ASTM D6365-99

(Practice)Standard Practice for the Nondestructive Testing of Geomembrane Seams using the Spark Test

Standard Practice for the Nondestructive Testing of Geomembrane Seams using the Spark Test

SCOPE

1.1 This practice describes the nondestructive testing of field seams in geomembranes using the spark test. A suspect area is indicated by the generation of a spark. The test is applicable to seams made by the extrusion method, seams made by using welding tape (a strip of the same type of material as the geomembrane, that is welded over adjacent sections of geomembrane to create a seam), or seams where it is practical to insert a conductive material in the seam just prior to or during fabrication.

1.2 The spark test may produce an electrical spark and therefore can only be used where an electrical spark would not create a hazard.

1.3 Unless the voltages and distances prescribed are carefully adhered to, a "false positive" indication may result. This false positive occurs when the arc distance is too large for the voltage applied at the time and conditions of testing.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6365–99

Standard Practice for

the Nondestructive Testing of Geomembrane Seams using

the Spark Test

This standard is issued under the fixed designation D 6365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 seam, n—a permanent joining of two or more mate-

rials.

1.1 This practice describes the nondestructive testing of

3.2 For definition of other terms, see Terminology D 4439.

field seams in geomembranes using the spark test. A suspect

area is indicated by the generation of a spark. The test is

4. Summary of Practice

applicable to seams made by the extrusion method, seams

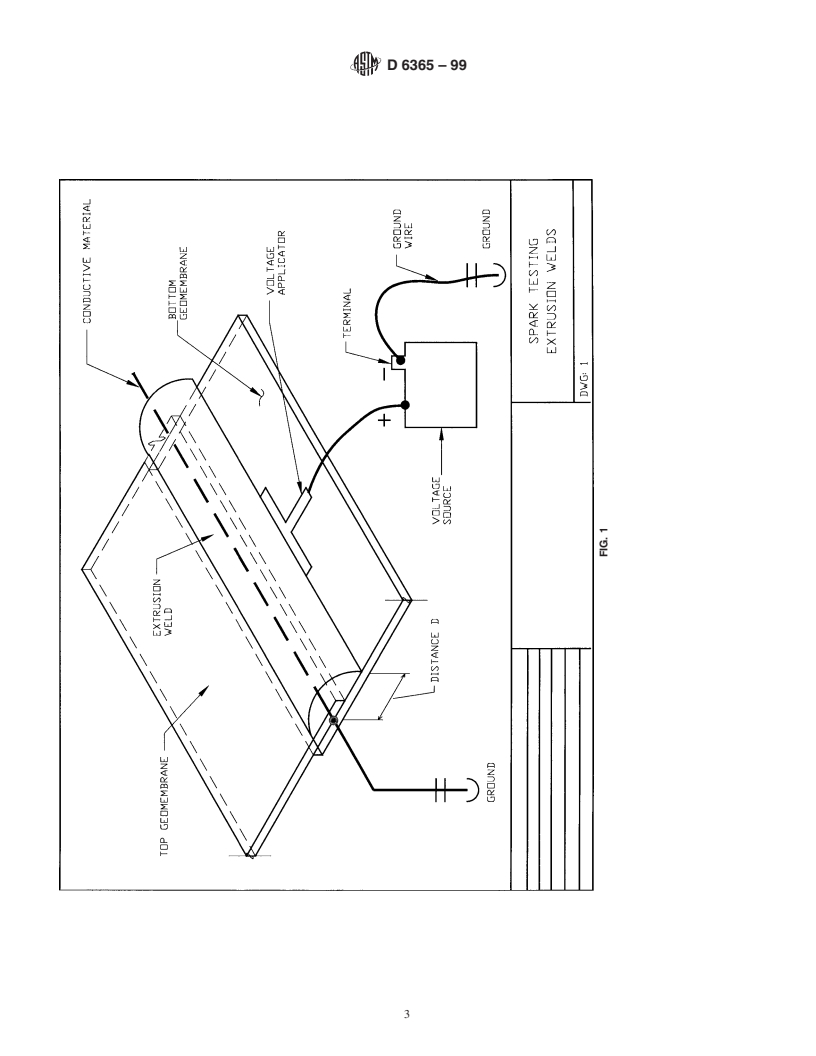

4.1 Tousethispracticeaconductivematerialisinsertedinto

made by using welding tape (a strip of the same type of

the field seam just prior to or during fabrication. The conduc-

material as the geomembrane, that is welded over adjacent

tive material in the seam is connected to the negative terminal

sections of geomembrane to create a seam), or seams where it

of the test apparatus, and a positive voltage is applied across

is practical to insert a conductive material in the seam just prior

the seam edge. A suspect area in the seam is indicated by a

to or during fabrication.

spark from the voltage source to the conductive material.

1.2 The spark test may produce an electrical spark and

therefore can only be used where an electrical spark would not

5. Significance and Use

create a hazard.

5.1 Spark testing of geomembrane field seams is particu-

1.3 Unless the voltages and distances prescribed are care-

larly useful in locations where other nondestructive test meth-

fully adhered to, a “false positive” indication may result. This

ods are not practical, for example in tight corners or a

false positive occurs when the arc distance is too large for the

circumferential seam around a pipe.

voltage applied at the time and conditions of testing.

1.4 This standard does not purport to address all of the

6. Apparatus

safety concerns, if any, associated with its use. It is the

6.1 The test apparatus consists of a high–voltage, low–cur-

responsibility of the user of this standard to establish appro-

rent source with a negative terminal for ground and a positive

priate health and safety practices and to determine the

terminal for a voltage applicator. A voltage applicator may

applicability of regulatory limitations prior to use.

consist of a handle and wire brush, conductive neoprene

squeegee, or other suitable applicator.

2. Referenced Documents

6.2 The range of the high voltage source is typically 20 000

2.1 ASTM Standards:

to 35 000 V.

D 4437 Practice for Determining the Integrity of Field

6.2.1 The voltage required to cause a discharge (spark)

Seams Used in Joining Flexible Polymeric Sheet

between the positive electrode and the negative electrode wire

Geomembranes

2 is expressed by the formula.

D 4439 Terminology for Geotextiles

V 5 K=D (1)

3. Terminology

where:

3.1 Definitions:

V = test voltage,

3.1.1 geomembrane, n—an essentially impermeable geo-

1/2

K = a constant (V/(mm) ), and

synthetic composed of one or more synthetic sheets.

D = the distance from the edge of the extrusion bead on the

3.1.1.1 Discussion—In geotechnical engineering, essen-

lower panel to the conductive material in mm.

tially impermeable means that no measurable liquid flows

6.2.2 If the voltage is not adequate due to underestimating

through a geosynthetic when tested in accordance with Termi-

D, a false positive test (a seam with a suspect area resulting in

nology D 4491.

no spark and testing as a good seam) may result.

6.2.3 Good results have been obtained using the test volt-

This practice is under the jurisdiction of ASTM Committee D-35 on Geosyn- ages a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.