ASTM A749/A749M-97

(Specification)Standard Specification for Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements for

Standard Specification for Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements for

SCOPE

1.1 This specification covers the general requirements for hot-rolled steel strip in coils and cut lengths. It applies to carbon steel and high-strength, low-alloy steel furnished as hot-rolled.

1.2 This specification is not applicable to hot-rolled heavy-thickness carbon sheet and strip coils (ASTM Specification A635/A635M), cold-rolled carbon steel strip (ASTM Specification A109 or A109M), high-strength, low-alloy cold-rolled steel (ASTM Specifications A606 and A607) or cold-rolled carbon spring steel (ASTM Specification A682 or A682M).

1.3 In case of any conflict in requirements, the requirements of the individual material specification shall prevail over those of this general specification.

1.4 For the purposes of determining conformance with this and the appropriate product specification referenced under 2.1, values shall be rounded to the nearest unit in the right hand place of figures used in expressing the limiting values in accordance with the rounding method of Practice E29.

1.5 Annex A1 lists permissible variations in dimensions and mass (Note 1) in S.I. [metric] units. The values listed are not exact conversions of the values listed in the inch-pound tables, but instead are rounded or rationalized values. Conformance to Annex A1 is mandatory when the "M" specification is used. Note 1-The term "weight" is used when inch-pound units are the standard; however, under S.I., the preferred term is "mass."

1.6 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.7 This specification and the applicable material specifications are expressed in both inch-pound units and SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 749/A749M – 97

Standard Specification for

Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-

Rolled, General Requirements for

This standard is issued under the fixed designation A 749/A749M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope fication designation (SI units), the material shall be furnished

to inch-pound units.

1.1 This specification covers the general requirements for

hot-rolled steel strip in coils and cut lengths. It applies to

2. Referenced Documents

carbon steel and high-strength, low-alloy steel furnished as

2.1 ASTM Standards:

hot-rolled.

A 109 Specification for Steel, Strip, Carbon, Cold-Rolled

1.2 This specification is not applicable to hot-rolled heavy-

A 109M Specification for Steel, Strip, Carbon, Cold-

thickness carbon sheet and strip coils (ASTM Specification

Rolled (Metric)

A 635/A 635M), cold-rolled carbon steel strip (ASTM Speci-

A 370 Test Methods and Definitions for Mechanical Testing

fication A 109 or A 109M), high-strength, low-alloy cold-

of Steel Products

rolled steel (ASTM Specifications A 606 and A 607) or cold-

A 606 Specification for Steel, Sheet and Strip, High-

rolled carbon spring steel (ASTM Specification A 682 or

Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, with

A 682M).

Improved Atmospheric Corrosion Resistance

1.3 In case of any conflict in requirements, the requirements

A 607 Specification for Steel, Sheet and Strip, High-

of the individual material specification shall prevail over those

Strength, Low-Alloy, Columbium or Vanadium, or Both,

of this general specification.

Hot-Rolled and Cold-Rolled

1.4 For the purposes of determining conformance with this

A 635/A635M Specification for Steel, Sheet and Strip,

and the appropriate product specification referenced under 2.1,

Heavy-Thickness Coils, Carbon, Hot-Rolled

values shall be rounded to the nearest unit in the right hand

A 682 Specification for Steel, Strip, High-Carbon, Cold-

place of figures used in expressing the limiting values in

Rolled, Spring Quality, General Requirements For

accordance with the rounding method of Practice E 29.

A 682M Specification for Steel, Strip, High-Carbon, Cold-

1.5 Annex A1 lists permissible variations in dimensions and

Rolled, Spring Quality, General Requirements For (Met-

mass (Note 1) in S.I.[metric] units. The values listed are not

ric)

exact conversions of the values listed in the inch-pound tables,

A 700 Practices for Packaging, Marking, and Loading

but instead are rounded or rationalized values. Conformance to

Methods for Steel Products for Domestic Shipment

Annex A1 is mandatory when the “M” specification is used.

A 751 Test Methods, Practices, and Terminology for Chem

NOTE 1—The term “weight” is used when inch-pound units are the

ical Analysis of Steel Products

standard; however, under S.I., the preferred term is “mass.”

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

1.6 The values stated in either inch-pound units or SI units

poses

are to be regarded as standard. Within the text, the SI units are

E 29 Practice for Using Significant Digits in Test Data to

shown in brackets. The values stated in each system are not

Determine Conformance with Specifications

exact equivalents; therefore, each system must be used inde-

E 290 Test Method for Semi-Guided Bend Test for Ductil-

pendently of the other. Combining values from the two systems

ity of Metallic Materials

may result in nonconformance with the specification.

2.2 Military Standards:

1.7 This specification and the applicable material specifica-

MIL-STD-129 Marking for Shipment and Storage

tions are expressed in both inch-pound units and SI units.

MIL-STD-163 Steel Mill Products, Preparation for Ship-

However, unless the order specifies the applicable “M” speci-

ment and Storage

Annual Book of ASTM Standards, Vol 01.03.

1 3

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, Annual Book of ASTM Standards, Vol 01.05.

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 14.02.

A01.19 on Steel Sheet and Strip. Annual Book of ASTM Standards, Vol 03.01.

Current edition approved March 10, 1997. Published November 1997. Originally Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

published as A 749 – 81. Last previous edition A 749 – 95. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 749/A749M

2.3 Federal Standards: 5. Chemical Composition

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

5.1 Limits:

Fed. Std. No. 183 Continuous Identification Marking of Iron 5.1.1 The chemical composition shall be in accordance with

and Steel Products the applicable product specification. However, if other compo-

sitions are required for carbon steel, they shall be prepared in

3. Terminology

accordance with Appendix X1.

5.1.2 Where the material is used for fabrication by welding,

3.1 Definitions of Terms Specific to This Standard: Descrip-

care must be exercised in the selection of chemical composi-

tions of Terms Specific to This Standard:

tion or mechanical properties to ensure compatibility with the

3.1.1 Steel Types:

welding process and its effect on altering the properties.

3.1.2 carbon steel—the designation for steel when no mini-

5.2 Cast or Heat (Formerly Ladle) Analysis:

mum content is specified or required for aluminum, chromium,

5.2.1 An analysis of each cast or heat of steel shall be made

cobalt, columbium, molybdenum, nickel, titanium, tungsten,

by the manufacturer to determine the percentage of elements

vanadium, zirconium, or any element added to obtain a desired

specified or restricted by the applicable specification.

alloying effect; when the specified minimum for copper does

5.2.2 When requested, cast or heat analysis for elements

not exceed 0.40 %; or when the maximum content specified for

listed or required shall be reported to the purchaser or to his

any of the following elements does not exceed the percentages

representative.

noted; manganese 1.65, silicon 0.60, or copper 0.60.

5.3 Product, Check, or Verification Analysis:

Discussion—In all carbon steels small quantities of certain

5.3.1 Nonkilled steels (such as capped or rimmed) are not

residual elements unavoidably retained from raw materials are

technologically suited to product analysis due to the nonuni-

sometimes found which are not specified or required, such as

form character of their chemical composition and therefore, the

copper, nickel, molybdenum, chromium, etc. These elements

tolerances in Table 1 do not apply. Product analysis is appro-

are considered as incidental and are not normally determined or

priate on these types of steel only when misapplication is

reported.

apparent or for copper when copper steel is specified.

3.1.3 high-strength, low-alloy steel—a specific group of

5.3.2 For steels other than nonkilled (capped or rimmed),

steels in which higher strength, and in some cases additional

product analysis may be made by the purchaser. The chemical

resistance to atmospheric corrosion, are obtained by moderate

analysis shall not vary from the limits specified by more than

amounts of one or more alloying elements.

the amounts in Table 1. The several determinations of any

3.1.4 Product Types:

element in a cast shall not vary both above and below the

3.1.5 hot-rolled strip—manufactured by hot rolling billets specified range.

or slabs to the required thickness. It may be produced single

5.4 Sampling for Product Analysis:

width or by rolling multiple width and slitting to the desired 5.4.1 To indicate adequately the representative composition

width. It can be supplied in coils or cut lengths as specified.

of a cast by product analysis, it is general practice to select

samples to represent the steel, as fairly as possible, from a

Width, in. Thickness, in.

Over Through Over Through

minimum number of pieces as follows: 3 pieces for lots up to

15 tons inclusive, and 6 pieces for lots over 15 tons [15 Mg].

... 3½ 0.044 0.203

3½ 6 0.044 0.203 5.4.2 When the steel is subject to tension test requirements,

6 12 0.044 0.230 excl

samples for product analysis may be taken either by drilling

Width, mm Thickness, mm

entirely through the used tension test specimens themselves or

Over Through Over Through

in accordance with 5.4.3.

... 100 1.2 5.0 5.4.3 When the steel is not subject to tension test require-

100 200 1.2 5.0

ments, the samples for analysis must be taken by milling or

200 300 1.2 6.0, excl

Hot-rolled, high-strength, low-alloy strip is commonly avail-

A

TABLE 1 Tolerances for Product Analysis

able by size as follows:

Width, in. Thickness, in.

Element Limit, or Maximum of Tolerances

Over Through From Through

Specified

Under Minimum Over Maximum

Element, %

Limit Limit

Coils & Cut Coils

Lengths Only

Carbon to 0.15, incl 0.02 0.03

... 6 0.054 0.203 0.230 excl

over 0.15 to 0.40, incl 0.03 0.04

6 12 0.054 0.230 0.230 excl

over 0.40 to 0.80, incl 0.03 0.05

Width, mm Thickness, mm

over 0.80 0.03 0.06

Over Through Over Through

Manganese to 0.60, incl 0.03 0.03

over 0.60 to 1.15, incl 0.04 0.04

... 200 1.8 5.0

over 1.15 to 1.65, incl 0.05 0.05

200 300 1.8 6.0, excl

Phosphorus . . . 0.01

Sulfur . . . 0.01

Silicon to 0.30, incl 0.02 0.03

4. Materials and Manufacture

over 0.30 to 0.60, incl 0.05 0.05

Copper 0.02 . . .

4.1 Unless otherwise specified, hot-rolled material shall be

A

furnished hot-rolled, not annealed or pickled. See 6.3.1.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 749/A749M

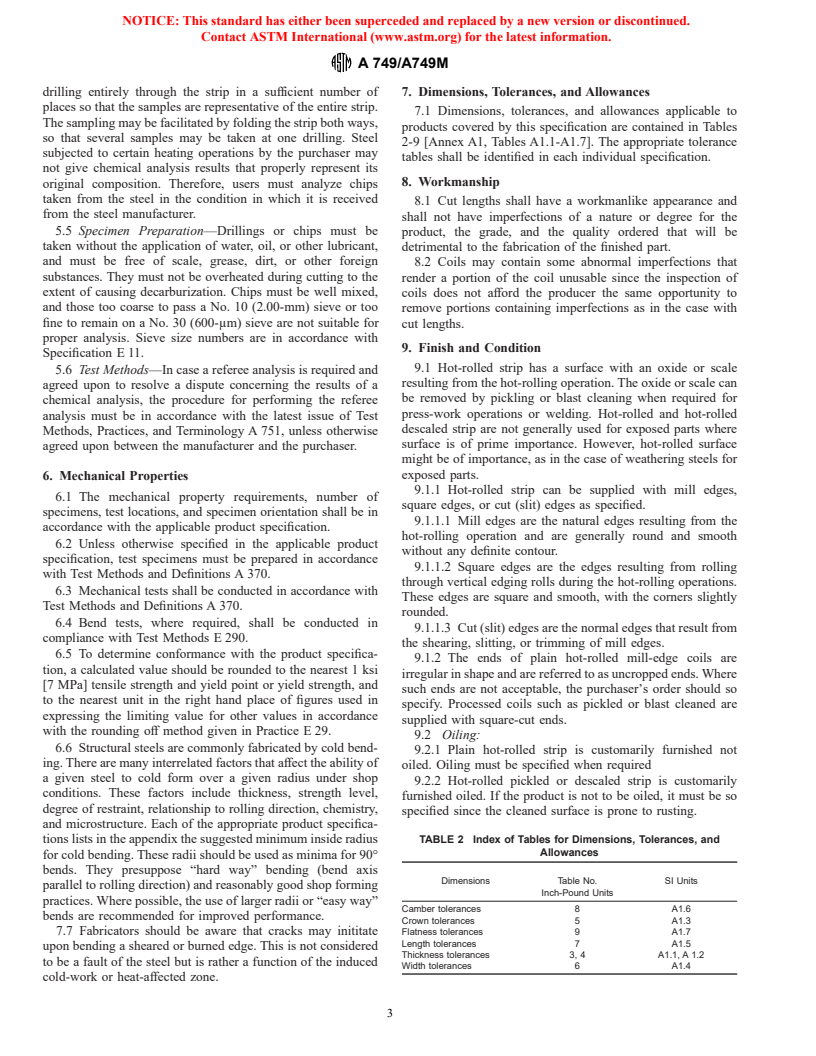

drilling entirely through the strip in a sufficient number of 7. Dimensions, Tolerances, and Allowances

places so that the samples are representative of the entire strip.

7.1 Dimensions, tolerances, and allowances applicable to

The sampling may be facilitated by folding the strip both ways,

products covered by this specification are contained in Tables

so that several samples may be taken at one drilling. Steel

2-9 [Annex A1, Tables A1.1-A1.7]. The appropriate tolerance

subjected to certain heating operations by the purchaser may

tables shall be identified in each individual specification.

not give chemical analysis results that properly represent its

8. Workmanship

original composition. Therefore, users must analyze chips

taken from the steel in the condition in which it is received

8.1 Cut lengths shall have a workmanlike appearance and

from the steel manufacturer.

shall not have imperfections of a nature or degree for the

5.5 Specimen Preparation—Drillings or chips must be product, the grade, and the quality ordered that will be

taken without the application of water, oil, or other lubricant,

detrimental to the fabrication of the finished part.

and must be free of scale, grease, dirt, or other foreign 8.2 Coils may contain some abnormal imperfections that

substances. They must not be overheated during cutting to the

render a portion of the coil unusable since the inspection of

extent of causing decarburization. Chips must be well mixed, coils does not afford the producer the same opportunity to

and those too coarse to pass a No. 10 (2.00-mm) sieve or too

remove portions containing imperfections as in the case with

fine to remain on a No. 30 (600-μm) sieve are not suitable for

cut lengths.

proper analysis. Sieve size numbers are in accordance with

9. Finish and Condition

Specification E 11.

9.1 Hot-rolled strip has a surface with an oxide or scale

5.6 Test Methods—In case a referee analysis is required and

resulting from the hot-rolling operation. The oxide or scale can

agreed upon to resolve a dispute concerning the results of a

be removed by pickling or blast cleaning when required for

chemical analysis, the procedure for performing the referee

press-work operations or welding. Hot-rolled and hot-rolled

analysis must be in accordance with the latest issue of Test

descaled strip are not generally used for exposed parts where

Methods, Practices, and Terminology A 751, unless otherwise

surface is of prime importance. However, hot-rolled surface

agreed upon between the manufacturer and the purchaser.

might be of importance, as in the case of weathering steels for

exposed parts.

6. Mechanical Properties

9.1.1 Hot-rolled strip can be supplied with mill edges,

6.1 The mechanical property requirements, number of

square edges, or cut (slit) edges as specified.

specimens, test locations, and specimen orientation shall be in

9.1.1.1 Mill edges are the natural edges resulting from the

accordance with the applicable product specification.

hot-rolling operation and are generally round and smooth

6.2 Unless otherwise specified in the applicable product

without any definite contour.

specification, test specimens must be prepared in accordance

9.1.1.2 Square edges are the edges resulting from rolling

with Test Methods and Definitions A 370.

through vertical edging rolls during the hot-rolling operations.

6.3 Mechanical tests shall be conducted in accordance with

These edges are square and smooth, with the corners slightly

Test Methods and Definitions A 370.

rounded.

6.4 Bend tests, where required, shall be conducted in

9.1.1.3 Cut (slit) edges are the normal edges that result from

compliance with Test Methods E 290.

the shearing, slitting, or trimming of mill edges.

6.5 To determine conformance with the product specifica-

9.1.2 The ends of plain hot-rolled mill-edge coils are

tion, a calculated value should be rounded to the nearest 1 ksi

irregular in shape and are referred to as uncropped ends. Where

[7 MPa] tensile strength and yield point or yield strength, and

such ends are not acceptable, the purchaser’s order should so

to the nearest unit in the right hand place of figures used in

specify. Processed coils such as pickled or blast cleaned are

expressing the limiting value for other values in accordance

supplied with square-cut ends.

with the rounding off method given in Practice E 29.

9.2 Oiling:

6.6 Structural steels are commonly fabricated by cold bend-

9.2.1 Plain hot-rolled strip is customarily furnished not

ing. There are many interrelated factors that aff

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.