ASTM D1266-13

(Test Method)Standard Test Method for Sulfur in Petroleum Products (Lamp Method)

Standard Test Method for Sulfur in Petroleum Products (Lamp Method)

SIGNIFICANCE AND USE

4.1 This test method provides a means of monitoring the sulfur level of various petroleum products and additives. This knowledge can be used to predict performance, handling, or processing properties. In some cases the presence of sulfur components is beneficial to the product and monitoring the depletion of sulfur compounds provides useful information. In other cases the presence of sulfur compounds is detrimental to the processing or use of the product.

SCOPE

1.1 This test method covers the determination of total sulfur in liquid petroleum products in concentrations from 0.01 to 0.4 mass % (Note 1). A special sulfate analysis procedure is described in Annex A1 that permits the determination of sulfur in concentrations as low as 5 mg/kg. Note 1—The comparable lamp method for the determination of sulfur in liquefied petroleum gas is described in Test Method D2784. For the determination of sulfur in heavier petroleum products that cannot be burned in a lamp, see the high pressure decomposition device method (Test Method D129) the quartz tube method (IP 63), or the high-temperature method (Test Method D1552).

1.2 The direct burning procedure (Section 9) is applicable to the analysis of such materials as gasoline, kerosine, naphtha, and other liquids that can be burned completely in a wick lamp. The blending procedure (Section 10) is applicable to the analysis of gas oils and distillate fuel oils, naphthenic acids, alkyl phenols, high sulfur content petroleum products, and many other materials that cannot be burned satisfactorily by the direct burning procedure.

1.3 Phosphorus compounds normally present in commercial gasoline do not interfere. A correction is given for the small amount of acid resulting from the combustion of the lead anti-knock fluids in gasolines. Appreciable concentrations of acid-forming or base-forming elements from other sources interfere when the titration procedure is employed since no correction is provided in these cases.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1266 − 13

Designation: 107/86

Standard Test Method for

1

Sulfur in Petroleum Products (Lamp Method)

This standard is issued under the fixed designation D1266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This test method covers the determination of total sulfur

in liquid petroleum products in concentrations from 0.01 to 0.4

2. Referenced Documents

mass % (Note 1). A special sulfate analysis procedure is

2

described in AnnexA1 that permits the determination of sulfur 2.1 ASTM Standards:

in concentrations as low as 5 mg/kg.

D129 Test Method for Sulfur in Petroleum Products (Gen-

eral High Pressure Decomposition Device Method)

NOTE 1—The comparable lamp method for the determination of sulfur

D1193 Specification for Reagent Water

in liquefied petroleum gas is described in Test Method D2784. For the

D1552 Test Method for Sulfur in Petroleum Products (High-

determination of sulfur in heavier petroleum products that cannot be

burned in a lamp, see the high pressure decomposition device method

Temperature Method)

(Test Method D129) the quartz tube method (IP 63), or the high-

D2784 Test Method for Sulfur in Liquefied Petroleum Gases

temperature method (Test Method D1552).

(Oxy-Hydrogen Burner or Lamp)

1.2 Thedirectburningprocedure(Section9)isapplicableto

D6299 Practice for Applying Statistical Quality Assurance

the analysis of such materials as gasoline, kerosine, naphtha,

and Control Charting Techniques to Evaluate Analytical

andotherliquidsthatcanbeburnedcompletelyinawicklamp.

Measurement System Performance

The blending procedure (Section 10) is applicable to the

D6300 Practice for Determination of Precision and Bias

analysis of gas oils and distillate fuel oils, naphthenic acids,

Data for Use in Test Methods for Petroleum Products and

alkyl phenols, high sulfur content petroleum products, and

Lubricants

manyothermaterialsthatcannotbeburnedsatisfactorilybythe

D6792 Practice for Quality System in Petroleum Products

direct burning procedure.

and Lubricants Testing Laboratories

E11 Specification for Woven Wire Test Sieve Cloth and Test

1.3 Phosphorus compounds normally present in commercial

Sieves

gasoline do not interfere. A correction is given for the small

3

amount of acid resulting from the combustion of the lead

2.2 Energy Institute Standard:

anti-knock fluids in gasolines. Appreciable concentrations of

IP 63 Sulfur Content—The Quartz Tube Method

acid-forming or base-forming elements from other sources

interfere when the titration procedure is employed since no

3. Summary of Test Method

correction is provided in these cases.

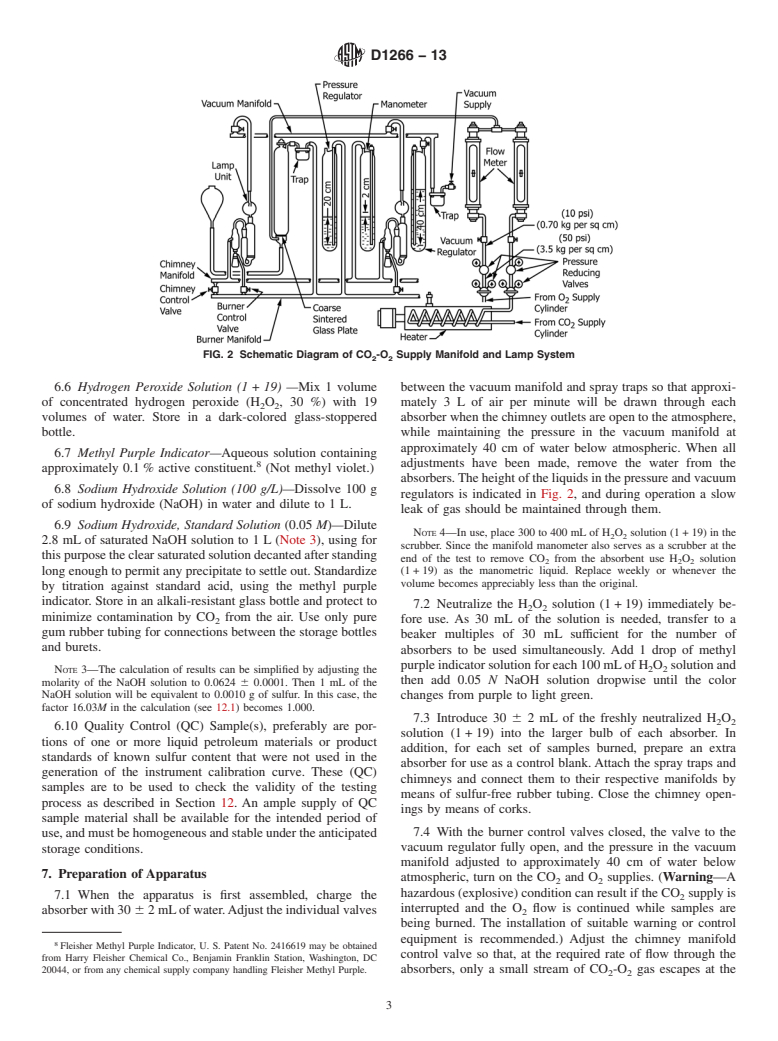

3.1 The sample is burned in a closed system, using a

1.4 The values stated in SI units are to be regarded as

suitablelamp(Fig.1)andanartificialatmospherecomposedof

standard. No other units of measurement are included in this

70 % carbon dioxide and 30 % oxygen to prevent formation of

standard.

nitrogen oxides. The oxides of sulfur are absorbed and oxi-

dized to sulfuric acid by means of hydrogen peroxide solution

1.5 This standard does not purport to address all of the

which is then flushed with air to remove dissolved carbon

safety concerns, if any, associated with its use. It is the

dioxide. Sulfur as sulfate in the absorbent is determined

responsibility of the user of this standard to establish appro-

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.03 on Elemental Analysis. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 15, 2013. Published August 2013. Originally the ASTM website.

3

approved in 1969. Last previous edition approved in 2007 as D1266 – 07. DOI: Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

10.1520/D1266-13. U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1266 − 13

4,5

5.2 Cotton Wicking —Clean, unused, uniform, twisted

white cotton yarn of good quality. For the burner

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1266 − 07 D1266 − 13

Designation: 107/86

Standard Test Method for

1

Sulfur in Petroleum Products (Lamp Method)

This standard is issued under the fixed designation D1266; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the determination of total sulfur in liquid petroleum products in concentrations from 0.01 to 0.4

mass % (Note 1). A special sulfate analysis procedure is described in Annex A1 that permits the determination of sulfur in

concentrations as low as 5 mg/kg.

NOTE 1—The comparable lamp method for the determination of sulfur in liquefied petroleum gas is described in Test Method D2784. For the

determination of sulfur in heavier petroleum products that cannot be burned in a lamp, see the bomb high pressure decomposition device method (Test

Method D129) the quartz tube method (IP 63), or the high-temperature method (Test Method D1552).

1.2 The direct burning procedure (Section 9) is applicable to the analysis of such materials as gasoline, kerosine, naphtha, and

other liquids that can be burned completely in a wick lamp. The blending procedure (Section 10) is applicable to the analysis of

gas oils and distillate fuel oils, naphthenic acids, alkyl phenols, high sulfur content petroleum products, and many other materials

that cannot be burned satisfactorily by the direct burning procedure.

1.3 Phosphorus compounds normally present in commercial gasoline do not interfere. A correction is given for the small amount

of acid resulting from the combustion of the lead anti-knock fluids in gasolines. Appreciable concentrations of acid-forming or

base-forming elements from other sources interfere when the titration procedure is employed since no correction is provided in

these cases.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D129 Test Method for Sulfur in Petroleum Products (General High Pressure Decomposition Device Method)

D1193 Specification for Reagent Water

D1552 Test Method for Sulfur in Petroleum Products (High-Temperature Method)

D2784 Test Method for Sulfur in Liquefied Petroleum Gases (Oxy-Hydrogen Burner or Lamp)

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3

2.2 Energy Institute Standard:

IP 63 Sulfur Content—The Quartz Tube Method

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved Dec. 1, 2007June 15, 2013. Published January 2008August 2013. Originally approved in 1969. Last previous edition approved in 20032007 as

ε1

D1266–98(2003)D1266 – 07. . DOI: 10.1520/D1266-07.10.1520/D1266-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR, U.K., http://www.energyinst.org.uk.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1266 − 13

FIG. 1 Illustrative Sketch of the Assembled Lamp Unit

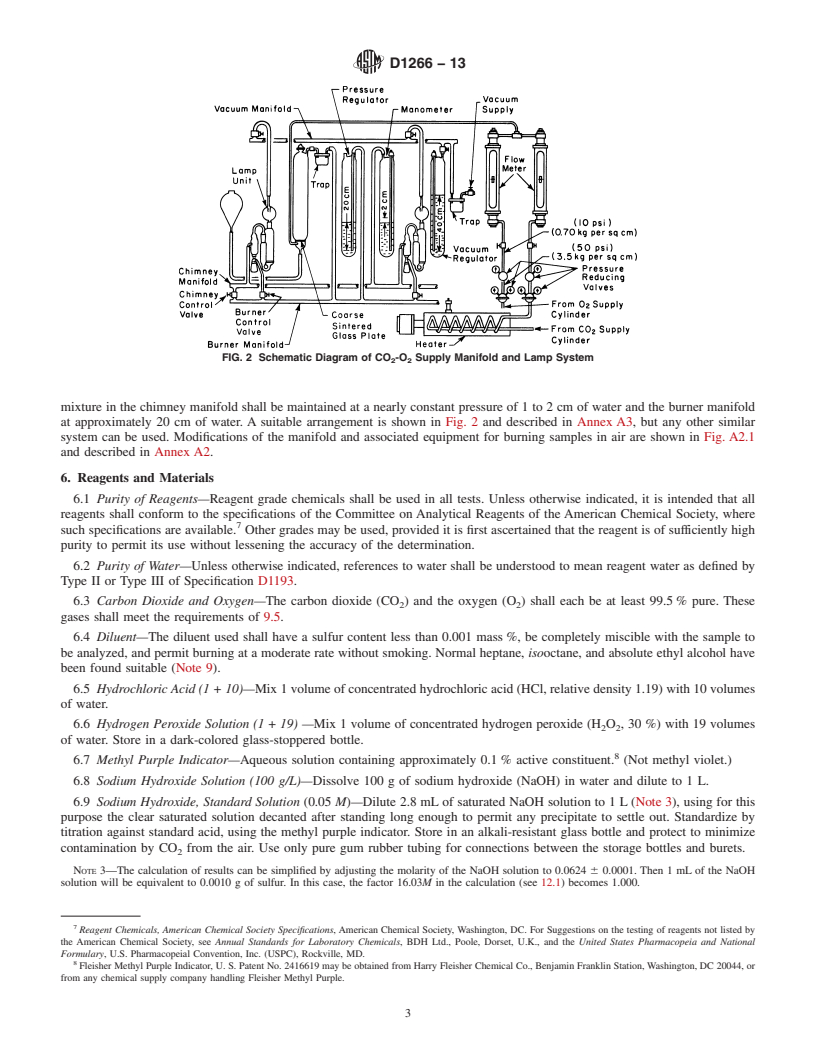

3. Summary of Test Method

3.1 The sample is burned in a closed system, using a suitable lamp (Fig. 1) and an artificial a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.