ASTM E290-97a(2004)

(Test Method)Standard Test Methods for Bend Testing of Material for Ductility

Standard Test Methods for Bend Testing of Material for Ductility

SIGNIFICANCE AND USE

Bend tests for ductility provide a simple way to evaluate the quality of materials by their ability to resist cracking or other surface irregularities during one continuous bend. No reversal of the bend force shall be employed when conducting these tests.

The type of bend test used determines the location of the forces and constraints on the bent portion of the specimen, ranging from no direct contact to continuous contact.

The test can terminate at a given angle of bend over a specified radius or continue until the specimen legs are in contact. The bend angle can be measured while the specimen is under the bending force (usually when the semi-guided bend test is employed), or after removal of the force as when performing a free-bend test. Product requirements for the material being tested determine the method used.

Materials with an as-fabricated cross section of rectangular, round, hexagonal, or similar defined shape can be tested in full section to evaluate their bend properties by using the procedures outlined in these test methods, in which case relative width and thickness requirements do not apply.

SCOPE

1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided-bend test in which the specimen is bent, while in contact with a mandrel, through a specified angle or to a specified inside radius (r) of curvature, measured while under the bending force; a free-bend test in which the ends of the specimen are brought toward each other, but in which no transverse force is applied to the bend itself and there is no contact of the concave inside surface of the bend with other material; a bend and flatten test, in which a transverse force is applied to the bend such that the legs make contact with each other over the length of the specimen.

1.2 After bending, the convex surface of the bend is examined for evidence of a crack or surface irregularity. If the specimen fractures, the material has failed the test. When complete fracture does not occur, the criterion for failure is the number and size of cracks or other surface irregularity visible to the unaided eye occurring on the convex surface of the specimen after bending, as specified by the product standard. Any cracks within one thickness of the edge of the specimen are not considered a bend test failure. Cracks occurring in the corners of the bent portion shall not be considered significant unless they exceed the size specified for corner cracks in the product standard.

1.3 The values stated in SI units are to be regarded as standard. Inch-pound values given in parentheses were used in establishing test parameters and are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E290–97a (Reapproved 2004)

Standard Test Methods for

Bend Testing of Material for Ductility

This standard is issued under the fixed designation E 290; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods cover bend testing for ductility of 2.1 ASTM Standards:

materials. Included in the procedures are four conditions of E6 Terminology Relating to Methods of Mechanical Test-

constraint on the bent portion of the specimen; a guided-bend ing

test using a mandrel or plunger of defined dimensions to force E8 Test Methods for Tension Testing of Metallic Materials

themid-lengthofthespecimenbetweentwosupportsseparated E8M Test Methods for Tension Testing of Metallic Mate-

by a defined space; a semi-guided-bend test in which the rials (Metric)

specimen is bent, while in contact with a mandrel, through a E18 Test Methods for Rockwell Hardness and Rockwell

specified angle or to a specified inside radius (r) of curvature, Superficial Hardness of Metallic Materials

measured while under the bending force; a free-bend test in E 190 Test Method for Guided Bend Test for Ductility of

which the ends of the specimen are brought toward each other, Welds

but in which no transverse force is applied to the bend itself

3. Summary of Test Methods

and there is no contact of the concave inside surface of the

bend with other material; a bend and flatten test, in which a 3.1 Four methods for ductility testing employing bending

are included in these test methods. Two methods have sub-

transverse force is applied to the bend such that the legs make

contact with each other over the length of the specimen. groups with specific procedures.

3.1.1 Guided-Bend

1.2 After bending, the convex surface of the bend is

examined for evidence of a crack or surface irregularity. If the 3.1.2 Semi-guided Bend:

3.1.2.1 Arrangement A, specimen held at one end.

specimen fractures, the material has failed the test. When

3.1.2.2 Arrangement B, for thin material.

complete fracture does not occur, the criterion for failure is the

number and size of cracks or other surface irregularity visible 3.1.2.3 Arrangement C, mandrel contact force in the bend.

3.1.3 Free-Bend:

to the unaided eye occurring on the convex surface of the

specimen after bending, as specified by the product standard. 3.1.3.1 Type 1, 180° bend.

3.1.3.2 Type 2, bend flat on itself.

Any cracks within one thickness of the edge of the specimen

are not considered a bend test failure. Cracks occurring in the 3.1.4 Bend and Flatten:

3.2 Aguided bend test for ductility of welds is described in

corners of the bent portion shall not be considered significant

unless they exceed the size specified for corner cracks in the Method E 190 and may be used for flat-rolled materials when

specified by the product standard. The essential features of this

product standard.

1.3 The values stated in SI units are to be regarded as bending method are employed in Method 1 Guided-Bend

(3.1.1).

standard. Inch-pound values given in parentheses were used in

establishing test parameters and are for information only. 3.3 Bend tests are made in one of two directions relative to

the principal working direction employed in production pro-

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the cessing of the material.

3.3.1 Longitudinal tests use a specimen with its long dimen-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- sion aligned with the processing direction such that the bend is

formed across the processing direction, as shown in Fig. 1.

bility of regulatory limitations prior to use.

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Ductility and Flexure Testing. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2004. Published October 2004. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1966. Last previous edition approved in 1997 as E 290 – 97a. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E290–97a (2004)

NOTE 1—Arrow indicates direction of processing.

FIG. 1 Longitudinal Bend Test

3.3.2 Transverse tests use a specimen with the long dimen-

NOTE 1—C = distance between lower supports,

sion perpendicular to the processing direction so that the bend r = radius of the end of the mandrel or plunger,

t = sheet specimen thickness,

axis is aligned with the processing direction, as shown in Fig.

d = round specimen diameter, and

2. The axis of bend is the center of the bend radius.

w = sheet specimen width.

3.3.3 Thin sheet products are generally produced by reduc-

FIG. 3 Schematic Fixture for the Guided-Bend Test

ingthethicknessofstockinrollingmillsandfromthistheterm

rolling direction is used to identify the principal processing

direction. Similarly, a product produced in coil form may have

thickness with a tolerance of one half thickness shall be

the processing direction referred to as the coiling direction.

provided between the pins, plunger, and specimen in the initial

3.4 The location of the force application to the specimen

bend fixture.

relative to the bend itself and the amount of bending differen-

3.6.1.1 The distance between supports (C) shall be three

tiate the four methods of bending covered in these test

thicknesses plus twice the plunger radius, with a tolerance of

methods. The two semi-guided-bend test procedures provide

one-half thickness, as shown in Fig. 3.

radiused surfaces over which the bend is formed. The results

3.6.2 The surfaces of the supports and plunger shall be

obtained by different test procedures may not be the same,

hardened to between 20 and 30 HRC. Refer to MethodE18.

especially for material with a tendency to crack or fracture.

3.6.3 The supports can be fixed or free to rotate.Alubricant

3.5 The test is completed when the designated angle of

may be applied to the supports and plunger.

bend, or other specified condition, has been reached.

3.6.4 The width of the guided-bend fixture, including the

3.5.1 If a defined amount of cracking is permitted by the

supports and plunger, shall be such that the specimen is subject

product standard, the convex surface of the bend region is

to the bending force across its width (w) during bending.

examined for cracks and surface irregularities.

3.6.5 When the thickness or strength of the specimen, or

3.5.2 Surface irregularities, such as orange peel, loss of

capacity of the guided-bend test fixture (shown in Fig. 3) does

coating adherence, or imperfections resulting from the bend,

not produce the required amount of bending, the specimen can

shall be noted as required by the product specification.

be removed from the fixture and the bend completed by

3.6 Guided-Bend—The guided-bend test is made by sup-

applying force against the ends of the specimen, as shown

porting the specimen on pins, rollers, or radiused flats near

schematically in Fig. 4. A spacer with a thickness equal to

each end and applying a force through a pin, mandrel, or

twice the required bend radius is inserted at the location of the

plunger midway between two supports, as shown schemati-

bend. The edges at the ends shall be constrained so the

cally in Fig. 3, until the desired bend is formed. No force is

specimencannotejectfromthefixtureunderthebendingforce.

applied directly to the outer face of the bend.

3.6.1 The radii of the plunger and of the two supports shall

be defined in the product specification as related to the

thickness (t) of the specimen being tested.Aclearance of three

NOTE 1—Arrow indicates direction of processing.

FIG. 4 Schematic Fixture for Completing the Guided-Bend Test

FIG. 2 Transverse Bend Test Started as Shown in Fig. 3

E290–97a (2004)

3.6.6 Surface cracks and imperfections resulting from the

bend shall be evaluated and reported.

3.7 Semi-guided Bend—Thesemi-guided-bendtestemploys

a constraining force on the inside of the bend during the

initiation of the bending and continuing until the final bend

condition is achieved.

3.7.1 Thesemi-guidedbendtestismadebyapplyingaforce

transversely to the specimen’s long axis in the portion that is

being bent.

3.7.2 The angle of bend in the semi-guided-bend test is

measured while the specimen is held stationary under the force

forming the bend.

3.7.3 The location of the bend along the length of the

specimen is unimportant. The specimen is clamped or sup-

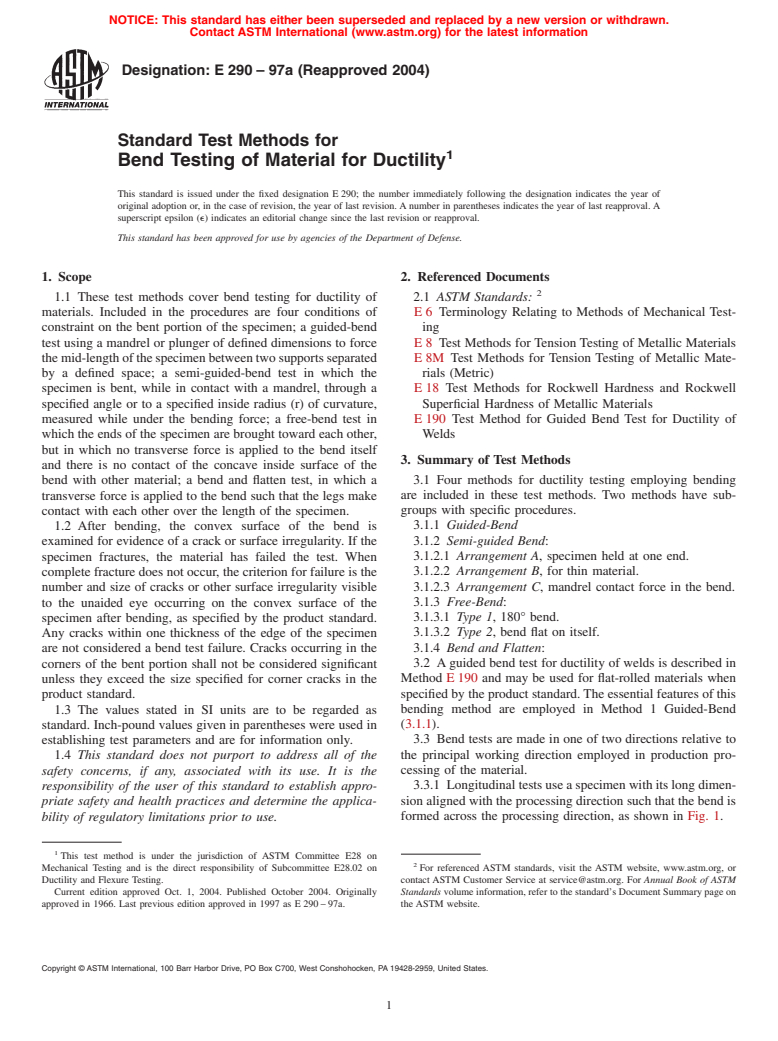

FIG. 6 Arrangement B for Semi-Guided-Bend Test of Thin

portedbyoneofthemethodsshownschematicallyinFigs.5-7.

Specimens—One End Held

It is possible that different results will be obtained with the use

of different devices. The method used shall be described in the

test report on the ductility of the material being evaluated.

3.7.4 Arrangement A—One End Held—Arrangement A in-

volves holding one end of the semi-guided bend specimen and

applying a force transversely near the free end as in Fig. 5.The

bend is formed around a stationary pin, mandrel, or roller of a

specified radius. Bending is continued until failure occurs or

the specified angle of bend has been achieved.

3.7.5 Arrangement B—Thin Materials— Arrangement B is

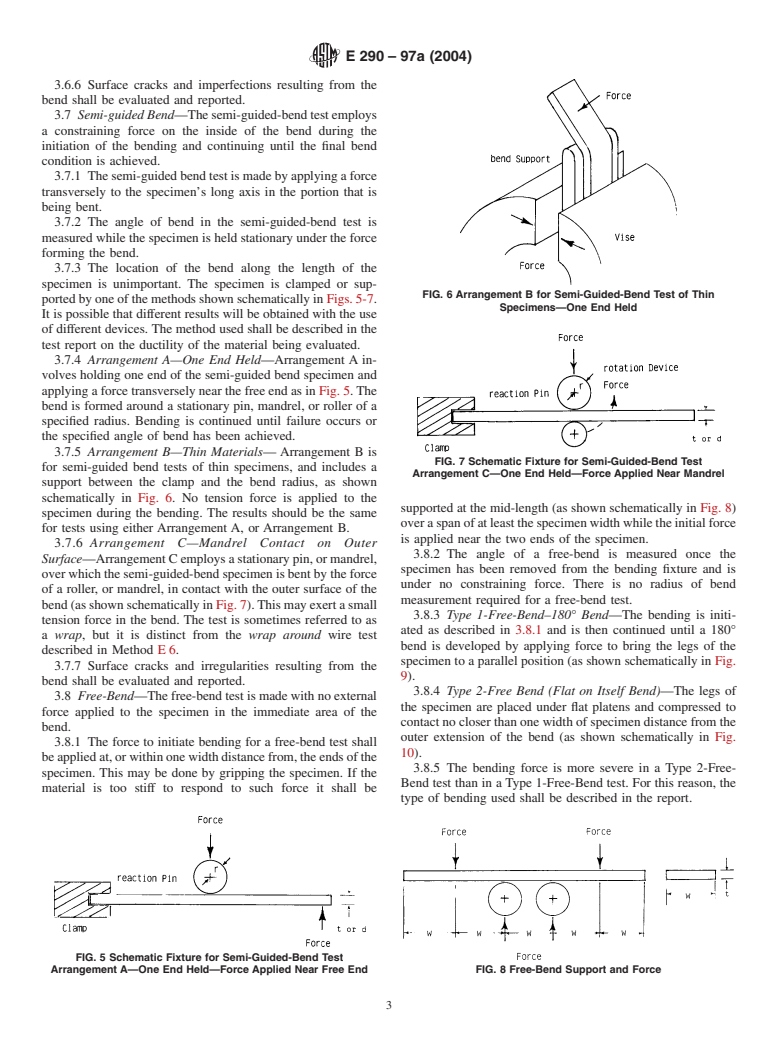

FIG. 7 Schematic Fixture for Semi-Guided-Bend Test

for semi-guided bend tests of thin specimens, and includes a

Arrangement C—One End Held—Force Applied Near Mandrel

support between the clamp and the bend radius, as shown

schematically in Fig. 6. No tension force is applied to the

supported at the mid-length (as shown schematically in Fig. 8)

specimen during the bending. The results should be the same

overaspanofatleastthespecimenwidthwhiletheinitialforce

for tests using either Arrangement A, or Arrangement B.

is applied near the two ends of the specimen.

3.7.6 Arrangement C—Mandrel Contact on Outer

3.8.2 The angle of a free-bend is measured once the

Surface—ArrangementCemploysastationarypin,ormandrel,

specimen has been removed from the bending fixture and is

overwhichthesemi-guided-bendspecimenisbentbytheforce

under no constraining force. There is no radius of bend

of a roller, or mandrel, in contact with the outer surface of the

measurement required for a free-bend test.

bend(asshownschematicallyinFig.7).Thismayexertasmall

3.8.3 Type 1-Free-Bend–180° Bend—The bending is initi-

tension force in the bend. The test is sometimes referred to as

ated as described in 3.8.1 and is then continued until a 180°

a wrap, but it is distinct from the wrap around wire test

bend is developed by applying force to bring the legs of the

described in MethodE6.

specimen to a parallel position (as shown schematically in Fig.

3.7.7 Surface cracks and irregularities resulting from the

9).

bend shall be evaluated and reported.

3.8.4 Type 2-Free Bend (Flat on Itself Bend)—The legs of

3.8 Free-Bend—The free-bend test is made with no external

the specimen are placed under flat platens and compressed to

force applied to the specimen in the immediate area of the

contact no closer than one width of specimen distance from the

bend.

outer extension of the bend (as shown schematically in Fig.

3.8.1 The force to initiate bending for a free-bend test shall

10).

beappliedat,orwithinonewidthdistancefrom,theendsofthe

3.8.5 The bending force is more severe in a Type 2-Free-

specimen. This may be done by gripping the specimen. If the

Bend test than in a Type 1-Free-Bend test. For this reason, the

material is too stiff to respond to such force it shall be

type of bending used shall be described in the report.

FIG. 5 Schematic Fixture for Semi-Guided-Bend Test

Arrangement A—One End Held—Force Applied Near Free End FIG. 8 Free-Bend Support and Force

E290–97a (2004)

4. Significance and Use

4.1 Bend tests for ductility provide a simple way to evaluate

the quality of materials by their ability to resist cracking or

other surface irregularities during one continuous bend. No

reversal of the bend force shall be employed when conducting

these tests.

4.2 Thetypeofbendtestuseddeterminesthelocationofthe

forces and constraints on the bent portion of the specimen,

ranging from no direct contact to continuous contact.

FIG. 9 Type 1 180° Free-Bend

4.3 The test can terminate at a given angle of bend over a

specified radius or continue until the specimen legs are in

contact.The bend angle can be measured while the specimen is

under the bending force (usually when the semi-guided bend

test is employed), or after removal of the force as when

performing a free-bend test. Product requirements for the

material being tested determine the method used.

4.4 Materials with an as-fabricated cross section of rectan-

gular, round, hexagonal, or similar defined shape can be tested

in full section to evaluate their bend properties by using the

procedures outlined in these test methods, in which case

relative width and thickness requirements do not apply.

NOTE 1—Thedistancefromtheclampingplatenstotheouterbendshall

5. Apparatus

not be less than the width (w) of the bend specimen.

5.1 To prevent the introduction of uncontrolled forces while

FIG. 10 Type 2 Flat-on-Itself Free-Bend

accomplishing the bend, the following clamping and force

application devices shall be used.

5.2 Guided-Bend Test—The shape of the material during

3.8.6 Materials that age harden at room temperature shall be

bending is controlled by employing a pair of pins, rollers, or

tested within the allowed period of time, as defined in the

surfaces with end radiused flat to support the specimen while a

product standard.

guided plunger bends the material at its mid-length, as shown

3.8.7 After completing the free-bend, the surface is exam-

schematically in Fig. 3.Amore detailed description of a fixture

ined for cracks and imperfections.

used for this test is given in Method E 190.

3.9 Bend and Flatten—For the bend and flatten test for

5.2.1 Whentheguided-bendtestistobefinishedbybending

ductility, an initial 180° bend is made as described in 3.8.1 and

through a 180° bend that cannot be achieved using the fixture

3.8.3. The specimen is then placed between two parallel

shown in Fig. 3, a fixture sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.