ASTM D3217-95

(Test Method)Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

SCOPE

1.1 These test methods cover the measurement of the breaking tenacity of manufactured textile fibers taken from filament yarns, staple, or tow fiber, either crimped or uncrimped, and tested in either a double loop or as a strand formed into a single overhand knot.

1.2 Methods for measuring the breaking tenacity of conditioned and wet (immersed) fibers in loop and knot form are included.

1.3 Elongation in loop or knot tests has no known significance, and is usually not recorded.

1.4 The basic distinction between the procedures described in these test methods and those included in Test Methods D2101 is the configuration of the specimen, that is, either as a double loop or in the configuration of a single overhand knot.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3217 – 95

Standard Test Methods for

Breaking Tenacity of Man-Made Textile Fibers in Loop or

Knot Configurations

This standard is issued under the fixed designation D 3217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 These test methods cover the measurement of the 3.1 Definitions:

breaking tenacity of man-made textile fibers taken from 3.1.1 breaking load, n—the maximum force applied to a

filament yarns, staple, or tow fiber, either crimped or un- specimen in a tensile test carried to rupture.

crimped, and tested in either a double loop or as a strand 3.1.1.1 Discussion—Force is commonly expressed in

formed into a single overhand knot. grams-force (gf ), kilograms-force (kgf ), pounds-force (lbf),

1.2 Methods for measuring the breaking tenacity of condi- newtons (N), or millinewtons (mN).

tioned and wet (immersed) fibers in loop and knot form are 3.1.2 breaking tenacity, n—the tenacity corresponding to

included. the breaking load.

1.3 Elongation in loop or knot tests has no known signifi- 3.1.2.1 Discussion—Breaking tenacity is commonly ex-

cance, and is usually not recorded. pressed as grams-force per tex (gf/tex), grams-force per denier

1.4 The basic distinction between the procedures described (gf/den), millinewtons per tex (mN/tex), or grams-force per

in these test methods and those included in Test Methods denier (gf/den). Millinewtons are numerically equal to grams-

D 2101 is the configuration of the specimen, that is, either as a force times 9.81.

double loop or in the configuration of a single overhand knot. 3.1.3 The breaking tenacity is calculated from the breaking

1.5 This standard does not purport to address all of the force and the linear density of the unstrained specimen, or

safety concerns, if any, associated with its use. It is the obtained directly from tensile testing machines which can be

responsibility of the user of this standard to establish appro- suitably adjusted to indicate tenacity instead of breaking force,

priate safety and health practices and determine the applica- for specimens of known linear density.

bility of regulatory limitations prior to use. 3.1.4 linear density, n—mass per unit length; the quotient

obtained by dividing the mass of a fiber or yarn by its length.

2. Referenced Documents

3.1.4.1 Discussion—The preferred units of measurement

2.1 ASTM Standards:

are grams and metres, or multiples or submultiples of these.

D 76 Specification for Tensile Testing Machines for Tex- The tex unit, grams per kilometre, is recommended for yarns.

tiles

3.1.5 man-made staple fiber, n—fibers of spinnable length

D 123 Terminology Relating to Textiles manufactured directly or by cutting filaments.

D 1577 Test Methods for Linear Density of Textile Fibers 3.1.5.1 Discussion—Man-made staple fiber does not in-

D 1776 Practice for Conditioning Textiles for Testing

clude cut waste.

D 2101 Test Methods for Tensile Properties of Single Man- 3.1.6 tenacity, n—in a tensile test, the force exerted on the

Made Textile Fibers Taken from Yarns and Tows

specimen based on the linear density of the unstrained material.

D 2258 Practice for Sampling Yarn for Testing 3.1.6.1 Discussion—Tenacity is commonly expressed as

D 3333 Practice for Sampling Man-Made Staple Fibers,

grams-force per tex (gf/tex), grams-force per denier (gf/den),

Sliver, or Tow for Testing millinewtons per tex (mN/tex), or grams-force per denier

D 4848 Terminology Relating to Force and Deformation

(gf/den).

Properties of Textiles 3.1.7 For definitions of other textile terms used in these test

methods, refer to Terminology D 123. For definitions of other

terms related to force and deformation in textiles, refer to

1 Terminology D 4848.

These test methods are under the jurisdiction of ASTM Committee D-13 on

Textiles and are the direct responsibility of Subcommittee D13.57 on Fiber Test

4. Summary of Test Methods

Methods, General.

Current edition approved May 15, 1995. Published July 1995. Originally

4.1 Single-fiber specimens in the form of a loop as de-

published as D 3217 – 73 T. Last previous edition D 3217 – 94a.

2 scribed in 9.4.1 are broken on a constant-rate-of-extensiontype

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 07.02. testing machine at a predetermined rate of elongation and the

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3217

NOTE 1—An adequate specification or other agreement between the

breaking load is determined.

purchaser or the supplier requires taking into account the variability

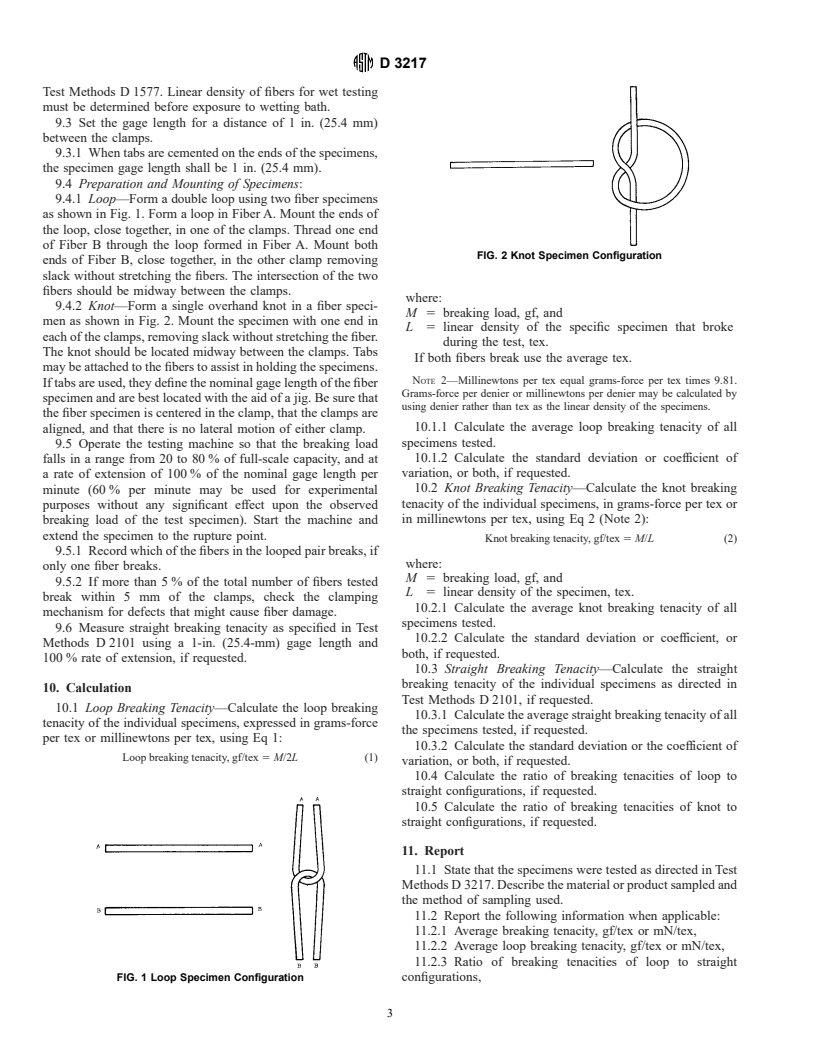

4.2 Single-fiber specimens in the form of a knot as de-

between shipping units, between packages, ends, or other laboratory

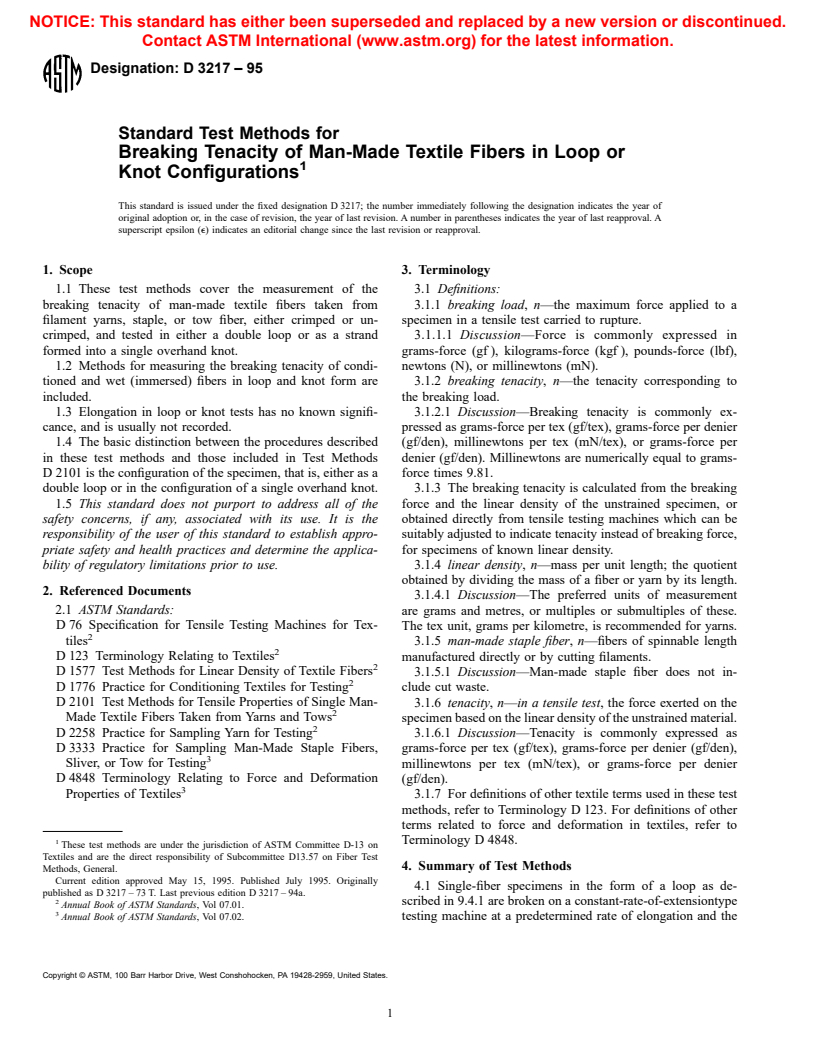

scribed in 9.4.2 are broken on a constant-rate-of-extensiontype

sampling unit within a shipping unit if applicable, and within specimens

testing machine at a predetermined rate of elongation, and the

from a single package, end, or other laboratory sampling unit to provide

breaking load is determined.

a sampling plan with a meaningful producer’s risk, consumer’s risk,

4.3 The breaking tenacity is calculated from the breaking

acceptable quality level, and limiting quantity level.

load registered on the load-elongation curve and the previously

7.2 Laboratory Sample—As a laboratory sample for accep-

determined linear density.

tance testing, take at random from each shipping container in

the lot sample the number of laboratory sampling units as

5. Significance and Use

directed in an applicable material specification or other agree-

5.1 Both the loop breaking tenacity and the knot breaking

ment between the purchaser and the supplier such as an

tenacity, calculated from the breaking load measured under the

agreement to use Practice D 3333 or Practice D 2258. Prefer-

conditions specified herein and the linear density of the fiber,

ably, the same number of laboratory sampling units are taken

are fundamental properties that are used to establish limitations

from each shipping container in the lot sample. If differing

on fiber-processing and upon their end-use applications. Physi-

numbers of laboratory sampling units are to be taken from

cal properties, such as brittleness, not well defined by tests for

shipping containers in the lot sample, determine at random

breaking load and elongation can be estimated from the ratio of

which shipping containers are to have each number of labora-

breaking tenacity measured in loop or knot tests, or both, and

tory units drawn.

the normal tenacity as measured by Test Methods D 2101.

7.2.1 For Staple Fiber—Take 50-g samples from laboratory

5.2 This test method is not recommended for acceptance

sampling units.

testing of commercial shipments in the absence of reliable

7.2.2 For Sliver (or Top) or Tow—Take 1 m from the

information on between-laboratory precision (see Note 3). In

leading end which has a clean, uniform appearance.

some cases the purchaser and the seller may have to test a

7.2.3 For Yarns—Prepare at least a 50-m skein from each

commercial shipment of one or more specific materials by the

package.

best available method, even though the method has not been

7.3 Test Specimens—From each laboratory sampling unit,

recommended for acceptance testing of commercial shipments.

take ten specimens at random. If the standard deviation

In such a case, if there is a disagreement arising from

determined for the ten specimens is more than a value agreed

differences in values reported by the purchaser and the seller

upon between the purchaser and the supplier, continue testing

when using this test method for acceptance testing, the statis-

in groups of ten specimens from the same laboratory sampling

tical bias, if any, between the laboratory of the purchaser and

unit in the container until the standard deviation for all

the laboratory of the seller should be determined with each

specimens tested is not more than the agreed to value or, by

comparison being based on testing specimens randomly drawn

agreement, stop testing after a specified number.

from one sample of material of the type being evaluated.

7.3.1 Carefully remove twist before taking specimens from

yarn. Using tweezers and grasping the specimens at the ends,

6. Apparatus and Reagents

gently remove the required number of specimens from the

6.1 Tensile Testing Machine, conforming to Specification

laboratory sampling units for testing. In some cases, if speci-

D 76 for Constant-Rate-of-Specimen-Extension-(CRE) type

mens are not to be tested immediately, place them on an

machines, having a full-scale capacity ranging from 2 to 100 g

identified short-pile of plush surface for storage until ready to

and equipped with provisions for breaking fibers immersed in

test.

a liquid if such tests on a wet specimen are desired.

6.2 Clamps, with flat jaws for gripping the fiber specimens 8. Conditioning

designed to minimize slippage in the clamps during the tests, or

8.1 Precondition and condition the specimens, as directed in

6.2.1 Tabs, of thin plastic or other material for use with

Practice D 1776.

cementing techniques, and

8.1.1 Specimens that are to be tested wet need not be

6.2.2 Cement or Adhesive—The adhesive must bind the tab

preconditioned or conditioned.

to the fiber without affecting an appreciable solution of the

9. Procedure

latter or any change in the moisture content of the specimen.

9.1 Test Conditions:

6.3 Wetting Agent (0.1 % solution)—Use a nonionic aque-

ous solution. 9.1.1 Standard—Test the adequately conditioned fibers in

the standard atmosphere for testing textiles which is 70 6 2°F

6.4 Jig, to aid in accurately mounting specimens on tabs at

the specified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.