ASTM D6143-09

(Test Method)Standard Test Method for Iron Content of Bisphenol A (4,4´ - Isopropylidenediphenol)

Standard Test Method for Iron Content of Bisphenol A (4,4´ - Isopropylidenediphenol)

SIGNIFICANCE AND USE

Iron may increase the color of bisphenol A and affect other properties of end-use products.

High purity bisphenol A typically has less than 1 mg/kg of iron.

SCOPE

1.1 This test method covers the procedure to determine the iron content of bisphenol A (4,4′-isopropylidenediphenol).

1.2 This test method has a lower detection limit of 0.1 mg/kg, and an upper limit of 10 mg/kg of iron in bisphenol A. If the iron content is higher, it may be necessary to dilute the sample. A longer path length cell can also be used for better accuracy at lower Fe levels, as well as calibration within the range expected (for example, 0 to 1 mg/kg versus 0 to 10 mg/kg for samples expected to be in the 0 to 1 mg/kg range.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limits prior to use. For a specific hazard statement, see Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6143 − 09

StandardTest Method for

1

Iron Content of Bisphenol A (4,4' - Isopropylidenediphenol)

This standard is issued under the fixed designation D6143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.1 This test method covers the procedure to determine the

E691 Practice for Conducting an Interlaboratory Study to

iron content of bisphenol A (4,4'-isopropylidenediphenol).

Determine the Precision of a Test Method

1.2 This test method has a lower detection limit of 0.1

2.2 Other Documents:

mg/kg, and an upper limit of 10 mg/kg of iron in bisphenolA.

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

If the iron content is higher, it may be necessary to dilute the 3

1910.1200

sample. A longer path length cell can also be used for better

accuracy at lower Fe levels, as well as calibration within the 3. Summary of Test Method

range expected (for example, 0 to 1 mg/kg versus 0 to 10

3.1 Bisphenol A is dissolved in methanol, then treated with

mg/kg for samples expected to be in the 0 to 1 mg/kg range.

hydroxylaminehydrochloridetoconvertanyferricironpresent

to ferrous iron. The ferrous iron is then complexed with

1.3 In determining the conformance of the test results using

FerroZine to form a purple/maroon chromophore that is

this method to applicable specifications, results shall be

quantified by visible spectrophotometry at 560 nm.

rounded off in accordance with the rounding-off method of

Practice E29.

4. Significance and Use

1.4 The values stated in SI units are to be regarded as

4.1 Iron may increase the color of bisphenol A and affect

standard. No other units of measurement are included in this

other properties of end-use products.

standard.

4.2 High purity bisphenolAtypically has less than 1 mg/kg

1.5 This standard does not purport to address all of the

of iron.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Interferences

priate safety and health practices and determine the applica-

5.1 No direct interferences have been observed in the use of

bility of regulatory limits prior to use. For a specific hazard

this method.

statement, see Section 8.

6. Apparatus

2. Referenced Documents

6.1 Visible Spectrophotometer, capable of measuring absor-

2

2.1 ASTM Standards:

bance at 560 nm.

D1193 Specification for Reagent Water

6.2 Analytical Balance, capable of weighing 100 g to the

D4297 Practice for Sampling and Handling Bisphenol A

nearest 0.01 g.

(4,4' -Isopropylidinediphenol)

6.3 Glassware, 100 mL and 1 L volumetric flasks, 500 mL

D6809 Guide for Quality Control and Quality Assurance

graduated cylinders, 10 mL volumetric pipettes, 1 cm square

Procedures for Aromatic Hydrocarbons and Related Ma-

quartz cuvettes.

terials

6.4 All Glassware used in this test method should be

dedicated and thoroughly cleaned prior to use.

1

This test method is under the jurisdiction of ASTM Committee D16 on

7. Reagents and Materials

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

D16.02 on Oxygenated Aromatics.

7.1 Methanol, ACS reagent grade, ≥ 99.8 % purity.

Current edition approved Dec. 1, 2009. Published December 2009. Originally

approved in 1997. Last previous edition approved in 2005 as D6143 – 05. DOI:

7.2 Sodium Acetate, pH 5.5.

10.1520/D6143-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6143 − 09

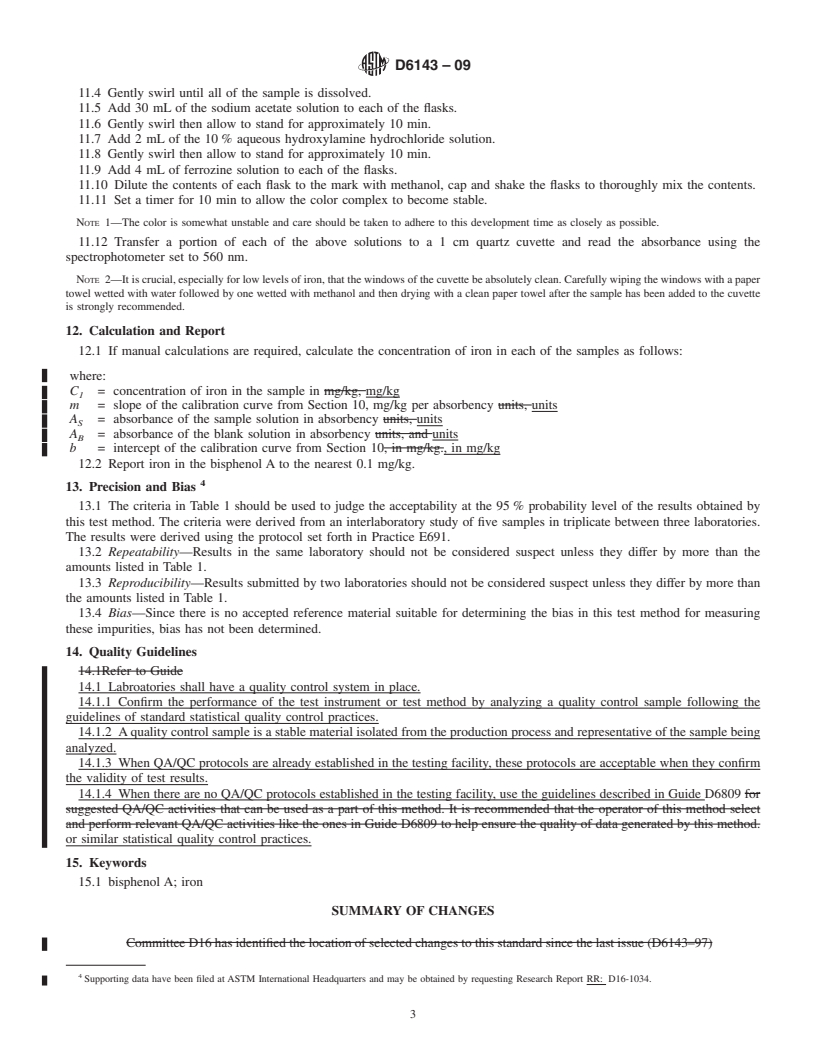

TABLE 1 Summary of Precision Data

7.2.1 This solution may be prepared by dissolving 272.0 g

6 0.1g of reagent grade sodium acetate in 1000 mL distilled Precision, characterized by repeatability, Sr, r,

and reproducibility, SR, R for analysis of Fe in BPA

water and adjusting to pH 5.5 with concentrated hydrochloric

mg/kg

acid.

Sample # Sr SR r R

Average

1 0.29 0.09 0.10 0.26 0.27

7.3 Distilled Water, conforming to Type IV of Specification

2 0.02 0.00 0.04 0.00 0.11

D1193.

3 7.30 0.32 0.65 0.90 1.83

4 0.51 0.15

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6143–05 Designation: D6143 – 09

Standard Test Method for

1

Iron Content of Bisphenol A (4,4* - Isopropylidenediphenol)

This standard is issued under the fixed designation D6143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the procedure to determine the iron content of bisphenol A (4,48-isopropylidenediphenol).

1.2 This test method has a lower detection limit of 0.1 mg/kg, and an upper limit of 10 mg/kg of iron in bisphenol A. If the

iron content is higher, it may be necessary to dilute the sample. A longer path length cell can also be used for better accuracy at

lower Fe levels, as well as calibration within the range expected (for example, 0 to 1 mg/kg versus 0 to 10 mg/kg for samples

expected to be in the 0 to 1 mg/kg range.

1.3In1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be

rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

oftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimits

prior to use. For a specific hazard statement, see Section 8.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D4297 Practice for Sampling and Handling Bisphenol A (4,4 -Isopropylidinediphenol)

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Other Documents:

3

OSHA Regulations 29CFROSHA Regulations, 29CFR paragraphs 1910.1000 and 1910.1200.

3. Summary of Test Method

3.1 Bisphenol A is dissolved in methanol, then treated with hydroxylamine hydrochloride to convert any ferric iron present to

ferrous iron.The ferrous iron is then complexed with FerroZine to form a purple/maroon chromophore that is quantified by visible

spectrophotometry at 560 nm.

4. Significance and Use

4.1 Iron may increase the color of bisphenol A and affect other properties of end-use products.

4.2 High purity bisphenol A typically has less than 1 mg/kg of iron.

5. Interferences

5.1 No direct interferences have been observed in the use of this method.

6. Apparatus

6.1 Visible Spectrophotometer, capable of measuring absorbance at 560 nm.

6.2 Analytical Balance, capable of weighing 100 g to the nearest 0.01 g.

1

This test method is under the jurisdiction of ASTM Committee D16 on Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of D16.02 on

Oxygenated Aromatics.

Current edition approved JulyDec. 1, 2005.2009. Published July 2005.December 2009. Originally approved in 1997. Last previous edition approved in 19972005 as

D6143–97.D6143 – 05. DOI: 10.1520/D6143-059.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6143 – 09

6.3 Glassware, 100 mLand 1 Lvolumetric flasks, 500 mLgraduated cylinders, 10 mLvolumetric pipettes, 1 cm square quartz

cuvettes.

6.4 All Glassware used in this test method should be dedicated and thoroughly cleaned prior to use.

7. Reagents and Materials

7.1 Methanol, ACS reagent grade,$ 99.8 % purity.

7.2 Sodium Acetate, pH 5.5.

7.2.1 This solution may be prepared by dissolving 272.0 g 6 0.1g of reagent grade sodium acetate in 1000 mL distilled water

and adjusting to pH 5.5 with concentrated hydrochlori

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.