ASTM D5767-95(1999)

(Test Method)Standard Test Methods for Instrumental Measurement of Distinctness-of-Image Gloss of Coating Surfaces

Standard Test Methods for Instrumental Measurement of Distinctness-of-Image Gloss of Coating Surfaces

SCOPE

1.1 This test method describes the measurement of the distinctness-of-image (DOI) gloss of coating surfaces using electro-optical measuring techniques. The coatings must be applied to planar rigid surfaces. The scale values obtained from the alternative methods cited do not agree.

1.2 Three test methods are covered as follows:

1.2.1 Test Method A -Gloss reflectance factor measurements are made on the specimen at the specular viewing angle and at an angle slightly off the specular viewing angle. The values obtained are combined to provide a DOI value. Very narrow source and receptor aperture angles are used in the measurements.

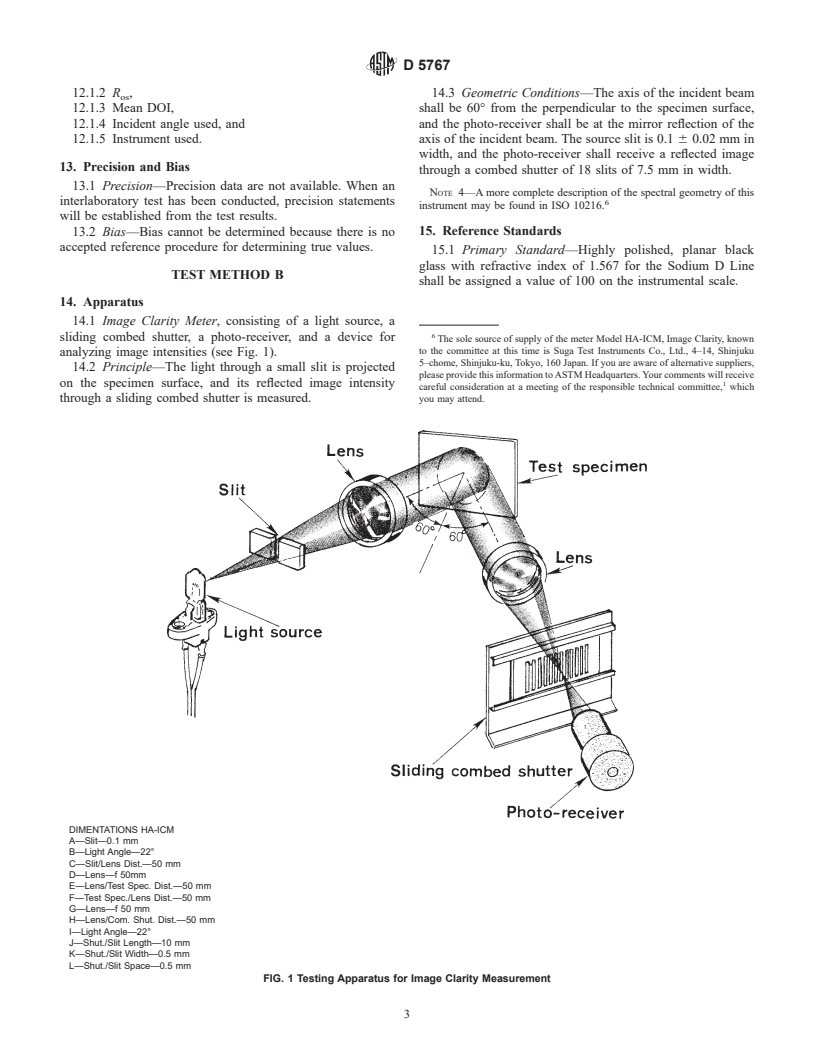

1.2.2 Test Method B -The light through a small slit is projected on the specimen surface and its reflected image intensity is measured through a sliding combed shutter to provide a value of image clarity.

1.2.3 Test Method C -The light through a pattern is projected on the specimen surface and its reflected image intensity is measured directly to provide a value of image clarity.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5767 – 95 (Reapproved 1999)

Standard Test Methods for

Instrumental Measurement of Distinctness-of-Image Gloss

of Coating Surfaces

This standard is issued under the fixed designation D 5767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 284 Terminology of Appearance

E 430 Test Methods for Measurement of Gloss of High-

1.1 This test method describes the measurement of the

Gloss Surfaces by Goniophotometry

distinctness-of-image (DOI) gloss of coating surfaces using

2.2 Other Standards:

electro-optical measuring techniques. The coatings must be

ISO 10216 Anodized Aluminum and Aluminum Alloys—

applied to planar rigid surfaces. The scale values obtained from

Instrumental Determination of Image Clarity of Anodic

the alternative methods cited do not agree.

Oxidation Coatings—Instrumental Method

1.2 Three test methods are covered as follows:

1.2.1 Test Method A—Gloss reflectance factor measure-

3. Terminology

ments are made on the specimen at the specular viewing angle

3.1 Terms and Definitions in Terminology E 284 are appli-

and at an angle slightly off the specular viewing angle. The

cable to these methods.

values obtained are combined to provide a DOI value. Very

3.2 Definitions:

narrow source and receptor aperture angles are used in the

3.2.1 distinctness-of-image gloss, n—aspect of gloss char-

measurements.

acterized by the sharpness of images of objects produced by

1.2.2 Test Method B—The light through a small slit is

reflection at a surface (E 284).

projected on the specimen surface and its reflected image

3.2.1.1 Discussion—This quality is sometimes called Image

intensity is measured through a sliding combed shutter to

Clarity.

provide a value of image clarity.

3.2.2 gloss reflectance factor, R , n—ratio of the specularly

s

1.2.3 Test Method C—The light through a pattern is pro-

reflected part of the (whole) flux reflected from the specimen to

jected on the specimen surface and its reflected image intensity

the flux reflected from a specified gloss standard under the

is measured directly to provide a value of image clarity.

same geometric and spectral conditions of measurements

1.3 This standard does not purport to address all of the

(E 284).

safety concerns, if any, associated with its use. It is the

3.2.2.1 Discussion—The gloss standard may be a black

responsibility of whoever uses this standard to consult and

glass or mirror and may be assigned one of a variety of scale

establish appropriate safety and health practices and deter-

values as specified.

mine the applicability of regulatory limitations prior to use.

3.2.3 specular angle, n—the angle of reflection equal and

2. Referenced Documents opposite to the angle of incidence (E 284).

2.1 ASTM Standards:

4. Significance and Use

D 523 Test Method for Specular Gloss

4.1 An important aspect of the appearance of glossy coating

D 823 Practices for Producing Films of Uniform Thickness

2 surfaces is the distinctness (clarity) of images reflected by

and Related Products on Test Panels

them. The values obtained by the measuring procedures given

D 2457 Test Method for Specular Gloss of Plastic Films and

3 in these methods generally correlate well with visual ratings for

Solid Plastics

DOI (image clarity).

D 3964 Practice for Selection of Coating Specimens for

2 4.2 Although Test Methods D 523 and D 4039 are useful in

Appearance Measurements

characterizing some aspects of glossy appearance, they do not

D 4039 Test Method for Reflection Haze of High-Gloss

2 provide satisfactory ratings for DOI (image clarity).

Surfaces

4.3 The measurement conditions given conform to the

conditions specified in Test Methods E 430.

These test methods are under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.26 on Optical Properties.

Current edition approved Sept. 15, 1995. Published November 1995. Available from ANSI, 11 W. 42nd St., 13th Floor, New York, NY 10036.

2 5

Annual Book of ASTM Standards, Vol 06.01. Supporting data are available from ASTM Headquarters. Request RR: D01-

Annual Book of ASTM Standards, Vol 08.02. 1092.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5767

4.4 The measurement conditions given in Test Methods B 8. Reference Standards

and C conform to the conditions specified in ISO Standard

8.1 Primary Standard—Highly polished, planar black glass

#10216.

with a refractive index of 1.567 for the Sodium D Line shall be

4.5 The scale values obtained with the measuring proce-

assigned a G value of 100 on the instrument reading scale.

s

dures of these methods range from 0 to 100 with a value of 100

8.2 Working Standard (Intermediate-Scale Standard)—

representing perfect DOI (image clarity).

Highly polished, planar black glass with a refractive index

4.6 The DOI (image clarity) scale value does not of itself, close to 1.527 may be used as a standard if its assigned value

indicate any specific cause for reduction in reflected image

has been established by measurement against the primary

sharpness. Surface irregularities such as haze, orange peel, and standard or by computation from its refractive index using the

wrinkle, when present, may be cited as causes for reduction of

Fresnel equation.

image sharpness. 8.2.1 It shall be assigned a scale value of G 5 89.4 for a

s

specular angle of 30°, or G 5 89.2 for a specular angle of 20°.

s

5. Preparation and Selection of Test Specimens

NOTE 1—Each 0.01 increment in index of refraction produces a change

of approximately 3 units in the assigned scale value of polished black

5.1 These test methods do not cover techniques for the

glass for 20° geometry and a change of approximately 2.5 units in the

preparation of test specimens. Whenever preparation of test

assigned scale value for 30° geometry.

specimens is required, use one of the procedures given in

NOTE 2—To determine the scale value, calculate the first surface

Practices D 823. Selection of specimens for measurement

(Fresnel) reflectance (see Test Method D 2457, 5.1) for n 5 1.567 and

D

should be done in accordance with Practice D 3964.

the specular angle of interest; for 30° it is 5.0436 % and for 20° it is

4.90 %. Assign this a scale value of 100 (see Test Method D 523, 7.1).

6. Correlation of Results of Test Methods A, B and C to Repeat the calculation for n 5 1.527 and the same specular angle; the

D

result for 30° is 4.5069 % and for 20°, 4.3769 %. The new scale value for

Visual Perception of Image Distinction of Coating

30° is 100 3 (4.5069/5.0436) 5 89.4, and for 20°, 100 3 (4.3769/

Surfaces

4.9078) 5 89.2. (The latter figure is identical to that given in Test Method

6.1 An analysis of the results of a round robin conducted by

D 523 for the same angle.)

Task Group D 01.26.11 demonstrates the level of correlation

8.3 Verification Standards—Depolished opaque black glass

between instruments currently included in these test methods

and ceramic tile having uniform, planar surfaces are suitable

and with visual perception.

when calibrated against a primary or working standard on an

abridged goniophotometer or gonioreflectometer known to

TEST METHOD A

meet the requirements of Test Method A.

7. Apparatus 9. Standardization of Apparatus

9.1 Adjust the instrument to read the assigned scale value of

7.1 Abridged Goniophotometer or Gonioreflectometer,

the polished black glass standard. Take readings on verification

which can be set to the beam and aperture angles indicated in

standards whose assigned values cover the range of the

Table 1.

instrument scale. The readings of the verification standards

7.1.1 Geometric Conditions—The axis of the incident beam

should agree within 61 unit of their assigned values.

shall be 20 or 30° from the perpendicular to the specimen

surface. Provisions shall be made so that receptor settings will

10. Procedure

be at the specular angle and at an angle of 0.2 to 0.4° off the

10.1 Position the specimen on the instrument. Place a clamp

specular angle. Suitable angular dimensions of the image of the

or weight on the specimen to flatten it. Take a reading, R ,atthe

s

source aperture and angular dimensions of the receptor aper-

specular angle. Without moving the specimen, take a reading,

tures are given in Table 1.

R , at a receptor angle of 0.2 to 0.4° off the specular angle.

os

7.1.2 Spectral Conditions—The measurement shall be made

10.2 Repeat this procedure on at least two other areas of the

with visible radiation (light) to give results in accordance with

specimen.

the CIE spectral luminous efficiency.

10.3 Take readings on the standards at the end of the series

7.1.3 Polarization—The incident flux shall be unpolarized

of specimen readings to ensure that the instrument has re-

and the receptor shall be insensitive to the state of polarization

mained in calibration throughout the operation.

of the reflected luminous flux.

11. Calculation

11.1 Combine the specular angle reading, R , with the off

s

TABLE 1 Angles and Dimensions of Source Image and

specular reading, R , as follows:

os

Receptors

DOI 5 @1 2 ~R /R !# 3 100 (1)

os s

Dimensions of Dimensions of the Dimensions of

Source Image at Viewed Area at the Viewed

NOTE 3—Some instruments perform this calculation internally and

Sample Plane, ° Sample Plane, ° Area DOI, °

provide a direct reading of DOI.

Center of window 20 or 30 20 or 30 0.3 6 0.1

A

Width 0.44 0.38 0.14

12. Report

B

Length 7.0 4.0 4.0

A 12.1 Report the following information:

In plane of the angle of reflection.

B

Across the plane of the angle of reflection. 12.1.1 R ,

s

D 5767

12.1.2 R , 14.3 Geometric Conditions—The axis of the incident beam

os

12.1.3 Mean DOI, shall be 60° from the perpendicular to the specimen surface,

12.1.4 Incident angle used, and and the photo-receiver shall be at the mirror reflection of the

12.1.5 Instrument used. axis of the incident beam. The source slit is 0.1 6 0.02 mm in

width, and the photo-receiver shall receive a reflected image

13. Precision and Bias

through a combed shutter of 18 slits of 7.5 mm in width.

13.1 Precision—Precision data are not available. When an

NOTE 4—A more complete description of the spectral geometry of this

int

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.