ASTM D8266-19

(Test Method)Standard Test Method for Analysis of Bisphenol A (4,4`-Isopropylidenediphenol) by High Performance Liquid Chromatography

Standard Test Method for Analysis of Bisphenol A (4,4`-Isopropylidenediphenol) by High Performance Liquid Chromatography

SIGNIFICANCE AND USE

4.1 Bisphenol A is used for production of polycarbonate or epoxy resin. The presence of impurities in bisphenol A is undesirable because they may slow down the polymerization and be impurities in the final product.

4.2 Determination of the trace impurities, such as isomer of bisphenol A and the unreacted raw material, is often required. This test method is suitable for setting specifications and for using as an internal quality control where these products are produced or used.

4.3 Purity is commonly reported by subtracting the determined expected impurities and water from 100 %. However, a HPLC analysis cannot determine absolute purity if unknown components are contained within the material being examined.

SCOPE

1.1 This test method covers the determination of trace impurities in bisphenol A (4,4′-Isopropylidenediphenol) by reverse-phase gradient high performance liquid chromatography (HPLC). It is generally meant for the analysis of bisphenol A of 99.5 % or greater.

1.2 This method is applicable to bisphenol A samples containing impurity concentration between 2 and 400 mg/kg. Users of this method believe it is linear over a wider range.

1.3 In determining the conformance of the test results using this method to applicable specification, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8266 − 19

Standard Test Method for

Analysis of Bisphenol A (4,4'-Isopropylidenediphenol) by

1

High Performance Liquid Chromatography

This standard is issued under the fixed designation D8266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope -Isopropylidinediphenol)

D6809 Guide for Quality Control and Quality Assurance

1.1 This test method covers the determination of trace

Procedures for Aromatic Hydrocarbons and Related Ma-

impurities in bisphenol A (4,4'-Isopropylidenediphenol) by

terials

reverse-phase gradient high performance liquid chromatogra-

E29 Practice for Using Significant Digits in Test Data to

phy (HPLC). It is generally meant for the analysis of bisphenol

Determine Conformance with Specifications

A of 99.5 % or greater.

E691 Practice for Conducting an Interlaboratory Study to

1.2 This method is applicable to bisphenol A samples

Determine the Precision of a Test Method

containing impurity concentration between 2 and 400 mg/kg.

3

2.2 Other document:

Users of this method believe it is linear over a wider range.

OSHA Regulations 29 CFR paragraphs 1910.1000 and

1.3 In determining the conformance of the test results using

1910.1200

thismethodtoapplicablespecification,resultsshallberounded

off in accordance with the rounding-off method of Practice

3. Summary of Test Method

E29.

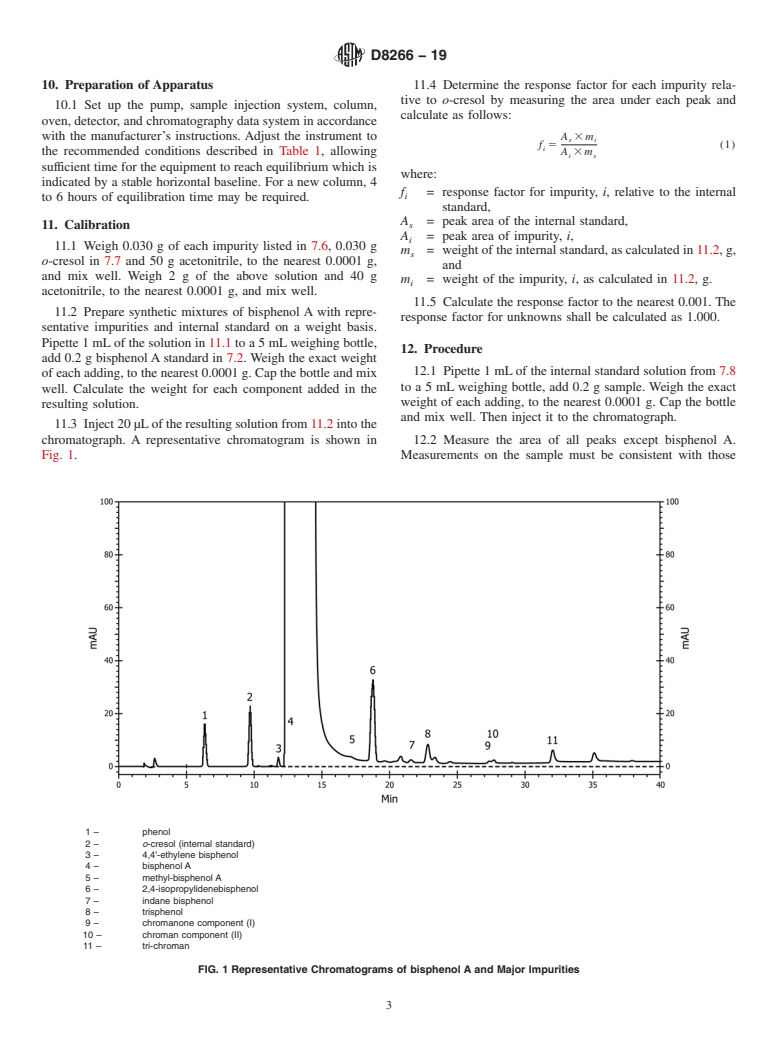

3.1 A known amount of an internal standard is added to a

1.4 The values stated in SI units are to be regarded as

sample of bisphenol A. The prepared sample is mixed and

standard. No other units of measurement are included in this

analyzed by a reverse-phase gradient liquid chromatography

standard.

(HPLC)equippedwithanultravioletdetector.Thepeakareaof

1.5 This standard does not purport to address all of the

each impurity and the internal standard is measured. The

safety concerns, if any, associated with its use. It is the

amountofeachimpurityiscalculatedfromtheratioofthepeak

responsibility of the user of this standard to establish appro-

area of the internal standard versus the peak area of the

priate safety, health, and environmental practices and deter-

impurity.

mine the applicability of regulatory limitations prior to use.

For a specific hazard statement, see Section 8.

4. Significance and Use

1.6 This international standard was developed in accor-

4.1 Bisphenol A is used for production of polycarbonate or

dance with internationally recognized principles on standard-

epoxy resin. The presence of impurities in bisphenol A is

ization established in the Decision on Principles for the

undesirable because they may slow down the polymerization

Development of International Standards, Guides and Recom-

and be impurities in the final product.

mendations issued by the World Trade Organization Technical

4.2 Determination of the trace impurities, such as isomer of

Barriers to Trade (TBT) Committee.

bisphenol A and the unreacted raw material, is often required.

2. Referenced Documents

This test method is suitable for setting specifications and for

2

using as an internal quality control where these products are

2.1 ASTM Standards:

produced or used.

D4297 PracticeforSamplingandHandlingBisphenolA(4,4'

4.3 Purity is commonly reported by subtracting the deter-

mined expected impurities and water from 100 %. However, a

1

This test method is under the jurisdiction of ASTM Committee D16 on

HPLC analysis cannot determine absolute purity if unknown

Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsi-

components are contained within the material being examined.

bility of Subcommittee D16.02 on Oxygenated Aromatics.

Current edition approved June 1, 2019. Published November 2019. DOI:

10.1520/D8266-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from U.S. Government Printing Office, Superintendent of

Standards volume information, refer to the standard’s Document Summary page on Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http://

the ASTM website. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8266 − 19

4

5. Interferences Society, where such specifications are available. Other grades

may be used, provided it is first ascertained that the reagent is

5.1 The internal st

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.