ASTM E1554/E1554M-13(2018)

(Test Method)Standard Test Methods for Determining Air Leakage of Air Distribution Systems by Fan Pressurization

Standard Test Methods for Determining Air Leakage of Air Distribution Systems by Fan Pressurization

SIGNIFICANCE AND USE

5.1 Air leakage between an air distribution system and unconditioned spaces affects the energy losses from the distribution system, the ventilation rate of the building, and the entry rate of air pollutants.

5.2 The determination of infiltration energy loads and ventilation rates of residences and small commercial buildings are typically based on the assumption that the principal driving forces for infiltration and ventilation are the wind and indoor/outdoor temperature differences. This can be an inappropriate assumption for buildings that have distribution systems that pass through unconditioned spaces, because the existence of relatively modest leakage from that system has a relatively large impact on overall ventilation rates. The air leakage characteristics of these exterior distribution systems are needed to determine their ventilation, energy, and pollutant-entry implications.

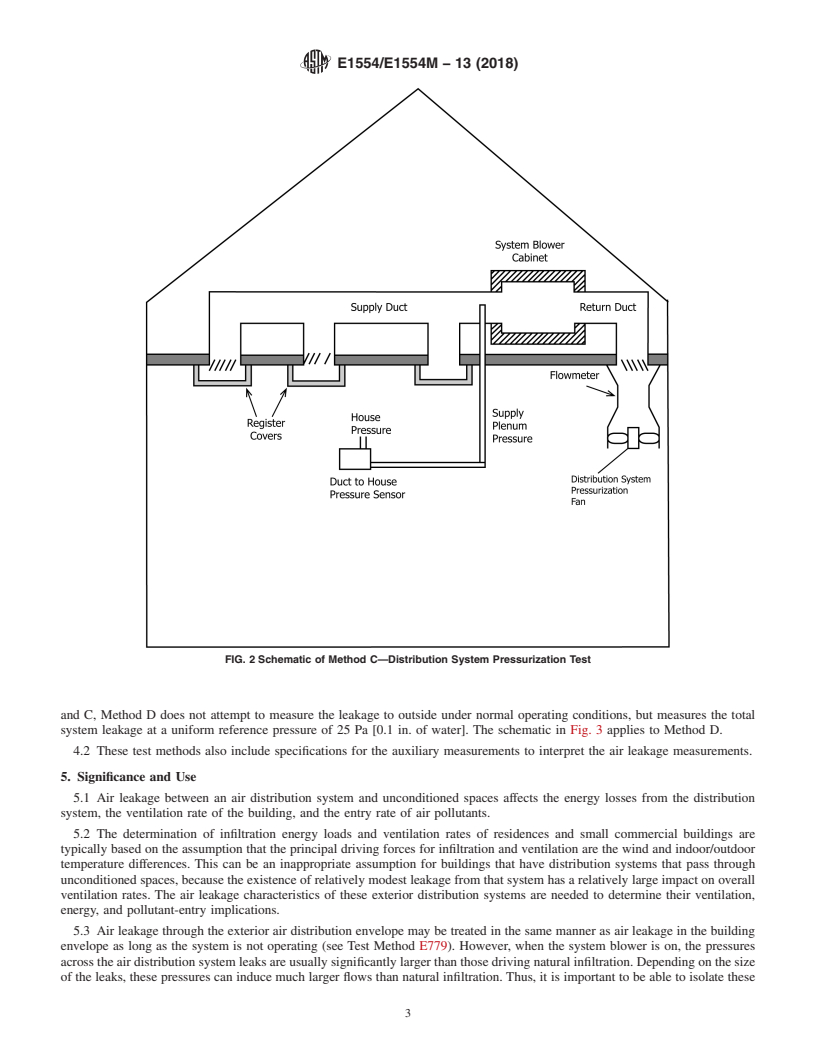

5.3 Air leakage through the exterior air distribution envelope may be treated in the same manner as air leakage in the building envelope as long as the system is not operating (see Test Method E779). However, when the system blower is on, the pressures across the air distribution system leaks are usually significantly larger than those driving natural infiltration. Depending on the size of the leaks, these pressures can induce much larger flows than natural infiltration. Thus, it is important to be able to isolate these leaks from building envelope leaks. The leakage of air distribution systems must be measured in the field, because it has been shown that workmanship and installation details are more important than design in determining the leakage of these systems.

5.4 For codes, standards, and other compliance or quality control applications, the precision and repeatability at meeting a specified target (for example, air flow at reference pressure) is more important than air leakage flows at operating conditions. Some existing codes, standards, and voluntary programs require ...

SCOPE

1.1 The test methods included in this standard are applicable to the air distribution systems in low-rise residential and commercial buildings.

1.2 These test methods cover four techniques for measuring the air leakage of air distribution systems. The techniques use air flow and pressure measurements to determine the leakage characteristics.

1.3 The test methods for two of the techniques also specify the auxiliary measurements needed to characterize the magnitude of the distribution system air leakage during normal operation.

1.4 A test method for the total recirculating air flow induced by the system blower is included so that the air distribution system leakage can be normalized as is often required for energy calculations.

1.5 The proper use of these test methods requires knowledge of the principles of air flow and pressure measurements.

1.6 Three of these test methods are intended to produce a measure of the air leakage from the air distribution system to outside. The other test method measures total air leakage including air leaks to inside conditioned space.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Developme...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1554/E1554M − 13 (Reapproved 2018)

Standard Test Methods for

Determining Air Leakage of Air Distribution Systems by Fan

Pressurization

ThisstandardisissuedunderthefixeddesignationE1554/E1554M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 Thetestmethodsincludedinthisstandardareapplicable

ization established in the Decision on Principles for the

to the air distribution systems in low-rise residential and

Development of International Standards, Guides and Recom-

commercial buildings.

mendations issued by the World Trade Organization Technical

1.2 These test methods cover four techniques for measuring

Barriers to Trade (TBT) Committee.

the air leakage of air distribution systems. The techniques use

air flow and pressure measurements to determine the leakage

2. Referenced Documents

characteristics.

2.1 ASTM Standards:

1.3 The test methods for two of the techniques also specify

E631 Terminology of Building Constructions

the auxiliary measurements needed to characterize the magni-

E779 Test Method for DeterminingAir Leakage Rate by Fan

tude of the distribution system air leakage during normal

Pressurization

operation.

E1258 Test Method for Airflow Calibration of Fan Pressur-

ization Devices

1.4 Atest method for the total recirculating air flow induced

2.2 ASME Standard:

by the system blower is included so that the air distribution

MFC-3M MeasurementofFluidFlowinPipesUsingOrifice

system leakage can be normalized as is often required for

Nozzle and Venturi

energy calculations.

1.5 The proper use of these test methods requires knowl-

3. Terminology

edge of the principles of air flow and pressure measurements.

3.1 Definitions—For definitions of general terms related to

1.6 Three of these test methods are intended to produce a

building construction used in these test methods, refer to

measure of the air leakage from the air distribution system to

Terminology E631.

outside. The other test method measures total air leakage

3.2 Definitions of Terms Specific to This Standard:

including air leaks to inside conditioned space.

3.2.1 building envelope—the boundary or barrier separating

theinteriorvolumeofabuildingfromtheoutsideenvironment.

1.7 The values stated in either SI units or inch-pound units

Even when a garage is conditioned, for this standard it is

are to be regarded separately as standard. The values stated in

considered to be outside the building envelope.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3.2.2 blower—the air moving device for a forced air space

values from the two systems may result in non-conformance

conditioning and/or ventilation system.

with the standard.

4. Summary of Test Methods

1.8 This standard does not purport to address all of the

4.1 Four alternative measurement and analysis methods are

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- specified and labeledAthrough D, Test MethodsAand B give

separate values for supply and return leakage to outside. Test

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. Methods C and D do not separate supply and return leakage.

For specific hazard statements, see Section 7.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

These test methods are under the jurisdiction of ASTM Committee E06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Performance of Buildings and are the direct responsibility of Subcommittee E06.41 Standards volume information, refer to the standard’s Document Summary page on

on Air Leakage and Ventilation Performance. the ASTM website.

Current edition approved July 1, 2018. Published July 2018. Originally approved Available from American Society of Mechanical Engineers (ASME), ASME

in 1993. Last previous edition approved in 2013 as E1554/E1554M – 13. DOI: International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

10.1520/E1554_E1554M-13R18. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1554/E1554M − 13 (2018)

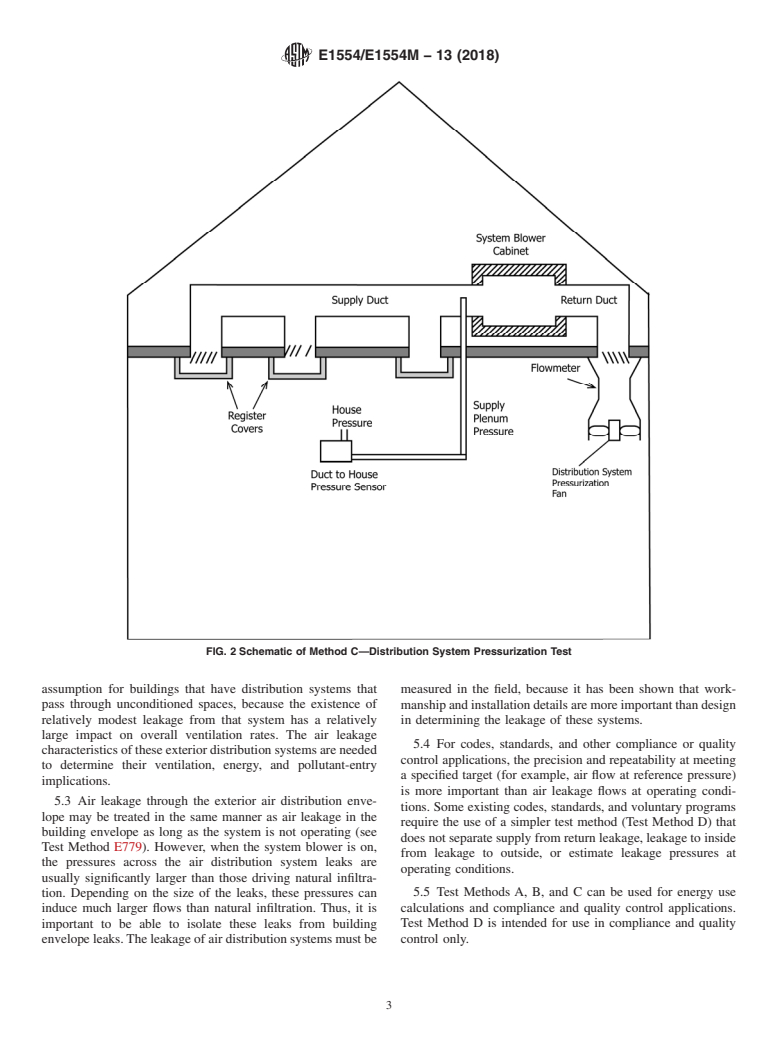

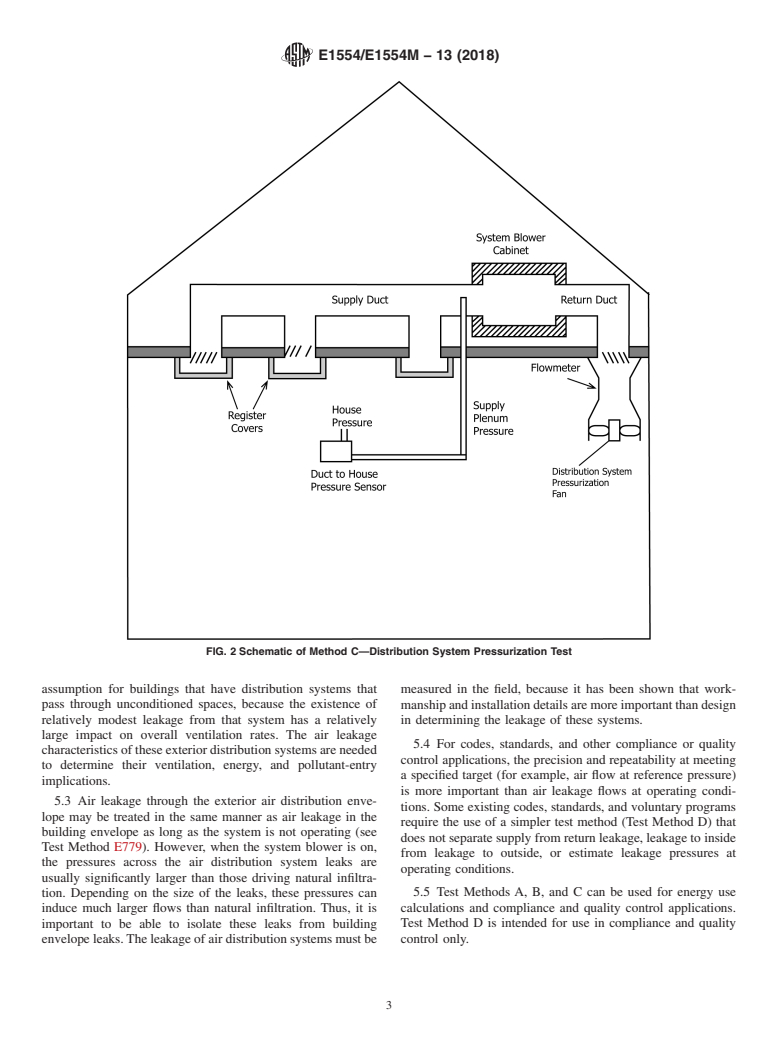

Test Methods A, B, and C determine leakage to outside, but operating conditions, but measures the total system leakage at

Test Method D measures total leakage, including leakage to a uniform reference pressure of 25 Pa [0.1 in. of water]. The

inside. Test Method A is based upon changes in flow through schematic in Fig. 3 applies to Method D.

distribution system leaks to outside due to blower operation

4.2 These test methods also include specifications for the

over a range of envelope pressure differences. The envelope

auxiliary measurements to interpret the air leakage measure-

pressure differences are generated by a separate air moving fan

ments.

and both pressurization and depressurization measurements are

performed. Test Methods B and C are based upon pressurizing

5. Significance and Use

thedistributionsystematthesametimeasthebuildinginorder

5.1 Air leakage between an air distribution system and

to isolate the leaks that are outside the building envelope. For

unconditioned spaces affects the energy losses from the distri-

Test Method B, measured system operating pressures are then

butionsystem,theventilationrateofthebuilding,andtheentry

used to estimate leakage under operating conditions. Test

rate of air pollutants.

Method C determines the leakage to outside at a uniform

5.2 The determination of infiltration energy loads and ven-

reference pressure of 25 Pa [0.1 in. of water] instead of

operating pressure, and does not separate supply and return tilation rates of residences and small commercial buildings are

leaks. Test Methods B and C are shown schematically in Fig. typically based on the assumption that the principal driving

1 and Fig. 2. Unlike MethodsA, B, and C, Method D does not forces for infiltration and ventilation are the wind and indoor/

attempt to measure the leakage to outside under normal outdoor temperature differences. This can be an inappropriate

FIG. 1 Schematic of Method B—Distribution System and Building Pressurization Test (for Supply Leakage)

E1554/E1554M − 13 (2018)

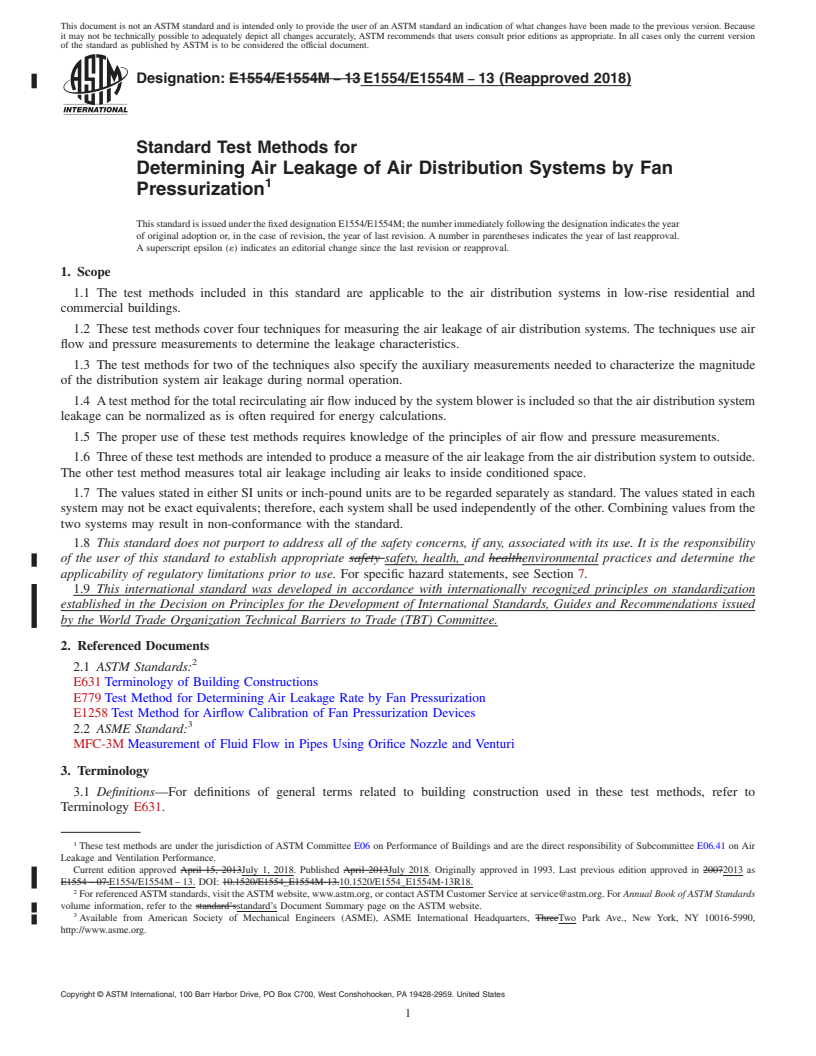

FIG. 2 Schematic of Method C—Distribution System Pressurization Test

assumption for buildings that have distribution systems that measured in the field, because it has been shown that work-

pass through unconditioned spaces, because the existence of

manshipandinstallationdetailsaremoreimportantthandesign

relatively modest leakage from that system has a relatively in determining the leakage of these systems.

large impact on overall ventilation rates. The air leakage

5.4 For codes, standards, and other compliance or quality

characteristicsoftheseexteriordistributionsystemsareneeded

control applications, the precision and repeatability at meeting

to determine their ventilation, energy, and pollutant-entry

a specified target (for example, air flow at reference pressure)

implications.

is more important than air leakage flows at operating condi-

5.3 Air leakage through the exterior air distribution enve-

tions. Some existing codes, standards, and voluntary programs

lope may be treated in the same manner as air leakage in the

require the use of a simpler test method (Test Method D) that

building envelope as long as the system is not operating (see

does not separate supply from return leakage, leakage to inside

Test Method E779). However, when the system blower is on,

from leakage to outside, or estimate leakage pressures at

the pressures across the air distribution system leaks are

operating conditions.

usually significantly larger than those driving natural infiltra-

5.5 Test Methods A, B, and C can be used for energy use

tion. Depending on the size of the leaks, these pressures can

induce much larger flows than natural infiltration. Thus, it is calculations and compliance and quality control applications.

important to be able to isolate these leaks from building Test Method D is intended for use in compliance and quality

envelope leaks.The leakage of air distribution systems must be control only.

E1554/E1554M − 13 (2018)

FIG. 3 Example of Air-Flow Difference and Envelope Pressure Plot for Test Method A.1

6. Apparatus 6.2.5 Pressure-Measuring Device (All methods)—A device

to measure pressure differences with an accuracy of 60.25 Pa

6.1 The following description of apparatus is general in

[60.001 in. of water] or 61 % of measured pressure, which-

nature. Any arrangement of equipment using the same prin-

ever is greater.

ciples and capable of performing the test procedure within the

6.2.6 Distribution System Pressure Measuring Probe (B, C,

allowable tolerances is permitted. The items are labeled for

and D)—A probe to measure the static pressure within a

each test method.

distribution system under flow conditions.

6.2 Major Components:

6.2.7 Air Temperature Measuring Device (All

6.2.1 Air-Moving Equipment (A, B, and C)—Afan, blower,

methods)—To give an accuracy of 60.5 °C [0.9 °F].

or blower door assembly that is capable of moving air into and

out of the building at the flow rates required to create the full

7. Hazards

range of test pressure differences. The air moving equipment

7.1 Glass should not break at the pressure differences

shall be able to accomplish both pressurization and depressur-

normally applied to the building, however, protective eye wear

ization of the building and distribution system.

shall be provided to personnel.

6.2.2 Air Flow-Regulating System (A, B, and C)—A device

such as a damper or variable speed motor control to regulate 7.2 When conducted in the field, safety equipment required

for general field work shall be supplied, such as safety shoes,

and maintain air flow through the air moving equipment (see

6.2.1). hard hats, and so forth.

6.2.3 Air Flow Measuring Device(A)—Adevicetomeasure

7.3 Because air-moving equipment is involved in this test, a

airflow with an accuracy of 65 % of the measured flow

proper guard or cage to house the fan or blower and to prevent

through air moving equipment in 6.2.1.The air flow measuring

accidentalaccesstoanymovingpartsoftheequipmentshallbe

system shall be calibrated in accordance with Test Method

provided.

E1258 or ASME MFC-3M, whichever is applicable. The

7.4 Hearing protection shall be provided for personnel who

temperature dependence and range of the calibration shall be

work close to noises such as those generated by moving air.

explicitly reported.

6.2.4 Distribution System Flow Measurement Device (B, C, 7.5 When the blower or fan is operating, a large volume of

and D)—A device to measure airflow with an accuracy of air is being forced into or out of the building, the air-

65 % of the measured flow. The airflow measuring system distribution system, or both. Precautions shall be undertaken

shall be calibrated in accordance with Test Method E1258 or such that plants, pets, occupants, or internal furnishings shall

ASME MFC-3M, whichever is applicable. The temperature not be damaged due to the influx of cold or warm air. Similar

dependence and range of the calibration shall be explicitly precautions shall be exercised with respect to sucking debris or

reported. exhaust gases from fireplaces and flues into the interior of the

E1554/E1554M − 13 (2018)

building extinguishing pilot lights, flame rollout for combus- 8.2.1 Environmental Measurements—At the beginning and

tion appliances and drawing sewer gas into the building. the end of each test, measure the outdoor temperature, indoor

temperature, and barometric pressure.

8. Procedure

8.2.2 Building Preparation:

8.2.2.1 Envelope—Open all interconnecting doors in the

8.1 General—The basic procedure involves pressurization

building. Fireplace and other operable dampers shall be closed.

and depressurization of air distribution systems and buildings

If the air handling unit is located in a closet, the closet door

with concurrent flow and pressure measurements to determine

shall be closed during testing. The condition of openings to

the air leakage of the distribution system.

outside for spaces that contain ducts (for example, garage

8.1.1 Test Method A (Flow Difference) for Air Leakage

doors or basement windows) shall be recorded.

Determination—This technique is based upon changing the

8.2.2.2 Distribution System—HVAC-balancingdampersand

flow through distribution system leaks by operating the blower

registers, in general, shall not be adjusted. However, for

fan and simultaneously pressurizing (or depressurizing) the

multiple zoned systems, the position of zonal dampers should

building envelope and distribution system. There are two

be fixed for the duration of the test. Several tests may be

alternatives for gathering the required test data utilizing the

performed with zone dampers fixed at different settings, but at

same analysis procedure.Test MethodA.1 records data at fixed

least one of the tests shall have all zone control dampers in the

envelope pressure stations. Test Method A.2 records data

fully open position.

continuously as the envelope air flows and pressure are

8.2.3 Air Flow Difference Measurements:

gradually changed by the envelope air moving equipment. The

blower speed and heating or cooling function shall be the same 8.2.3.1 Connect the air moving/flow-regulating/flow mea-

for all steps of the test procedure. surement assembly to the building envelope using a window or

8.1.2 Test Method B: Fan Pressurization of Distribution door opening. Seal or tape openings to avoid leakage at these

System and Building for Air Leakage Determination—This points.

technique is based upon sealing the registers of the distribution

8.2.3.2 Install the envelope pressure difference sensor. The

system and pressurizing the system to measure the flow

outside pressure measurement location shall be sheltered from

through the leaks at the imposed pressure difference. With the wind and sunshine. The inside pressure measurement location

building pressurized to the same pressure, this test isolates the

sh

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1554/E1554M − 13 (Reapproved 2018)

Standard Test Methods for

Determining Air Leakage of Air Distribution Systems by Fan

Pressurization

This standard is issued under the fixed designation E1554/E1554M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 The test methods included in this standard are applicable

ization established in the Decision on Principles for the

to the air distribution systems in low-rise residential and

Development of International Standards, Guides and Recom-

commercial buildings.

mendations issued by the World Trade Organization Technical

1.2 These test methods cover four techniques for measuring

Barriers to Trade (TBT) Committee.

the air leakage of air distribution systems. The techniques use

air flow and pressure measurements to determine the leakage

2. Referenced Documents

characteristics. 2

2.1 ASTM Standards:

1.3 The test methods for two of the techniques also specify

E631 Terminology of Building Constructions

the auxiliary measurements needed to characterize the magni-

E779 Test Method for Determining Air Leakage Rate by Fan

tude of the distribution system air leakage during normal

Pressurization

operation. E1258 Test Method for Airflow Calibration of Fan Pressur-

ization Devices

1.4 A test method for the total recirculating air flow induced

2.2 ASME Standard:

by the system blower is included so that the air distribution

MFC-3M Measurement of Fluid Flow in Pipes Using Orifice

system leakage can be normalized as is often required for

Nozzle and Venturi

energy calculations.

1.5 The proper use of these test methods requires knowl-

3. Terminology

edge of the principles of air flow and pressure measurements.

3.1 Definitions—For definitions of general terms related to

1.6 Three of these test methods are intended to produce a

building construction used in these test methods, refer to

measure of the air leakage from the air distribution system to

Terminology E631.

outside. The other test method measures total air leakage

3.2 Definitions of Terms Specific to This Standard:

including air leaks to inside conditioned space.

3.2.1 building envelope—the boundary or barrier separating

the interior volume of a building from the outside environment.

1.7 The values stated in either SI units or inch-pound units

Even when a garage is conditioned, for this standard it is

are to be regarded separately as standard. The values stated in

considered to be outside the building envelope.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

3.2.2 blower—the air moving device for a forced air space

values from the two systems may result in non-conformance

conditioning and/or ventilation system.

with the standard.

4. Summary of Test Methods

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4.1 Four alternative measurement and analysis methods are

specified and labeled A through D, Test Methods A and B give

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- separate values for supply and return leakage to outside. Test

Methods C and D do not separate supply and return leakage.

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see Section 7.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

These test methods are under the jurisdiction of ASTM Committee E06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Performance of Buildings and are the direct responsibility of Subcommittee E06.41 Standards volume information, refer to the standard’s Document Summary page on

on Air Leakage and Ventilation Performance. the ASTM website.

Current edition approved July 1, 2018. Published July 2018. Originally approved Available from American Society of Mechanical Engineers (ASME), ASME

in 1993. Last previous edition approved in 2013 as E1554/E1554M – 13. DOI: International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

10.1520/E1554_E1554M-13R18. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1554/E1554M − 13 (2018)

Test Methods A, B, and C determine leakage to outside, but operating conditions, but measures the total system leakage at

Test Method D measures total leakage, including leakage to a uniform reference pressure of 25 Pa [0.1 in. of water]. The

inside. Test Method A is based upon changes in flow through schematic in Fig. 3 applies to Method D.

distribution system leaks to outside due to blower operation

4.2 These test methods also include specifications for the

over a range of envelope pressure differences. The envelope

auxiliary measurements to interpret the air leakage measure-

pressure differences are generated by a separate air moving fan

ments.

and both pressurization and depressurization measurements are

performed. Test Methods B and C are based upon pressurizing

5. Significance and Use

the distribution system at the same time as the building in order

5.1 Air leakage between an air distribution system and

to isolate the leaks that are outside the building envelope. For

unconditioned spaces affects the energy losses from the distri-

Test Method B, measured system operating pressures are then

bution system, the ventilation rate of the building, and the entry

used to estimate leakage under operating conditions. Test

rate of air pollutants.

Method C determines the leakage to outside at a uniform

reference pressure of 25 Pa [0.1 in. of water] instead of 5.2 The determination of infiltration energy loads and ven-

operating pressure, and does not separate supply and return tilation rates of residences and small commercial buildings are

leaks. Test Methods B and C are shown schematically in Fig. typically based on the assumption that the principal driving

1 and Fig. 2. Unlike Methods A, B, and C, Method D does not forces for infiltration and ventilation are the wind and indoor/

attempt to measure the leakage to outside under normal outdoor temperature differences. This can be an inappropriate

FIG. 1 Schematic of Method B—Distribution System and Building Pressurization Test (for Supply Leakage)

E1554/E1554M − 13 (2018)

FIG. 2 Schematic of Method C—Distribution System Pressurization Test

assumption for buildings that have distribution systems that measured in the field, because it has been shown that work-

pass through unconditioned spaces, because the existence of manship and installation details are more important than design

relatively modest leakage from that system has a relatively

in determining the leakage of these systems.

large impact on overall ventilation rates. The air leakage

5.4 For codes, standards, and other compliance or quality

characteristics of these exterior distribution systems are needed

control applications, the precision and repeatability at meeting

to determine their ventilation, energy, and pollutant-entry

a specified target (for example, air flow at reference pressure)

implications.

is more important than air leakage flows at operating condi-

5.3 Air leakage through the exterior air distribution enve-

tions. Some existing codes, standards, and voluntary programs

lope may be treated in the same manner as air leakage in the

require the use of a simpler test method (Test Method D) that

building envelope as long as the system is not operating (see

does not separate supply from return leakage, leakage to inside

Test Method E779). However, when the system blower is on,

from leakage to outside, or estimate leakage pressures at

the pressures across the air distribution system leaks are

operating conditions.

usually significantly larger than those driving natural infiltra-

tion. Depending on the size of the leaks, these pressures can 5.5 Test Methods A, B, and C can be used for energy use

induce much larger flows than natural infiltration. Thus, it is calculations and compliance and quality control applications.

important to be able to isolate these leaks from building Test Method D is intended for use in compliance and quality

envelope leaks. The leakage of air distribution systems must be control only.

E1554/E1554M − 13 (2018)

FIG. 3 Example of Air-Flow Difference and Envelope Pressure Plot for Test Method A.1

6. Apparatus 6.2.5 Pressure-Measuring Device (All methods)—A device

to measure pressure differences with an accuracy of 60.25 Pa

6.1 The following description of apparatus is general in

[60.001 in. of water] or 61 % of measured pressure, which-

nature. Any arrangement of equipment using the same prin-

ever is greater.

ciples and capable of performing the test procedure within the

6.2.6 Distribution System Pressure Measuring Probe (B, C,

allowable tolerances is permitted. The items are labeled for

and D)—A probe to measure the static pressure within a

each test method.

distribution system under flow conditions.

6.2 Major Components:

6.2.7 Air Temperature Measuring Device (All

6.2.1 Air-Moving Equipment (A, B, and C)—A fan, blower,

methods)—To give an accuracy of 60.5 °C [0.9 °F].

or blower door assembly that is capable of moving air into and

out of the building at the flow rates required to create the full

7. Hazards

range of test pressure differences. The air moving equipment

7.1 Glass should not break at the pressure differences

shall be able to accomplish both pressurization and depressur-

normally applied to the building, however, protective eye wear

ization of the building and distribution system.

shall be provided to personnel.

6.2.2 Air Flow-Regulating System (A, B, and C)—A device

such as a damper or variable speed motor control to regulate 7.2 When conducted in the field, safety equipment required

and maintain air flow through the air moving equipment (see for general field work shall be supplied, such as safety shoes,

hard hats, and so forth.

6.2.1).

6.2.3 Air Flow Measuring Device (A)—A device to measure

7.3 Because air-moving equipment is involved in this test, a

airflow with an accuracy of 65 % of the measured flow

proper guard or cage to house the fan or blower and to prevent

through air moving equipment in 6.2.1. The air flow measuring

accidental access to any moving parts of the equipment shall be

system shall be calibrated in accordance with Test Method

provided.

E1258 or ASME MFC-3M, whichever is applicable. The

7.4 Hearing protection shall be provided for personnel who

temperature dependence and range of the calibration shall be

work close to noises such as those generated by moving air.

explicitly reported.

6.2.4 Distribution System Flow Measurement Device (B, C, 7.5 When the blower or fan is operating, a large volume of

and D)—A device to measure airflow with an accuracy of air is being forced into or out of the building, the air-

65 % of the measured flow. The airflow measuring system distribution system, or both. Precautions shall be undertaken

shall be calibrated in accordance with Test Method E1258 or such that plants, pets, occupants, or internal furnishings shall

ASME MFC-3M, whichever is applicable. The temperature not be damaged due to the influx of cold or warm air. Similar

dependence and range of the calibration shall be explicitly precautions shall be exercised with respect to sucking debris or

reported. exhaust gases from fireplaces and flues into the interior of the

E1554/E1554M − 13 (2018)

building extinguishing pilot lights, flame rollout for combus- 8.2.1 Environmental Measurements—At the beginning and

tion appliances and drawing sewer gas into the building. the end of each test, measure the outdoor temperature, indoor

temperature, and barometric pressure.

8. Procedure 8.2.2 Building Preparation:

8.2.2.1 Envelope—Open all interconnecting doors in the

8.1 General—The basic procedure involves pressurization

building. Fireplace and other operable dampers shall be closed.

and depressurization of air distribution systems and buildings

If the air handling unit is located in a closet, the closet door

with concurrent flow and pressure measurements to determine

shall be closed during testing. The condition of openings to

the air leakage of the distribution system.

outside for spaces that contain ducts (for example, garage

8.1.1 Test Method A (Flow Difference) for Air Leakage

doors or basement windows) shall be recorded.

Determination—This technique is based upon changing the

8.2.2.2 Distribution System—HVAC-balancing dampers and

flow through distribution system leaks by operating the blower

registers, in general, shall not be adjusted. However, for

fan and simultaneously pressurizing (or depressurizing) the

multiple zoned systems, the position of zonal dampers should

building envelope and distribution system. There are two

be fixed for the duration of the test. Several tests may be

alternatives for gathering the required test data utilizing the

performed with zone dampers fixed at different settings, but at

same analysis procedure. Test Method A.1 records data at fixed

least one of the tests shall have all zone control dampers in the

envelope pressure stations. Test Method A.2 records data

fully open position.

continuously as the envelope air flows and pressure are

8.2.3 Air Flow Difference Measurements:

gradually changed by the envelope air moving equipment. The

blower speed and heating or cooling function shall be the same 8.2.3.1 Connect the air moving/flow-regulating/flow mea-

for all steps of the test procedure. surement assembly to the building envelope using a window or

8.1.2 Test Method B: Fan Pressurization of Distribution door opening. Seal or tape openings to avoid leakage at these

System and Building for Air Leakage Determination—This points.

technique is based upon sealing the registers of the distribution

8.2.3.2 Install the envelope pressure difference sensor. The

system and pressurizing the system to measure the flow outside pressure measurement location shall be sheltered from

through the leaks at the imposed pressure difference. With the

wind and sunshine. The inside pressure measurement location

building pressurized to the same pressure, this test isolates the shall

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1554/E1554M − 13 E1554/E1554M − 13 (Reapproved 2018)

Standard Test Methods for

Determining Air Leakage of Air Distribution Systems by Fan

Pressurization

This standard is issued under the fixed designation E1554/E1554M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The test methods included in this standard are applicable to the air distribution systems in low-rise residential and

commercial buildings.

1.2 These test methods cover four techniques for measuring the air leakage of air distribution systems. The techniques use air

flow and pressure measurements to determine the leakage characteristics.

1.3 The test methods for two of the techniques also specify the auxiliary measurements needed to characterize the magnitude

of the distribution system air leakage during normal operation.

1.4 A test method for the total recirculating air flow induced by the system blower is included so that the air distribution system

leakage can be normalized as is often required for energy calculations.

1.5 The proper use of these test methods requires knowledge of the principles of air flow and pressure measurements.

1.6 Three of these test methods are intended to produce a measure of the air leakage from the air distribution system to outside.

The other test method measures total air leakage including air leaks to inside conditioned space.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E631 Terminology of Building Constructions

E779 Test Method for Determining Air Leakage Rate by Fan Pressurization

E1258 Test Method for Airflow Calibration of Fan Pressurization Devices

2.2 ASME Standard:

MFC-3M Measurement of Fluid Flow in Pipes Using Orifice Nozzle and Venturi

3. Terminology

3.1 Definitions—For definitions of general terms related to building construction used in these test methods, refer to

Terminology E631.

These test methods are under the jurisdiction of ASTM Committee E06 on Performance of Buildings and are the direct responsibility of Subcommittee E06.41 on Air

Leakage and Ventilation Performance.

Current edition approved April 15, 2013July 1, 2018. Published April 2013July 2018. Originally approved in 1993. Last previous edition approved in 20072013 as

E1554 – 07.E1554/E1554M – 13. DOI: 10.1520/E1554_E1554M-13.10.1520/E1554_E1554M-13R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, ThreeTwo Park Ave., New York, NY 10016-5990,

http://www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1554/E1554M − 13 (2018)

3.2 Definitions of Terms Specific to This Standard:

3.2.1 building envelope—the boundary or barrier separating the interior volume of a building from the outside environment.

Even when a garage is conditioned, for this standard it is considered to be outside the building envelope.

3.2.2 blower—the air moving device for a forced air space conditioning and/or ventilation system.

4. Summary of Test Methods

4.1 Four alternative measurement and analysis methods are specified and labeled A through D, Test Methods A and B give

separate values for supply and return leakage to outside. Test Methods C and D do not separate supply and return leakage. Test

Methods A, B, and C determine leakage to outside, but Test Method D measures total leakage, including leakage to inside. Test

Method A is based upon changes in flow through distribution system leaks to outside due to blower operation over a range of

envelope pressure differences. The envelope pressure differences are generated by a separate air moving fan and both

pressurization and depressurization measurements are performed. Test Methods B and C are based upon pressurizing the

distribution system at the same time as the building in order to isolate the leaks that are outside the building envelope. For Test

Method B, measured system operating pressures are then used to estimate leakage under operating conditions. Test Method C

determines the leakage to outside at a uniform reference pressure of 25 Pa [0.1 in. of water] instead of operating pressure, and does

not separate supply and return leaks. Test Methods B and C are shown schematically in Fig. 1 and Fig. 2. Unlike Methods A, B,

FIG. 1 Schematic of Method B—Distribution System and Building Pressurization Test (for Supply Leakage)

E1554/E1554M − 13 (2018)

FIG. 2 Schematic of Method C—Distribution System Pressurization Test

and C, Method D does not attempt to measure the leakage to outside under normal operating conditions, but measures the total

system leakage at a uniform reference pressure of 25 Pa [0.1 in. of water]. The schematic in Fig. 3 applies to Method D.

4.2 These test methods also include specifications for the auxiliary measurements to interpret the air leakage measurements.

5. Significance and Use

5.1 Air leakage between an air distribution system and unconditioned spaces affects the energy losses from the distribution

system, the ventilation rate of the building, and the entry rate of air pollutants.

5.2 The determination of infiltration energy loads and ventilation rates of residences and small commercial buildings are

typically based on the assumption that the principal driving forces for infiltration and ventilation are the wind and indoor/outdoor

temperature differences. This can be an inappropriate assumption for buildings that have distribution systems that pass through

unconditioned spaces, because the existence of relatively modest leakage from that system has a relatively large impact on overall

ventilation rates. The air leakage characteristics of these exterior distribution systems are needed to determine their ventilation,

energy, and pollutant-entry implications.

5.3 Air leakage through the exterior air distribution envelope may be treated in the same manner as air leakage in the building

envelope as long as the system is not operating (see Test Method E779). However, when the system blower is on, the pressures

across the air distribution system leaks are usually significantly larger than those driving natural infiltration. Depending on the size

of the leaks, these pressures can induce much larger flows than natural infiltration. Thus, it is important to be able to isolate these

E1554/E1554M − 13 (2018)

FIG. 3 Example of Air-Flow Difference and Envelope Pressure Plot for Test Method A.1

leaks from building envelope leaks. The leakage of air distribution systems must be measured in the field, because it has been

shown that workmanship and installation details are more important than design in determining the leakage of these systems.

5.4 For codes, standards, and other compliance or quality control applications, the precision and repeatability at meeting a

specified target (for example, air flow at reference pressure) is more important than air leakage flows at operating conditions. Some

existing codes, standards, and voluntary programs require the use of a simpler test method (Test Method D) that does not separate

supply from return leakage, leakage to inside from leakage to outside, or estimate leakage pressures at operating conditions.

5.5 Test Methods A, B, and C can be used for energy use calculations and compliance and quality control applications. Test

Method D is intended for use in compliance and quality control only.

6. Apparatus

6.1 The following description of apparatus is general in nature. Any arrangement of equipment using the same principles and

capable of performing the test procedure within the allowable tolerances is permitted. The items are labeled for each test method.

6.2 Major Components:

6.2.1 Air-Moving Equipment (A, B, and C)—A fan, blower, or blower door assembly that is capable of moving air into and out

of the building at the flow rates required to create the full range of test pressure differences. The air moving equipment shall be

able to accomplish both pressurization and depressurization of the building and distribution system.

6.2.2 Air Flow-Regulating System (A, B, and C)—A device such as a damper or variable speed motor control to regulate and

maintain air flow through the air moving equipment (see 6.2.1).

6.2.3 Air Flow Measuring Device (A)—A device to measure airflow with an accuracy of 65 % of the measured flow through

air moving equipment in 6.2.1. The air flow measuring system shall be calibrated in accordance with Test Method E1258 or ASME

MFC-3M, whichever is applicable. The temperature dependence and range of the calibration shall be explicitly reported.

6.2.4 Distribution System Flow Measurement Device (B, C, and D)—A device to measure airflow with an accuracy of 65 %

of the measured flow. The airflow measuring system shall be calibrated in accordance with Test Method E1258 or ASME MFC-3M,

whichever is applicable. The temperature dependence and range of the calibration shall be explicitly reported.

6.2.5 Pressure-Measuring Device (All methods)—A device to measure pressure differences with an accuracy of 60.25 Pa

[60.001 in. of water] or 61 % of measured pressure, whichever is greater.

6.2.6 Distribution System Pressure Measuring Probe (B, C, and D)—A probe to measure the static pressure within a distribution

system under flow conditions.

6.2.7 Air Temperature Measuring Device (All methods)—To give an accuracy of 60.5°C [0.9°F].60.5 °C [0.9 °F].

E1554/E1554M − 13 (2018)

7. Hazards

7.1 Glass should not break at the pressure differences normally applied to the building, however, protective eye wear shall be

provided to personnel.

7.2 When conducted in the field, safety equipment required for general field work shall be supplied, such as safety shoes, hard

hats, and so forth.

7.3 Because air-moving equipment is involved in this test, a proper guard or cage to house the fan or blower and to prevent

accidental access to any moving parts of the equipment shall be provided.

7.4 Hearing protection shall be provided for personnel who work close to noises such as those generated by moving air.

7.5 When the blower or fan is operating, a large volume of air is being forced into or out of the building, the air-distribution

system, or both. Precautions shall be undertaken such that plants, pets, occupants, or internal furnishings shall not be damaged due

to the influx of cold or warm air. Similar precautions shall be exercised with respect to sucking debris or exhaust gases from

fireplaces and flues into the interior of the building extinguishing pilot lights, flame rollout for combustion appliances and drawing

sewer gas into the building.

8. Procedure

8.1 General—The basic procedure involves pressurization and depressurization of air distribution systems and buildings with

concurrent flow and pressure measurements to determine the air leakage of the distribution system.

8.1.1 Test Method A (Flow Difference) for Air Leakage Determination—This technique is based upon changing the flow through

distribution system leaks by operating the blower fan and simultaneously pressurizing (or depressurizing) the building envelope

and distribution system. There are two alternatives for gathering the required test data utilizing the same analysis procedure. Test

Method A.1 records data at fixed envelope pressure stations. Test Method A.2 records data continuously as the envelope air flows

and pressure are gradually changed by the envelope air moving equipment. The blower speed and heating or cooling function shall

be the same for all steps of the test procedure.

8.1.2 Test Method B: Fan Pressurization of Distribution System and Building for Air Leakage Determination—This technique

is based upon sealing the registers of the distribution system and pressurizing the system to measure the flow through the leaks

at the imposed pressure difference. With the building pressurized to the same pressure, this test isolates the leaks that are to outside

only. Measurements of system operating pressures allow the leakage flow at the fixed test pressure to be converted to the leakage

flow at operating pressures. Often air distribution systems are located outside the conditioned space of a building, but are not

completely outside. Example locations include attics, crawlspaces, and garages. These locations are defined as buffer zones.

8.1.3 Test Method C: Fan Pressurization of Distribution System and Building for Air Leakage Determination at a Determination

at a Reference Pressure—This technique is based upon sealing the registers of the distribution system and pressurizing the system

to measure the flow through the leaks at a reference pressure difference of 25 Pa [0.1 in. of water]. With the building pressurized

to the same pressure, this test isolates the leaks that are to outside only, but does not separate supply and return leaks or convert

results to operating pressures.

8.1.4 Test Method D: Fan Pressurization of Distribution Sys

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.