ASTM B236-07(2015)

(Specification)Standard Specification for Aluminum Bars for Electrical Purposes (Bus Bars)

Standard Specification for Aluminum Bars for Electrical Purposes (Bus Bars)

ABSTRACT

This specification covers Aluminum 1350 bar for electric conductors in the tempers. The tempers are designated as H12, H112, and H111. The products covered by this specification shall be produced by extruding or rolling. Bars in the H12 temper shall be furnished with a rolled mill finish; bars in the H111 temper, with an as-extruded mill finish; and bars in the H112 temper, with a rolled mill finish except that the edges shall be as sawed. The bars shall be subjected to tension test to determine their tensile and yield strengths. Bars in the H12, and H111, and H112 tempers shall be capable of being bent flatwise at room temperature, through an angle of 90° around a pin or mandrel having a radius equal to the thickness of the specimen, without cracking or evidence of slivers or other imperfections. For a flatwise bend, the pin or mandrel shall be 90° from the working (extrusion or rolling) direction, and across the greater (width) dimension of the bar. The required 90° bend shall be in the working (extrusion or rolling) direction. Bars in the H12 and H111 tempers whose width-to-thickness ratios are not in excess of 12 and whose width is 100 mm or less, shall be capable of being bent at room temperature edgewise 90° around a mandrel without cracking or localized thinning to less than 90 % of the maximum thickness within the central 60° of the bend when measured along the outer edge of the bend. Electrical resistivity and conductivity shall be measured.

SCOPE

1.1 This specification covers Aluminum 1350 bar for electric conductors in the tempers shown in Table 1. (A) For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded to the nearest 0.1 ksi in accordance with the rounding method of Practice E29.(B) See Annex A1.

1.2 Aluminum and temper designations are in accordance with ANSI H35.1/H35.1(M). The equivalent Unified Numbering System designation is A91350 in accordance with Practice E527.

Note 1: For Alloy 6101 bus conductors, refer to Specification B317/B317M.

Note 2: Prior to 1975, Aluminum 1350 was designated as EC aluminum.

1.3 A complete metric companion to Specification B236 has been developed—B236M; therefore, no metric equivalents appear in this specification.

1.4 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B236 −07 (Reapproved 2015)

Standard Specification for

Aluminum Bars for Electrical Purposes (Bus Bars)

This standard is issued under the fixed designation B236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B666/B666MPractice for Identification Marking of Alumi-

num and Magnesium Products

1.1 This specification covers Aluminum 1350 bar for elec-

B881Terminology Relating toAluminum- and Magnesium-

tric conductors in the tempers shown in Table 1.

Alloy Products

1.2 Aluminum and temper designations are in accordance

E29Practice for Using Significant Digits in Test Data to

withANSI H35.1/H35.1(M). The equivalent Unified Number-

Determine Conformance with Specifications

ing System designation isA91350 in accordance with Practice

E34Test Methods for Chemical Analysis of Aluminum and

E527.

Aluminum-Base Alloys

E55Practice for Sampling Wrought Nonferrous Metals and

NOTE 1—For Alloy 6101 bus conductors, refer to Specification B317/

B317M. Alloys for Determination of Chemical Composition

NOTE 2—Prior to 1975, Aluminum 1350 was designated as EC

E290Test Methods for Bend Testing of Material for Ductil-

aluminum.

ity

1.3 AcompletemetriccompaniontoSpecificationB236has

E527Practice for Numbering Metals and Alloys in the

been developed—B236M; therefore, no metric equivalents

Unified Numbering System (UNS)

appear in this specification.

E607 Test Method for Atomic Emission Spectrometric

Analysis Aluminum Alloys by the Point to Plane Tech-

1.4 For acceptance criteria for inclusion of new aluminum

nique Nitrogen Atmosphere (Withdrawn 2011)

and aluminum alloys in this specification, see Annex A2.

E716Practices for Sampling and Sample Preparation of

Aluminum and Aluminum Alloys for Determination of

2. Referenced Documents

Chemical Composition by Spectrochemical Analysis

2.1 The following documents of the issue in effect on date

E1004Test Method for Determining Electrical Conductivity

of order acceptance form a part of this specification to the

Using the Electromagnetic (Eddy-Current) Method

extent referenced herein:

E1251Test Method for Analysis of Aluminum and Alumi-

2.2 ASTM Standards:

num Alloys by Spark Atomic Emission Spectrometry

B193Test Method for Resistivity of Electrical Conductor

2.3 ANSI Standards:

Materials

H35.1/H35.1(M)AlloyandTemperDesignationSystemsfor

B317/B317MSpecification for Aluminum-Alloy Extruded

Aluminum

Bar, Rod, Tube, Pipe, Structural Profiles, and Profiles for

H35.2 DimensionalTolerancesforAluminumMillProducts

Electrical Purposes (Bus Conductor)

2.4 Military Standard:Available from Standardization

B557Test Methods for Tension Testing Wrought and Cast

Documents Order Desk, DODSSP, Bldg. 4, Section D, 700

Aluminum- and Magnesium-Alloy Products

Robbins Ave., Philadelphia, PA 19111-5098, http://

B660Practices for Packaging/Packing of Aluminum and

www.dodssp.daps.mil.

Magnesium Products

MIL-STD-129Marking for Shipment and Storage

2.5 Federal Standard:

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

This specification is under the jurisdiction ofASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

3. Terminology

Aluminum Alloy Wrought Products.

Current edition approved Oct. 1, 2015. Published October 2015. Originally

3.1 Definitions: Refer to Terminology B881 for definitions

approved in 1948. Last previous edition approved in 2007 as B236–07. DOI:

of product terms used in this specification.

10.1520/B0236-07R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

B236 − 07 (2015)

A,B

TABLE 1 Tensile Property Limits

requirements specified herein. Except as otherwise specified in

Tensile Yield Strength

the contract or order, the producer may use his own or any

Specified

Temper Strength, (0.2% offset),

Thickness, in. other suitable facilities for the performance of the inspection

min, ksi min, ksi

and test requirements specified herein, unless disapproved by

H12 0.125–1.000 12.0 8.0

the purchaser. The purchaser shall have the right to perform

H112 0.125–0.499 11.0 6.0

0.500–1.000 10.0 4.0

any of the inspections and tests set forth in this specification

1.001–3.000 9.0 3.5

where such inspections are deemed necessary to assure that

H111 All 8.5 3.5

material conforms to prescribed requirements.

A

For purposes of determining conformance with this specification, each value for

tensile strength and yield strength shall be rounded to the nearest 0.1 ksi in

6.2 Lot Definition—An inspection lot shall consist of an

accordance with the rounding method of Practice E29.

B identifiable quantity of material of the same aluminum

See AnnexA1.

designation, temper, and thickness subjected to inspection at

one time.

3.2 Definitions of Terms Specific to This Standard:

7. Chemical Composition Requirements

3.2.1 capable of—the term capable of as used in this

7.1 The material shall conform to the composition in Table

specification means that the test need not be performed by the

2. Conformance shall be determined by the producer by

producer of the material. However, should testing by the

analyzing samples taken at the time the ingots or continuously

purchaser establish that the material does not meet these

cast bars are poured, or samples taken from the finished or

requirements, the material shall be subject to rejection.

semifinished product. If the producer has determined the

4. Ordering Information composition of the material during the course of manufacture,

he shall not be required to sample and analyze the finished

4.1 Ordersformaterialtothisspecificationshallincludethe

product.

following information:

4.1.1 This specification designation (which includes the NOTE 3—It is standard practice in the United States aluminum industry

to determine conformance to the composition limits prior to further

number, the year, and the revision letter, if applicable),

processing of ingots into wrought products. Due to the continuous nature

4.1.2 Quantity in pieces or pounds,

oftheprocess,itisnotpracticaltokeepaspecificingotanalysisidentified

4.1.3 Temper (8.1),

with a specific quantity of finished material.

4.1.4 Edge contour (Section 12),

7.2 Number of Samples—The number of samples taken for

4.1.5 Diameter for rounds; distance across flats for square-

determination of chemical composition shall be as follows:

cornered squares, hexagons, or octagons; width and depth for

7.2.1 When samples are taken at the time the ingots are

square-cornered rectangles,

poured, at least one sample shall be taken for each group of

4.1.6 Length (specific or stock) (Section 14),

ingots poured simultaneously from the same source of molten

4.2 Additionally, orders for material to this specification

metal.

shall include the following information when required by the

7.2.2 When samples are taken from the finished or semifin-

purchaser:

ished product, a sample shall be taken to represent each 4000

4.2.1 Whether inspection or witness of inspection and tests

by the purchaser’s representative is required prior to material

shipment (16.1),

A

TABLE 2 Chemical Composition Limits

4.2.2 Whether marking for identification is required (18.1),

Element Composition, %

4.2.3 Whether Practices B660 applies and, if so, the levels

Silicon, max 0.10

of preservation, packaging, and packing required (19.3), and

Iron, max 0.40

Copper, max 0.05

4.2.4 Whethercertificationofthematerialbytheproduceris

Manganese, max 0.01

required (Section 20).

Chromium, max 0.01

Zinc, max 0.05

5. Manufacture

Boron, max 0.05

Gallium, max 0.03

5.1 The products covered by this specification shall be

Vanadium+titanium, total, max 0.02

B

produced by extruding or rolling, at the option of the producer, Other elements, each, max 0.03

B,C

Other elements, total, max 0.10

provided that the production method results in material that

D

Aluminum, min 99.50

meets all requirements of this specification.

A

Analysis shall be made for the elements for which limits are shown in this table.

B

5.2 Bars in the H12 temper shall be furnished with a rolled Others includes all unlisted metallic elements. The producer may analyze

samples for trace elements not specified in the specification. However, such

mill finish; bars in the H111 temper, with an as-extruded mill

analysis is not required and may not cover all metallic Others elements. Should

finish; and bars in the H112 temper, with a rolled mill finish

any analysis by the producer or the purchaser establish that an Others element

exceeds the limit of Each or that the aggregate of several Others elements

except that the edges shall be as sawed.

exceeds the limit of Total, the material shall be considered non-conforming.

C

OtherElements—Totalshallbethesumofunspecifiedmetallicelements0.010%

6. Responsibility for Quality Assurance

or more, rounded to the second decimal before determining the sum.

D

Thealuminumcontentshallbecalculatedbysubtractingfrom100.00%thesum

6.1 Responsibility for Inspection and Tests—Unless other-

of all metallic elements present in amounts of 0.010% or more each, rounded to

wisespecifiedinthecontractorpurchaseorder,theproduceris

the second decimal before determining the sum.

responsible for the performance of all inspection and test

B236 − 07 (2015)

TABLE 3 Edgewise Bend Radii

lb, or fraction thereof, in the shipment, except that not more

than one sample shall be required per piece. Specified Width, in. Mandrel Radius, in.

0.500 and under ⁄2

7.3 Methods of Sampling—Samples for determination of

0.501–1.000 1

chemical composition shall be taken in accordance with one of 1

1.001–1.500 1 ⁄2

1.501–2.000 2

the following methods:

2.001–2.500 2 ⁄2

7.3.1 Samples for chemical analysis shall be taken from the

2.501–3.000 3

material by drilling, sawing, milling, turning, or clipping a 3.001–3.500 3 ⁄2

3.501–4.000 4

representative piece or pieces to obtain a prepared sample of

not less than 75 g. Sampling shall be in accordance with

Practice E55.

7.3.2 Sampling for spectrochemical analysis shall be in

accordance with Practices E716. Samples for other methods of

(thckness) dimension of the bar. This is also a longitudinal

analysis shall be taken by methods suitable for the form of

bend as defined and shown in Test Methods E290, Fig. 1.

material being analyzed and the type of analytical method

9.2 Test Specimens—Bend test specimens shall be a full

used.

section of the material.

7.4 Methods of Analysis—The determination of chemical

9.3 Test Methods—Bend tests shall be made in accordance

composition shall be made in accordance with suitable chemi-

with Test Methods E290.

cal (Test Methods E34) or spectrochemical (Test Methods

E607 and E1251) methods. Other methods may be used only

10. Density

when no published ASTM method is available. In case of

10.1 The density of aluminum 1350 shall be taken as 0.097

dispute, the methods of analysis shall be agreed upon between

lb/in.

the producer and purchaser.

11. Electrical Properties

8. Tensile Properties

11.1 Limits—The resistivity of specimens selected shall not

8.1 Limits—The bars shall conform to the requirements for

exceed 0.0283 Ω·mm /m at 20°C corresponding to a conduc-

tensile properties as specified in Table 1.

tivity not less than 61.0% of the International Annealed

8.2 Number of Specimens—One tension test specimen shall

Copper Standard. To determine conformance with this

be taken from a random bar representing each 3000 lb of bar,

specification, each value for electrical resistivity shall be

or fraction thereof, of the same temper, thickness, and width in

rounded to the nearest unit in the last right-hand place of

the shipment.

figures, in accordance with the rounding method of Practice

E29.

8.3 Test Methods—The tension test shall be made in accor-

dance with Test Methods B557.

11.2 Number of Specimens—One specimen shall be taken

fromarandombarrepresentingeach3000lbofbar,orfraction

9. Bend Properties

thereof, of the same temper and thickness in the inspection lot.

9.1 Limits:

11.3 Test Specimens—Specimens for determining resistivity

9.1.1 Flatwise Bend—Bars in the H12, and H111, and H112

or conductivity shall preferably be a full section of the

tempers shall be capable of being bent flatwise at room

material, but may be of any suitable size or shape appropriate

temperature, through an angle of 90° around a pin or mandrel

to the instrument used in making the determination.

havingaradiusequaltothethicknessofthespecimen,without

11.4 Test Methods—Electrical resistivity or conductivity

cracking or evidence of slivers or other imperfections. For a

shall be determined in accordance with Test Methods B193 or

flatwisebend,thepinormandrelshallbe90°fromtheworking

E1004, provided that, in case of dispute, the results secured by

(extrusion or rolling) direction, and across the greater (width)

Test Method B193 shall be the basis for acceptance.

dimension of the bar. The required 90° bend shall be in the

working (extrusion or rolling) direction. This is a longitudinal

12. Edge Contours

bend as defined and shown in Test Methods E290, Fig. 1.

12.1 Unless otherwise specified, bar shall be furnished with

9.1.2 Edgewise Bend—Bars in the H12 and H111 tempers

square corners. When specified, bar shall be furnished with

whose width-to-thickness ratios are not in excess of 12 and

rounded corners, rounded edges or full rounded edges, as

whose width is 4 in. or less, shall be capable of being bent at

shown in Table19.1.11 for rolled bar and Table19.3.4 for

room temperature edgewise 90° around a mandrel having the

extruded bar or with corners and edges for sawed-plate bar as

radius shown in Table 3 without cracking or localized thinning

shown in Table19.2.4, of ANSI H35.2.

to less than 90% of the maximum thickness within the central

60° of the bend when measured along the outer edge of the

13. Dimensional Tolerances

bend.Bendingrequirementsforbarwiderthan4in.shallbeas

agreed upon by the producer and the purcha

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B236 − 07 (Reapproved 2015)

Standard Specification for

Aluminum Bars for Electrical Purposes (Bus Bars)

This standard is issued under the fixed designation B236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B666/B666M Practice for Identification Marking of Alumi-

num and Magnesium Products

1.1 This specification covers Aluminum 1350 bar for elec-

B881 Terminology Relating to Aluminum- and Magnesium-

tric conductors in the tempers shown in Table 1.

Alloy Products

1.2 Aluminum and temper designations are in accordance

E29 Practice for Using Significant Digits in Test Data to

with ANSI H35.1/H35.1(M). The equivalent Unified Number-

Determine Conformance with Specifications

ing System designation is A91350 in accordance with Practice

E34 Test Methods for Chemical Analysis of Aluminum and

E527.

Aluminum-Base Alloys

E55 Practice for Sampling Wrought Nonferrous Metals and

NOTE 1—For Alloy 6101 bus conductors, refer to Specification B317/

B317M.

Alloys for Determination of Chemical Composition

NOTE 2—Prior to 1975, Aluminum 1350 was designated as EC

E290 Test Methods for Bend Testing of Material for Ductil-

aluminum.

ity

1.3 A complete metric companion to Specification B236 has

E527 Practice for Numbering Metals and Alloys in the

been developed—B236M; therefore, no metric equivalents

Unified Numbering System (UNS)

appear in this specification.

E607 Test Method for Atomic Emission Spectrometric

Analysis Aluminum Alloys by the Point to Plane Tech-

1.4 For acceptance criteria for inclusion of new aluminum

nique Nitrogen Atmosphere (Withdrawn 2011)

and aluminum alloys in this specification, see Annex A2.

E716 Practices for Sampling and Sample Preparation of

Aluminum and Aluminum Alloys for Determination of

2. Referenced Documents

Chemical Composition by Spectrochemical Analysis

2.1 The following documents of the issue in effect on date

E1004 Test Method for Determining Electrical Conductivity

of order acceptance form a part of this specification to the

Using the Electromagnetic (Eddy-Current) Method

extent referenced herein:

E1251 Test Method for Analysis of Aluminum and Alumi-

2.2 ASTM Standards:

num Alloys by Spark Atomic Emission Spectrometry

B193 Test Method for Resistivity of Electrical Conductor

2.3 ANSI Standards:

Materials

H35.1/H35.1(M) Alloy and Temper Designation Systems for

B317/B317M Specification for Aluminum-Alloy Extruded

Aluminum

Bar, Rod, Tube, Pipe, Structural Profiles, and Profiles for

H35.2 Dimensional Tolerances for Aluminum Mill Products

Electrical Purposes (Bus Conductor)

2.4 Military Standard:Available from Standardization

B557 Test Methods for Tension Testing Wrought and Cast

Documents Order Desk, DODSSP, Bldg. 4, Section D, 700

Aluminum- and Magnesium-Alloy Products

Robbins Ave., Philadelphia, PA 19111-5098, http://

B660 Practices for Packaging/Packing of Aluminum and

www.dodssp.daps.mil.

Magnesium Products

MIL-STD-129 Marking for Shipment and Storage

2.5 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

3. Terminology

Aluminum Alloy Wrought Products.

Current edition approved Oct. 1, 2015. Published October 2015. Originally

3.1 Definitions: Refer to Terminology B881 for definitions

approved in 1948. Last previous edition approved in 2007 as B236 – 07. DOI:

of product terms used in this specification.

10.1520/B0236-07R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B236 − 07 (2015)

A,B

TABLE 1 Tensile Property Limits

requirements specified herein. Except as otherwise specified in

Tensile Yield Strength

the contract or order, the producer may use his own or any

Specified

Temper Strength, (0.2 % offset),

Thickness, in. other suitable facilities for the performance of the inspection

min, ksi min, ksi

and test requirements specified herein, unless disapproved by

H12 0.125–1.000 12.0 8.0

the purchaser. The purchaser shall have the right to perform

H112 0.125–0.499 11.0 6.0

0.500–1.000 10.0 4.0

any of the inspections and tests set forth in this specification

1.001–3.000 9.0 3.5

where such inspections are deemed necessary to assure that

H111 All 8.5 3.5

material conforms to prescribed requirements.

A

For purposes of determining conformance with this specification, each value for

tensile strength and yield strength shall be rounded to the nearest 0.1 ksi in

6.2 Lot Definition—An inspection lot shall consist of an

accordance with the rounding method of Practice E29.

identifiable quantity of material of the same aluminum

B

See Annex A1.

designation, temper, and thickness subjected to inspection at

one time.

3.2 Definitions of Terms Specific to This Standard:

7. Chemical Composition Requirements

3.2.1 capable of—the term capable of as used in this

7.1 The material shall conform to the composition in Table

specification means that the test need not be performed by the

2. Conformance shall be determined by the producer by

producer of the material. However, should testing by the

analyzing samples taken at the time the ingots or continuously

purchaser establish that the material does not meet these

cast bars are poured, or samples taken from the finished or

requirements, the material shall be subject to rejection.

semifinished product. If the producer has determined the

composition of the material during the course of manufacture,

4. Ordering Information

he shall not be required to sample and analyze the finished

4.1 Orders for material to this specification shall include the

product.

following information:

4.1.1 This specification designation (which includes the

NOTE 3—It is standard practice in the United States aluminum industry

to determine conformance to the composition limits prior to further

number, the year, and the revision letter, if applicable),

processing of ingots into wrought products. Due to the continuous nature

4.1.2 Quantity in pieces or pounds,

of the process, it is not practical to keep a specific ingot analysis identified

4.1.3 Temper (8.1),

with a specific quantity of finished material.

4.1.4 Edge contour (Section 12),

7.2 Number of Samples—The number of samples taken for

4.1.5 Diameter for rounds; distance across flats for square-

determination of chemical composition shall be as follows:

cornered squares, hexagons, or octagons; width and depth for

7.2.1 When samples are taken at the time the ingots are

square-cornered rectangles,

poured, at least one sample shall be taken for each group of

4.1.6 Length (specific or stock) (Section 14),

ingots poured simultaneously from the same source of molten

4.2 Additionally, orders for material to this specification

metal.

shall include the following information when required by the

7.2.2 When samples are taken from the finished or semifin-

purchaser:

ished product, a sample shall be taken to represent each 4000

4.2.1 Whether inspection or witness of inspection and tests

by the purchaser’s representative is required prior to material

shipment (16.1),

A

TABLE 2 Chemical Composition Limits

4.2.2 Whether marking for identification is required (18.1),

Element Composition, %

4.2.3 Whether Practices B660 applies and, if so, the levels

Silicon, max 0.10

of preservation, packaging, and packing required (19.3), and

Iron, max 0.40

Copper, max 0.05

4.2.4 Whether certification of the material by the producer is

Manganese, max 0.01

required (Section 20).

Chromium, max 0.01

Zinc, max 0.05

5. Manufacture

Boron, max 0.05

Gallium, max 0.03

5.1 The products covered by this specification shall be

Vanadium + titanium, total, max 0.02

B

produced by extruding or rolling, at the option of the producer, Other elements, each, max 0.03

B,C

Other elements, total, max 0.10

provided that the production method results in material that

D

Aluminum, min 99.50

meets all requirements of this specification.

A

Analysis shall be made for the elements for which limits are shown in this table.

B

Others includes all unlisted metallic elements. The producer may analyze

5.2 Bars in the H12 temper shall be furnished with a rolled

samples for trace elements not specified in the specification. However, such

mill finish; bars in the H111 temper, with an as-extruded mill

analysis is not required and may not cover all metallic Others elements. Should

finish; and bars in the H112 temper, with a rolled mill finish

any analysis by the producer or the purchaser establish that an Others element

exceeds the limit of Each or that the aggregate of several Others elements

except that the edges shall be as sawed.

exceeds the limit of Total, the material shall be considered non-conforming.

C

Other Elements—Total shall be the sum of unspecified metallic elements 0.010 %

6. Responsibility for Quality Assurance

or more, rounded to the second decimal before determining the sum.

D

The aluminum content shall be calculated by subtracting from 100.00 % the sum

6.1 Responsibility for Inspection and Tests—Unless other-

of all metallic elements present in amounts of 0.010 % or more each, rounded to

wise specified in the contract or purchase order, the producer is

the second decimal before determining the sum.

responsible for the performance of all inspection and test

B236 − 07 (2015)

TABLE 3 Edgewise Bend Radii

lb, or fraction thereof, in the shipment, except that not more

than one sample shall be required per piece. Specified Width, in. Mandrel Radius, in.

0.500 and under ⁄2

7.3 Methods of Sampling—Samples for determination of

0.501–1.000 1

chemical composition shall be taken in accordance with one of

1.001–1.500 1 ⁄2

1.501–2.000 2

the following methods:

2.001–2.500 2 ⁄2

7.3.1 Samples for chemical analysis shall be taken from the

2.501–3.000 3

material by drilling, sawing, milling, turning, or clipping a 3.001–3.500 3 ⁄2

3.501–4.000 4

representative piece or pieces to obtain a prepared sample of

not less than 75 g. Sampling shall be in accordance with

Practice E55.

7.3.2 Sampling for spectrochemical analysis shall be in

accordance with Practices E716. Samples for other methods of

(thckness) dimension of the bar. This is also a longitudinal

analysis shall be taken by methods suitable for the form of

bend as defined and shown in Test Methods E290, Fig. 1.

material being analyzed and the type of analytical method

9.2 Test Specimens—Bend test specimens shall be a full

used.

section of the material.

7.4 Methods of Analysis—The determination of chemical

9.3 Test Methods—Bend tests shall be made in accordance

composition shall be made in accordance with suitable chemi-

with Test Methods E290.

cal (Test Methods E34) or spectrochemical (Test Methods

E607 and E1251) methods. Other methods may be used only

10. Density

when no published ASTM method is available. In case of

10.1 The density of aluminum 1350 shall be taken as 0.097

dispute, the methods of analysis shall be agreed upon between

lb/in.

the producer and purchaser.

11. Electrical Properties

8. Tensile Properties

11.1 Limits—The resistivity of specimens selected shall not

8.1 Limits—The bars shall conform to the requirements for

exceed 0.0283 Ω·mm /m at 20°C corresponding to a conduc-

tensile properties as specified in Table 1.

tivity not less than 61.0 % of the International Annealed

8.2 Number of Specimens—One tension test specimen shall

Copper Standard. To determine conformance with this

be taken from a random bar representing each 3000 lb of bar,

specification, each value for electrical resistivity shall be

or fraction thereof, of the same temper, thickness, and width in

rounded to the nearest unit in the last right-hand place of

the shipment.

figures, in accordance with the rounding method of Practice

E29.

8.3 Test Methods—The tension test shall be made in accor-

dance with Test Methods B557.

11.2 Number of Specimens—One specimen shall be taken

from a random bar representing each 3000 lb of bar, or fraction

9. Bend Properties

thereof, of the same temper and thickness in the inspection lot.

9.1 Limits:

11.3 Test Specimens—Specimens for determining resistivity

9.1.1 Flatwise Bend—Bars in the H12, and H111, and H112

or conductivity shall preferably be a full section of the

tempers shall be capable of being bent flatwise at room

material, but may be of any suitable size or shape appropriate

temperature, through an angle of 90° around a pin or mandrel

to the instrument used in making the determination.

having a radius equal to the thickness of the specimen, without

11.4 Test Methods—Electrical resistivity or conductivity

cracking or evidence of slivers or other imperfections. For a

shall be determined in accordance with Test Methods B193 or

flatwise bend, the pin or mandrel shall be 90° from the working

E1004, provided that, in case of dispute, the results secured by

(extrusion or rolling) direction, and across the greater (width)

Test Method B193 shall be the basis for acceptance.

dimension of the bar. The required 90° bend shall be in the

working (extrusion or rolling) direction. This is a longitudinal

12. Edge Contours

bend as defined and shown in Test Methods E290, Fig. 1.

12.1 Unless otherwise specified, bar shall be furnished with

9.1.2 Edgewise Bend—Bars in the H12 and H111 tempers

square corners. When specified, bar shall be furnished with

whose width-to-thickness ratios are not in excess of 12 and

rounded corners, rounded edges or full rounded edges, as

whose width is 4 in. or less, shall be capable of being bent at

shown in Table 19.1.11 for rolled bar and Table 19.3.4 for

room temperature edgewise 90° around a mandrel having the

extruded bar or with corners and edges for sawed-plate bar as

radius shown in Table 3 without cracking or localized thinning

shown in Table 19.2.4, of ANSI H35.2.

to less than 90 % of the maximum thickness within the central

60° of the bend when measured along the outer edge of the

13. Dimensional Tolerances

bend. Bending requirements for bar w

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B236 − 07 B236 − 07 (Reapproved 2015)

Standard Specification for

Aluminum Bars for Electrical Purposes (Bus Bars)

This standard is issued under the fixed designation B236; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers Aluminum 1350 bar for electric conductors in the tempers shown in Table 1.

1.2 Aluminum and temper designations are in accordance with ANSI H35.1/H35.1(M). The equivalent Unified Numbering

System designation is A91350 in accordance with Practice E527.

NOTE 1—For Alloy 6101 bus conductors, refer to Specification B317/B317M.

NOTE 2—Prior to 1975, Aluminum 1350 was designated as EC aluminum.

1.3 A complete metric companion to Specification B236 has been developed—B236M; therefore, no metric equivalents appear

in this specification.

1.4 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of order acceptance form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B317/B317M Specification for Aluminum-Alloy Extruded Bar, Rod, Tube, Pipe, Structural Profiles, and Profiles for Electrical

Purposes (Bus Conductor)

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B660 Practices for Packaging/Packing of Aluminum and Magnesium Products

B666/B666M Practice for Identification Marking of Aluminum and Magnesium Products

B881 Terminology Relating to Aluminum- and Magnesium-Alloy Products

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E34 Test Methods for Chemical Analysis of Aluminum and Aluminum-Base Alloys

E55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

E290 Test Methods for Bend Testing of Material for Ductility

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

E607 Test Method for Atomic Emission Spectrometric Analysis Aluminum Alloys by the Point to Plane Technique Nitrogen

Atmosphere (Withdrawn 2011)

E716 Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical

Composition by Spectrochemical Analysis

E1004 Test Method for Determining Electrical Conductivity Using the Electromagnetic (Eddy-Current) Method

E1251 Test Method for Analysis of Aluminum and Aluminum Alloys by Spark Atomic Emission Spectrometry

2.3 ANSI Standards:

H35.1/H35.1(M) Alloy and Temper Designation Systems for Aluminum

H35.2 Dimensional Tolerances for Aluminum Mill Products

This specification is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Aluminum

Alloy Wrought Products.

Current edition approved June 1, 2007Oct. 1, 2015. Published July 2007October 2015. Originally approved in 1948. Last previous edition approved in 20062007 as

B236B236 – 07.–00 (2006). DOI: 10.1520/B0236-07.10.1520/B0236-07R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B236 − 07 (2015)

A,B

TABLE 1 Tensile Property Limits

Tensile Yield Strength

Specified

Temper Strength, (0.2 % offset),

Thickness, in.

min, ksi min, ksi

H12 0.125–1.000 12.0 8.0

H112 0.125–0.499 11.0 6.0

0.500–1.000 10.0 4.0

1.001–3.000 9.0 3.5

H111 All 8.5 3.5

A

For purposes of determining conformance with this specification, each value for

tensile strength and yield strength shall be rounded to the nearest 0.1 ksi in

accordance with the rounding method of Practice E29.

B

See Annex A1.

2.4 Military Standard:Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave.,

Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

MIL-STD-129 Marking for Shipment and Storage

2.5 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

3. Terminology

3.1 Definitions: Refer to Terminology B881 for definitions of product terms used in this specification.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 capable of—the term capable of as used in this specification means that the test need not be performed by the producer

of the material. However, should testing by the purchaser establish that the material does not meet these requirements, the material

shall be subject to rejection.

4. Ordering Information

4.1 Orders for material to this specification shall include the following information:

4.1.1 This specification designation (which includes the number, the year, and the revision letter, if applicable),

4.1.2 Quantity in pieces or pounds,

4.1.3 Temper (8.1),

4.1.4 Edge contour (Section 12),

4.1.5 Diameter for rounds; distance across flats for square-cornered squares, hexagons, or octagons; width and depth for

square-cornered rectangles,

4.1.6 Length (specific or stock) (Section 14),

4.2 Additionally, orders for material to this specification shall include the following information when required by the

purchaser:

4.2.1 Whether inspection or witness of inspection and tests by the purchaser’s representative is required prior to material

shipment (16.1),

4.2.2 Whether marking for identification is required (18.1),

4.2.3 Whether Practices B660 applies and, if so, the levels of preservation, packaging, and packing required (19.3), and

4.2.4 Whether certification of the material by the producer is required (Section 20).

5. Manufacture

5.1 The products covered by this specification shall be produced by extruding or rolling, at the option of the producer, provided

that the production method results in material that meets all requirements of this specification.

5.2 Bars in the H12 temper shall be furnished with a rolled mill finish; bars in the H111 temper, with an as-extruded mill finish;

and bars in the H112 temper, with a rolled mill finish except that the edges shall be as sawed.

6. Responsibility for Quality Assurance

6.1 Responsibility for Inspection and Tests—Unless otherwise specified in the contract or purchase order, the producer is

responsible for the performance of all inspection and test requirements specified herein. Except as otherwise specified in the

contract or order, the producer may use his own or any other suitable facilities for the performance of the inspection and test

requirements specified herein, unless disapproved by the purchaser. The purchaser shall have the right to perform any of the

inspections and tests set forth in this specification where such inspections are deemed necessary to assure that material conforms

to prescribed requirements.

B236 − 07 (2015)

6.2 Lot Definition—An inspection lot shall consist of an identifiable quantity of material of the same aluminum designation,

temper, and thickness subjected to inspection at one time.

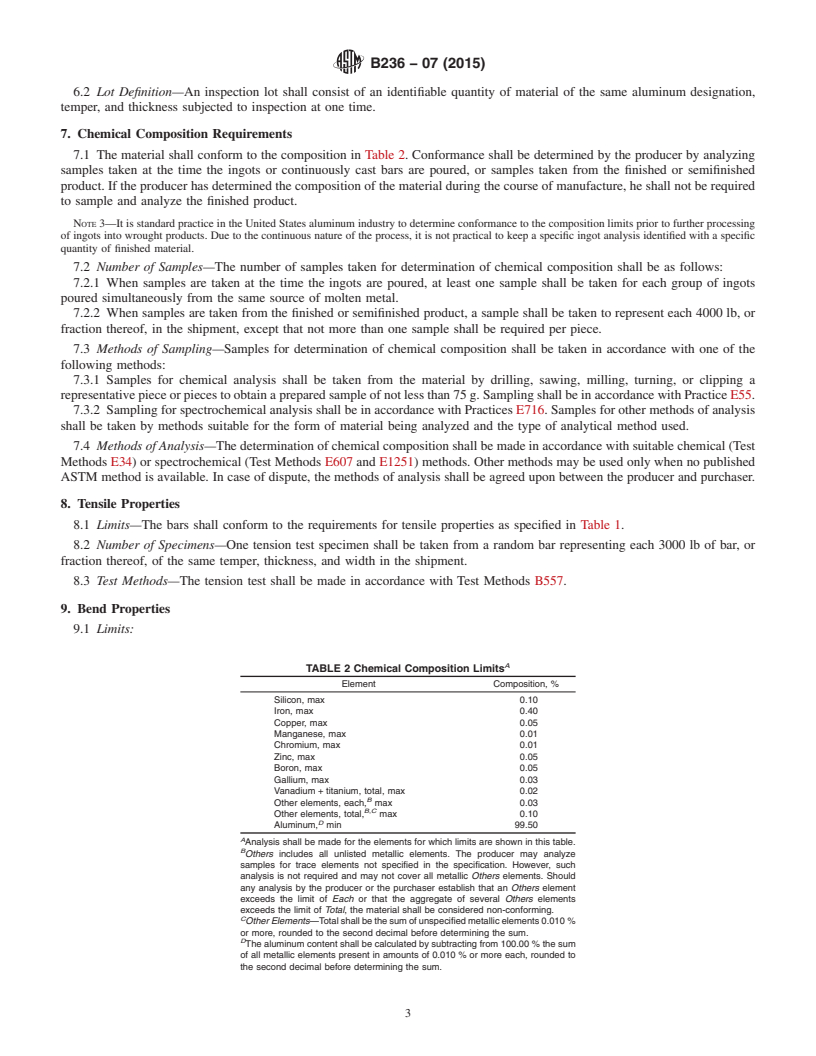

7. Chemical Composition Requirements

7.1 The material shall conform to the composition in Table 2. Conformance shall be determined by the producer by analyzing

samples taken at the time the ingots or continuously cast bars are poured, or samples taken from the finished or semifinished

product. If the producer has determined the composition of the material during the course of manufacture, he shall not be required

to sample and analyze the finished product.

NOTE 3—It is standard practice in the United States aluminum industry to determine conformance to the composition limits prior to further processing

of ingots into wrought products. Due to the continuous nature of the process, it is not practical to keep a specific ingot analysis identified with a specific

quantity of finished material.

7.2 Number of Samples—The number of samples taken for determination of chemical composition shall be as follows:

7.2.1 When samples are taken at the time the ingots are poured, at least one sample shall be taken for each group of ingots

poured simultaneously from the same source of molten metal.

7.2.2 When samples are taken from the finished or semifinished product, a sample shall be taken to represent each 4000 lb, or

fraction thereof, in the shipment, except that not more than one sample shall be required per piece.

7.3 Methods of Sampling—Samples for determination of chemical composition shall be taken in accordance with one of the

following methods:

7.3.1 Samples for chemical analysis shall be taken from the material by drilling, sawing, milling, turning, or clipping a

representative piece or pieces to obtain a prepared sample of not less than 75 g. Sampling shall be in accordance with Practice E55.

7.3.2 Sampling for spectrochemical analysis shall be in accordance with Practices E716. Samples for other methods of analysis

shall be taken by methods suitable for the form of material being analyzed and the type of analytical method used.

7.4 Methods of Analysis—The determination of chemical composition shall be made in accordance with suitable chemical (Test

Methods E34) or spectrochemical (Test Methods E607 and E1251) methods. Other methods may be used only when no published

ASTM method is available. In case of dispute, the methods of analysis shall be agreed upon between the producer and purchaser.

8. Tensile Properties

8.1 Limits—The bars shall conform to the requirements for tensile properties as specified in Table 1.

8.2 Number of Specimens—One tension test specimen shall be taken from a random bar representing each 3000 lb of bar, or

fraction thereof, of the same temper, thickness, and width in the shipment.

8.3 Test Methods—The tension test shall be made in accordance with Test Methods B557.

9. Bend Properties

9.1 Limits:

A

TABLE 2 Chemical Composition Limits

Element Composition, %

Silicon, max 0.10

Iron, max 0.40

Copper, max 0.05

Manganese, max 0.01

Chromium, max 0.01

Zinc, max 0.05

Boron, max 0.05

Gallium, max 0.03

Vanadium + titanium, total, max 0.02

B

Other elements, each, max 0.03

B,C

Other elements, total, max 0.10

D

Aluminum, min 99.50

A

Analysis shall be made for the elements for which limits are shown in this table.

B

Others includes all unlisted metallic elements. The producer may analyze

samples for trace elements not specified in the specification. However, such

analysis is not required and may not cover all metallic Others elements. Should

any analysis by the producer or the purchaser establish that an Others element

exceeds the limit of Each or that the aggregate of several Others elements

exceeds the limit of Total, the material shall be considered non-conforming.

C

Other Elements—Total shall be the sum of unspecified metallic elements 0.010 %

or more, rounded to the second decimal before determining the sum.

D

The aluminum content shall be calculated by subtracting from 100.00 % the sum

of all metallic elements present in amounts of 0.010 % or more each, rounded to

the second decimal before determining the sum.

B236 − 07 (2015)

9.1.1 Flatwise Bend—Bars in the H12, and H111, and H112 tempers shall be capable of being bent flatwise at room temperature,

through an angle of 90° around a pin or mandrel having a radius equal to the thickness of the specimen, without cracking or

evidence of slivers or other imperfections. For a flatwise bend, the pin or mandrel shall be 90° from the working (extrusion or

rolling) direction, and across the greater (width) dimension of the bar. The required 90° bend shall be in the working (extrusion

or rolling) direction. This is a longitudinal bend as defined and shown in Test Methods E290, Fig. 1.

9.1.2 Edgewise Bend—Bars in the H12 and H111 tempers whose width-to-thickness ratios are not in excess of 12 and whose

width is 4 in. or less, shall be capable of being bent at room temperature edgewise 90° around a mandrel having the radius shown

in Table 3 without cracking or localized thinning to less than 90 % of the maximum thickness within the central 60° of the bend

when measured along the outer edge of the bend. Bending requirements for bar wider than 4 in. shall be as agreed upon by the

producer and the purchaser. For an edgewise bend, the pin or mandrel shall be 90° from the working (extrusion or rolling) direction,

and across the lesser (thckness) dimension of the bar. This is also a longitudinal bend as defined and shown in Test Methods E290,

Fig. 1.

9.2 Test Specimens—Bend test specimens shall be a full section of the material.

9.3 Test Methods—Bend tests shall be made in accordance with Test Methods E290.

10. Density

10.1 The density of aluminum 1350 shall be taken as 0.097 lb/in.

11. Electrical Properties

11.1 Limits—The resistivity of specimens selected shall not exceed 0.0283 Ω·mm /m at 20°C corresponding to a conductivity

not less than 61.0 % of the International Annealed Copper Standard. To determine conformance with this specification, each value

for electrical resistivity shall be rounded to the nearest unit in the last right-hand place of figures, in accordance with the rounding

method of Practice E29.

11.2 Number of Specimens—One specimen shall be taken from a random bar representing each 3000 lb of bar, or fraction

thereof, of the same temper and thickness in the inspection lot.

11.3 Test Specimens—Specimens for determining resistivity or conductivity shall preferably be a full section of the material, but

may be of any suitable size or shape appropriate to the instrument used in making the determination.

11.4 Test Methods—Electrical resistivity or conductivity shall be determined in accordance with Test Methods B193 or E1004,

provided that, in case of dispute, the results secured by Test Method B193 shall be the basis for acceptance.

12. Edge Contours

12.1 Unless otherwise specified,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.