ASTM E779-19

(Test Method)Standard Test Method for Determining Air Leakage Rate by Fan Pressurization

Standard Test Method for Determining Air Leakage Rate by Fan Pressurization

SIGNIFICANCE AND USE

5.1 Air leakage accounts for a significant portion of the thermal space conditioning load. In addition, it affects occupant comfort and indoor air quality.

5.2 In most commercial or industrial buildings, outdoor air is often introduced by design; however, air leakage is a significant addition to the designed outdoor airflow. In most residential buildings, indoor-outdoor air exchange is attributable primarily to air leakage through cracks and construction joints and is induced by pressure differences due to temperature differences, wind, operation of auxiliary fans (for example, kitchen and bathroom exhausts), and the operation of combustion equipment in the building.

5.3 The fan-pressurization method is simpler than tracer gas measurements and is intended to characterize the air tightness of the building envelope. It is used to compare the relative air tightness of several similar buildings to identify the leakage sources and rates of leakage from different components of the same building envelope, and to determine the air leakage reduction for individual retrofit measures applied incrementally to an existing building, and to determine ventilation rates when combined with weather and leak location information.

SCOPE

1.1 This test method measures air-leakage rates through a building envelope under controlled pressurization and de-pressurization.

1.2 This test method is applicable to small temperature differentials and low-wind pressure differential, therefore strong winds and large indoor-outdoor temperature differentials shall be avoided.

1.3 This test method is intended to quantify the air tightness of a building envelope. This test method does not measure air change rate or air leakage rate under normal weather conditions and building operation.

Note 1: See Test Method E741 to directly measure air-change rates using the tracer gas dilution method.

1.4 This test method is intended to be used for measuring the air tightness of building envelopes of single-zone buildings. For the purpose of this test method, many multi-zone buildings can be treated as single-zone buildings by opening interior doors or by inducing equal pressures in adjacent zones.

1.5 Only metric SI units of measurement are used in this standard. If a value for measurement is followed by a value in other units in parentheses, the second value may be approximate. The first stated value is the requirement.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 7.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E779 − 19

Standard Test Method for

1

Determining Air Leakage Rate by Fan Pressurization

This standard is issued under the fixed designation E779; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method measures air-leakage rates through a 2.1 ASTM Standards:

building envelope under controlled pressurization and de- E631Terminology of Building Constructions

pressurization.

E741Test Method for Determining Air Change in a Single

Zone by Means of a Tracer Gas Dilution

1.2 This test method is applicable to small temperature

E1258Test Method for Airflow Calibration of Fan Pressur-

differentials and low-wind pressure differential, therefore

ization Devices

strong winds and large indoor-outdoor temperature differen-

tials shall be avoided.

3. Terminology

1.3 Thistestmethodisintendedtoquantifytheairtightness

3.1 Fordefinitionsoftermsusedinthistestmethod,referto

of a building envelope. This test method does not measure air

Terminology E631.

changerateorairleakagerateundernormalweatherconditions

and building operation.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 air-change rate, n—air-leakage rate in volume units/h

NOTE 1—See Test Method E741 to directly measure air-change rates

divided by the building space volume with identical volume

using the tracer gas dilution method.

units, normally expressed as air changes/h, ACH.

1.4 This test method is intended to be used for measuring

3.2.2 air-leakage, n—the movement/flow of air through the

theairtightnessofbuildingenvelopesofsingle-zonebuildings.

building envelope, which is driven by either or both positive

Forthepurposeofthistestmethod,manymulti-zonebuildings

(infiltration) and negative (exfiltration) pressure differences

can be treated as single-zone buildings by opening interior

across the envelope.

doors or by inducing equal pressures in adjacent zones.

3.2.3 air-leakage graph, n—the graph that shows the rela-

1.5 Only metric SI units of measurement are used in this

tionship of measured airflow rates to the corresponding mea-

standard. If a value for measurement is followed by a value in

sured pressure differences, plotted on a log-log scale.

other units in parentheses, the second value may be approxi-

mate. The first stated value is the requirement.

3.2.4 air-leakage rate, n—the volume of air movement/unit

time across the building envelope including airflow through

1.6 This standard does not purport to address all of the

joints, cracks, and porous surfaces, or a combination thereof

safety concerns, if any, associated with its use. It is the

driven by mechanical pressurization and de-pressurization,

responsibility of the user of this standard to establish appro-

naturalwindpressures,orairtemperaturedifferentialsbetween

priate safety, health, and environmental practices and deter-

the building interior and the outdoors, or a combination

mine the applicability of regulatory limitations prior to use.

thereof.

For specific hazard statements see Section 7.

1.7 This international standard was developed in accor-

3.2.5 building envelope, n—the boundary or barrier separat-

dance with internationally recognized principles on standard-

ing different environmental conditions within a building and

ization established in the Decision on Principles for the

from the outside environment.

Development of International Standards, Guides and Recom-

3.2.6 effective leakage area, n—the area of a hole, with a

mendations issued by the World Trade Organization Technical

discharge coefficient of 1.0, which, witha4Pa pressure

Barriers to Trade (TBT) Committee.

difference, leaks the same as the building, also known as the

sum of the unintentional openings in the structure.

1

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.41

2

on Air Leakage and Ventilation Performance. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2019. Published January 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approvedin1981.Lastpreviouseditionapprovedin2018asE779–10(2018).DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E0779–19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United St

...

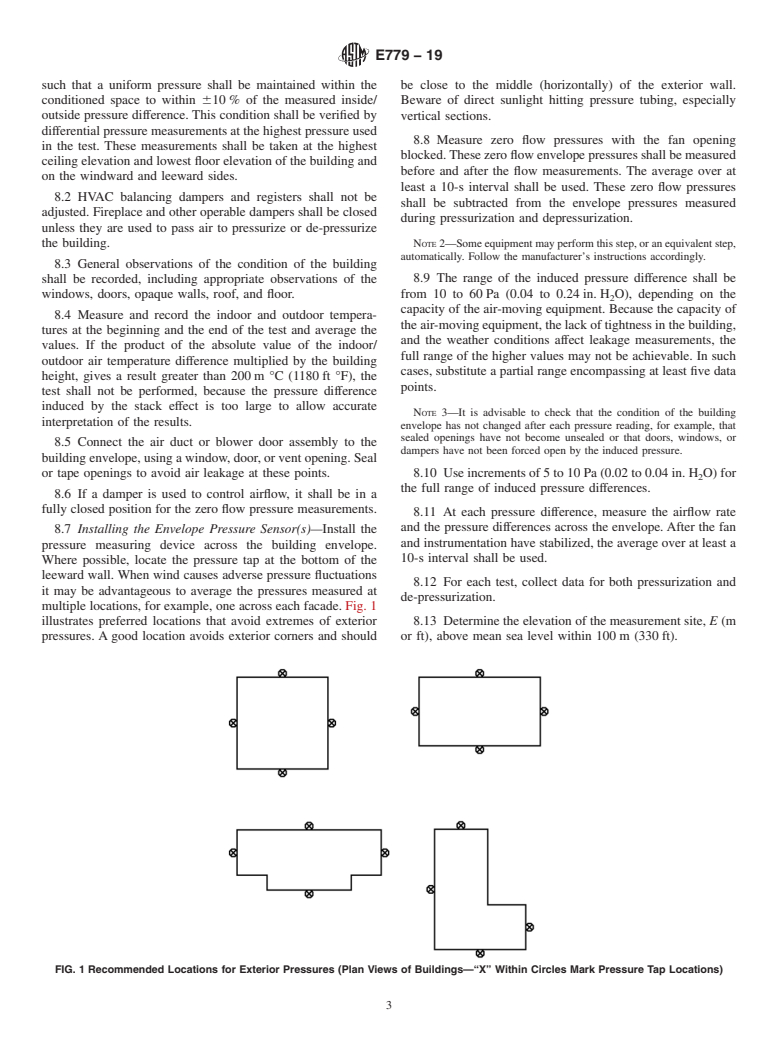

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E779 − 10 (Reapproved 2018) E779 − 19

Standard Test Method for

1

Determining Air Leakage Rate by Fan Pressurization

This standard is issued under the fixed designation E779; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method measures air-leakage rates through a building envelope under controlled pressurization and de-

pressurization.

1.2 This test method is applicable to small temperature differentials and low-wind pressure differential, therefore strong winds

and large indoor-outdoor temperature differentials shall be avoided.

1.3 This test method is intended to quantify the air tightness of a building envelope. This test method does not measure air

change rate or air leakage rate under normal weather conditions and building operation.

NOTE 1—See Test Method E741 to directly measure air-change rates using the tracer gas dilution method.

1.4 This test method is intended to be used for measuring the air tightness of building envelopes of single-zone buildings. For

the purpose of this test method, many multi-zone buildings can be treated as single-zone buildings by opening interior doors or

by inducing equal pressures in adjacent zones.

1.5 Only metric SI units of measurement are used in this standard. If a value for measurement is followed by a value in other

units in parentheses, the second value may be approximate. The first stated value is the requirement.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific hazard statements see Section 7.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E631 Terminology of Building Constructions

E741 Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution

E1258 Test Method for Airflow Calibration of Fan Pressurization Devices

3. Terminology

3.1 For definitions of terms used in this test method, refer to Terminology E631.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 air-change rate, n—air-leakage rate in volume units/h divided by the building space volume with identical volume units,

normally expressed as air changes/h, ACH.

3.2.2 air-leakage, n—the movement/flow of air through the building envelope, which is driven by either or both positive

(infiltration) and negative (exfiltration) pressure differences across the envelope.

3.2.3 air-leakage graph, n—the graph that shows the relationship of measured airflow rates to the corresponding measured

pressure differences, plotted on a log-log scale.

1

This test method is under the jurisdiction of ASTM Committee E06 on Performance of Buildings and is the direct responsibility of Subcommittee E06.41 on Air Leakage

and Ventilation Performance.

Current edition approved July 15, 2018Jan. 1, 2019. Published July 2018January 2019. Originally approved in 1981. Last previous edition approved in 20102018 as

E779 – 10.E779–10 (2018). DOI: 10.1520/E0779-10R18.10.1520/E0779–19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E779 − 19

3.2.4 air-leakage rate, n—the volume of air movement/unit time across the building envelope including airflow through joints,

cracks, and porous surfaces, or a combination thereof driven by mechanical pressurization and de-pressurization, natural wind

pressures, or air temperature differentials between the building interior and the outdoors, or a combination thereof.

3.2.5 building envelope, n—the boundary or barri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.