ASTM D3513-02(2018)

(Test Method)Standard Test Method for Overlength Fiber Content of Manufactured Staple Fiber

Standard Test Method for Overlength Fiber Content of Manufactured Staple Fiber

SIGNIFICANCE AND USE

5.1 The existence of overlength fiber in manufactured staple can cause serious problems in the spinning of these fibers into yarn. Overlength fibers may create problems in carding, but more especially high-strength multiple cut fibers may cause cockling in spinning.

5.2 Since the overlength fibers are caused by dull or damaged cutting knives or by uneven flow of tow to the staple cutter, their existence within the fiber population is not uniform and their occurrence in the population follows a highly skewed distribution.

5.3 Manual methods of determining overlength fiber require much more operator time, and the standard deviations of the test between laboratories and operators are high. Use of the Fibrosampler method greatly reduces both operator time and standard deviation of testing.

5.4 In manufacturing it is important to know if fibers are overlength due to looping of the tow or multiple length due to damaged cutters.

5.5 This method for testing staple fiber for overlength fiber is not recommended for acceptance testing (see 13.1).

5.5.1 In some cases the purchaser and the supplier may have to test a commercial shipment of one or more specific materials by the best available method, even though the method has not been recommended for acceptance testing of commercial shipments. If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, use the samples for such a comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If a...

SCOPE

1.1 This test method covers the determination of the percent by number of overlength or multiple length fibers in a sample of manufactured cut staple. The method is applicable to fiber taken immediately after manufacturing, from the bale, or from partially processed stock.

Note 1: For measurement of length and length distribution of manufactured staple fibers, refer to Test Method D5103.

1.2 This test method covers procedures using the Fibrosampler Model 335A (inch-pound units), the Fibrosampler Model 335B (SI units), and Fibrosampler combs Model 336.

1.2.1 The Fibrosampler Model 335A is equipped with a sample plate that has 15.8-mm (5/8-in.) diameter sample holes and is recommended for use on blended staple taken from the fiber blender or from a carding machine.

1.2.2 The Fibrosampler Model 335B is equipped with a sample plate that has 10-mm (0.4-in.) diameter sample holes and is recommended for use on unblended staple as may be taken from the fiber cutter or from a bale of staple fiber.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. The values stated in each unit are not exact equivalents; therefore, each unit must be used independently of the other.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3513 − 02 (Reapproved 2018)

Standard Test Method for

Overlength Fiber Content of Manufactured Staple Fiber

This standard is issued under the fixed designation D3513; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the percent

D123 Terminology Relating to Textiles

by number of overlength or multiple length fibers in a sample

D1447 Test Method for Length and Length Uniformity of

of manufactured cut staple. The method is applicable to fiber

Cotton Fibers by Photoelectric Measurement

taken immediately after manufacturing, from the bale, or from

D2258 Practice for Sampling Yarn for Testing

partially processed stock.

D3333 Practice for Sampling Manufactured Staple Fibers,

NOTE 1—For measurement of length and length distribution of manu- Sliver, or Tow for Testing

factured staple fibers, refer to Test Method D5103.

D3888 Terminology for Yarn Spinning Systems

D3990 Terminology Relating to Fabric Defects

1.2 This test method covers procedures using the Fibrosam-

D4849 Terminology Related to Yarns and Fibers

pler Model 335A (inch-pound units), the Fibrosampler Model

D5103 Test Method for Length and Length Distribution of

335B (SI units), and Fibrosampler combs Model 336.

Manufactured Staple Fibers (Single-Fiber Test)

1.2.1 The Fibrosampler Model 335A is equipped with a

sample plate that has 15.8-mm ( ⁄8-in.) diameter sample holes

3. Terminology

and is recommended for use on blended staple taken from the

3.1 Definitions:

fiber blender or from a carding machine.

3.1.1 For definitions of textile terms used in this test

1.2.2 The Fibrosampler Model 335B is equipped with a

method: fiber beard, staple, overlength staple fibers and

sample plate that has 10-mm (0.4-in.) diameter sample holes

multiple-length staple fibers, refer to Terminology D4849.

and is recommended for use on unblended staple as may be

3.1.2 For definitions of other textile terms used in this test

taken from the fiber cutter or from a bale of staple fiber.

method, refer to Terminologies D123, D3888, D3990, and

D4849.

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as the standard. The values stated

4. Summary of Test Method

in each unit are not exact equivalents; therefore, each unit must

be used independently of the other.

4.1 Fibers are caught randomly on a comb to form a fiber

beard. The probability that a given fiber length group repre-

1.4 This standard does not purport to address all of the

sented in the original fiber population will appear in the test

safety concerns, if any, associated with its use. It is the

specimen is proportional to the ratio of the total length of that

responsibility of the user of this standard to establish appro-

fiber length group to the total fiber length of the original

priate safety, health, and environmental practices and deter-

sample. The beard is biased in the favor of long fibers.

mine the applicability of regulatory limitations prior to use.

4.2 The fiber beard is brushed out and laid on a specimen

1.5 This international standard was developed in accor-

board.The density of the beard of the cut staple tapers to a line

dance with internationally recognized principles on standard-

that is parallel to the base of the comb. The overlength fibers

ization established in the Decision on Principles for the

are observed to extend beyond this line and they can be

Development of International Standards, Guides and Recom-

identified easily.

mendations issued by the World Trade Organization Technical

4.3 The noticeably longer fibers are pulled from the fiber

Barriers to Trade (TBT) Committee.

beard, verified for over- or multiple-length and counted. The

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2018. Published August 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1976. Last previous edition approved in 2007 as D3513 – 02(2012). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D3513-02R18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3513 − 02 (2018)

result is then expressed as the percent overlength and percent

multiple-length fiber in the original population.

5. Significance and Use

5.1 The existence of overlength fiber in manufactured staple

can cause serious problems in the spinning of these fibers into

yarn. Overlength fibers may create problems in carding, but

more especially high-strength multiple cut fibers may cause

cockling in spinning.

5.2 Since the overlength fibers are caused by dull or

damaged cutting knives or by uneven flow of tow to the staple

cutter,theirexistencewithinthefiberpopulationisnotuniform

and their occurrence in the population follows a highly skewed

distribution.

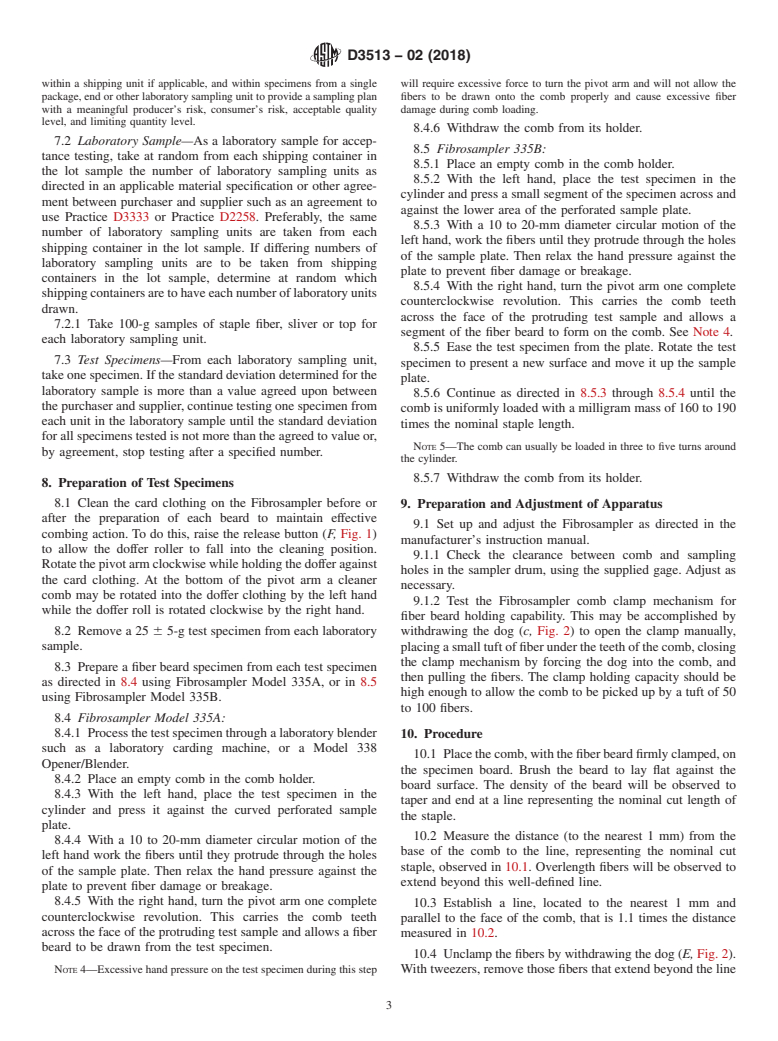

FIG. 2 Fibrosampler Combs

5.3 Manual methods of determining overlength fiber require

much more operator time, and the standard deviations of the

unpaired data, a probability level chosen prior to the testing

test between laboratories and operators are high. Use of the

series. If a bias is found, either its cause must be found and

Fibrosampler method greatly reduces both operator time and

corrected, or future test results for that material must be

standard deviation of testing.

adjusted in consideration of the known bias.

5.4 In manufacturing it is important to know if fibers are

6. Apparatus

overlength due to looping of the tow or multiple length due to

damaged cutters.

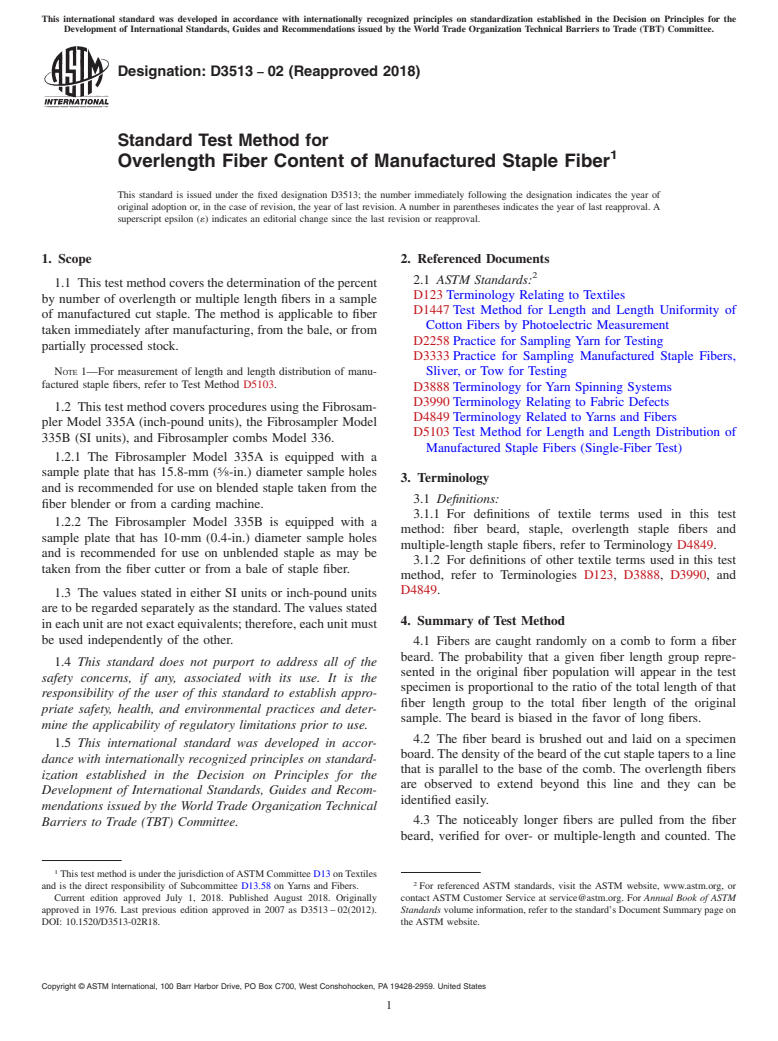

6.1 Fibrosampler, Model 335A of 335B (Fig. 1), equipped

with the following:

5.5 This method for testing staple fiber for overlength fiber

is not recommended for acceptance testing (see 13.1). 6.1.1 Combs, Model 336 (Fig. 2).

5.5.1 Insomecasesthepurchaserandthesuppliermayhave 6.1.2 Spacing Gage.

totestacommercialshipmentofoneormorespecificmaterials 6.1.3 Specimen Board, board covered with short pile or

by the best available method, even though the method has not plush surface on one side, for displaying the test specimen.

been recommended for acceptance testing of commercial 6.1.4 Brush, for brushing the test specimen.

shipments. If there are differences of practical significance 6.1.5 Tweezers, for removing the long fibers from the

specimen board for verification.

between reported test results for two laboratories (or more),

comparative test should be performed to determine if there is a

NOTE 2—Fibrosampler Model 192, which is used for sampling cotton,

statistical bias between them, using competent statistical assis-

(Method D1447) has been used successfully with this method, but the

tance. As a minimum, use the samples for such a comparative

above listed models and combs yield better results because long fibers are

less likely to be pulled from the combs during beard preparation.

teststhatareashomogeneousaspossible,drawnfromthesame

lot of material as the samples that resulted in disparate results

6.2 Laboratory Carding Machine or Opener/Blender Model

during initial testing and randomly assigned in equal numbers

338 is needed for use with Fibrosampler Model 335A.

to each laboratory. The test results from the laboratories

6.3 Analytical Balance, capable of weighing the specimen

involved should be compared using a statistical test for

to within 0.01 % of its mass.

6.4 Scale, graduated to the nearest 1 mm ( ⁄16-in.).

7. Sampling

7.1 Lot Sampling—As a lot sample for acceptance testing,

take at random the number of shipping containers directed in

the applicable material specification or other agreement be-

tween the purchaser and supplier, such as an agreement to use

Practice D3333 or Practice D2258. Consider shipping contain-

ers to be the primary sampling units.

NOTE 3—An adequate specification or other agreement between the

purchaser or supplier requires taking into account the variability between

shipping units, between packages, ends or other laboratory sampling unit

The sole source of supply of the apparatus known to the committee at this time

is Special Instruments Laboratory, Inc., 312 W. Vine Ave., P.O. Box 1950,

Knoxville, TN. 37901. If you are aware of alternative suppliers, please provide this

information to ASTM International Headquarters. Your comments will receive

careful consideration at a meeting of the responsible technical committee, which

FIG. 1 Fibrosampler you may attend.

D3513 − 02 (2018)

within a shipping unit if applicable, and within specimens from a single will require excessive force to turn the pivot arm and will not allow the

package, end or other laboratory sampling unit to provide a sampling plan fibers to be drawn onto the comb properly and cause excessive fiber

with a meaningful producer’s risk, consumer’s risk, acceptable quality damage during comb loading.

level, and limiting quantity level.

8.4.6 Withdraw the comb from its holder.

7.2 Laboratory Sample—As a laboratory sample for accep-

8.5 Fibrosampler 335B:

tance testing, take at random from each shipping container in

8.5.1 Place an empty comb in the comb holder.

the lot sample the number of laboratory sampling units as

8.5.2 With the left hand, place the test specimen in the

directed in an applicable material specification or other agree-

cylinder and press a small segment of the specimen across and

ment between purchaser and supplier such as an agreement to

against the lower area of the perforated sample plate.

use Practice D3333 or Practice D2258. Preferably, the same

8.5.3 With a 10 to 20-mm diameter circular motion of the

number of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.