for the grade of material used.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound units.

Note 1: Grades 1 and 1A are composed of different chemistries but have the same mechanical requirements.

Note 2: Designations have been changed as follows:

Current

Formerly

Grade 1

Class 1

Grade 1A

Class 1A

Grade 2 Class 1

Class 2

Grade 2 Class 2

Class 2A

Grade 3 Class 1

Class 3

Grade 3 Class 2

Class 3A

Grade 4N Class 1

Class 4

Grade 4N Class 2

Class 4A

Grade 4N Class 3

Class 4B

Grade 5 Class 1

Class 5

Grade 5 Class 2

Class 5A

Grade 22 Class 3

Class 22B

Grade 22 Classes 4, 5, 6, and 7

Grade 3V

Class 3V

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification9 pagesEnglish languagesale 15% off

- Technical specification9 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers hot-rolled carbon steel sheet for pressure vessels involving fusion welding or brazing. Tensile and yield strengths shall be determined after a tension test of the sheets. The material shall be furnished without removing the hot-rolled oxide or scale. When required, the material may be specified to be pickled or blast cleaned. When specified to be pickled or blast cleaned, the material shall be furnished oiled. When required, pickled or blast-cleaned material may be specified to be furnished dry.

SCOPE

1.1 This specification2 covers hot-rolled carbon steel sheet for pressure vessels involving fusion welding or brazing. Welding and brazing technique is of fundamental importance and shall be in accordance with commercial practices.

1.2 The following grades are included in this specification:

Mechanical Requirements

Yield Strength, min

Tensile Strength, min

Grade

ksi

MPa

ksi

MPa

A

25

170

45

310

B

30

205

50

345

C

33

230

55

380

D

35

240

60

415

E

38

260

65

450

F

42

290

70

485

G

45

310

75

515

H

45

310

75

515

1.3 Hot-rolled carbon steel sheet is generally furnished in cut lengths and to decimal thickness only. Coils may be furnished, provided tension test specimens are taken to represent the middle of the slab as required by 6.1.3. The purchaser should recognize this may require cutting the coils to obtain test samples and results in half-size coils. The sheet is furnished to the following size limits:

Width, in. [mm]

Thickness, in. [mm]

Over 12 [Over 300]

0.270 to 0.230 [7.0 to 6.0]

sheet (coils only)

Under 0.230 to 0.057 [6.0 to 1.5]

sheet

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Tolerances are found in General Requirements Specifications A568/A568M and A635/A635M. The appropriate General Requirements specification is applied based on the thickness and width of the product ordered.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification4 pagesEnglish languagesale 15% off

- Technical specification4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers chromium-molybdenum alloy steel plates for welded broilers and pressure vessels designed for elevated temperature service. Materials considered under this specification are available in grades 2, 12, 11, 22, 22L, 21, 21L, 5, 9 and 91. The steel materials shall be killed and shall be thermally treated. The steel specimens shall undergo heat analysis and product analysis and shall conform to the chemical requirements for carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, nickel, vanadium, columbium, boron, nitrogen, aluminum, titanium, and zirconium. The steel specimens shall also undergo tension tests and shall conform to the required values of tensile strength, yield strength, and elongation.

SCOPE

1.1 This specification2 covers chromium-molybdenum alloy steel plates intended primarily for welded boilers and pressure vessels designed for elevated temperature service.

1.2 Plates are available under this specification in several grades having different alloy contents as follows:

Nominal

Nominal

Chromium

Molybdenum

Grade

Content, %

Content, %

2

0.50

0.50

12

1.00

0.50

11

1.25

0.50

22

2.25

1.00

21

3.00

1.00

5

5.00

0.50

9

9.00

1.00

91

9.00

1.00

1.3 Each grade except Grade 91 is available in two classes of tensile strength levels as defined in the Tensile Requirements tables. Grade 91 is available only as Class 2. Grade 91 consists of two types, with Type 2 differentiated from Type 1 by requiring restricted composition for the enhancement of creep resistance.

Note 1: Grade 911, previously covered by this specification, is now covered by Specification A1017/A1017M.

1.4 The maximum thickness of plates is limited only by the capacity of the composition to meet the specified mechanical property requirements.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents. Therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification6 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers nickel-alloy steel plates intended primarily for welded pressure vessels. As a steel making practice, the steel shall be killed and shall conform to fine grain size requirements. The heat treatment requirements for all plates are presented, and all plates under Grades A, B, D, and E shall be normalized as required. The steel shall conform to the required chemical compositions. Two mechanical test requirements are presented that includes, tension test requirements and impact test requirements.

SCOPE

1.1 This specification2 covers nickel-alloy steel plates intended primarily for welded pressure vessels.

1.2 Plates under this specification are available with four strength levels and two nickel compositions as follows:

Grade

Nominal Nickel

Content %

Yield Strength, min, ksi [MPa]

Tensile Strength, min, ksi [MPa]

A

2.25

37 [255]

65 [450]

B

2.25

40 [275]

70 [485]

D

3.50

37 [255]

65 [450]

E

3.50

40 [275]

70 [485]

F

3.50

2 in. [50 mm] and under

55 [380]

80 [550]

Over 2 in. [50 mm]

50 [345]

75 [515]

1.3 The maximum thickness of plates is limited only by the capacity of the composition to meet the specified mechanical property requirements.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents. Therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers hot- and cold-finished bars of stainless steel, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction. Four grades of the stainless steel are available which includes austenitic, austenitic-ferritic, ferritic, and martensitic grades. Mechanical properties such as tensile strength, yield strength, elongation, and hardness shall be determined for the specimens subjected to normalized, tempered, annealed, and quenched conditions. The austenitic stainless steels shall be subjected to heat treatment and shall undergo corrosion test.

SCOPE

1.1 This specification2 covers hot- and cold-finished bars of stainless steel, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction.2

Note 1: There are standards covering high nickel, chromium, austenitic corrosion, and heat-resisting alloy materials. These standards are under the jurisdiction of ASTM Subcommittee B02.07 and may be found in Annual Book of ASTM Standards, Vol 02.04.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound units.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification8 pagesEnglish languagesale 15% off

- Technical specification8 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.