ASTM D3170-03

(Test Method)Standard Test Method for Chipping Resistance of Coatings

Standard Test Method for Chipping Resistance of Coatings

SCOPE

1.1 This test method covers the determination of the resistance of coatings to chipping damage by stones or other flying objects.

Note1—This test method is similar to SAE J-400.

1.2 The values stated in metric units are to be regarded as the standard. The English units given in parentheses are for information only. All dimensions are nominal unless otherwise specified.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3170–03

Standard Test Method for

1

Chipping Resistance of Coatings

This standard is issued under the fixed designation D 3170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 Other Documents:

4

Test for Chip Resistance of Surface Coatings (J-400)

1.1 This test method covers the determination of the resis-

tance of coatings to chipping damage by stones or other flying

3. Summary of Test Method

objects.

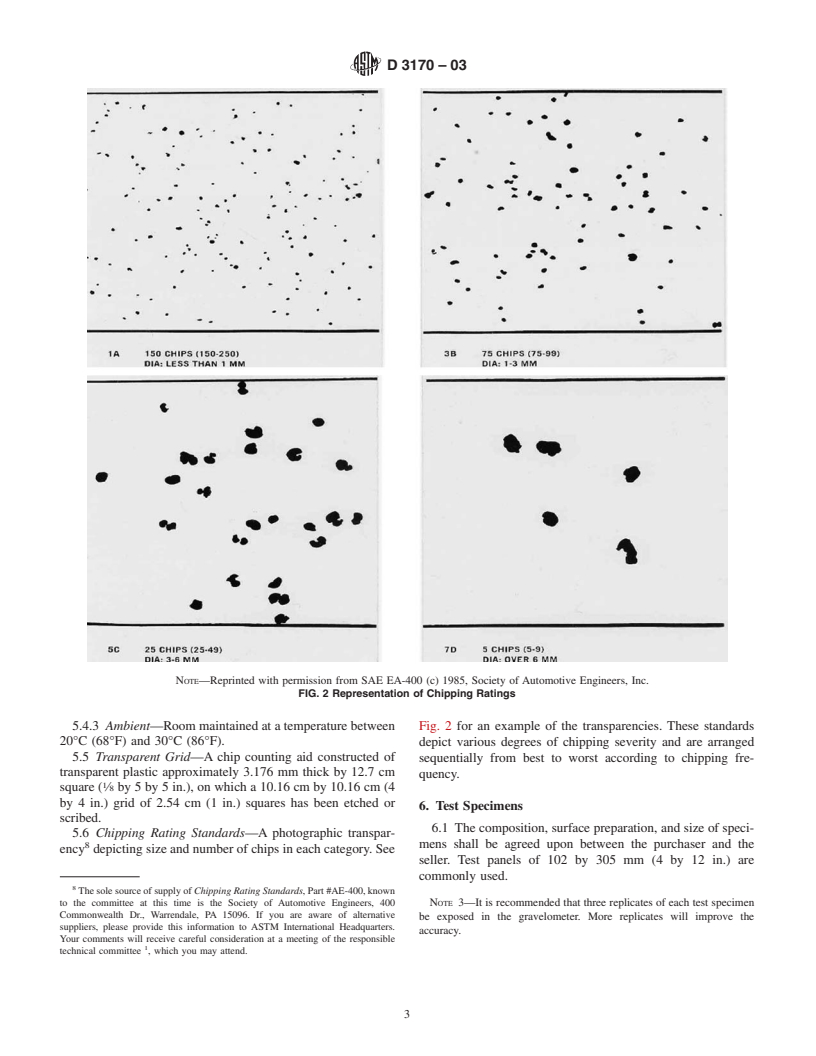

3.1 Standardized road gravel is projected by means of a

NOTE 1—This test method is similar to SAE J-400.

controlled air blast at the coated specimens. All testing is

conducted under controlled temperature conditions, generally

1.2 The values stated in metric units are to be regarded as

the standard. The English units given in parentheses are for either at ambient (room) temperature or at -29°C 6 3°C (-20°

6 5°F).After the gravel impact, tape is applied to remove any

information only.All dimensions are nominal unless otherwise

specified. loose coating chips and the degree of chipping is determined.

1.3 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 Owners consider chipping of coatings, particularly on

responsibility of the user of this standard to establish appro-

the leading faces and edges of automobile surfaces, unaccept-

priate safety and health practices and determine the applica-

able.Informulatingacoatingorcoatingsystemtomeetservice

bility of regulatory limitations prior to use.

requirements, the resistance to chipping damage by flying

2. Referenced Documents

objects such as gravel is one of the properties of importance

since it can vary considerably as other properties are adjusted.

2.1 ASTM Standards:

D 609 Practice for Preparation of Cold-Rolled Steel Panels Since resistance to chipping decreases at lower temperatures

partly as the result of decreased flexibility, the test may be

for Testing Paint, Varnish, Conversion Coatings, and

2

Related Coating Products more directly related to service conditions by performing it at

a low temperature. This test method is designed to produce a

D 823 Practices for Producing Films of Uniform Thickness

2

controlled amount of impact by the media on the coated panel

of Paint, Varnish, and Related Products on Test Panels

D 1005 Test Method for Measurement of Dry-Film Thick- in order to enhance reproducibility.

2

ness of Organic Coatings Using Micrometers

5. Apparatus

D 1186 Test Methods for Nondestructive Measurement of

5.1 Gravel-Projecting Machine (Gravelometer), con-

Dry Film Thickness of Nonmagnetic Coatings Applied to

2

structed according to the design specifications shown in Fig.

a Ferrous Base

5

1. There are two types of Gravelometers: the old cabinet style

D 1400 Test Method for Nondestructive Measurement of

and the newer, modular style with an electronic feed mecha-

DryFilmThicknessofNonconductiveCoatingsAppliedto

2

nism.

a Nonferrous Metal Base

D 1733 Method of Preparation of Aluminum-Alloy Panels

NOTE 2—It is recommended that the operation/maintenance checklist

3

for Testing Paint, Varnish, Lacquer, and Related Products

shown in Appendix X1 should be completed at least once per month for

D 2201 Practice for Preparation of Zinc-Coated and Zinc-

gravelometers that are operated on a weekly basis, and once every 6

months for gravelometers that are operated less frequently. Note that

Alloy-Coated Steel Panels for Testing Paint and Related

2

values in the checklist are specific to the standard gravel testing protocol.

Products

1 4

This test method is under the jurisdiction of ASTM Committee D01 on Paint Available from the Society ofAutomotive Engineers, 400 Commonwealth Dr.,

and Related Coatings, Materials, andApplications and is the direct responsibility of Warrendale, PA 15096.

5

Subcommittee D01.55 on Factory Applied Coatings on Preformed Products. The sole source of a suitable apparatus meeting these specifications known to

Current edition approved July 10, 2003. Published September 2003. Originally the committee at this time is Q-Panel Co., 26200 First St., Westlake, OH 44135. If

approved in 1973. Last previous edition approved in 2001 as D 3170 - 01. you are aware of alternative suppliers, please provide this information to ASTM

2

Annual Book of ASTM Standards, Vol 06.01. Headquarters.Your comments will receive careful consideration at a meeting of the

3 1

Discontinued, see 1980 Annual Book of ASTM Standards, Part 27. responsible technical committee, which you

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.