ASTM E1258-88(2012)

(Test Method)Standard Test Method for Airflow Calibration of Fan Pressurization Devices

Standard Test Method for Airflow Calibration of Fan Pressurization Devices

SIGNIFICANCE AND USE

5.1 The fan pressurization procedure provides a relatively fast evaluation of the airtightness of building envelopes. In order for the accuracy of the test results to be known, the airflow rate measurement technique of the fan pressurization system must be calibrated.

5.2 This test method is applicable to fan pressurization systems that are installed in an opening in the building envelope, as opposed to pressurization techniques involving the mechanical ventilation system of the building.

5.3 The technique of pressurization testing of buildings puts specific requirements on the calibration of fan pressurization systems. The calibration must cover the range of fan pressure differences (approximately 12.5 to 75 Pa) that is induced during pressurization tests. The calibration must also cover a range in fan airflow rates corresponding to the range in building size and airtightness that the fan pressurization system will encounter in the field.

5.4 The fan pressurization system must be calibrated in both directions of airflow used to pressurize and depressurize a building if the system airflow direction is reversible. These two calibrations can be conducted using the various setups described in this test method; however some of the setups can be combined such that a single calibration facility can be used to calibrate the fan in both directions. Such a single setup may involve moving the fan pressurization system from one end of the chamber to the other, reversing the orientation of the system at the same end of the chamber, or it may not require moving the system at all.

5.5 The calibration technique is applicable to the two basic types of fan pressurization systems in use, r/min doors and signal doors.

5.6 For fan pressurization systems that operate in multiple ranges of airflow rate, the system must be calibrated in each range.

5.7 The calibration technique is intended to provide a complete calibration of a fan pressurization system. After cali...

SCOPE

1.1 This test method covers the airflow measurement calibration techniques for fan pressurization systems used for measuring air leakage rates through building envelopes.

1.2 This test method is applicable to systems used for air leakage measurement as described in Practice E779.

1.3 This test method involves the installation of the fan pressurization system in a calibration chamber. Use of the fan pressurization system in an actual building may introduce additional errors in the airflow measurement due to operator influence, interference of internal partitions and furnishings, weather effects, and other factors.

1.4 The proper use of this test method requires a knowledge of the principles of airflow and pressure measurement.

1.5 This standard includes two basic procedures, a preferred procedure, based on ASHRAE 51/AMCA 210, and an optional procedure based on a nonstandard airflow measurement technique, commonly used by manufacturers of fan pressurization devices, but which has not been compared with standard airflow measurement techniques.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1258 −88 (Reapproved 2012)

Standard Test Method for

Airflow Calibration of Fan Pressurization Devices

This standard is issued under the fixed designation E1258; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E779TestMethodforDeterminingAirLeakageRatebyFan

Pressurization

1.1 This test method covers the airflow measurement cali-

2.2 American Society of Heating, Refrigerating, and Air-

bration techniques for fan pressurization systems used for

Conditioning Engineers Standard:

measuring air leakage rates through building envelopes.

ASHRAE51⁄AMCA210Laboratory Methods for Testing

1.2 This test method is applicable to systems used for air

Fans for Rating

leakage measurement as described in Practice E779. 4

2.3 American Society of Mechanical Engineers Standard:

1.3 This test method involves the installation of the fan ASME MFC-3MStandard Measurement of Fluid Flow in

pressurization system in a calibration chamber. Use of the fan Pipes Using Orifice, Nozzle, and Venturi

pressurization system in an actual building may introduce

3. Terminology

additional errors in the airflow measurement due to operator

influence, interference of internal partitions and furnishings, 3.1 Definitions—For definitions used in this test method,

weather effects, and other factors.

see Terminology E631.

1.4 Theproperuseofthistestmethodrequiresaknowledge 3.2 Definitions of Terms Specific to This Standard:

of the principles of airflow and pressure measurement.

3.2.1 ambient conditions, n—conditions in the space from

which air is drawn into the calibration chamber and into which

1.5 Thisstandardincludestwobasicprocedures,apreferred

the chamber air is expelled.

procedure,basedonASHRAE51⁄AMCA210,andanoptional

3.2.2 chamber, n—an enclosure of rectangular or circular

procedure based on a nonstandard airflow measurement

technique, commonly used by manufacturers of fan pressur- cross section to simulate the entrance and exit conditions that

the fan is expected to encounter in service.

ization devices, but which has not been compared with

standard airflow measurement techniques.

3.2.3 fan air density, n—density of air at the fan inlet

expressed in kilograms per cubic metre.

1.6 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.2.4 fan airflow rate, n—volumetric airflow rate at the fan

standard.

air density expressed in cubic metres per second.

1.7 This standard does not purport to address all of the

3.2.5 fan outlet area, n—gross inside area measured in the

safety concerns, if any, associated with its use. It is the

plane of the fan outlet opening expressed in square metres.

responsibility of the user of this standard to establish appro-

3.2.6 fan pressure difference, n—the static pressure differ-

priate safety and health practices and determine the applica-

ence between two stations expressed in pascals, measured

bility of regulatory limitations prior to use.

usingthestaticpressuretapsdescribedinFig.1.Onestationis

located within the chamber between the fan and the nearest

2. Referenced Documents

flow conditioners. The other station is outside the chamber.

2.1 ASTM Standards:

3.2.7 fan pressurization system, n—a device for measuring

E631Terminology of Building Constructions

the air leakage rate of a building envelope under controlled

pressurization or depressurization of the building interior. The

system includes controllable air-moving equipment, an airflow

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.41 ratemeasuringsystem,andadeviceformeasuringthepressure

on Air Leakage and Ventilation Performance.

Current edition approved Oct. 1, 2012. Published October 2012. Originally

approved in 1988. Last previous edition approved in 2008 as E1258–88(2008). Available from American Society of Heating, Refrigerating, and Air-

DOI: 10.1520/E1258-88R12. Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 30329, http://www.ashrae.org.

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1258−88 (2012)

3.2.11 nozzle, n—a gradually tapered constriction, of very

precise elliptical shape, used in airflow rate measurement (see

Fig. 2).

3.2.12 nozzle chamber pressure difference, n—static pres-

sure difference measured across a nozzle or bank of nozzles

when nozzles are installed in a chamber expressed in pascals.

3.2.13 nozzle throat diameter, n—diameter of nozzle dis-

charge end expressed in square metres.

3.2.14 nozzle throat pressure difference, n—static pressure

differenceacrossthenozzleinaductmeasuredwiththroattaps

expressed in pascals (see Fig. 2).

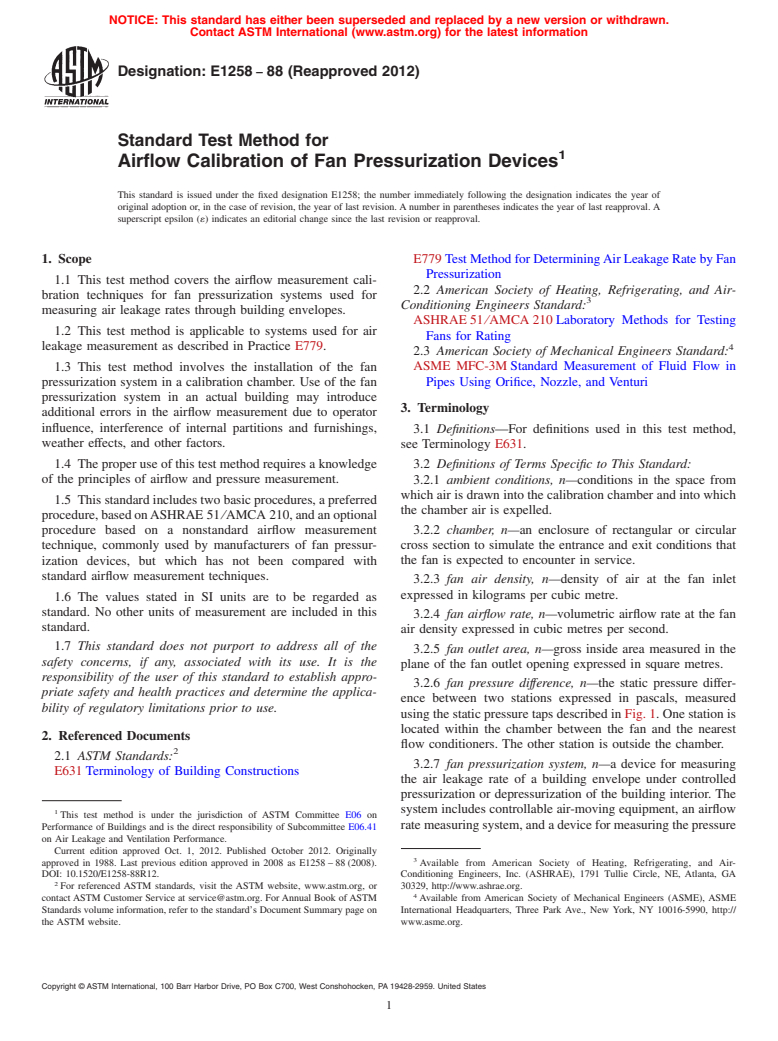

3.2.15 orifice,n—asharp-edgedcircularconstrictionusedin

airflow measurement (see Fig. 3).

FIG. 1Static Pressure Tap Specifications

3.2.16 orifice pressure difference, n—static pressure differ-

ence measured across an orifice when the orifice is installed in

difference across the building envelope. Such a system is often

a chamber expressed in pascals.

referred to as a blower door.

3.2.17 revolution-per-minute (r/min) door, n—a fan pressur-

3.2.8 fan signal, n—an output from a fan pressurization

izationsystemwithacalibrationthatrelatesthefanairflowrate

system (other than fan speed) that is related to fan airflow rate

to the fan speed.

by the system calibration, such as the static pressure difference

3.2.18 signal door, n—a fan pressurization system with a

across a constriction that is integral to the system.

calibration that relates the fan airflow rate to an output signal

3.2.9 fan speed, n—speed of rotation of the fan impeller

other than fan speed.

expressed in inverse seconds.

3.2.19 transformation piece, n—an element to connect a

3.2.10 flow conditioners, n—a combination of screens or

duct with a measuring station to a fan when the fan connection

perforated plates located within the calibration chamber to

reduce pressure disturbances within the chamber. is a different size than the duct (see Fig. 4).

Nozzle with throat taps Nozzle without throat taps

NOTE 1—Nozzle throat dimension L shall be either 0.6 D 60.005 D (recommended) or 0.5 D 60.005 D .

n n n n

NOTE 2—Nozzle shall have elliptical section as shown. Two and three radii approximations to the elliptical form that do not differ at any point in the

normaldirectionmorethan1.5% D fromtheellipticalformmaybeused.Theoutletedgeofthenozzleshallbesquare,sharp,andfreefromburrs,nicks,

n

or roundings.

NOTE 3—The nozzle throat shall be measured (to an accuracy of 0.001 D ) at the minor axis of the ellipse and the nozzle exit. At each place, four

n

diameters, approximately 45° apart must be within 60.002 D of the mean.At the entrance to the throat the mean may be 0.002 D greater, but no less

n n

than the mean at the nozzle exit.

NOTE 4—The nozzle surface shall fair smoothly so that a straightedge may be rocked over the surface without clicking and the surface waves shall

not be greater than 0.001 D peak to peak.

n

NOTE 5—When nozzles are used in a chamber, either of the types shown above may be used. Where a nozzle discharges directly to a duct, nozzles

with throat taps shall be used, and the nozzle outlet should be flanged.

NOTE 6—Throat tap nozzles shall have four static pressure taps 90° apart connected to a piezometer ring.

FIG. 2Nozzle Specifications

E1258−88 (2012)

4.2 Both procedures involve the installation of the fan

pressurization system in a chamber.

4.3 The calibration consists of a comparison of the airflow

rate through the fan pressurization system measured by the

system itself, and the airflow rate measured in the calibration

facility. In the preferred procedure, three modes of airflow

measurementareacceptable:(1)anozzleorbankofnozzlesin

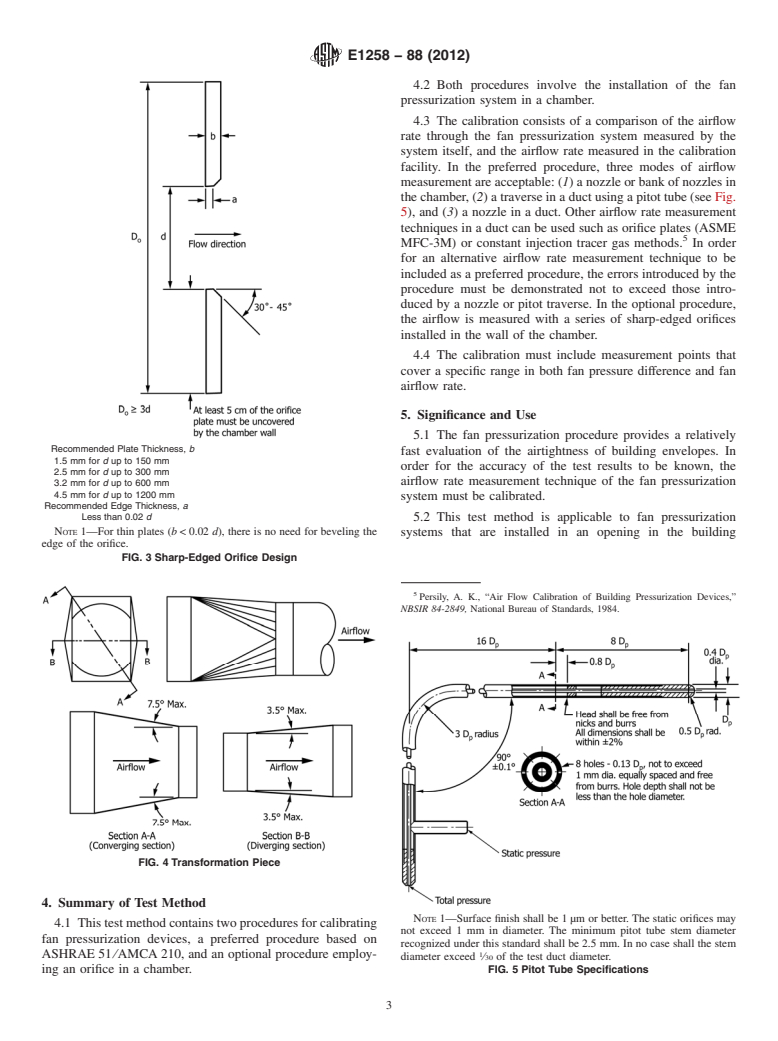

thechamber,(2)atraverseinaductusingapitottube(seeFig.

5), and (3) a nozzle in a duct. Other airflow rate measurement

techniques in a duct can be used such as orifice plates (ASME

MFC-3M) or constant injection tracer gas methods. In order

for an alternative airflow rate measurement technique to be

included as a preferred procedure, the errors introduced by the

procedure must be demonstrated not to exceed those intro-

duced by a nozzle or pitot traverse. In the optional procedure,

the airflow is measured with a series of sharp-edged orifices

installed in the wall of the chamber.

4.4 The calibration must include measurement points that

cover a specific range in both fan pressure difference and fan

airflow rate.

5. Significance and Use

5.1 The fan pressurization procedure provides a relatively

Recommended Plate Thickness, b

fast evaluation of the airtightness of building envelopes. In

1.5mmfor d up to 150 mm

order for the accuracy of the test results to be known, the

2.5mmfor d up to 300 mm

airflow rate measurement technique of the fan pressurization

3.2mmfor d up to 600 mm

4.5mmfor d up to 1200 mm

system must be calibrated.

Recommended Edge Thickness, a

Less than 0.02 d

5.2 This test method is applicable to fan pressurization

NOTE 1—For thin plates (b<0.02 d), there is no need for beveling the

systems that are installed in an opening in the building

edge of the orifice.

FIG. 3Sharp-Edged Orifice Design

Persily, A. K., “Air Flow Calibration of Building Pressurization Devices,”

NBSIR 84-2849, National Bureau of Standards, 1984.

FIG. 4Transformation Piece

4. Summary of Test Method

NOTE 1—Surface finish shall be 1 µm or better. The static orifices may

4.1 Thistestmethodcontainstwoproceduresforcalibrating

not exceed 1 mm in diameter. The minimum pitot tube stem diameter

fan pressurization devices, a preferred procedure based on

recognized under this standard shall be 2.5 mm. In no case shall the stem

ASHRAE51⁄AMCA210, and an optional procedure employ-

diameter exceed ⁄30 of the test duct diameter.

ing an orifice in a chamber. FIG. 5Pitot Tube Specifications

E1258−88 (2012)

envelope, as opposed to pressurization techniques involving 7. Apparatus

the mechanical ventilation system of the building.

7.1 The calibration facility must include the following

components:

5.3 Thetechniqueofpressurizationtestingofbuildingsputs

specific requirements on the calibration of fan pressurization 7.1.1 Preferred Procedure:

7.1.1.1 Chamber—An enclosure of rectangular or circular

systems. The calibration must cover the range of fan pressure

differences (approximately 12.5 to 75 Pa) that is induced cross section with characteristic dimension, M. In the case of a

during pressurization tests. The calibration must also cover a rectangular cross section, the height H shall be at least 2.1 m,

range in fan airflow rates corresponding to the range in

thewidth Wshallbeatleast2.4m,and Misgivenby =4HW/π.

buildingsizeandairtightnessthatthefanpressurizationsystem

In the case of a circular cross section, the chamber diameter

will encounter in the field.

shall be at least 2.5 m and M is equal to the chamber diameter.

When multiple nozzles are used in a chamber, the chamber

5.4 Thefanpressurizationsystemmustbecalibratedinboth

must be large enough to accommodate all the nozzles as

directions of airflow used to pressurize and depressurize a

described in 7.1.2.1 and 7.1.2.2.

buildingifthesystemairflowdirectionisreversible.Thesetwo

calibrations can be conducted using the various setups de-

7.1.1.2 Flow Conditioners—A combination of screens or

scribed in this test method; however some of the setups can be perforated plates located in the chamber to reduce pressure

combined such that a single calibration facility can be used to

disturbances within the enclosure. These air to be located

calibrate the fan in both directions. Such a single setup may within the chamber in accordance with 7.1.2. Where a mea-

involve moving the fan pressurization system from one end of

suring plane is located downstream of the flow conditioners,

the chamber to the other, reversing the orientation of the

the flow conditioners are provided to ensure a substantially

system at the same end of the chamber, or it may not require

uniform flow ahead of the measuring plane. Where a measur-

moving the system at all.

ing plane is located upstream of the flow conditioners, the

purposeofthesescreensistoabsorbsomeofthekineticenergy

5.5 The calibration technique is applicable to the two basic

of the upstream jet, and allow its normal expansion as if in an

types of fan pressurization systems in use, r/min doors and

unconfined space. Screens of square-mesh round wire with

signal doors.

openareasof50to60%aresuggestedandseveralwillusually

5.6 For fan pressurization systems that operate in multiple

be needed. Any combination of screens or perforated plates

ranges of airflow rate, the system must be calibrated in each

that provide this flow conditioning may be used.

range.

7.1.1.3 Airflow Rate Measurement System, for measuring

the fan airflow rate. Acceptable systems include a nozzle or

5.7 The calibration technique is intended to provide a

complete calibration of a fan pressurization system. After bank of nozzles within the chamber, a nozzle in a duct, or a

pitot traverse in a duct in accordance with 7.1.2.

calibratingseveralsystemsofanidenticalorsimilardesign,the

fan airflow rate may be found to be independent of certain 7.1.1.4 Flow Straighteners, for straightening the flow up-

stream of the measuring stations when the airflow rate mea-

parameters such as fan pressure difference. Other simplifying

surement system uses a nozzle in a duct or a pitot traverse in

relations between fan airflow rate and fan speed or fan signal

a duct. The downstream plane of the straightener shall be

may be observed. If these relations are observed, a manufac-

located between 5 and 5.25 duct diameters upstream of the

turer or other calibrator may choose to simplify the calibration

plane of the pitot traverse or nozzle.Arecommended form for

procedure by reducing the number of calibration points.

the straightener is shown in Fig. 6. The dimension D is the

5.8 Theuseoffanpressurizationsystemsinactualbuildings

inside diameter of the duct. The dimen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.