ASTM D7463-08

(Test Method)Standard Test Method for Adenosine Triphosphate (ATP) Content of Microorganisms in Fuel, Fuel/Water Mixtures and Fuel Associated Water

Standard Test Method for Adenosine Triphosphate (ATP) Content of Microorganisms in Fuel, Fuel/Water Mixtures and Fuel Associated Water

SIGNIFICANCE AND USE

This test method measures the concentration of ATP present in the sample. ATP is a constituent of all living cells including bacteria and fungi. Consequently, the presence of ATP is a reliable indicator of microbial contamination in fuel systems. ATP is not associated with matter of non-biological origin.

This test method differs from Test Method D 4012 as follows:

By providing for the rapid determination of ATP present in a fuel (petroleum) sample, a fuel and water mixture sample, fuel-associated bottom water sample and extracellular ATP freely available in the fuel or aqueous sample matrix;

By providing for a method to capture, extract and quantify ATP using self-contained test device and luminometer;

By providing a method of quantifying ATP present in fuel or water matrices in generally less than 10 min; and

By providing for the rapid separation of the ATP from chemical interferences that have previously prevented the use of ATP determinations in complex fluids containing hydrocarbons and other organic molecules.

This test method does not require the use of hazardous materials and does not generate biohazard waste.

This test method can be used to estimate viable microbial biomass, to evaluate the efficacy of antimicrobial pesticides, and to monitor microbial contamination in fuel storage and distribution systems.

SCOPE

1.1 This test method provides a protocol for capturing, extracting and quantifying the adenosine triphosphate (ATP) content associated with:

1.1.1 Microorganisms found in conventional liquid fuels with kinematic viscosities (at 40°C) of ≤ 8 mm2 · s–1 as described in Table X6.1,

1.1.2 Microorganisms found in fuel-associated bottom water, and

1.1.3 Extracellular (non-cellular) ATP present in the sample matrix.

1.2 The ATP is measured using a patented bioluminescence enzyme assay, whereby light is generated in amounts proportional to the concentration of ATP in the sample. The light is produced and measured quantitatively using dedicated ATP test pens and a dedicated luminometer and reported in (instrument specific) Relative Light Units.

1.3 This test method is equally suitable for use in the laboratory or field.

1.4 Although bioluminescence is a reliable and proven method for qualifying and quantifying ATP, this method does not differentiate between ATP from different sources, for example, from different types of microorganism such as bacteria or fungi.

1.5 For water or capture solution samples, the concentration range of ATP detectable by this test method is 1 × 10–11 M to 3 × 10–8 M which is equivalent to 1 × 10–14 moles/mL to 3 × 10–11 moles/mL for water samples or capture solution. Assuming testing on fuel phase is performed on a 500 mL volume of fuel the equivalent concentrations is fuel would be: 6 × 10–11 M to 2 × 10–14 M.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7463 − 08

StandardTest Method for

Adenosine Triphosphate (ATP) Content of Microorganisms

in Fuel, Fuel/Water Mixtures and Fuel Associated Water

This standard is issued under the fixed designation D7463; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This test method provides a protocol for capturing,

standard.

extracting and quantifying the adenosine triphosphate (ATP)

1.7 This standard does not purport to address all of the

content associated with:

safety concerns, if any, associated with its use. It is the

1.1.1 Microorganisms found in conventional liquid fuels

2 –1

responsibility of the user of this standard to establish appro-

with kinematic viscosities (at 40°C) of ≤ 8mm ·s as

priate safety and health practices and determine the applica-

described in Table X6.1,

bility of regulatory limitations prior to use.

1.1.2 Microorganisms found in fuel-associated bottom

water, and

2. Referenced Documents

1.1.3 Extracellular (non-cellular)ATPpresent in the sample

matrix.

2.1 ASTM Standards:

D396Specification for Fuel Oils

1.2 TheATPis measured using a patented bioluminescence

D975Specification for Diesel Fuel Oils

enzyme assay, whereby light is generated in amounts propor-

D1129Terminology Relating to Water

tional to the concentration of ATP in the sample. The light is

D1655Specification for Aviation Turbine Fuels

producedandmeasuredquantitativelyusingdedicatedATPtest

2 2

D2069Specification for Marine Fuels (Withdrawn 2003)

pens and a dedicated luminometer and reported in (instru-

D2880Specification for Gas Turbine Fuel Oils

ment specific) Relative Light Units.

D3699Specification for Kerosine

1.3 This test method is equally suitable for use in the

D4012TestMethodforAdenosineTriphosphate(ATP)Con-

laboratory or field.

tent of Microorganisms in Water

1.4 Although bioluminescence is a reliable and proven

D4057Practice for Manual Sampling of Petroleum and

method for qualifying and quantifying ATP, this method does

Petroleum Products

not differentiate between ATP from different sources, for

D4175 Terminology Relating to Petroleum, Petroleum

example, from different types of microorganism such as

Products, and Lubricants

bacteria or fungi.

D6161TerminologyUsedforMicrofiltration,Ultrafiltration,

Nanofiltration and Reverse Osmosis Membrane Processes

1.5 Forwaterorcapturesolutionsamples,theconcentration

–11

D6469GuideforMicrobialContaminationinFuelsandFuel

range ofATP detectable by this test method is1×10 Mto

–8 –14

Systems

3×10 M which is equivalent to1×10 moles/mL to 3 ×

–11

D6751Specification for Biodiesel Fuel Blend Stock (B100)

10 moles/mLfor water samples or capture solution.Assum-

for Middle Distillate Fuels

ing testing on fuel phase is performed on a 500 mLvolume of

–11

fuel the equivalent concentrations is fuel would be:6×10

–14

3. Terminology

Mto2×10 M.

3.1 Definitions:

3.1.1 For definition of terms used in this test method, refer

This test method is under the jurisdiction of ASTM Committee D02 on to Terminologies D1129 and D4175, and Guide D6469.

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

D02.14 on Stability and Cleanliness of Liquid Fuels.

CurrenteditionapprovedDec.1,2008.PublishedFebruary2009.DOI:10.1520/

D7463-08. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

is Merck KGaA, 64271 Darmstadt, Germany. If you are aware of alternative Standards volume information, refer to the standard’s Document Summary page on

suppliers, please provide this information to ASTM International Headquarters. the ASTM website.

Your comments will receive careful consideration at a meeting of the responsible The last approved version of this historical standard is referenced on

technical committee, which you may attend. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7463 − 08

3.1.2 adenosine triphosphate, n—molecule comprised of a 3.1.17 viable microbial biomass, n—metabolically active

purine and three phosphate groups, that serves as the primary (living) micro-organisms

energy transport molecule in all biological cells.

3.2 Abbreviations:

3.1.3 adenosine monophosphate, n—molecule formed by 3.2.1 AMP—adenosine monophosphate

the removal of two (2) molecules of phosphate (one pyrophos-

3.2.2 ATP—adenosine triphosphate

phate molecule) from ATP.

3.2.3 HDPE—high density polyethylene

3.1.4 aseptic, adj—sterile, free from viable microbiological

3.2.4 PP—polypropylene

contamination.

3.2.5 RLU—relative light units

3.1.5 bioluminescence, n—production and emission of light

byalivingorganismastheresultofachemicalreactionduring

4. Summary of Test Method

which chemical energy is converted to light energy.

4.1 A fuel sample is obtained either for condition monitor-

3.1.6 biomass, n—any matter which is or was a living ing or for diagnostic testing, for example, fuel from a fuel

organism or excreted from a microorganism. D6161

system that is exhibiting problems such as sediment formation

or filter plugging where the presence of micro-organisms is

3.1.7 capture solution, n—aqueous solution of proprietary

suspected.

composition used to capture and concentrate hydrophilic com-

pounds and particles from liquid fuels. 4.2 Microbial ATP is captured, extracted, and quantified

using a bioluminescence reaction. The light generated by the

3.1.8 culturable, adj—microorganisms that proliferate as

luminescence reaction is measured in a luminometer.

indicated by the formation of colonies in or on solid growth

media, or the development of turbidity in liquid growth media 4.3 Specialized test methods for fuel samples, water

samples, extracellular determination or resolving potential

under specified growth conditions.

matrix interference in bottom water samples are described in

3.1.9 extracellular ATP, n—ATPthat is not contained inside

the appendixes.

a cell.

3.1.9.1 Discussion—ATP is released into the environment

5. Significance and Use

when cells die and break open (lyse), for example, as when

5.1 This test method measures the concentration of ATP

theyarekilledbyexposuretosomemicrobicides.ATPreleased

present in the sample. ATP is a constituent of all living cells

intotheenvironmentcanpersistforseveraldaysafteracellhas

including bacteria and fungi. Consequently, the presence of

beenlysed.ConsequentlyextracellularATPmustbesubtracted

ATP is a reliable indicator of microbial contamination in fuel

from total ATP to determine the concentration of viable

systems. ATP is not associated with matter of non-biological

cell-associated (biomass associated) ATP. However, extracel-

origin.

lular ATP can also be an indicator of “distant” biomass, for

example, biofilm in the system. 5.2 This test method differs from Test Method D4012 as

follows:

3.1.10 fungus, (pl. fungi), n—singlecell(yeasts)orfilamen-

5.2.1 By providing for the rapid determination of ATP

tous (molds) microorganisms that share the property of having

present in a fuel (petroleum) sample, a fuel and water mixture

the true intracellular membranes (organelles) that characterize

sample, fuel-associated bottom water sample and extracellular

all higher life forms (Eukaryotes).

ATP freely available in the fuel or aqueous sample matrix;

3.1.11 invert emulsion layer, n—interfacebetweenthewater

5.2.2 By providing for a method to capture, extract and

phase and fuel phase of a fuel water sample which consists of

quantify ATP using self-contained test device and luminom-

water micelles dispersed in the fuel.

eter;

5.2.3 By providing a method of quantifyingATP present in

3.1.12 luciferase, n—general term for a class of enzymes

fuel or water matrices in generally less than 10 min; and

that catalyze bioluminescent reactions.

5.2.4 By providing for the rapid separation of theATPfrom

3.1.13 luciferin,n—generaltermforaclassoflight-emitting

chemical interferences that have previously prevented the use

biological pigments found in organisms capable of biolumi-

ofATP determinations in complex fluids containing hydrocar-

nescence.

bons and other organic molecules.

3.1.14 luminometer, n—instrument capable of measuring

5.3 This test method does not require the use of hazardous

light emitted as a result of non-thermal excitation.

materials and does not generate biohazard waste.

3.1.15 pyrogen free, n—freeofsubstanceswhichcaninduce

5.4 This test method can be used to estimate viable micro-

fever.

bial biomass, to evaluate the efficacy of antimicrobial

pesticides, and to monitor microbial contamination in fuel

3.1.16 relative light unit (RLU), n—instrument-specific unit

storage and distribution systems.

of measurement reflecting the number of photons emitted by

theLuciferin-LuciferasedrivenhydrolysisofATPtoAMPplus

6. Interferences

pyrophosphate.

3.1.16.1 Discussion—RLU is not an SI unit, however, RLU 6.1 Sample containers and sampling devices shall be clean

are proportional to ATP concentration. and free of both ATP and microbial contamination.

D7463 − 08

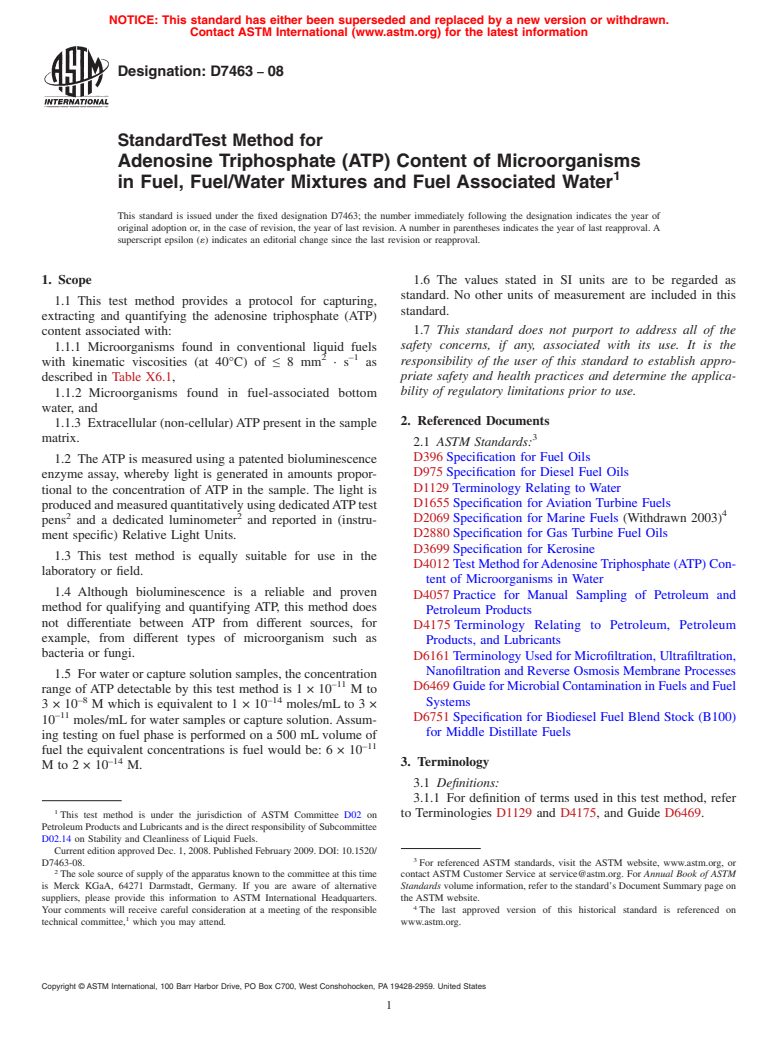

FIG. 1 Luminometer

6.2 EnsurethatthesamplingstickontheATPTestPendoes 8.2.1.1 HY-LiTE Fuel Test Pen, as shown in Fig. 2.

not come into contact with any contaminating surfaces. Con- 8.2.1.2 HY-LiTE Free ATP Pen, as shown in Fig. 2.

tact with a surface or substance can cause contamination with 8.2.2 Pasteur pipettes, sterile, disposable, polyethylene, 1.0

high levels of ATP, giving erroneous results. mL.

8.2.3 Pasteur pipettes sterile, disposable, polyethylene, 10.0

6.3 Luciferase is an enzyme, which can be inhibited or

mL.

denatured by high temperatures, the presence of heavy metals

and high salt concentrations in the sample. These conditions

9. Sampling, Test Specimens, and Test Units

are unlikely to occur except in samples containing large

9.1 Samples shall be drawn in accordance with Practice

volumes of bottom-water samples from storage tanks and

D4057 as amplified by Hill.

similar systems.

9.2 To reduce the risk of accidental contamination, samples

6.3.1 For samples in which inhibition is suspected or likely

intended for microbiological testing shall not be used for other

to occur, testing of a dilution of the sample is described in

tests until after they are no longer needed for microbiological

Appendix X4.

testing.

7. Apparatus

9.3 It may be possible to accidentally cross contaminate the

sample under field conditions. To reduce risk of potential

7.1 An example of the luminometer is shown as a diagram

cross-contamination, rinse the sample device(s) and sample

in Fig. 1.

container(s)witha70%alcohol(ethanol,methanol,orisopro-

7.2 WARNING. The apparatus is not explosion proof. The

panol) and water solution and let air dry. All devices (except

instrument should not be operated in explosive atmospheres or

factorynew,cleanbottles)shouldbedisinfectedisthismanner

in locations where there may be explosive fumes, as it cannot

to minimize the likelihood of cross-contamination. Use care to

be grounded.

not touch the interior of the freshly decontaminated sample

7.3 Samplebottle,roundwide-mouth,nominalcapacity500

devices or sample bottles. Remove the container lid immedi-

mL, HDPE (High Density Poly Ethylene) or equivalent.There

ately before dispensing the sample into the container and

shall be sufficient excess volume in the sample bottle so that

replace the lid on the container as soon as possible.

there is at least 10% head space in addition to the 500 mL

9.4 Microbial contaminant populations are dynamic. Mi-

sample volume to facilitate the shearing and mixing of the

crobes within the sample can proliferate or die during the

capture solution.

interval between collection and testing. Consequently, samples

7.3.1 Sample bottles may be reused provided they are

shall be processed within 24 h after collection.

cleanedanddriedcorrectly.Refertotestsupplier’sinformation

9.5 Ifsamplesaretobetestedlaterthan4haftercollection,

regarding recommended cleaning procedure.

storethesampleseitheronice,orrefrigeratedat>0to5°Cuntil

7.4 Pipettors, fixed volume or adjustable capable of provid-

tested.Avoidfreezingsamples.Allowsamplestoequilibrateto

ingdiscreetvolumesofbottomwatertodeterminethepresence

room temperature before testing.

of matrix interference as described in Appendix X4. Example

pipettor volumes include 10 µL, 50 µL, and 100 µL.

10. Calibration and Standardization

10.1 The luminometer which is specific to this test is

8. Reagents and Materials

factorycalibratedandtemperaturecompensatedtogivealinear

8.1 Reagents:

8.1.1 ATP di-sodium salt.

Registered trademark of Merck KGaA, 64271 Darmstadt, Germany.

8.1.2 Water, Pyrogen free. Hill, G., “Sampling Methods for Detecting Microbial Contamination in Fuels

and Fuel Systems,” Fuels and Fuel Systems Microbiology: Fundamentals,

8.2 Materials:

Diagnosis, and Contamination Control, ASTM MNL 47,ASTM International, West

8.2.1 ATP test pens: Conshohocken, PA, 2002, p. 14.

D7463 − 08

FIG. 2 Fuel Test Pen and Free ATP Test Pen

Thepresenceofwaterinthesamplewillcausethedilutedcapturesolution

response from 0-99,000 RLU at temperatures between 41 and

to look paler than the undiluted capture solution.

95°F (5 and 35°C). No calibration is necessary because

NOTE 2—Highly colored or hazy samples may color the capture

calibrations checks are performed automatically during start-

solution. This will not affect the RLU reading.

up.

11.1.10 Ensure that the luminometer is powered on and has

10.2 RLU data may be converted to ATP concentration by

successfullycompletedtheself-checkandisreadyforanalysis.

interpolating from a standard curve as described in Appendix

11.1.11 After the 5 min standing as prescribed in 11.1.9,

X5.

11.1.11.1 Obtain the large pipette from the fuel test kit,

–15

10.3 1 RLU is equivalent to approximately5×10 grams

11.1.11.2 Usingacleanimplement(forexample,scissorsor

ATP.

knife), cut the plastic protective sleeve open at the bulb-end

andremovethepipette.Donottouchthetipandlowerstemof

11. Procedure

the pipette by hand or against any surfaces.

11.1 Analysis of Fuel and Combined Fuel and Water

11.1.12 Coalesce the capture solution and any water phase

Samples:

present into a single drop or phase and use the large pipette to

11.1.1 Collect sample according to 9.1.

retrieve a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.